NS 25 AM-Atex

Contents

1 Introduction..................................................................................................................................................................................................................... 2

1.1 Intended Use.........................................................................................................................................................................................................2

1.2 Product Description............................................................................................................................................................................................2

1.3 Scope of Delivery..................................................................................................................................................................................................2

1.4 Ordering Instructions......................................................................................................................................................................................... 2

1.5 Type plate ..............................................................................................................................................................................................................2

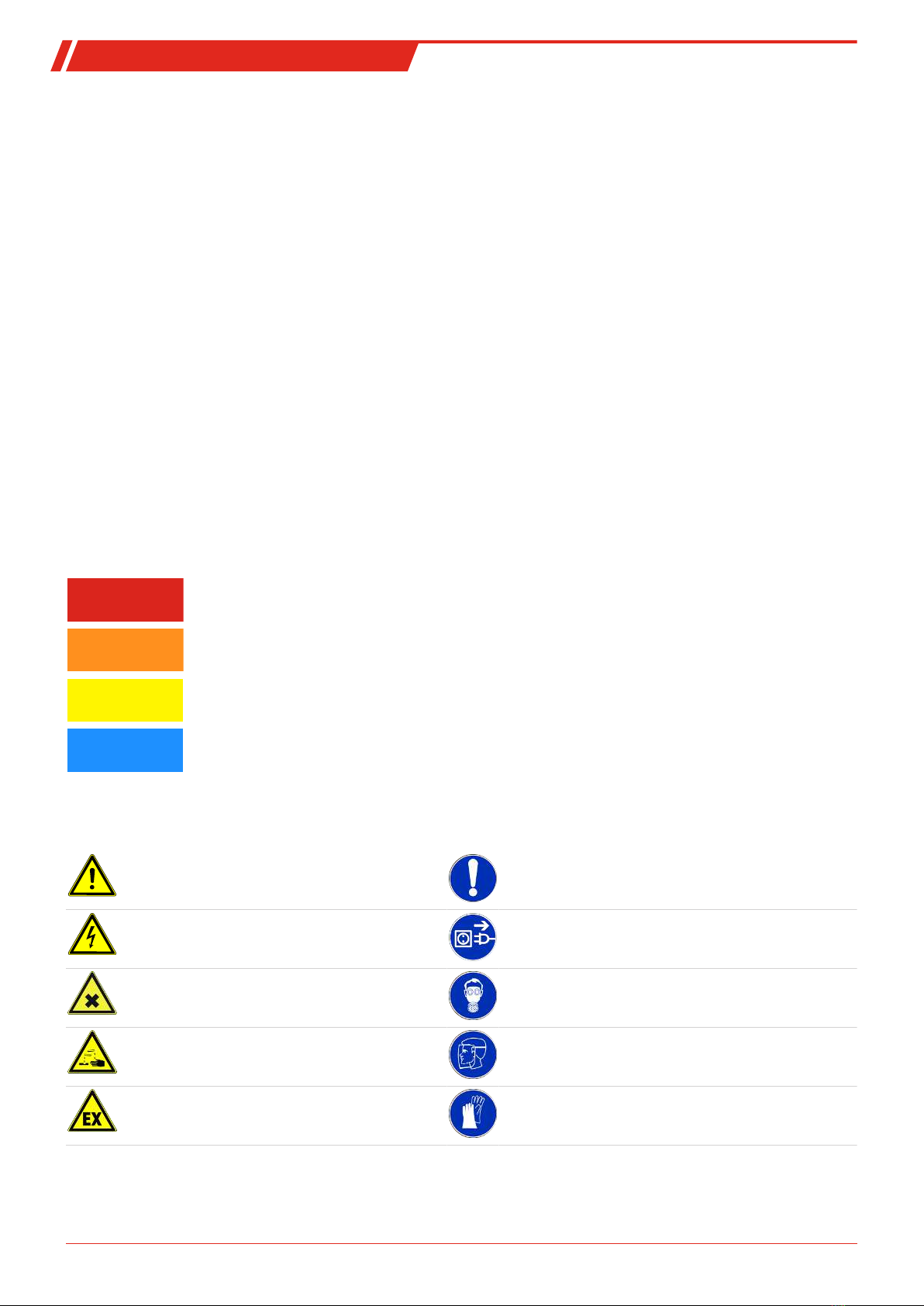

2 Safety instructions......................................................................................................................................................................................................... 3

2.1 Important advice................................................................................................................................................................................................. 3

2.2 General hazard warnings .................................................................................................................................................................................4

3 Transport and storage .................................................................................................................................................................................................. 5

4 Installation and connection........................................................................................................................................................................................6

4.1 Installation ............................................................................................................................................................................................................6

4.2 Electrical connections (intrinsically safe).....................................................................................................................................................6

4.2.1 Intrinsically-safe connection............................................................................................................................................................ 6

4.2.2 PA connection (potential equalisation) .........................................................................................................................................7

4.3 Information on the correct operation of reed contacts in Bühler level switches.............................................................................8

5 Operation and control ..................................................................................................................................................................................................9

6 Cleaning and Maintenance........................................................................................................................................................................................11

7 Service and repair..........................................................................................................................................................................................................12

7.1 Accessories........................................................................................................................................................................................................... 12

8 Disposal............................................................................................................................................................................................................................13

9 Appendices..................................................................................................................................................................................................................... 14

9.1 Technical Data.................................................................................................................................................................................................... 14

9.2 Contacts ................................................................................................................................................................................................................15

10 Attached documents................................................................................................................................................................................................... 16

iBühler Technologies GmbHBE200005 ◦ 10/2020