2

4D LABS, Simon Fraser University 8888 University Drive, Burnaby, B.C. V5A 1S6

E nanoimaging@4dlabs.ca T 778.782.8158 F 778.782.3765 W www.4dlabs.ca

Table of Contents

Overview..................................................................................................................................................1

Revision History........................................................................................................................................1

Table of Contents.....................................................................................................................................2

General Information .................................................................................................................................4

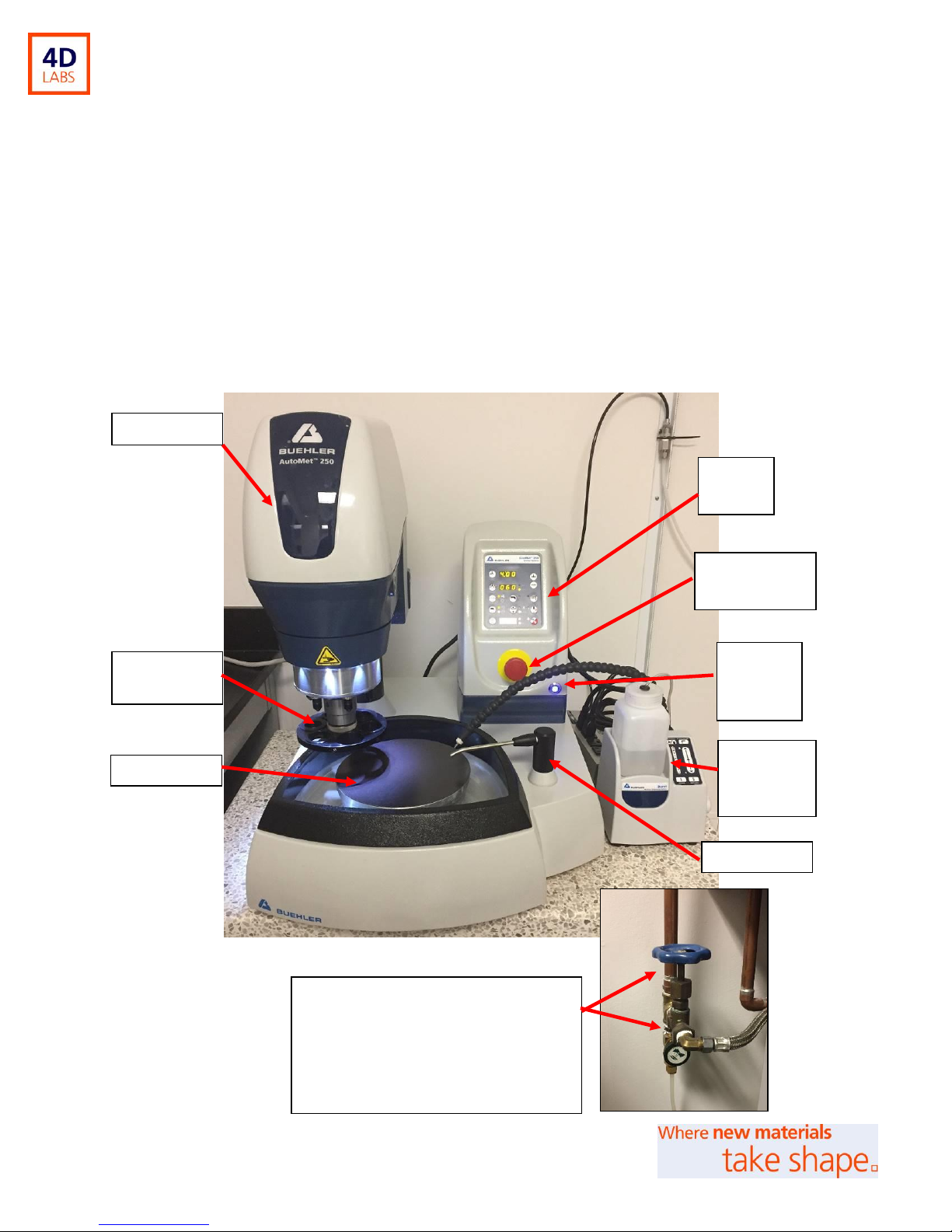

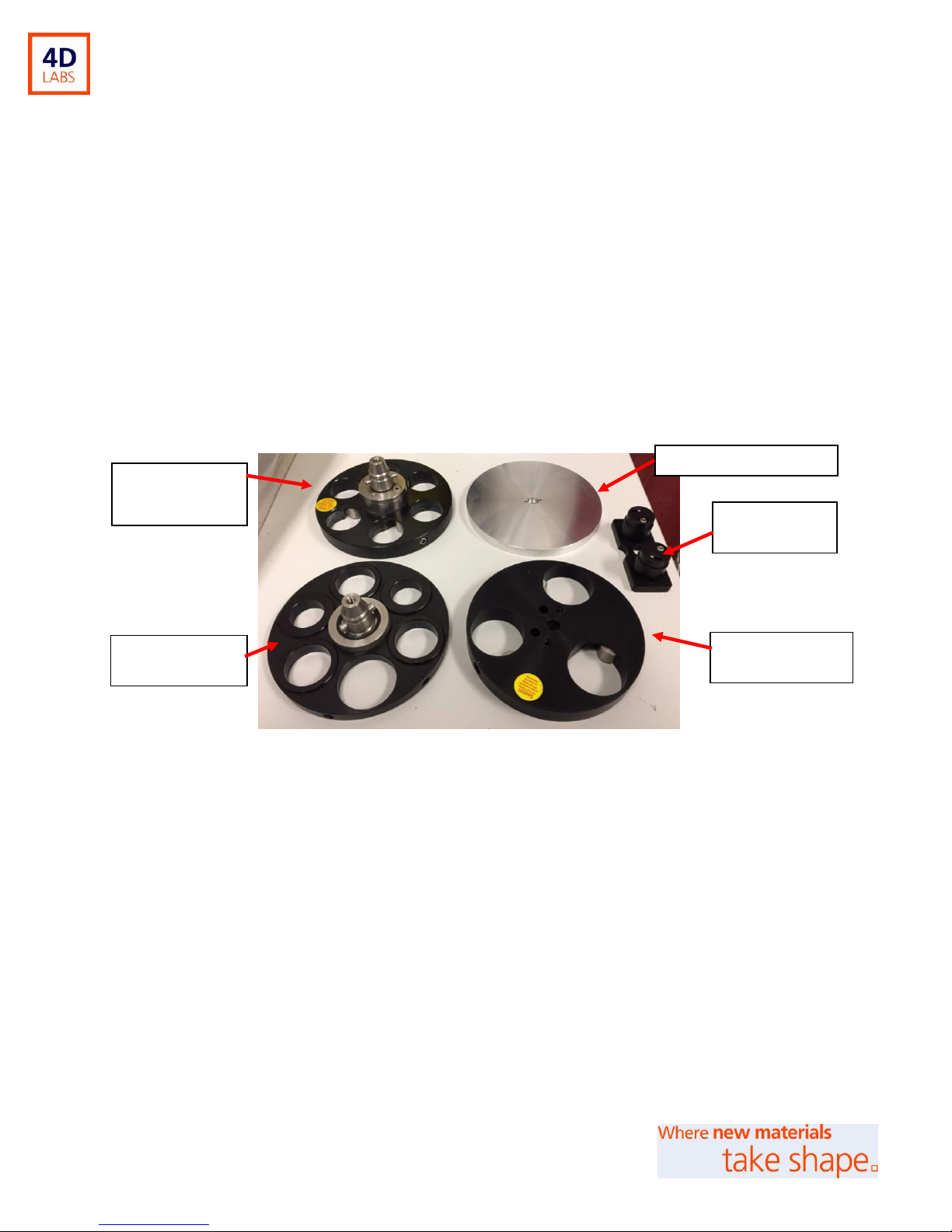

Main components: ...................................................................................................................................4

Safety ......................................................................................................................................................5

Operation ................................................................................................................................................6

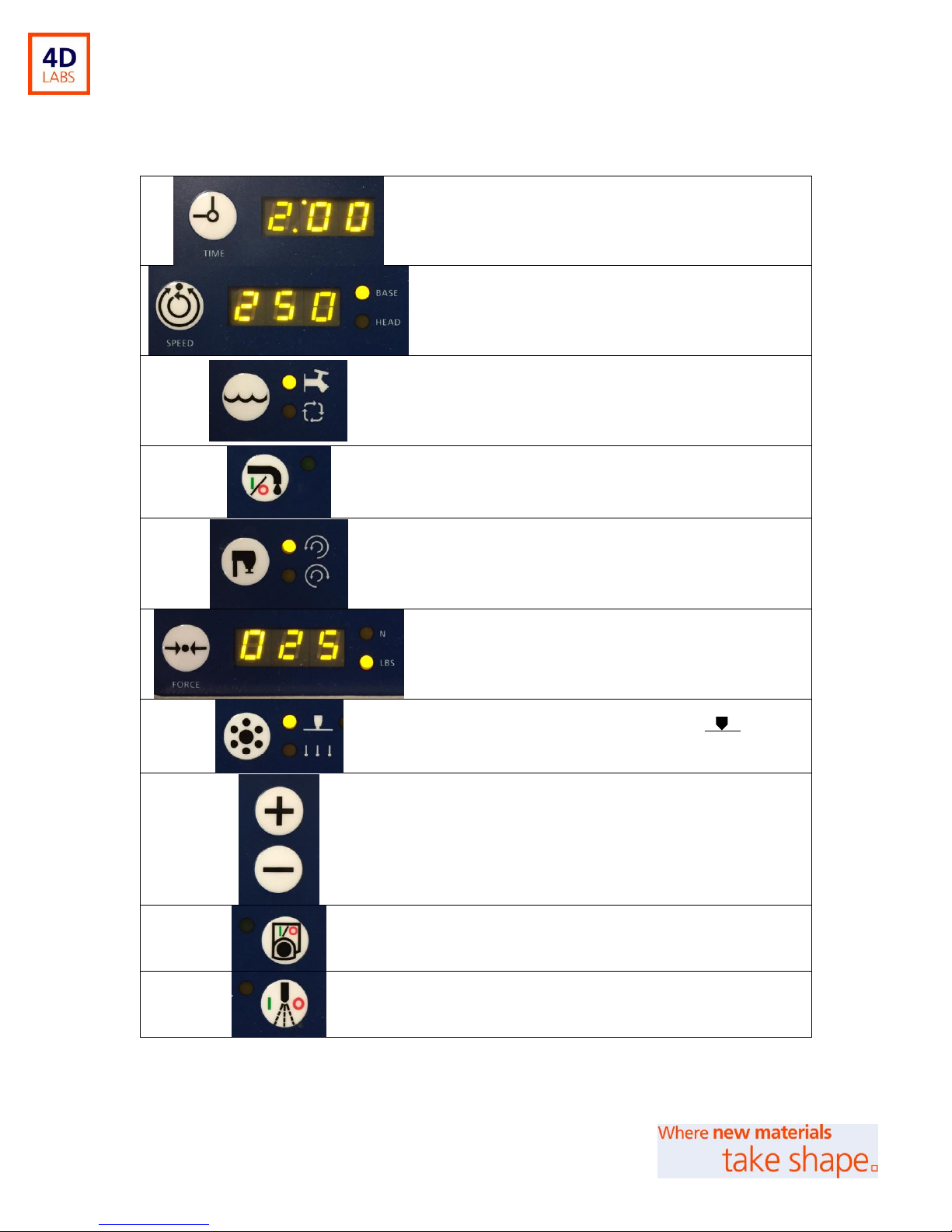

Control Panel:......................................................................................................................................6

Preparing your grinding or polishing platens: ............................................................................................8

Using Diamond Polishing Solutions.......................................................................................................8

Preparing Samples in the Power Head:......................................................................................................9

Specimen Holders.................................................................................................................................9

Loading a Specimen Holder ................................................................................................................10

Removing a Specimen Holder .............................................................................................................11

Single Force .......................................................................................................................................11

Central Force .....................................................................................................................................11

Mounting the Glass Slide Holder.........................................................................................................12

Begin the Grinding / Polishing Procedure ................................................................................................14

Exchanging grinding and polishing discs .................................................................................................16

After use................................................................................................................................................16

References and Files...............................................................................................................................17

Contact Information ...............................................................................................................................17

Supplementary Information ....................................................................................................................18

Silicon Carbide Abrasive Grinding Discs ..............................................................................................18

Diamond Polishing Solutions ..............................................................................................................18