Safety Tips

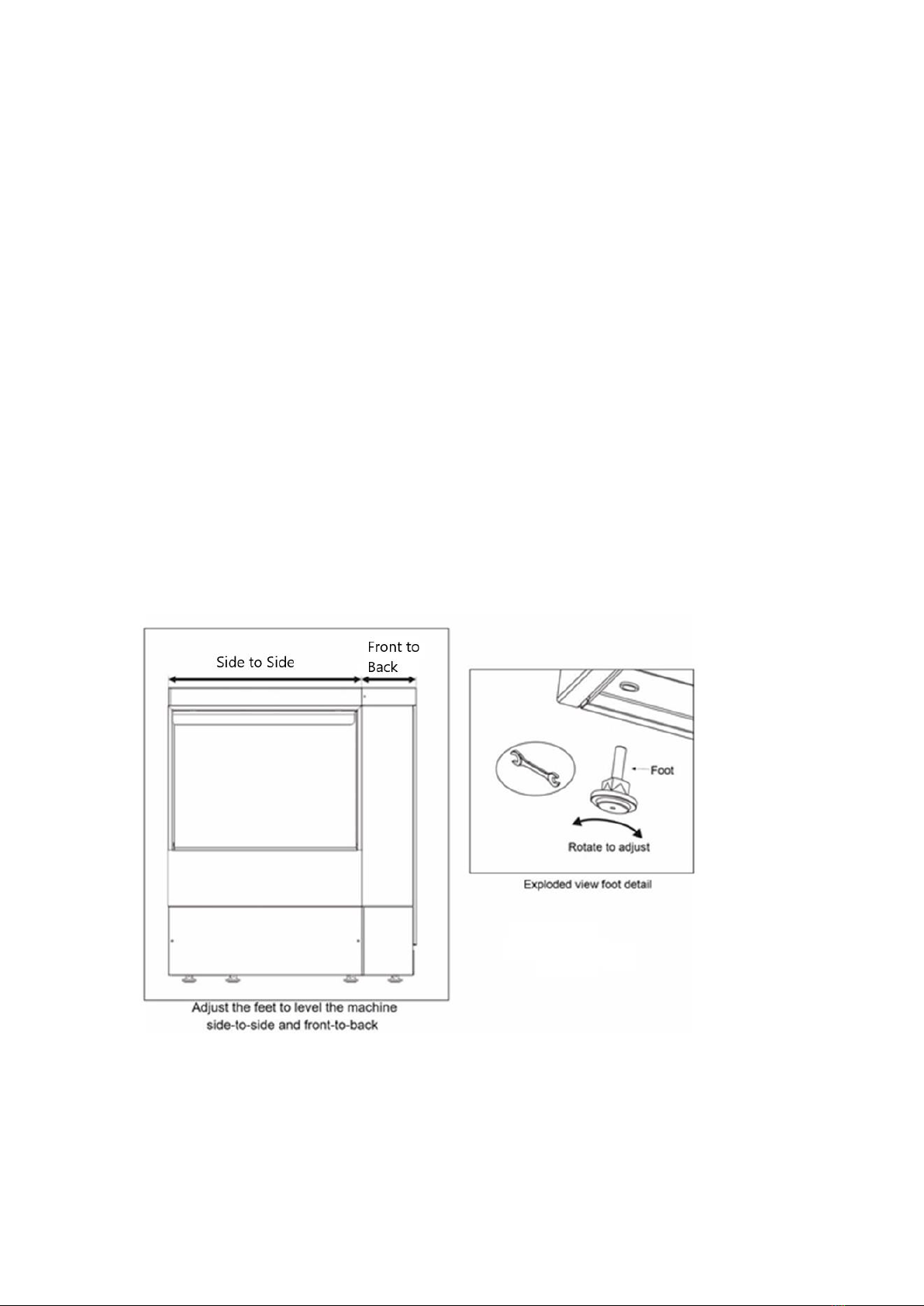

Position on a flat, stable surface.

A service agent/qualified technician should carry out installation and

any repairs if required. Do not remove any components on this

product.

Consult Local and National Standards to comply with the following:

•Health and Safety at Work Legislation

•BS EN Codes of Practice

•Fire Precautions

•IEE Wiring Regulations

•Building Regulations

DO NOT immerse the appliance in water.

Always switch off and disconnect the power supply to the appliance

when not in use.

Not suitable for outdoor use.

Keep all packaging away from children. Dispose of the packaging in

accordance to the regulations of local authorities.

Children should be supervised to ensure they do not play with, or

operate the Dishwasher

The function of this Dishwasher is the washing of Dishes and similar

ONLY.

Do not use cleaning agents that contain Chlorine, Bleach or

Hypochlorite

Only use commercial grade detergents and rinse aids in your

Dishwasher

Wear the correct personal protective equipment when handling

chemicals and observe all safety notes

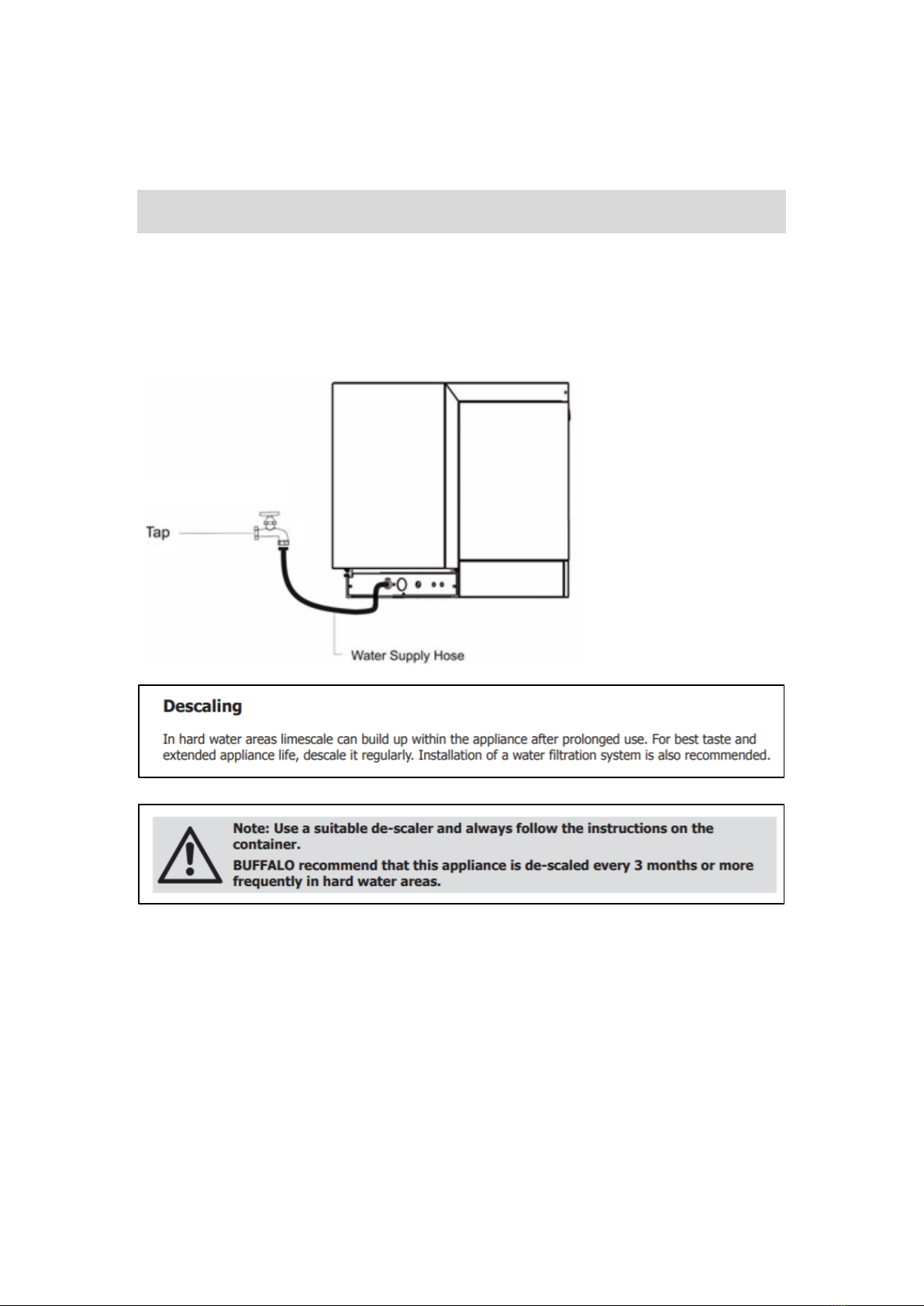

Damage to the Dishwasher caused by lime scale or poor water quality

will NOT be covered by the manufacturers warranty –fitting of a water

softener is recommended

The installer and user are responsible for ensuring the installation and

operation of this Dishwasher

Ensure the base of the unit is never submerged or standing in water

when operating the Dishwasher

Do not use electrical extension lead(s) to supply power to your

Dishwasher

If the power cord is damaged, it must be replaced by a BUFFALO agent

or a recommended qualified technician in order to avoid a hazard.

This appliance can be used by children aged from 8 years and persons

with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe way and if they

understand the hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall not be made by

children without supervision.