1.2 18BRegister of tables

Tab. 1: Switching values.................................................................................................23

Tab. 2: Parameter settings (factory settings)..................................................................24

Tab. 3: Connections vacuum system VO 0040 B AAA G3XX........................................37

Tab. 4: Connections vacuum system VO 0040 B AAA G3AX (mobile)..........................38

Tab. 5: Connections vacuum system VO 0060 B AAA H3XX........................................39

Tab. 6: Connections vacuum system VO 0060 B AAA H3AX (mobile)..........................40

Tab. 7: Connections vacuum system VO 0080 B AAA I3XX..........................................41

Tab. 8: Connections vacuum system VO 0080 B AAA I3AX (mobile)............................42

Tab. 9: Connecting values of the vacuum systems VO..................................................43

Tab. 10:Electrical data of the terminals of the control unit ..............................................46

Tab. 11:Technical data ....................................................................................................47

Tab. 12:Gear oil...............................................................................................................48

1.3 19BRegister of illustrations

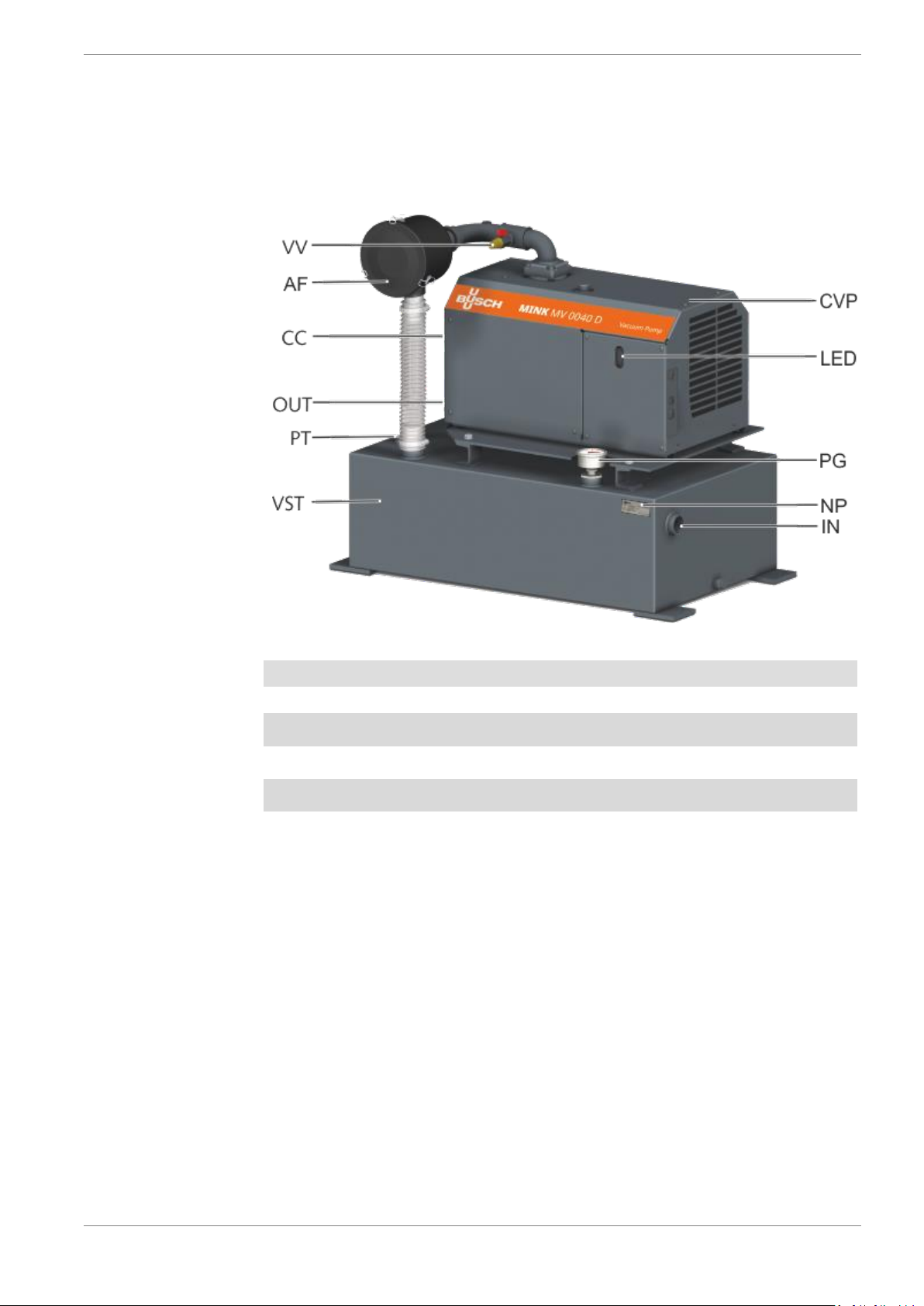

Fig. 1: View vacuum system VO......................................................................................7

Fig. 2: View claw vacuum pump Mink type MV...............................................................8

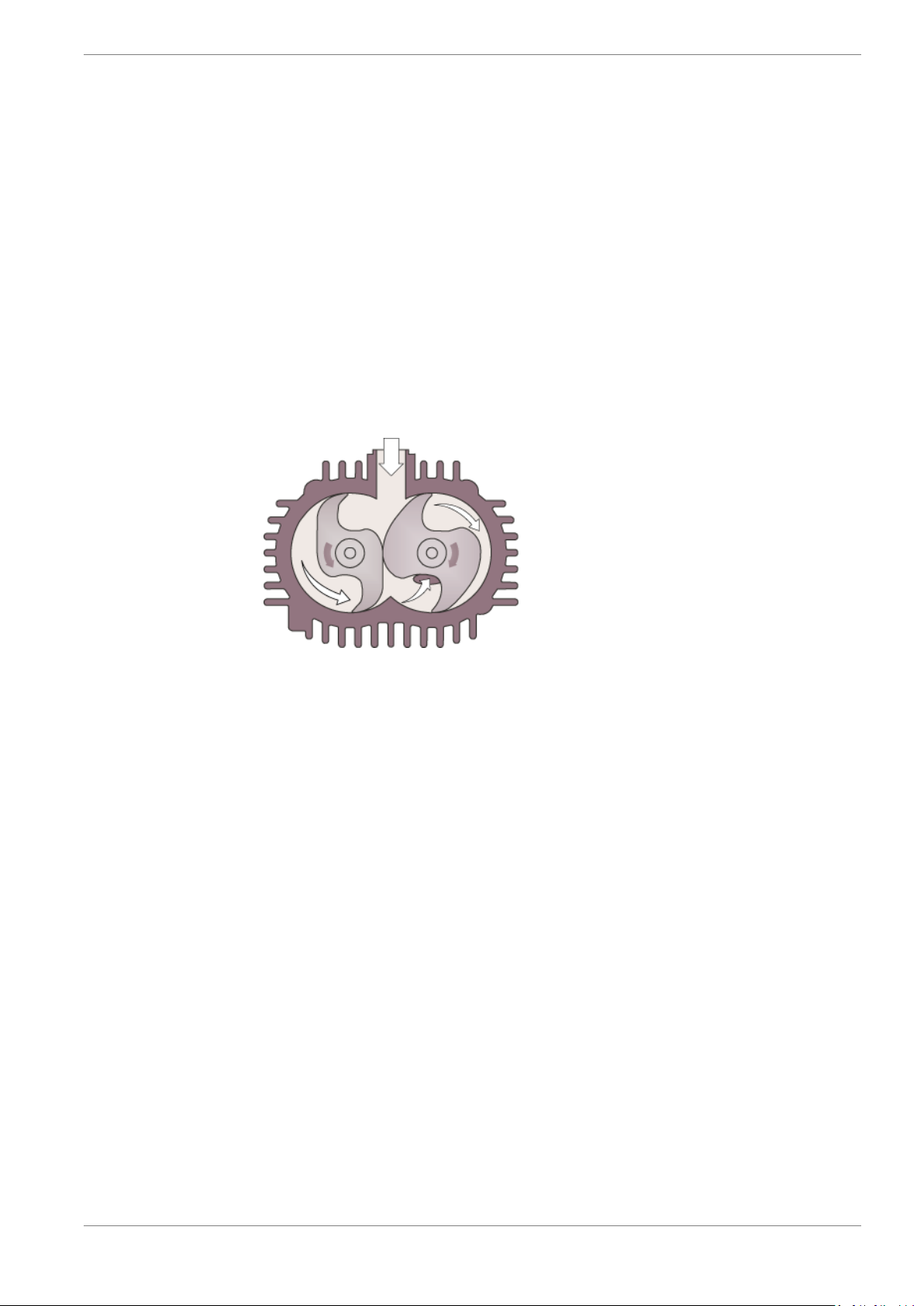

Fig. 3: Operating principle of the claw vacuum pump MV...............................................9

Fig. 4: Transport of the vacuum system........................................................................11

Fig. 5: Transport of the vacuum pump on the eye bolts................................................12

Fig. 6: Installation environment......................................................................................14

Fig. 7: Gas outlet ...........................................................................................................16

Fig. 8: Topping up oil.....................................................................................................19

Fig. 9: Motor protection switch.......................................................................................20

Fig. 10:LED displays at the vacuum pump.....................................................................20

Fig. 11:DIP switch on the vacuum pump........................................................................21

Fig. 12:Display of the manual operating unit..................................................................22

Fig. 13:Display overview.................................................................................................22

Fig. 14:Connection of the operating unit to vacuum pump.............................................23

Fig. 15:Clean vacuum pump...........................................................................................27

Fig. 16:Drain oil ..............................................................................................................28

Fig. 17:Filling in oil..........................................................................................................28

Fig. 18:Cleaning of the air filter element.........................................................................29

Fig. 19:Installing the intake screen.................................................................................29

Fig. 20:Dimensions vacuum system VO 0040 B AAA G3XX.........................................37

Fig. 21:Dimensions vacuum system VO 0040 B AAA G3AX (mobile)...........................38

Fig. 22:Dimensions vacuum system VO 0060 B AAA H3XX .........................................39

Fig. 23:Dimensions vacuum system VO 0060 B AAA H3AX (mobile)...........................40

Fig. 24:Dimensions vacuum system VO 0080 B AAA I3XX...........................................41

Fig. 25:Dimensions vacuum system VO 0080 B AAA I3XX(mobile)..............................42

Fig. 26:Circuit diagram vacuum systems VO.................................................................44

Fig. 27:Circuit diagram MV 0040 D / MV 0060 D / MV 0080 D, 3 phase.......................45