SAFETY WARNINGS

WARNING: For your own safety, please read this manual before attempting to operate

your new unit. Failure to follow instructions can result in serious personal injury.

Spend a few moments to familiarize yourself with your blower before each use. If you

give this tool to another person, also hand over this manual.

Use this tool as described in this manual. Any mishandling and any use contrary to the

instructions will not in any way engage the liability of the manufacturer.

Non-compliance with safety instructions and use can cause a risk of electric shock,

fire and /or injury to persons.

READ YOUR USER MANUAL THOROUGHLY BEFORE OPERATING YOUR UNIT.

.

Never allow children, persons with reduced physical, sensory or mental capabilities or

lack of experience and knowledge or people unfamiliar with these instructions to use

the machine, local regulations may restrict the age of the operator.

Keep children, other bystanders and pets away from the machine while operating.

Remember that the operator or user is responsible for accidents or hazards occurring

to persons or their belongings.

Do not disassemble the tool yourself. Disassembly, repair or verification must be made

exclusively by qualified personnel.

WEAR CLOSE FITTING, TOUGH WORK CLOTHING that will provide protection, such

as long slacks or trousers, safety work shoes, heavy duty work gloves, hard hat, a

safety face shield, or safety glasses for eye protection. The tool is extremely noisy and

requires the use of ear protection, such as a good grade of ear plugs or other sound

barriers.

Always carry the machine by its handle; never use any other part of the machine.

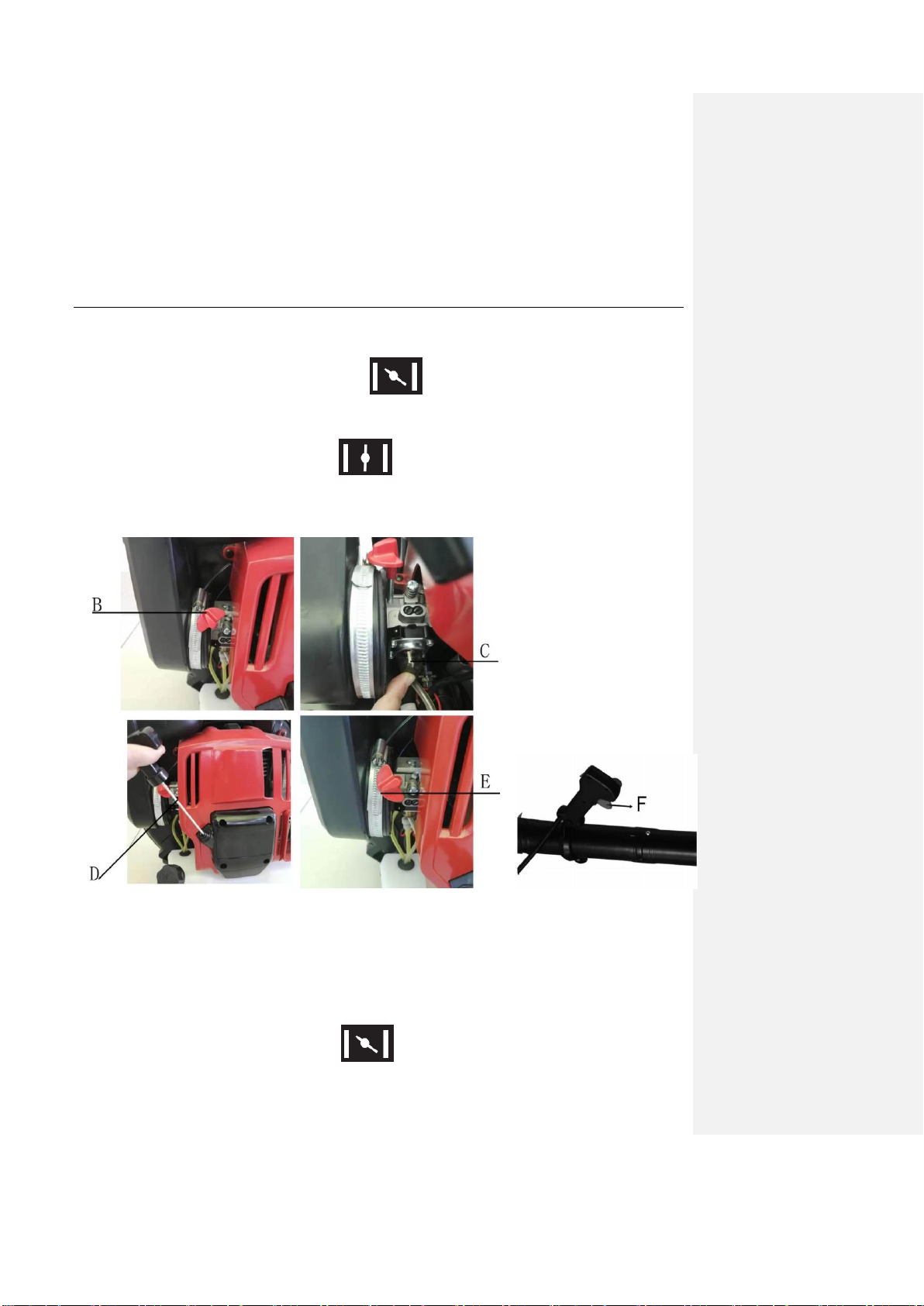

REFUEL IN A SAFE PLACE. Open fuel cap slowly to release any pressure which may

have formed in fuel tank. Always wipe unit of fuel or oil spills before starting. To prevent

a fire hazard, move at least 10 feet (3meters) from fueling area before starting.

TURN UNIT OFF before setting it down and also before installing or removing

attachments.

KEEP ALL SCREWS AND FASTENERS TIGHT and the unit in good operating

condition. Never operate this equipment if it is improperly adjusted or not completely

and securely assembled.

KEEP HANDLES DRY, clean and free of fuel mixture.

STORE EQUIPMENT AWAY FROM POSSIBLE IGNITION SOURCES, such as gas-

powered water heaters, clothes dryers, or oil-fired furnaces, portable heaters, etc.

ALWAYS KEEP the engine free of debris build-up.

OPERATION OF EQUIPMENT should always be restricted to mature and properly

instructed individuals.

ALL PERSONS WITH RESPIRATORY PROBLEMS and persons operating blower in

very dusty environments, should wear a dust particle mask at all times. Paper dust

masks are available at most paint and hardware stores.

Operate the machine only at reasonable hours - not early in the morning or late at

night when people might be disturbed. Comply with times listed in local ordinances.

Avoid using the machine in bad weather, especially when there is a risk of

thunderstorms and lightning.

In case of accident, immediately stop using the machine. Turn the machine off and

check the problem. Do not use the machine while the machine is damaged.