NIR-Online GmbH Table of contents

Operation Manual Process Analyser PA2 iii

Contents

1 About this document...........................................................................................................5

1.1 Warning notices in this document........................................................................................................ 5

1.2 Symbols ............................................................................................................................................... 5

1.2.1 Warning symbols .....................................................................................................................5

1.2.2 Mandatory directive symbols ...................................................................................................5

1.3 Mark-ups and symbols......................................................................................................................... 6

2 Safety....................................................................................................................................7

2.1 Proper use ........................................................................................................................................... 7

2.2 Use other than that intended ............................................................................................................... 7

2.3 Location of safety notices and warning signs on the product .............................................................. 7

2.4 Safety features..................................................................................................................................... 8

2.4.1 Thermostat............................................................................................................................... 8

2.5 Residual risks ...................................................................................................................................... 8

2.5.1 Risk of explosion from opening up the sensor ......................................................................... 8

2.5.2 Risk of explosion from unplugging the device power plug ....................................................... 8

2.6 Staff qualification ................................................................................................................................. 9

2.7 Personal protective equipment (laboratory)......................................................................................... 9

2.8 Personal protective equipment (production) ........................................................................................ 9

2.9 Modifications........................................................................................................................................ 9

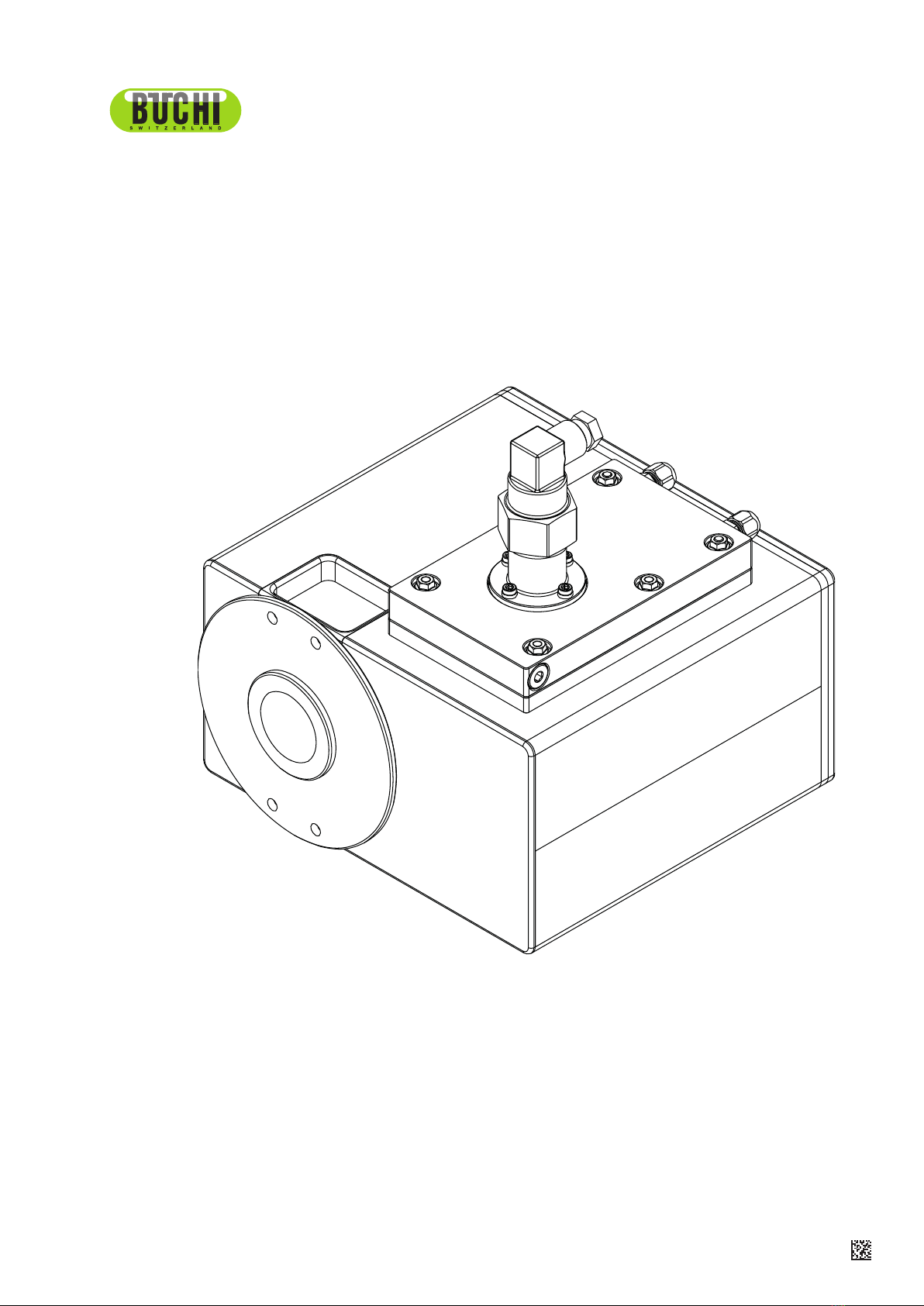

3 Product description...........................................................................................................11

3.1 Description of function ....................................................................................................................... 11

3.2 Configuration ..................................................................................................................................... 11

3.2.1 Front view ..............................................................................................................................11

3.2.2 Rear view ............................................................................................................................... 12

3.3 Type plate .......................................................................................................................................... 12

3.4 ATEX rating ....................................................................................................................................... 14

3.5 Scope of delivery ............................................................................................................................... 14

3.6 Technical data ................................................................................................................................... 15

3.6.1 Sensor.................................................................................................................................... 15

3.6.2 Installation box ....................................................................................................................... 15

3.6.3 Ambient conditions................................................................................................................. 15

3.6.4 Materials ................................................................................................................................16

3.6.5 Computer system requirements............................................................................................. 16

3.6.6 Software................................................................................................................................. 16

4 Transport and storage ......................................................................................................18

4.1 Transport ........................................................................................................................................... 18

4.2 Storage .............................................................................................................................................. 18

5 Installation..........................................................................................................................19

5.1 Installation site (production)............................................................................................................... 19

5.2 Installation site (laboratory)................................................................................................................ 19

5.3 Installation point in piping system (example) ..................................................................................... 20

5.4 Installation (example)......................................................................................................................... 21

5.5 Establishing installation point............................................................................................................. 21

5.6 Sensor installation ............................................................................................................................. 22

5.7 Connecting the sensor....................................................................................................................... 23

5.8 Connecting the video cable (optional accessory) .............................................................................. 25

5.9 Connecting the thermostat................................................................................................................. 26

5.10 Connecting the coolant ...................................................................................................................... 26

5.11 Establishing the electrical connection to the installation box............................................................. 26