5

TEMPERATURE CONTROLLER:

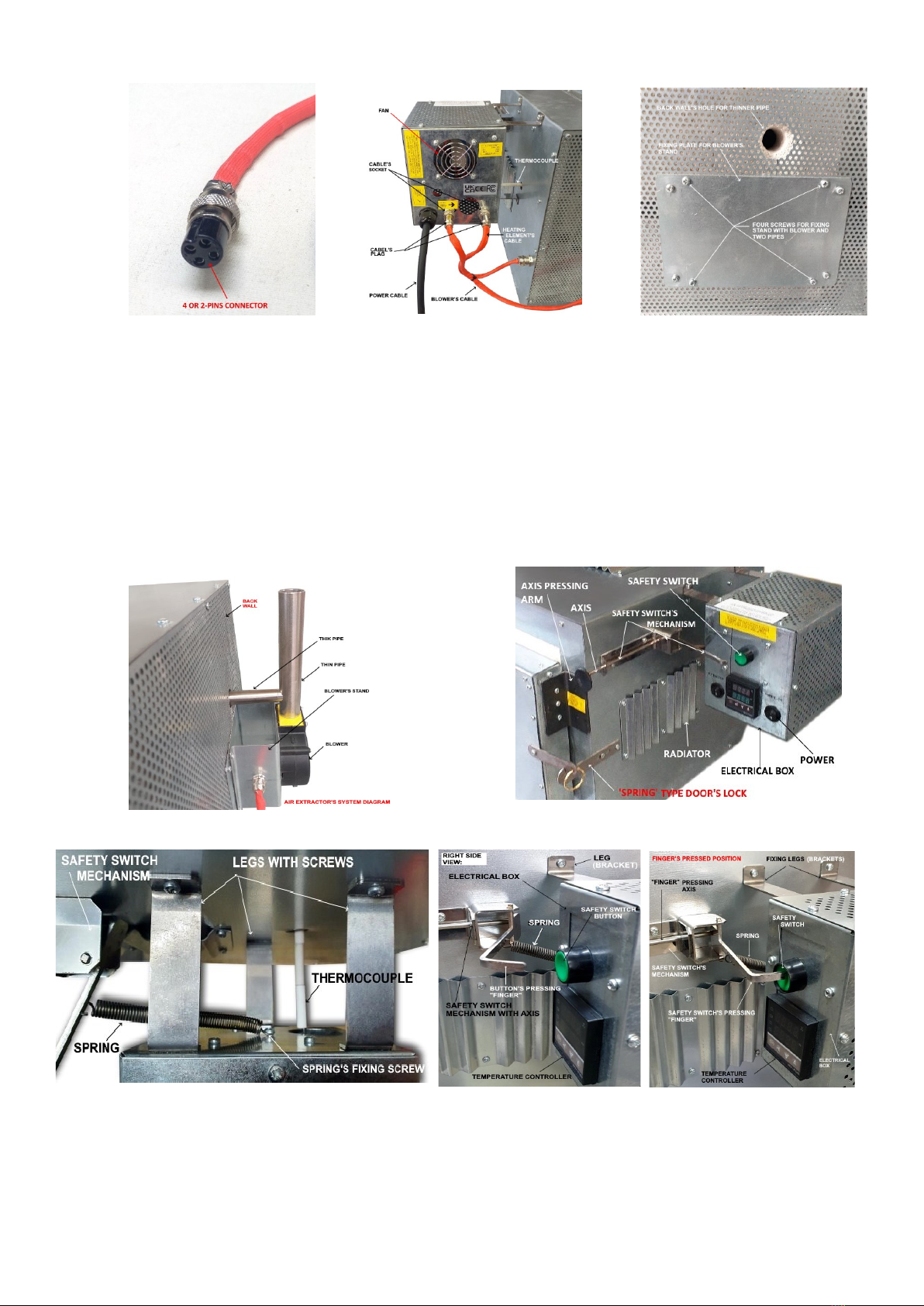

The programmable temperature controller (XMTG-7000) has already been set up for chamber drying by

the manufacturer (if you have not requested a different setting). If you want to re-program this controller,

please refer to the controller’s user manual or contact us for help on Skype. Below are some useful tips

for using this controller:

1. “SET” – setting/confirmation button (used for setting all of the controller’s

parameters).

2. “Arrow Left” or “A/M” – segment selector (to choose from four segments).

3. “Arrow Down” – decrease (used to set the required temperature).

4. “Arrow Up” – increase (used to set the required temperature).

Example program: Increase from room temperature up to 450°C within 99

minutes, soak at 450°C for 4 minutes and then decrease to room tempera-

ture within 145 minutes.

Example instructions:

1.Open your kiln’s door to trigger the safety-switch mechanism, which will disconnect the power supply from the

heating element(s) and prevent the kiln from heating up while you program the temperature controller. Alternative-

ly, simply press button 4 for 3 seconds until you see “STOP” on the bottom display. Now you can start program-

ming your controller.

2. Each of the following steps consists of first setting the temperature and then setting the time period in which the

NEXT temperature should be reached. There are 32 available input slots each consisting of a pair of temperature

and time inputs, i.e. there are a total of 32 temperature inputs alternating with 32 time inputs. To start program-

ming, short-press the ‘SET’ button.

3. After you have pressed the ‘SET’ button, you will set the starting temperature (“C1” on the top display). In this

case, input the desired room temperature (usually 20°C), i.e. “0020”, into the BOTTOM display using buttons 2, 3

and 4. Now press ‘SET’ to confirm this initial temperature and to proceed to the next input (“Г1”). This input is the

required TIME to reach the NEXT required temperature. For this example, insert “0099” (99 minutes) into the

BOTTOM display, and then press ‘SET’ again to set this input and to proceed to the next step.

4. The next step begins by setting the second required temperature (“C2”). To set this, insert “0450” (450°C) into the

bottom display. Next, press ‘SET’ again to proceed to the next input (“Г2”), where you will set the required time to

the NEXT temperature. In this case, this is our soaking time of 4 minutes - “0004”. Press ‘SET’ again to confirm

this time and to proceed to the next step.

5. The next step begins by setting the third required temperature (“C3”), in this case the required soaking tempera-

ture. Enter “0450” (450°C) into the bottom display again. Next press ‘SET’ once more to proceed to the next time

input (“Г3”), which in this case will be 145 minutes. Input “0145” into the bottom display, then press ‘SET’ again.

6. For the next step, set the fourth and final required temperature (“C4”) – “0020” (20°C).

7. To indicate the end of the program, press the ‘SET’ button again, insert “0000” into the bottom display and press

the ‘SET’ button once more. Your program will automatically finish when it reaches this last input.

A. When you have finished programming the controller, short-press the ‘SET’ button or simply leave the

controller for about 30 seconds for your new setting to be remembered and for your job to start.

B. Close the kiln door to disconnect the safety-switch mechanism, allowing your kiln to start heating up.

Alternatively, if you pressed button 4 in step 1 above, now press button 3 for 3 seconds until the word

“RUN” appears on the bottom display.

C. Important: you’ll have about 20-30 seconds to change EACH temperature/time setting. Please do not

worry if you take too much time and the controller resets and starts displaying the current temperature

inside the chamber again. Simply restart the programming process by short-pressing the ‘SET’ button

again. If you are a beginner and are having difficulty programming your controller, please feel free to

contact the manufacturer or agent/shop for free help with this matter during the warranty period.