2

Introduction 2-5

Safe y symbol and signal word review........................2

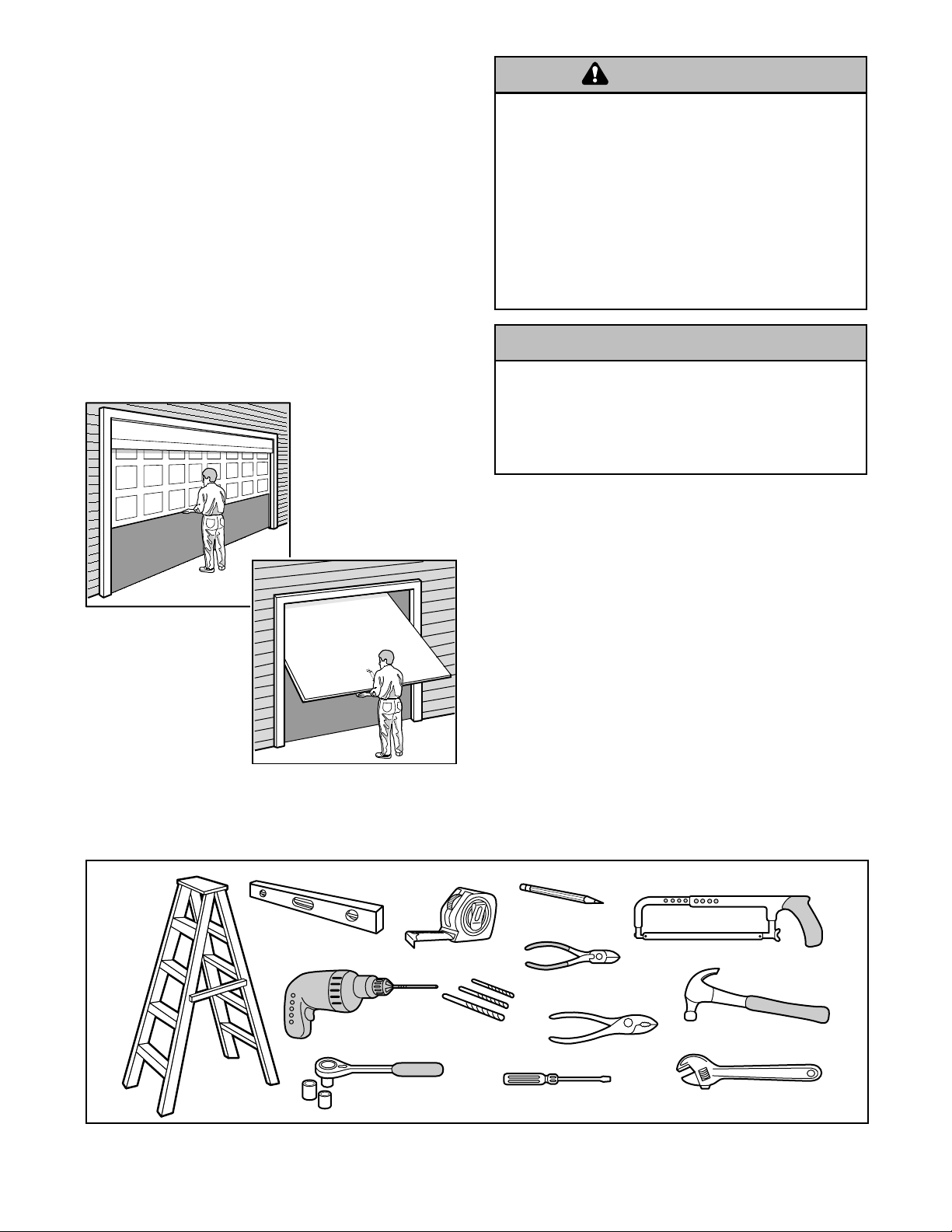

Preparing your garage door ........................................3

Tools needed...............................................................3

Planning .....................................................................4

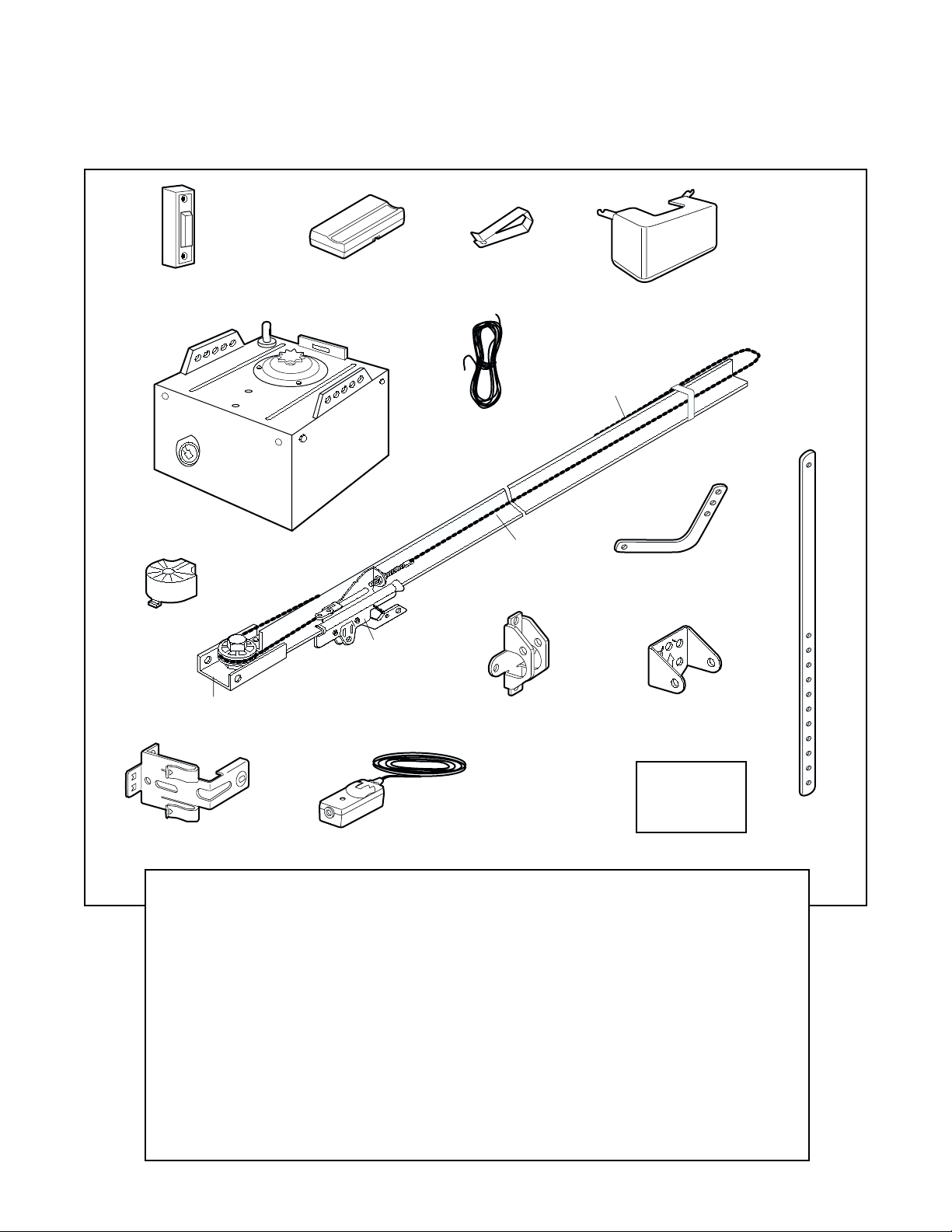

Car on inven ory..........................................................5

Hardware inven ory .....................................................5

Assembly 6-7

A ach he rail o he mo or uni ...................................6

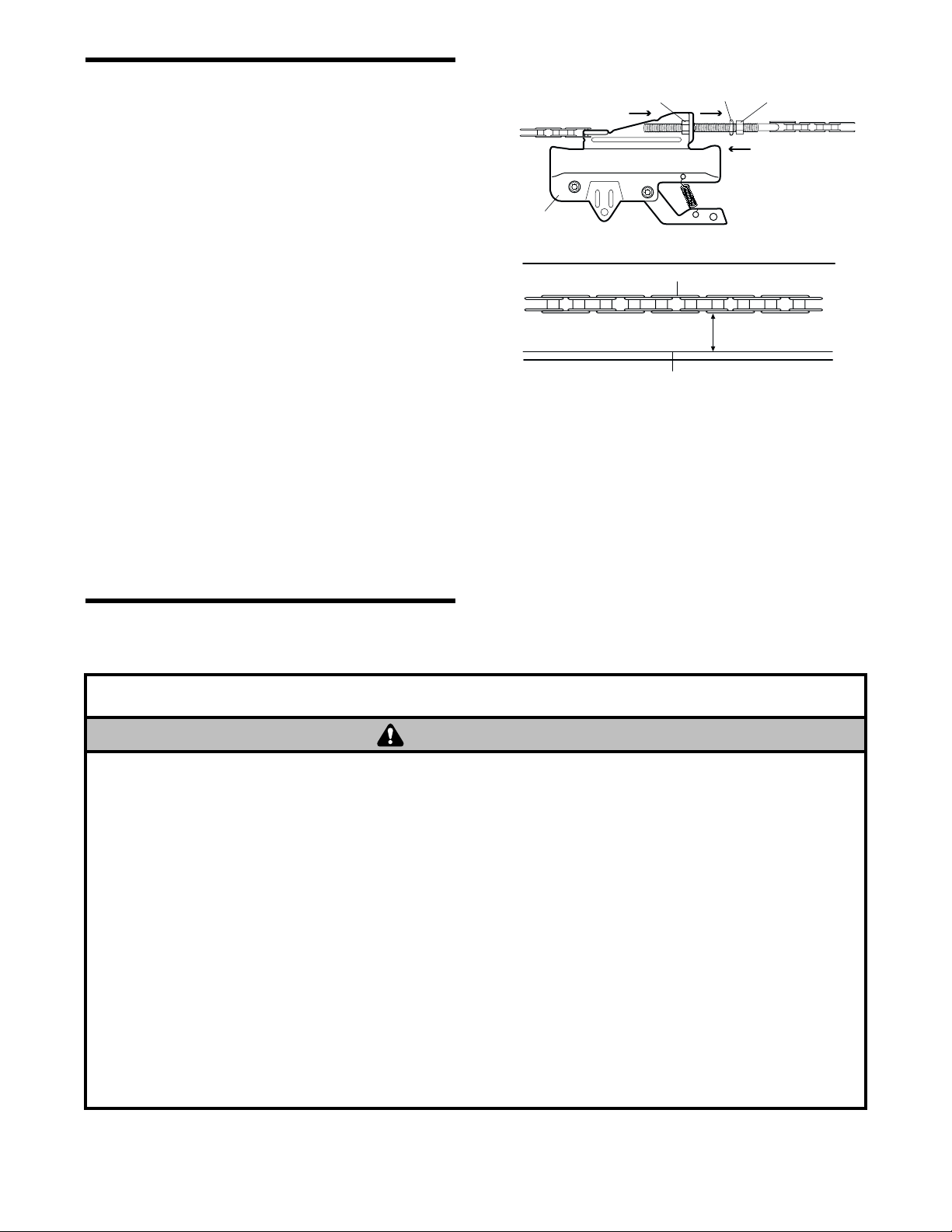

A ach he chain o he sprocke ..................................6

Tigh en he chain.........................................................7

Installation 7-23

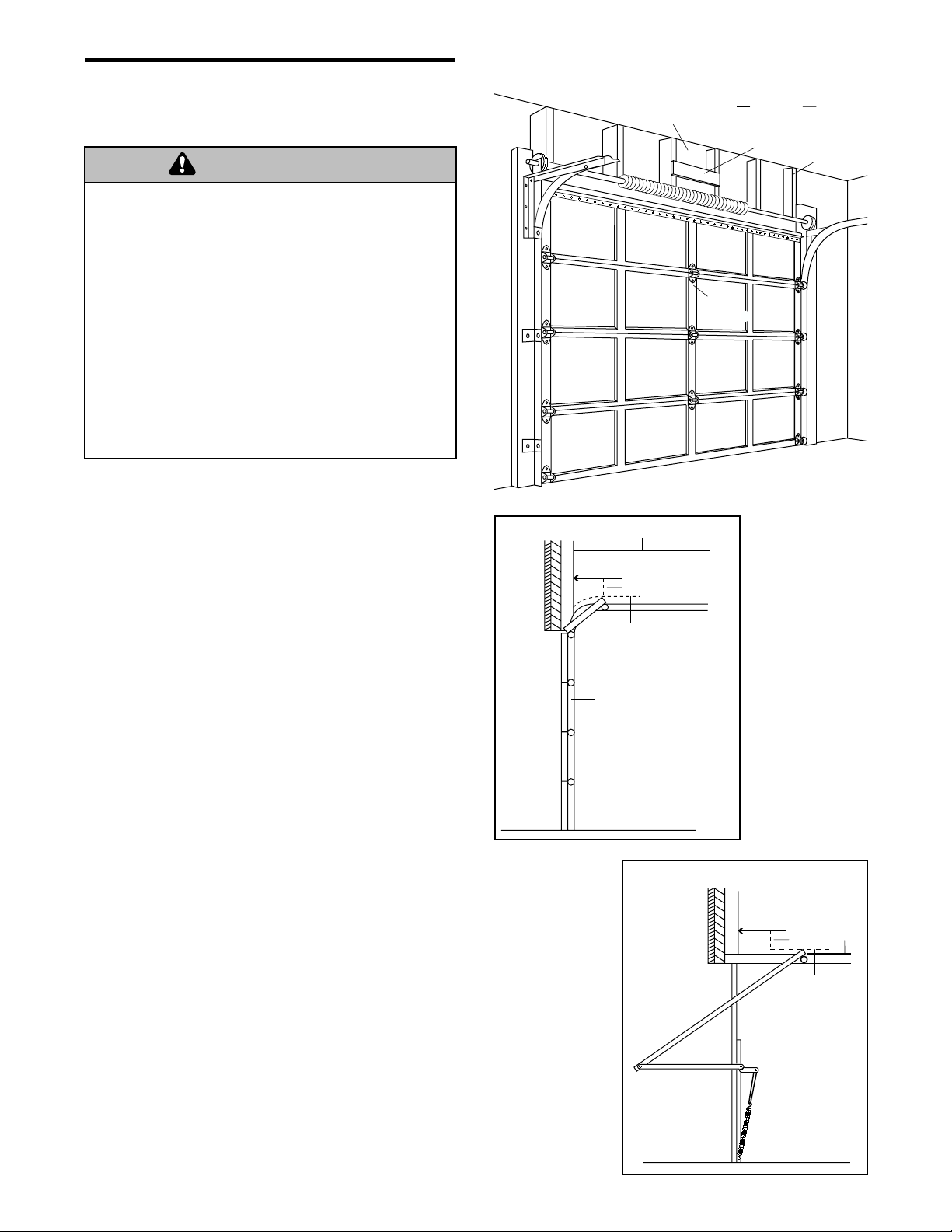

Ins alla ion safe y ins ruc ions .....................................7

De ermine he header bracke loca ion....................8-9

Ins all he header bracke ..........................................10

A ach he rail o he header bracke .........................11

Posi ion he opener ...................................................12

Hang he opener .......................................................13

Ins all he door con rol...............................................14

Ins all he ligh s .........................................................15

A ach he emergency release rope and handle .......15

Elec rical requiremen s..............................................16

Ins all he Pro ec or Sys em®................................17-19

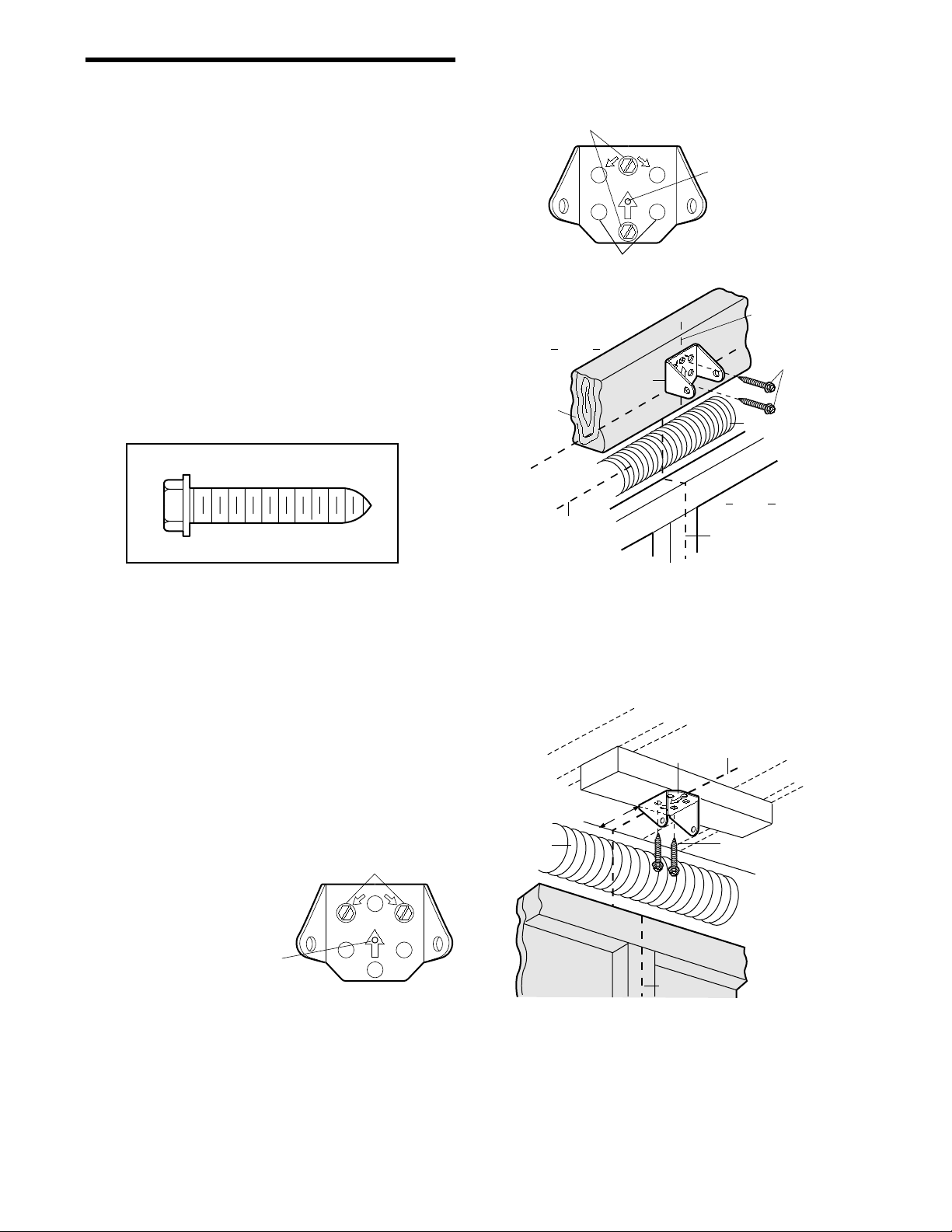

Fas en he door bracke .......................................20-21

Connec he door arm o he rolley .....................22-23

Adjustment 24-26

Adjus he ravel limi s ...............................................24

Adjus he force .........................................................25

Tes he safe y reversal sys em.................................26

Tes he Pro ec or Sys em®........................................26

Operation 27-30

Opera ion safe y ins ruc ions.....................................27

Using your garage door opener ................................27

Using he wall-moun ed door con rol ........................28

To open he door manually........................................28

Care of your garage door opener..............................29

Having a problem?...............................................29-30

Programming 31-32

To add a hand-held remo e con rol ...........................31

To erase all codes .....................................................31

3-Channel remo es....................................................31

To add or change a Keyless En ry PIN.....................32

Repair Parts 33-34

Rail assembly par s...................................................33

Ins alla ion par s ........................................................33

Mo or uni assembly par s .........................................34

Accessories 35

Repair Parts and Service 36

Warranty 36

TABLE OF CONTENTS

When you see hese Safe y Symbols and Signal

Words on he following pages, hey will aler you o

he possibili y of serious injury or death if you do

no comply wi h he warnings ha accompany hem.

The hazard may come from some hing mechanical

or from elec ric shock. Read he warnings carefully.

When you see his Signal Word on he following

pages, i will aler you o he possibili y of damage o

your garage door and/or he garage door opener if

you do no comply wi h he cau ionary s a emen s

ha accompany i . Read hem carefully.

INTRODUCTION

Safety Symbol

and Signal Word Review

This garage door opener has been designed and es ed o offer safe service provided i is ins alled, opera ed,

main ained and es ed in s ric accordance wi h he ins ruc ions and warnings con ained in his manual.

Mechanical

Electrical