1 | Contents

0870S03226_VRD 2072-3108_-0000_IM_en

3/

1Contents

1.1 Table of contents

1Contents ......................................................................................... 3

1.1 Table of contents .............................................................................................................3

1.2 Register of tables .............................................................................................................5

1.3 Register of illustrations.....................................................................................................5

2Safety.............................................................................................. 6

2.1 Safety devices..................................................................................................................6

2.2 Emergency information....................................................................................................6

3Product description......................................................................... 7

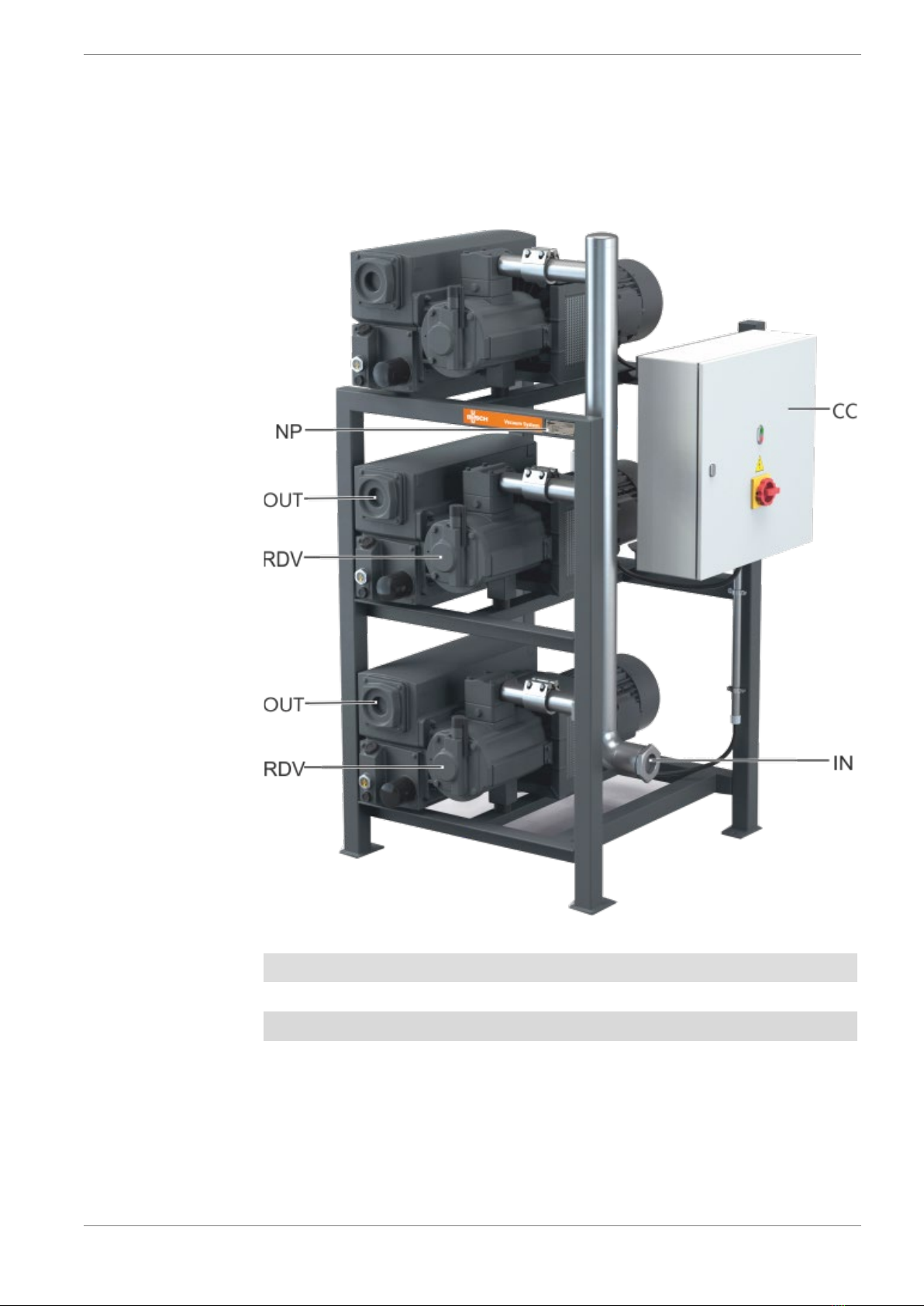

3.1 View vacuum system VRD (TRIPLEX) ..............................................................................7

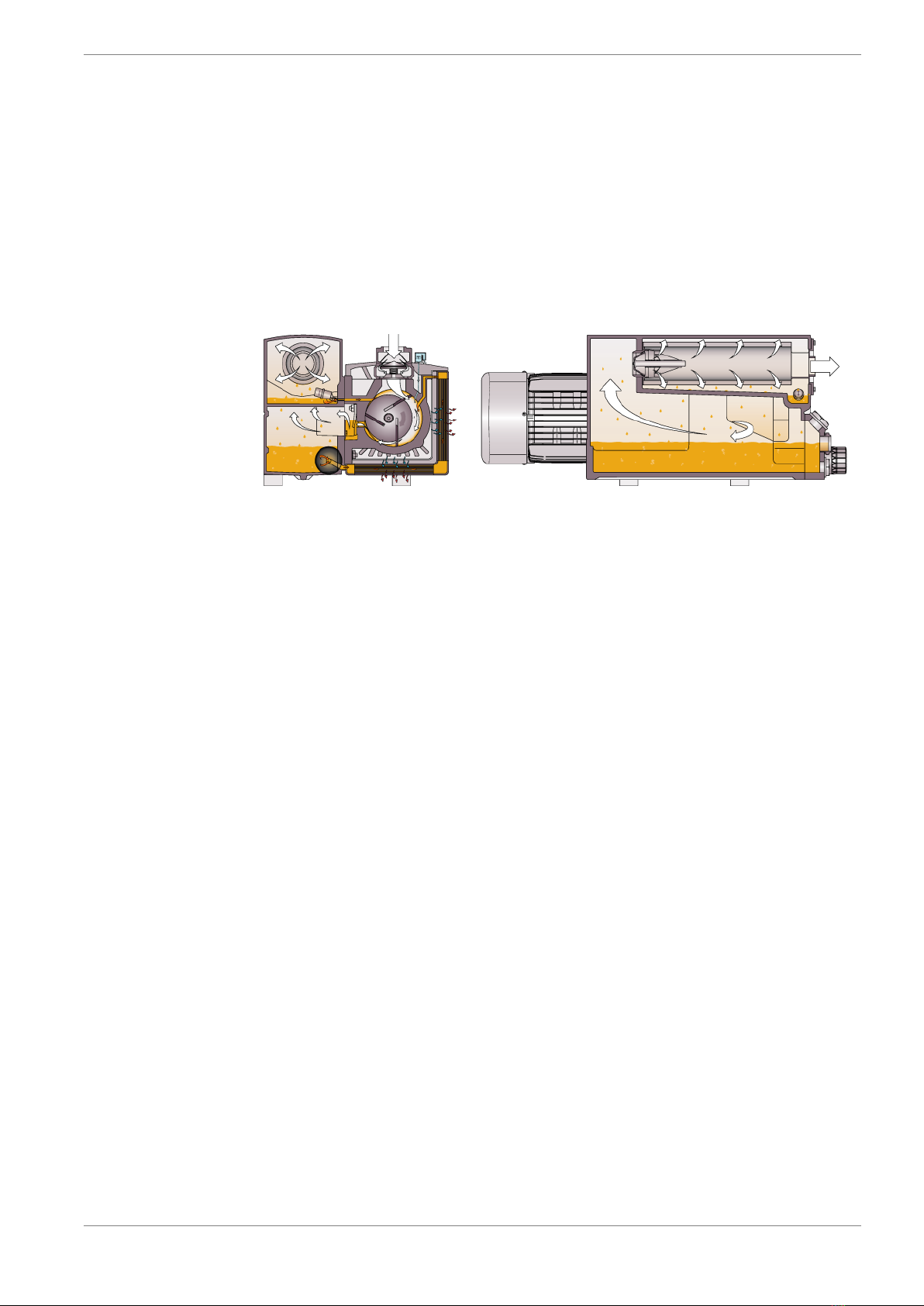

3.2 View of the rotary vane vacuum pump RD......................................................................8

3.3 Setup ...............................................................................................................................8

3.4 Function principle ............................................................................................................9

3.4.1 Vacuum system VRD .......................................................................................................9

3.4.2 Rotary vane vacuum pump R5 RD...................................................................................9

3.4.3 Gas ballast valve ..............................................................................................................9

3.5 Intended use....................................................................................................................9

4Transport ...................................................................................... 10

5Storage ......................................................................................... 13

6Installation.................................................................................... 14

6.1 Installation .....................................................................................................................14

6.2 Connection lines/pipes ..................................................................................................15

6.2.1 Gas inlet ........................................................................................................................15

6.2.2 Gas outlet ......................................................................................................................16

6.2.3 Cooling water connection (optional)..............................................................................17

6.3 Electrical connection ......................................................................................................18

6.3.1 Connection of the power supply....................................................................................18

7Start-up......................................................................................... 19

7.1 Indication and control elements .....................................................................................19

7.1.1 Topping up with oil........................................................................................................19

7.1.2 Display and control elements at the switching and control cabinet ................................20

7.1.3 Indicators and control elements on the vacuum system .................................................20

7.2 Operation ......................................................................................................................20

7.3 Conveying condensing vapors .......................................................................................21

8Maintenance................................................................................. 22

8.1 Maintenance plan..........................................................................................................22

8.2 Check oil level................................................................................................................23

8.3 Oil and oil filter change .................................................................................................23

8.4 Replacing the exhaust filters ..........................................................................................25

8.5 Cleaning the air heat exchanger ....................................................................................26