3

Table of Contents

Warranty and Service ..............................................................................................................................2

Table of Contents....................................................................................................................................3

Warning...................................................................................................................................................4

Introduction..............................................................................................................................................6

Specifications ..........................................................................................................................................6

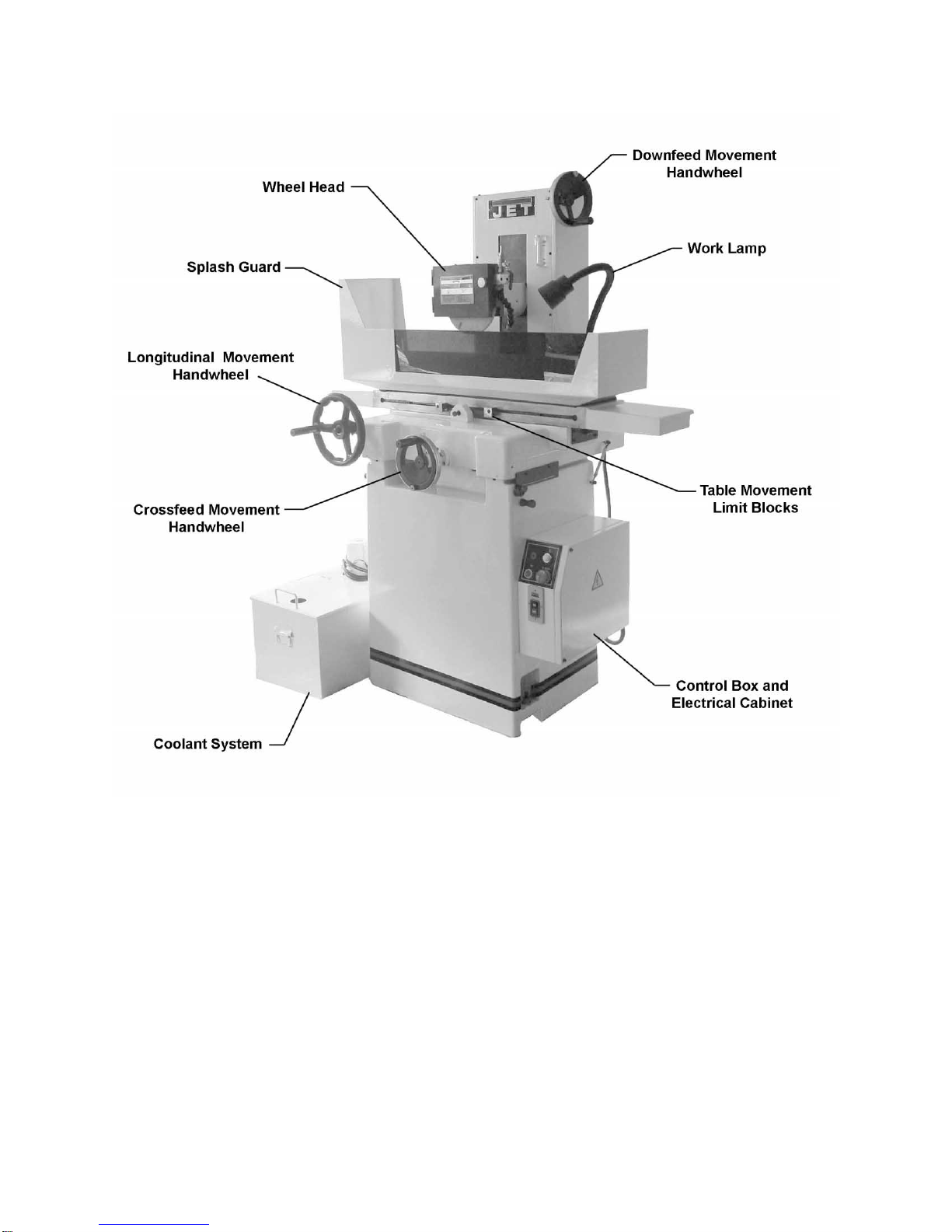

Features of the JPSG-618M1...................................................................................................................7

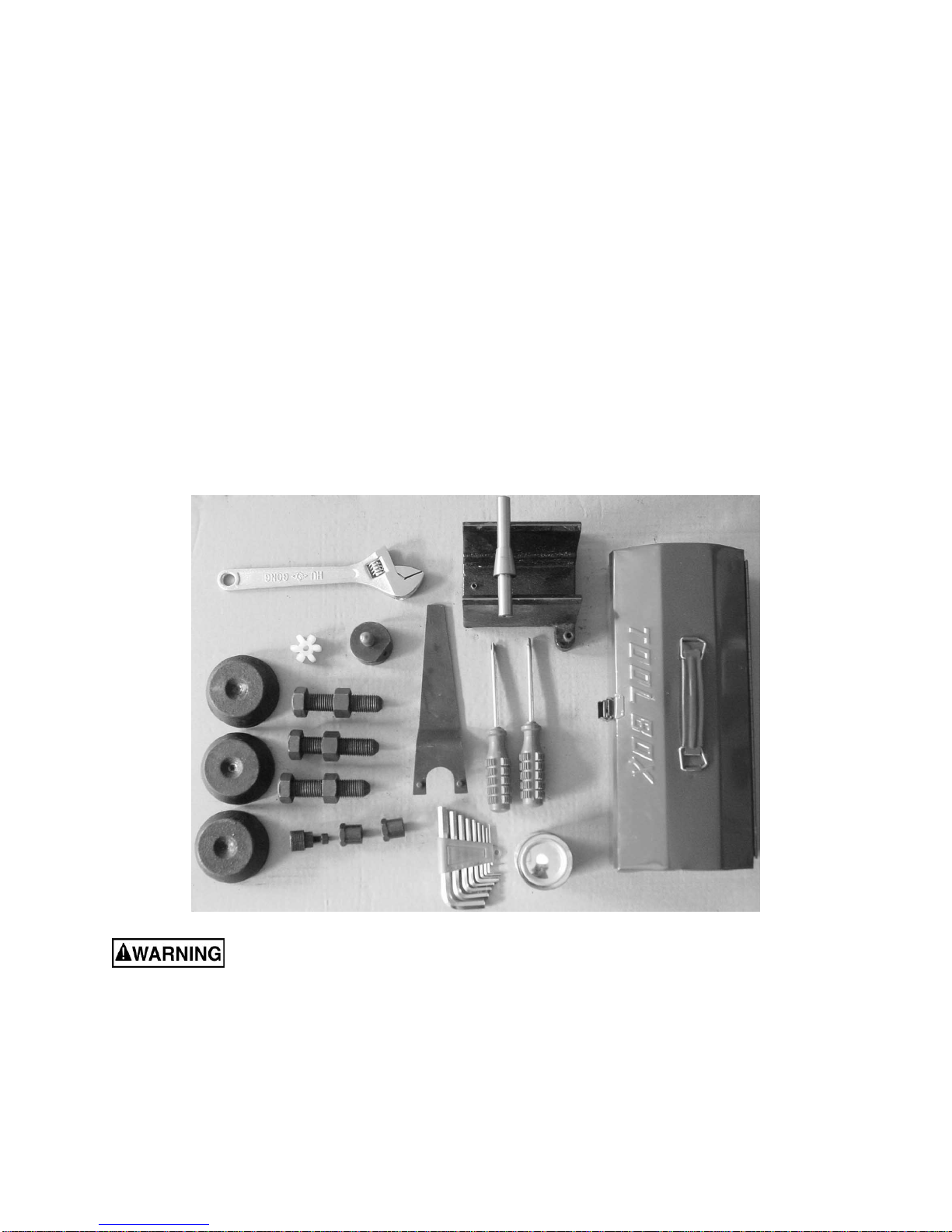

Unpacking ...............................................................................................................................................9

Contents of the Shipping Container......................................................................................................9

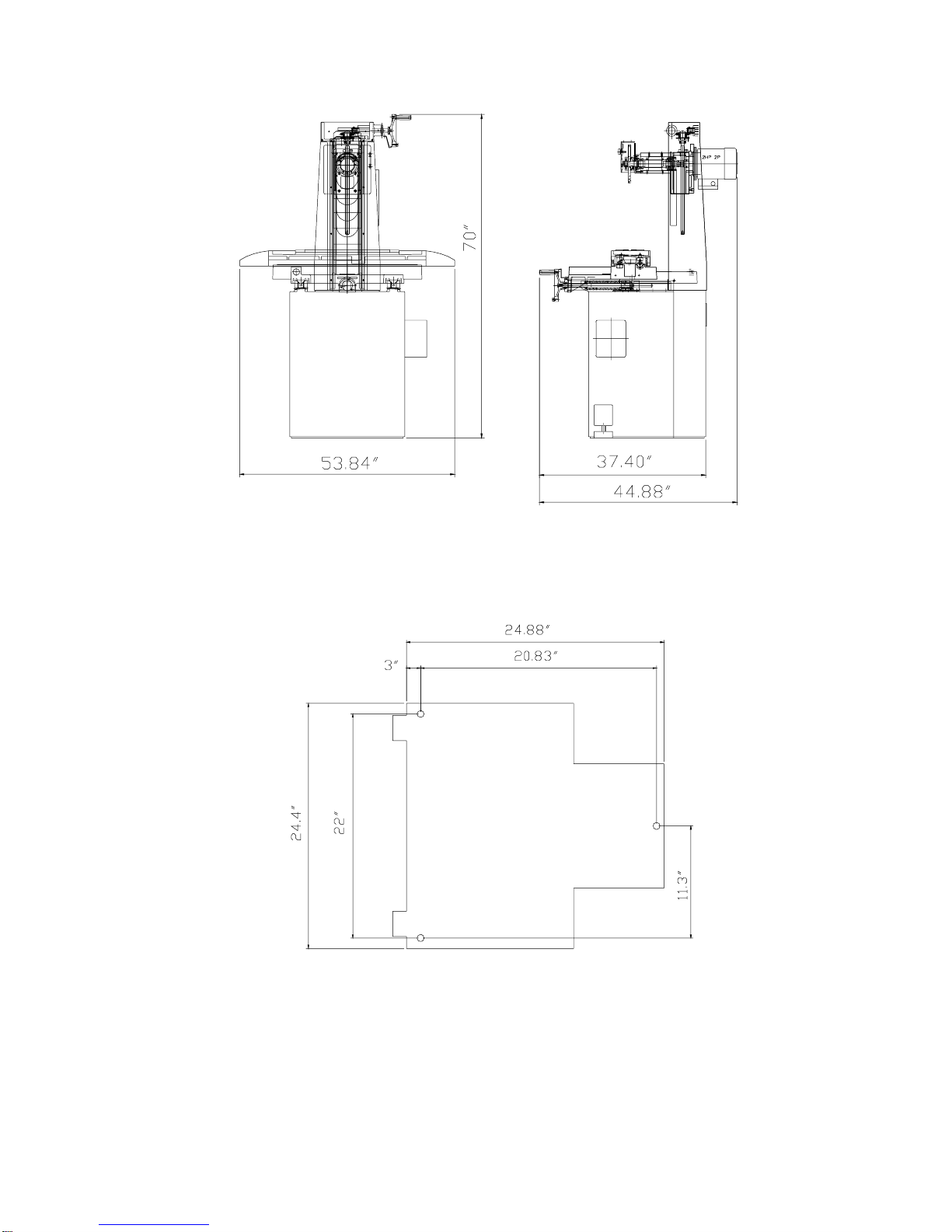

Installation and Assembly ......................................................................................................................10

Installing Table...................................................................................................................................11

Leveling the Machine .........................................................................................................................11

Installing Splash Guard......................................................................................................................12

Installing Coolant System...................................................................................................................12

Installing Grinding Wheel....................................................................................................................12

Removing Wheel Assembly................................................................................................................13

Wheel Dressing..................................................................................................................................13

Wheel Balancing................................................................................................................................14

Grounding Instructions...........................................................................................................................14

Extension cords..................................................................................................................................15

230 Volt, Three Phase Operation........................................................................................................15

Converting from 230 Volt to 460 Volt..................................................................................................15

Adjustments...........................................................................................................................................16

Timing Belt.........................................................................................................................................16

Operating Controls.................................................................................................................................16

Operation...............................................................................................................................................16

Longitudinal Movement of Table.........................................................................................................16

Crossfeed Movement of Table............................................................................................................16

Coolant System..................................................................................................................................17

Auto Lubrication System.....................................................................................................................17

Grinding Wheel Selection Chart.............................................................................................................18

Troubleshooting.....................................................................................................................................19

Replacement Parts................................................................................................................................19

Parts List: Spindle Assembly..............................................................................................................20

Spindle Assembly...............................................................................................................................21

Parts List: Column Assembly..............................................................................................................22

Column Assembly..............................................................................................................................26

Parts List: Saddle and Base Assembly ...............................................................................................22

Saddle and Base Assembly................................................................................................................23

Parts List: Table Assembly.................................................................................................................27

Table Assembly..................................................................................................................................29

Parts List: Base Assembly..................................................................................................................30

Base Assembly..................................................................................................................................31

Parts List: Guard and Electrical Assembly ..........................................................................................32

Guard and Electrical Assembly...........................................................................................................33

Parts List: Coolant System .................................................................................................................34

Coolant System..................................................................................................................................35

Parts List: Electrical Panel..................................................................................................................36

Electrical Panel ..................................................................................................................................37

Electrical Connections ...........................................................................................................................38