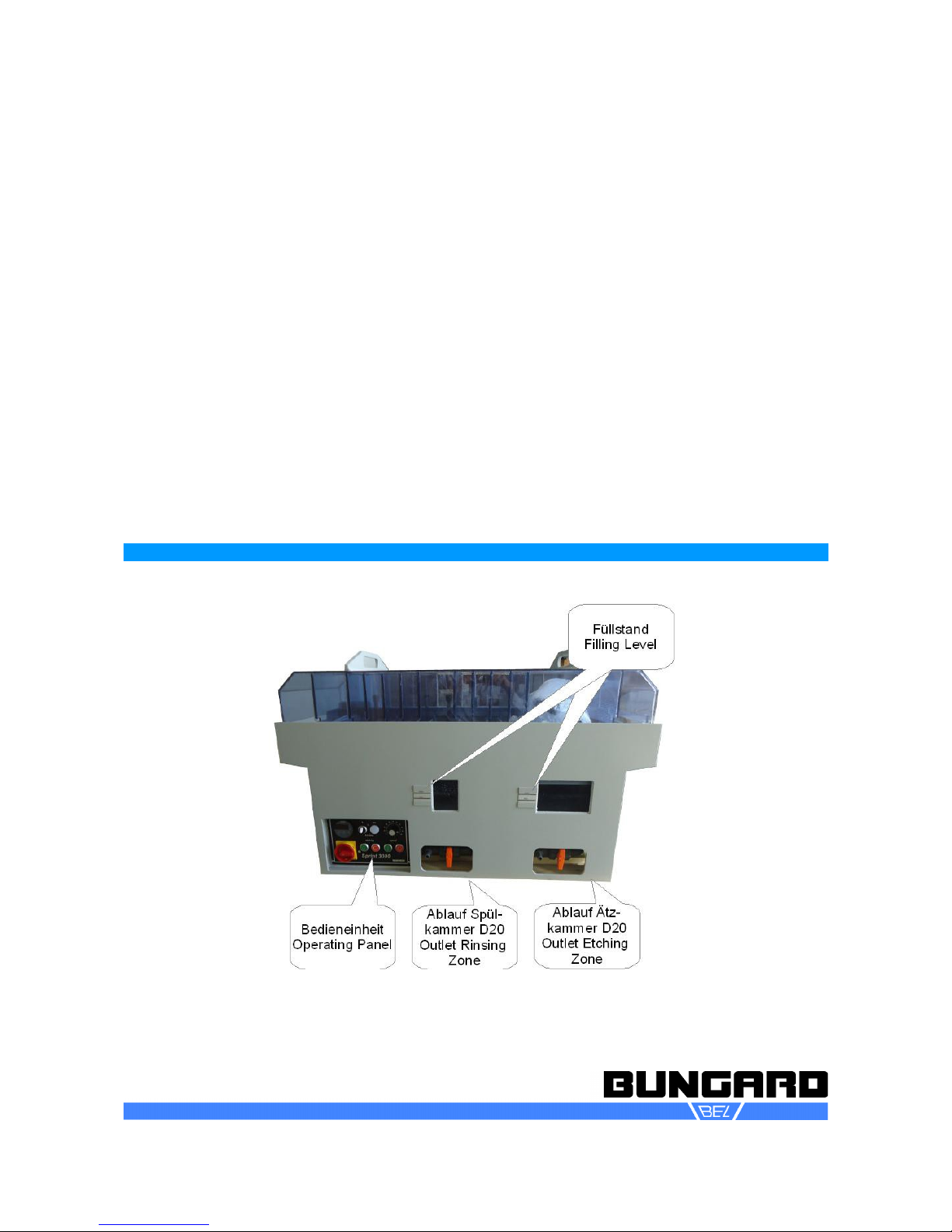

sprint-3000-manual-e Page 6 / 12

Transport

Only use suitable lifting and transport equipment such as forklifts or pallet lifts. Secure the machine

against sliding / tilting.

Place of installation

The machine must be standing level and around the machine there has to be sufficient space for oper-

ation and maintenance work (approx m on all sides). To prevent the penetration of chemicals into the

ground, set up the machine either in a room with solid, waterproof and chemical resistant floor (no tiles

nor concrete!) or in a chemical resistant waterproof collection tray which can take the whole filling

volume (safety tray available as an option).

Electricity

The machine is made from certified parts according to standard practice for electrical safety. This does

not relieve the user of his duty of care when handling electrically powered devices.

The yellow-red main switch disconnects the machine from the power supply. We presuppose that the

safety fuses of the circuit and the residual current circuit are provided by the building's power supply.

After completion of the work, the main switch should always be turned off.

Before all maintenance work on the machine (filling, emptying, cleaning, etc.) turn off machine and pull

the plug.

The chemicals used in the machines often have a high electrical conductivity. Any contact of the liquid

with live parts therefore constitutes a serious threat to electrical safety. In such a case, the machine

must be immediately disconnected from the mains and the defect must be eliminated immediately and

professionally. This applies correspondingly with leaked or spilled etchant.

Water connection

After work or prolonged interruption close the cock valve of the building water supply to prevent water

damage from a possible leak in the hose.

Personal protection equipment

When handling corrosive chemicals make sure to wear protective clothing, gloves and face protection.

Observe the safety instructions of the manufacturer or the supplier.

Temperature

Switch on machine only when tanks are filled! The heater must always be sufficiently covered with li-

quid! Uncovered heaters can cause damage of machine!

The electronic thermostat is protected against breakage and short circuit of the cable to the thermal

sensor. This does not relieve the operator from the obligation, to monitor the temperature of the liquid.

Exothermic chemical reactions may under certain circumstances, which we cannot influence, cause

overheating of the etchant. The maximum operating temperature of the machine is 45 °C.

If the etchant is prepared by dissolving salts or mixing liquids, do that in any event outside of the ma -

chine! Observe the safety instructions of the chemical supplier.

If you want to use liquids which may react exothermic, take additional measures to prevent overheat-

ing. If, despite all precautions, overheating of the etchant occurs, the heater must be switched off first.

The pump however must remain switched on, so that the etchant is cooled by the circulation.

Before draining the tanks, let the heater cool down for approx. 0 min, so the heaters will not get dam-

aged.

Working safety

The machine has a lid safety switch which stops the pump circuit when opening the cover. Please

check the function regularly of the position switch.