A

1 - 3

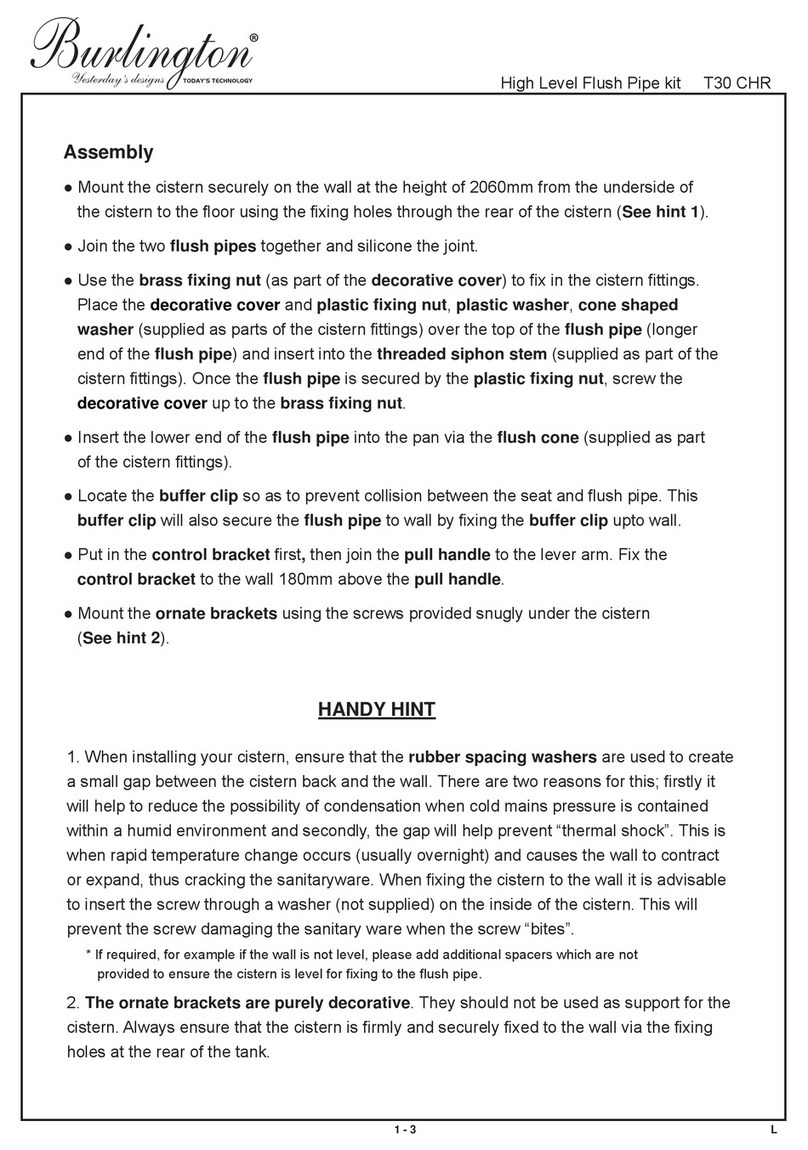

Assembly

●Mount the cistern securely on the wall at the height of 2405mm from the underside of

the cistern to the floor using the fixing holes through the rear of the cistern (See hint 1).

●Join the four flush pipes (flush pipe A, flush pipe B, flush pipe C and flush pipe D)

together and silicone the joint.

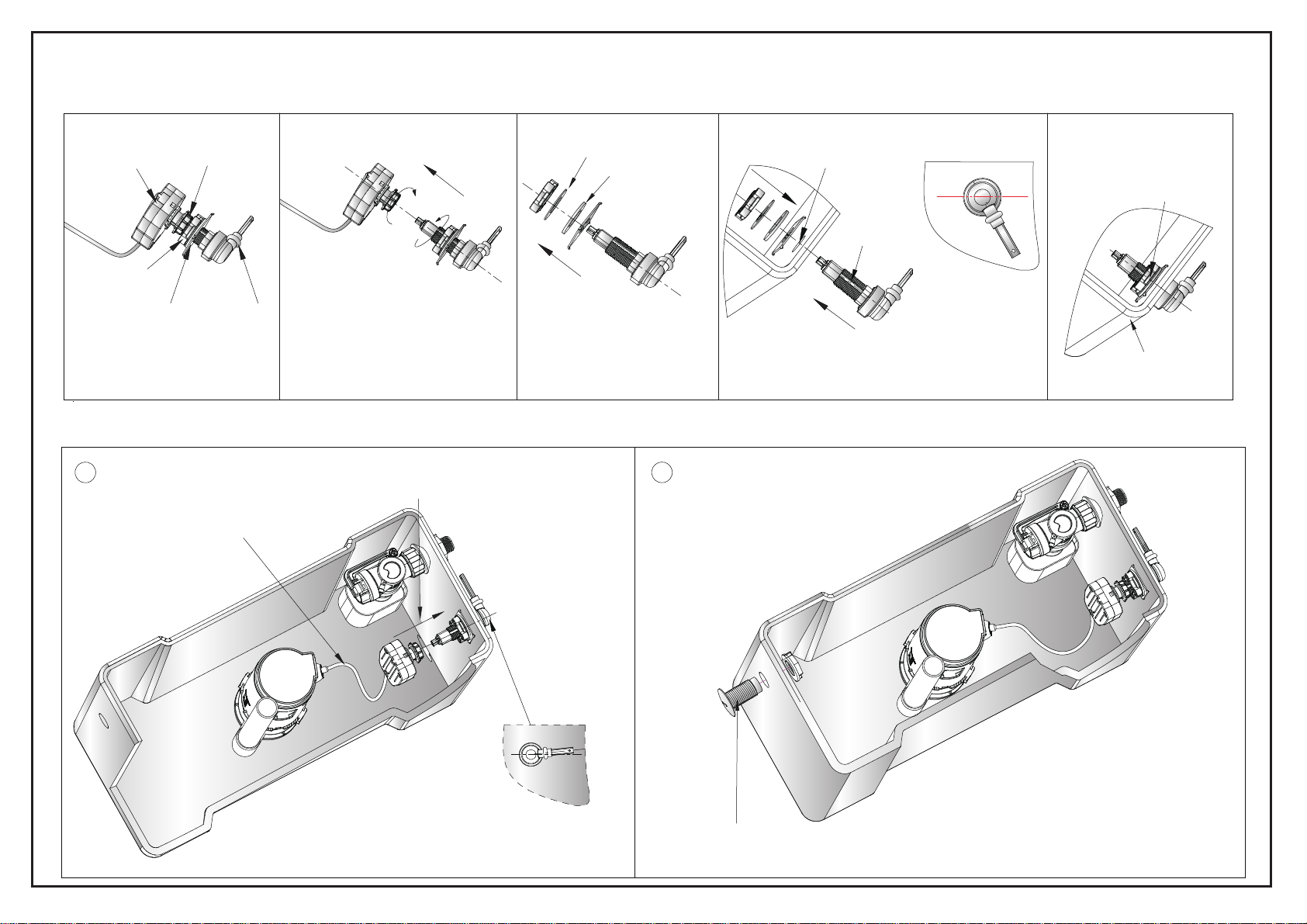

●Use the brass fixing nut (as part of the decorative cover) to fix in the cistern fittings.

Place the

decorative cover

and plastic fixing nut, plastic washer, cone shaped

washer (supplied as parts of the cistern fittings) over the top of the flush pipe (flush

pipe D) and insert into the threaded siphon stem (supplied as part of the

cistern fittings). Once the flush pipe is secured by the plastic fixing nut, screw the

decorative cover

up to the brass fixing nut.

●Insert the lower end of the flush pipe (flush pipe A) into the pan via the flush cone

(supplied as part of the cistern fittings).

●Locate the two buffer clips so as to secure the flush pipe to wall by fixing the wall

bracket upto wall. The buffer clip A will also prevent collision between the seat and

flush pipe.

●Put in the control bracket first,then join the pull handle to the lever arm. Fix the

control bracket to the wall 180mm above the pull handle.

●Mount the ornate brackets using the screws provided snugly under the cistern

(See hint 2).

Angled High Level Flush pipes (4 parts) T34 CHR

1. When installing your cistern, ensure that the rubber spacing washers are used to create

a small gap between the cistern back and the wall. There are two reasons for this; firstly it

will help to reduce the possibility of condensation when cold mains pressure is contained

within a humid environment and secondly, the gap will help prevent “thermal shock”. This is

when rapid temperature change occurs (usually overnight) and causes the wall to contract

or expand, thus cracking the sanitaryware. When fixing the cistern to the wall it is advisable

to insert the screw through a washer (not supplied) on the inside of the cistern. This will

prevent the screw damaging the sanitary ware when the screw “bites”.

* If required, for example if the wall is not level, please add additional spacers which are not

provided to ensure the cistern is level for fixing to the flush pipe.

2. The ornate brackets are purely decorative. They should not be used as support for the

cistern. Always ensure that the cistern is firmly and securely fixed to the wall via the fixing

holes at the rear of the tank.

HANDY HINT