BST eltromat CCDPro 30000 Operational manual

CCD Camera EDV-No.: MD.167.01.07/2.6.8

CCDPro 30000/5000 Issued: 30.03.2011

BST-eltromat CCD Camera

CCDPro 30000/5000

Translation of the Original

Operating Manual

BST eltromat International GmbH

Heidsieker Heide 53

33739 Bielefeld, Germany

Tel: +49 (0) 5206/999 – 0

Fax: +49 (0) 5206/999 – 999

Email: info@bst-international.com

CCD Camera EDV-No.:MD.167.01.07/2.6.8

CCDPro 30000/5000 Date: 30.03.2011

Symbols used in this operating manual

Warning signs

Symbols are used in this operating manual in order to clearly

indicate particularly important places.

Attention!

You must obey this type of warning, in order to protect

yourself, as the operator, from bodily injuries arising

from mechanical movements.

Beware!

You must obey by this type of warning without fail, in

order to protect yourself, as the operator, from life

threatening injuries caused by electrical voltages.

Note

This symbol is used to point out additional useful tips,

which will help you to make optimum use of all of the

functions.

!

Contents

CCD Camera EDV-No.:MD.167.01.07/2.6.8 Chapter:

CCDPro 30000/5000: Date: 30.03.2011 Page: 1/1

Contents

Table of contents

1 Description

1.1 General information: 1-2

1.2 Utilisation 1-2

1.3 Safety information 2-2

1.4 Emissions 2-2

2 Display and operating controls

2.1 Camera control panel 1-2

2.2 Connections 2-2

3 Menus

3.1 Entering the numerical values 1-6

3.2 Foot line menu 2-6

3.3 Set-up menu 5-6

4 Assembly / Installation

4.1 Installation site requirements 1-3

4.2 Installing the camera 1-3

4.3 Installing the light source 1-3

4.4 Background determination 2-3

4.5 Fitting a support roller 2-3

4.6 Installation 3-3

5 Commissioning

5.1 Camera settings 1-18

5.2 Mechanical alignment 3-18

5.3 Camera configuration 11-18

5.4 Programming the camera for asynchronous

operation PDO transfer 18-18

6 Operation

6.1 General information 1-4

6.2 Changing the settings during operation 2-4

7 Maintenance 1-1

8 Specifications 1-2

9 Transport 1-1

10 Decommissioning 1-1

Appendix

Annex 1 CCD Pro 28 mm lens measuring distances

Annex 2 CCD Pro 50 mm lens measuring distances

Description 1

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 1.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 1/2

1. Description

General information

This operating manual covers all CCDPro … model CCD-

cameras.

It describes the standard web guiding application using one or two

cameras and the width measurement application used with a

running material web.

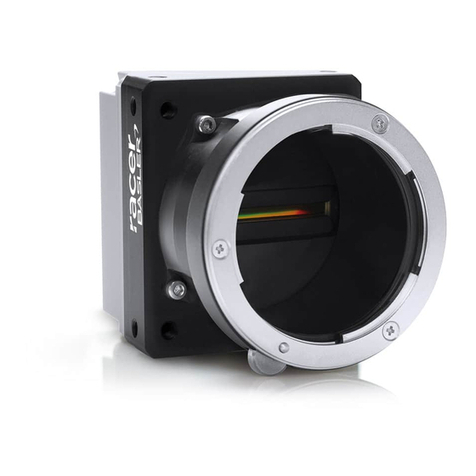

The camera is fitted with an RGB-chip and this enables it to

evaluate the three basic colours. This ensures safe recognition as

well as reliable system operation.

The camera parameters can be stored externally in the machine

controller or PC, etc., thus ensuring that they are always available

for any repeat jobs that might occur later on.

Optimisation of the camera parameters as a result of alterations

made to the material parameters can be implemented during

ongoing operation (as necessary). This means that downtime is no

longer required if such a case occurs.

1.2 Utilisation

The CCDPro … CCD-camera has been designed for use as a non-

contact positional measurement system. It determines the position

from the contrast generated by edges, lines, grooves etc., in and on

the running material.

The camera can scan in both directions.

The measurement results are used to control the material or for

measuring the width of the material. The contrast transition is

recorded, depending on the job definition, using:

a) A transmission light process b) A reflection copy light process

Transmission light process: the light source is seen by the

camera to be behind the material web that is being scanned. Only

the edges of the material can be recorded when non-transparent

materials are being used. You can use one or two cameras to scan

the edges, depending on the job definition.

camera

Position settings for the

contrast transitions

material

0 5000 (30000)

Description 1

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 1.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 2/2

!

It is important that both edges must always lie within the visual

range of the camera when using a single camera for width

measurement or web centre control. One edge must lie within each

of the camera’s visual range when using two cameras. This must

be guaranteed if the web position fluctuates.

Reflection copy light process: the light source and the camera

must be positioned on the same side of the material web that has

to be scanned. The camera records the light from the light source

that is reflected from the material web. The reflection copy process

enables lines, grooves, creases, etc., to be recorded as well.

All of the data coming from and going to the camera is transferred

via a CAN-interface.

A keypad with 8 keys and a graphics display is used for executing

the basic operating functions and displaying the web position(s).

1.3 Safety information

The safety relevant information in accordance with DIN EN ISO

13857, EN 349 and the industry specific safety regulations must be

taken into consideration when installing the BST-eltromat

equipment in the production machine, these include:

•There must be a safe distance between the BST-eltromat

equipment and the machinery already installed on-site, such as

machine panels, building structure, etc.

•The interconnecting lines between the control equipment and

the control components or edge sensors must be laid so that

nobody can trip over them, they are not taught and they are well

anchored.

Only trained specialist personnel are permitted

to carry out the assembly, installation and

commissioning!

The mains power must be switched off before the

equipment is opened.

If it becomes necessary to work on the open

equipment with voltage applied, then only Protection

class IP 20 is provided.

There is always increased danger because of the

mains voltage!

1.4 Emissions

The A-evaluated equivalent continuous noise level generated by

the equipment is les than 70 dB(A).

Operating controls 2

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 2.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 1/2

2. Display and operating controls

2.1 Camera control panel

Graphics display

The graphics display is used to display the brightness curve, edge

positions, set-up menus, parameters and bus status information.

The scan direction that the camera is scanning is shown beneath

the graphic display. It shows the direction from which the image will

be taken.

Note: However, the camera is positioned to be able to scan in the

opposite direction as well.

This means: That the first pixel in the scan direction displayed

above is pixel 0 and the last pixel in this direction is

pixel 4999 (CCDPro 5000) or pixel 29999 (CCDPro

30000).

Keypad

The camera can be aligned for operation using this keypad.

Key Function

Call up set-up mode

Save the entered setting

Exit set-up mode

The function depends on the selected

menu or the planned operation and is

described in detail in the relevant section.

Operating controls 2

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 2.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 2/2

2.2 Connections

24V power supply

PIN assignments: 1 = 24 V

2 = 24 V (internally connected to PIN1)

3 = 0 V

Ethernet 10/100 MB (optional)

CAN-bus connections

CAN-connection PIN assignments

(as seen from the soldered or screw side)

Socket (female) Plug (male)

PIN No. Assignments

1 shield

2 nc

3 ground

4 CAN high

5 CAN low

Menus 3

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 3.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 1/6

3. Menus

Two menus are available, one for camera alignment and one for

operating the camera.

3.1. Entering the numerical values

Numerical values must be entered in different places in the menus

(e.g. setting the trigger threshold).

Procedure:

1. Select the required setting, e.g. trigger threshold A.

The value will be displayed “inversely”.

2. Press the “ENTER“ button. An input box will be displayed

on the screen.

The decimal place setting and the length of the input are

set to default settings when the input box is called up and

these cannot be altered.

3. You can now increase or decrease the value

using the arrow keys.

Keep pressing the relevant key to increase or decrease the

value by 1. If a major value change is required, keep the

relevant key pressed down until the required value is

reached.

Pressing the “SET-UP“ key will reset the value to zero.

4. Press the “ENTER“ to import the new value and to exit the

inputting routine.

Press the “ESC“ key if you do not want to import the new

value that you have entered. This will exit the inputting

routine without changing the original setting.

Menus 3

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 3.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 2/6

3.2. Foot line menu

This menu is activated when the camera is operating normally. One

line from the menu will be displayed in the bottom line of the

graphic display.

3.2.1 Menu navigation

Use the “Up“ or “Down“ arrows to select the required menu line or

the entries in the sub-menu.

Use the “Right“ or “Left“ arrow keys to select from within the line

displayed on the screen.

Press the “ENTER“ key to confirm the selection.

The relevant sub-menu (if available) will be displayed afterwards.

The menu will be exited automatically after the last sub-menu has

been edited.

Press the “ESC“ key to abort the entry in the set-up menu.

The parameters of the selected edge cannot be fully displayed due

to the display size in the menu bar.

The entries in columns 1 and 2 as well as 16 and 17 are always

displayed. The parameters in columns 3 – 15 shift to the right or

left, according to which parameter is selected with the arrow key.

Example:

Trigger A selected Search mode selected

3.2.2 Menu lines and the edge parameter significances

The first 8 lines display the most important edge parameters for

the 8 edges.

Default values are shown for the first 4 edges and the values for

edges 5 - 8 are freely selectable.

Menus 3

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 3.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 3/6

column

line

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

1 1 1> A 127 B 125 a 8 b 69 AB

A

12.3

N

2500

VWN

Focus value of the

corresponding edge

2 2 1< A 127 B 125 a 69 b 8 AB

3 3 1< A 125 B 127 a 8 b 69 AB

4 4 1> A 125 B 127 a 69 b 8 AB

5 5

--♦

A 125 B 127 a b

6 6 --

♦

A 125 B 127 a b

7 7 --

♦

A 125 B 127 a b

8 8 --

♦

A 125 B 127 a b

9 edge 1 edge 2 edge 3 edge 4 n = standardised

10 edge 5 edge 6 edge 7 edge 8 n

11 edge 1 edge 2 edge 3 edge 4 p = physically

12 edge 5 edge 6 edge 7 edge 8 p

13 web width left middle between the web centres

- 2500

web width right

The first 8 lines display the most important edge parameters for the

8 edges.

The first 4 edges are assigned default values.

In general, all of the edge definitions are freely selectable.

Column 1: Column 1 displays the edge number.

Column 2: Column 2 contains the edge definition.

The construction of the entry is explained in the following

example:

1>

•The number states how many edges should be

used in the search direction.

•The search direction must be set afterwards.

Search direction to the right = >

Search direction to the left = <.

•The contrast is defined in the third position.

= Contrast dark/bright

= Contrast bright/dark

Columns 3 and 4: Show trigger threshold A and the associated

trigger setting.

Columns 5 and 6: Show trigger threshold B and the associated

trigger setting.

Columns 7 and 8: Show the minimum edge width a and the

corresponding trigger setting.

Columns 9 and 10: Show the minimum edge width b and the

corresponding trigger setting.

Menus 3

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 3.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 4/6

Column 11: Defines the increment used for the edge numbers.

The edge entry is possibly on Aor Bor on the

middle value between A and B (AB).

The default setting is AB.

The block entry on A or B is used in specific cases in

order to achieve better recognition (e.g. in the case

of bad splice recognition).

Column 12: Displays the selected exposure mode.

A= Automatic exposure “ON“

F= Automatic exposure “OFF“. The exposure time is

fixed and depends on the setting displayed.

Column 13: Displays the current exposure time in ms.

Column 14: The entry states whether the edge is being searched

from the first pixel of the viewing range (N) or from a

fixed starting position (P).

For standard web guide control, please keep the following in

mind: If option P is selected, the edges must be

reconfigured. The configuration should be applied to the

camera.

Example:

Searching from the first pixel in the visible field (option N)

Searching from a fixed pixel position (option P)

Column 15: The entry states the starting pixel for the edge

search when option Pis selected.

If you enter a value while option N is selected in

column 14, this value will be ignored by the system.

When searching the edge from a fixed starting position

(option P), the beginning of the search can be set in the web

centre. The advantage of this approach lies in the reduced

susceptibility of the system to contamination and thus

provides a more effective measurement.

Column 16: Displays the current curve mode in abbreviated form.

V = video curve

W = white balance curve

VW = video curve with white balance correction

VWN = VW standardised display

Scan direction edge 1 = 1>

Scan direction edge 2 = 1<

Scan direction edge 1 = 1< P 2500

Scan direction edge 2 = 1> P 2500

Menus 3

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 3.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 5/6

Lines 9 and 10 show the standardised edge positions.

Lines 11 and 12 show the physical edge positions.

When line 13 is selected, alignment mode is automatically

activated. Displayed here is the width of the left web, the centre of

the web minus half the resolution and the width of the right web.

Attention: Alignment mode interrupts a running control or

web width measurement!

Thus it should never be started during normal

operation.

3.3 Set-up menu

This menu is displayed at the front of the graphics display.

Press the “SET UP“ key to call up this menu.

Other display sections are not updated whilst the “Set-up” menu is

displayed.

3.3.1 Menu navigation

Use the “Up“ or “Down“ arrow keys to select the required menu

option.

The selected entry will be displayed “inversely”.

As the screen window does not display the entire menu, scrolling

will occur as necessary when the respective end has been

reached. The menu displayed in the window will be moved upwards

automatically when scrolling downwards and downwards when

scrolling upwards.

Press the “ENTER“ key to confirm the selection.

The relevant sub-menu (if available) will be displayed afterwards.

The set-up menu will be exited automatically and the operating

screen will be displayed after the last sub-menu has been edited.

Press the “ESC“ key to abort the entry in the set-up menu.

Menus 3

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 3.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 6/6

3.3.2 Menu hierarchy

The explanations of the individual menu options are given in the

chapter in which they are used.

Save parameters

Parameters

Remote

Set defaults

Curve mode

White balance

Black balance

● Language

● German

● English

● Curve mode

● dot

● line

● Bus info

● off

● on

● Yes

● No

● Remote off

● Camera x, y

● Camera x, z

● Yes

● No

● Reset communication

● Reset application

● Reset all

● WD

-Test

● Video Abs

● White Abs

● V

∗W Abs

● V ∗W standard

White bal. min. lvl.

Aut. exp. target lvl.

Assembly / Installation 4

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 4.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 1/3

4 Assembly / Installation

4.1Installation site requirements

The CCDPro … camera must be installed in a dry,

non-vibrating position.

Ambient conditions: Temperature: 0 to a max. 45°C

Humidity: 5 - 90%,

no condensation

4.2 Installing the camera

A BST-eltromat-holder, which enables you to align the camera to

the material web in three axes, is provided as the camera-

mounting unit.

The installation version depends on the job definition and the site

chosen as the installation site in the production machine.

For example:

4.3 Installing the light source

The installation of the light source depends on the scanning

method that you plan to use.

However, you must bear in mind that a build up of dirt must be

prevented.

The following must also be taken into consideration when using

reflection copy:

•The light source must be installed so that the light beam being

reflected from the surface is reflected into the camera when

scanning the edges of transparent material.

For example:

Material web

Material background

camera

Light source

Assembly / Installation 4

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 4.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 2/3

•The light source should be aligned so that diffuse reflection is

produced for recognising lines and colour contrasts on

transparent and non-transparent material webs. This is

dependent on the type of light source being used and the

material that is being scanned.

For example:

You must ensure without fail that the light source is never

positioned in the camera’s visual path when working with reflection

copy.

4.4 Background determination

If necessary, a matt black material background plate must be

installed behind the material web so that it is always in the

camera’s visual area. This will prevent ambient light from having

any effect and thus guarantee correct scanning of the edge of the

material web.

4.5 Fitting a support roller

You must ensure that the material web is never creased nor

becomes wavy as both of these problems will affect the edges.

You must also prevent any height fluctuations from occurring with

regard to the material web, as these will have a detrimental affect

on the measured results.

These problems can be eliminated by fitting a support roller.

Material background

Material web

Light source

camera

Assembly / Installation 4

CCD Camera EDV-No.: MD.167.01.07/2.6.8 Chapter: 4.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 3/3

4.6 Installation

Connect up the electrical supplies as shown in the connection

diagram.

The CAN-bus lines must be screened and must be laid separately

from any other lines that might interfere with them or those carrying

high power.

You must ensure that and that the lines are connected up correctly,

are protected and that the insulation is not damaged.

You are only permitted to use HF-fluorescent lamps (≥30 kHz) as

the light source.

Commissioning 5

CCD Camera EDV-No.:MD.167.01.07/2.6.8 Chapter: 5.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 1/18

5. Commissioning

5.1 Camera settings

5.1.1 Setting the CAN-address

If the camera is a constituent part of a BST-eltromat projection

system, then the CAN-address has already been set up in

accordance with the job details. You do not have to reset anything

with regard to this.

If the CAN-address has to be set up on site, then proceed as

follows:

There are two stoppers on the camera’s

connection side and you will find a BCD

switch or a DIL-switch for setting up the

CAN address behind these.

Remove the stoppers.

BCD switch S41 is fitted in the

upper opening and DIL-switch

S42 is fitted in the lower opening.

The CAN address is created as follows:

CAN address = Tens address + Units address

The function number (sensor 1 – 4 assignment) is set up using

DIL-switches S42.1 and S42.2. It has the following assignments:

S42.2 S42.1 Tens address Sensor

assignment

OFF OFF 20 Sensor 1

OFF ON 30 Sensor 2

ON OFF 40 Sensor 3

ON ON 50 Sensor 4

S41

S42

Commissioning 5

CCD Camera EDV-No.:MD.167.01.07/2.6.8 Chapter: 5.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 2/18

The rotary switch S41 is used to determine the “units” of the CAN

address. BST-eltromat devices with the same „Units“ (e.g. EKR11,

CCD21 and CCD31) each form a control.

Example:Setting up a CCDPro … camera as sensor 2 for an

ekrPro … using node number 13:

S41 = 3; S42.1 = ON; S42.2 = OFF

This corresponds to node number 33

5.1.2 Key lock

After commissioning is complete, it is possible to protect the

camera against unauthorised parameter changes. This is achieved

with a keyboard lock. The keyboard lock can be

activated/deactivated using the DIL switch S42.3.

S 42.3 ON Key operations locked

OFF

Key operations not locked

5.1.3 Setting up the terminator resistor

The terminator resistor is set up using the DIL switch S 42.4.

S 42.4

ON

Terminator active

OFF

Terminator inactive

Commissioning 5

CCD Camera EDV-No.:MD.167.01.07/2.6.8 Chapter: 5.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 3/18

5.2 Mechanical alignment

5.2.1 Mounting and optical adjustment

The first step is coarse camera adjustment, so that the line sensor

is viewing the entire viewing range with regard to background

illumination. The material web should not be fed in.

If the material web cannot be removed for making the coarse

adjustment, another option is to place a light coloured object on the

web as an alternative background (opaque white paper or white

film) on the web. This will then be illuminated from the camera

side.

Procedure:

1. Position the camera in accordance with the job details (as

edge controller or centre controller).

Align the camera’s viewing range so that it is at a 90°

angle to the material web.

2. Set camera the curve mode to “Video Abs“.

3. Black balance must be run now.

The “Set-up” menu must be called up to do this.

∗Select the “Black balance“ menu option

∗Press the “ENTER“ button

∗Press the “ESC“ button.

Black balance has now been completed and you will also

exit the “Set-up” menu.

Center line guiding

using one camera

Center line guiding

using two cameras

Camera 1

Camera 2

Edge guiding

Commissioning 5

CCD Camera EDV-No.:MD.167.01.07/2.6.8 Chapter: 5.0

CCDPro 30000/5000 Date: 30.03.2011 Page: 4/18

4. Remove the protective cover from the camera. To do this

you must undo the grub screw in the protective cover and

the one in the lens focusing ring and then pull the

protective cover downwards.

5. Switch the power on to the camera.

6. Set the aperture so that the exposing time is > 10 ms.

The exposing time will now be displayed in the bottom line

in the graphics display.

7. Set the curve mode in the “Set-up“ menu to “Dot“

8. Place an opaque strip (e.g. paper strip) in camera’s visual

area.

Now set the lens focus.

The default setting must be set up using the distance

between the camera and the material web.

Focus

Aperture

This manual suits for next models

1

Table of contents