Table of Contents

2 / 36 0870206364_WV1200-2400A_Ex_-0004_IM_en

Table of Contents

1 Safety .......................................................................................................................................4

2 Product Description ..................................................................................................................5

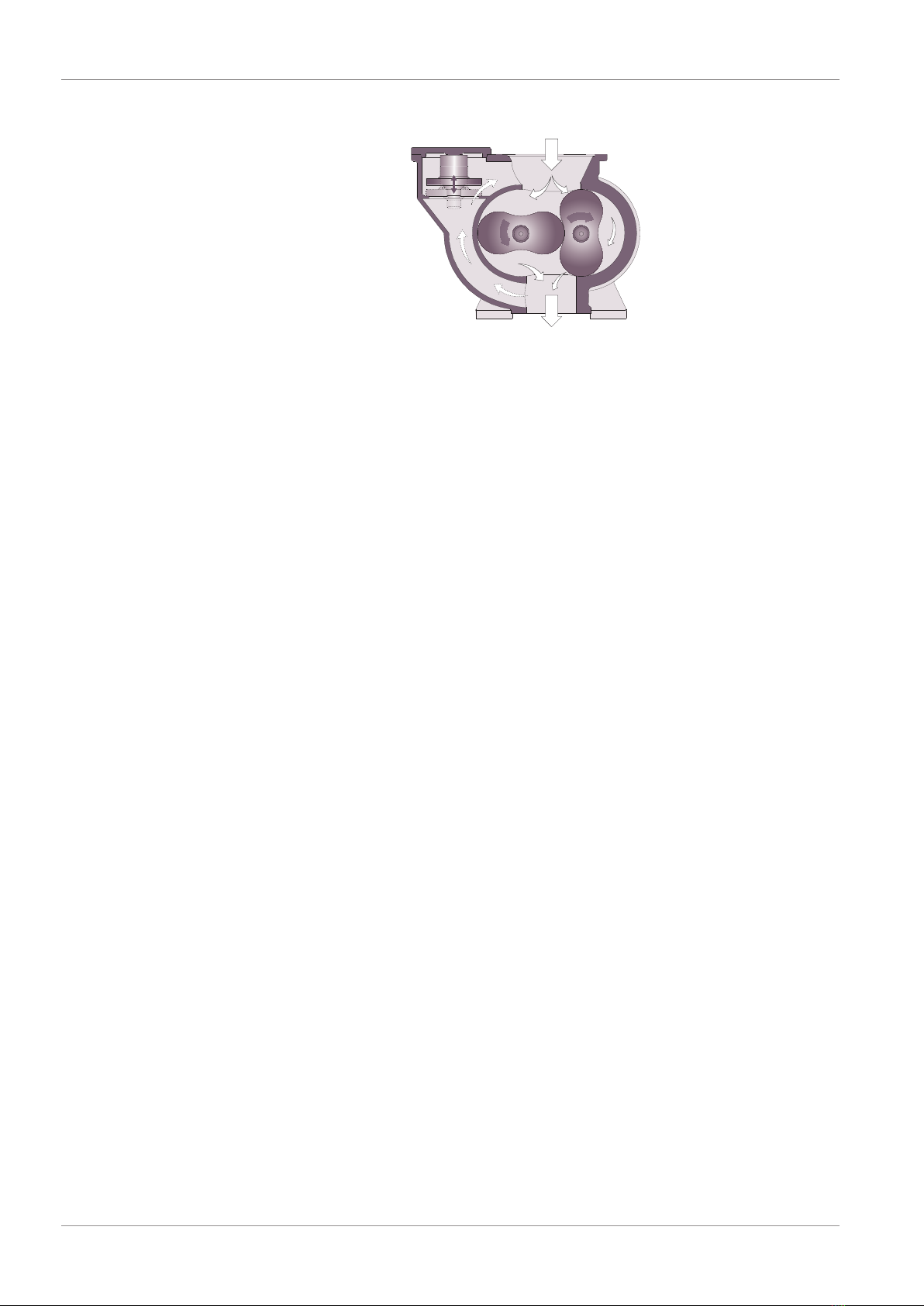

2.1 Operating Principle .......................................................................................................... 6

2.2 Application....................................................................................................................... 6

2.3 Shaft Sealing Variants....................................................................................................... 6

2.3.1 Mechanical Seal..................................................................................................... 7

2.3.2 Lip Seals (Optional) ............................................................................................... 7

2.4 Accessories....................................................................................................................... 7

2.4.1 Resistance Thermometer ....................................................................................... 7

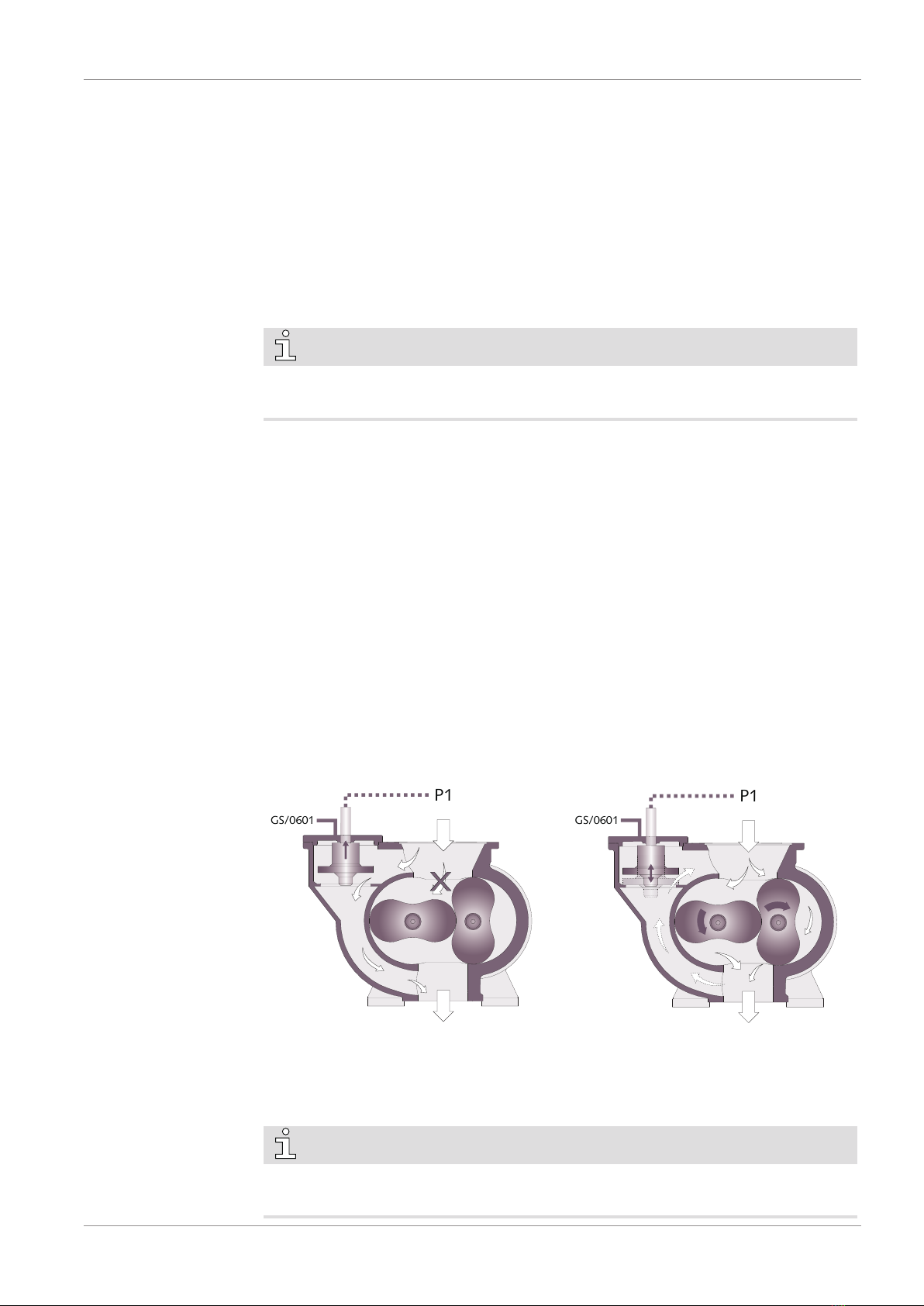

2.4.2 Active Bypass Valve...............................................................................................7

2.5 Explanation of ATEX Classification.................................................................................... 8

2.6 Safety concept ................................................................................................................. 8

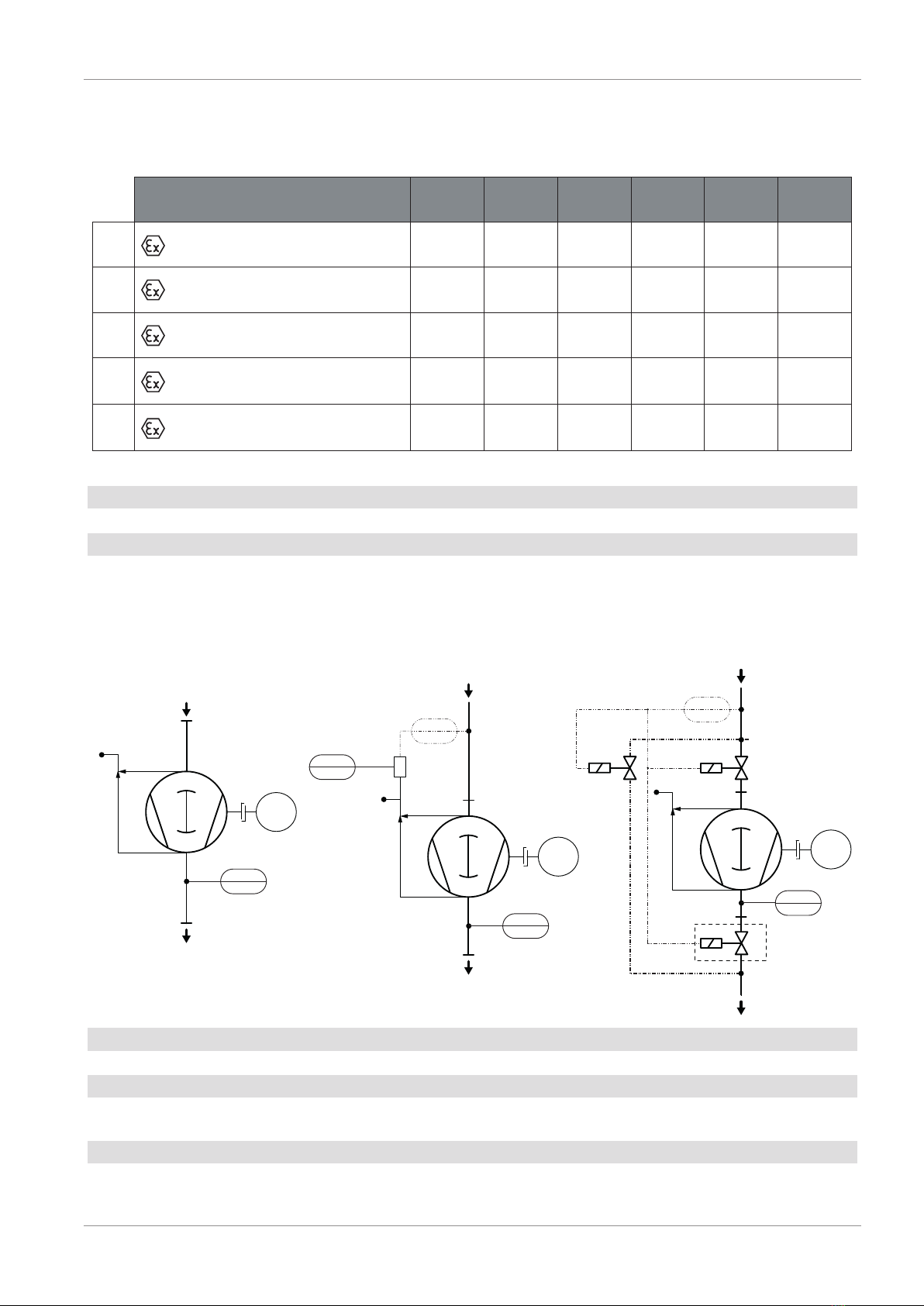

2.6.1 ATEX Classifications and Associated Accessories .................................................... 9

2.6.2 P&ID "Piping and Instrumentation Diagram" ........................................................ 9

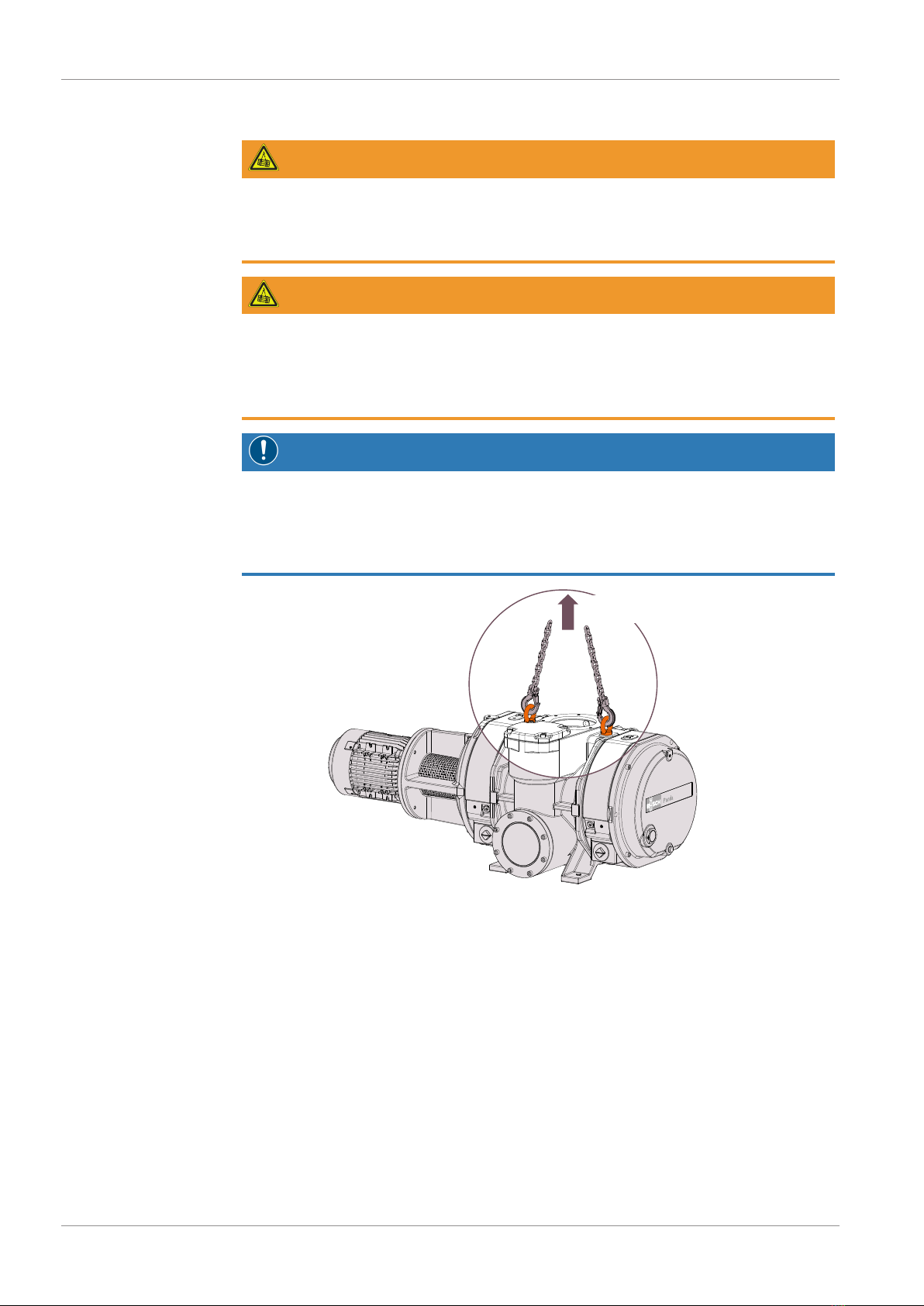

3 Transport ..................................................................................................................................10

4 Storage .....................................................................................................................................10

5 Installation................................................................................................................................11

5.1 Installation Conditions...................................................................................................... 11

5.2 Connecting Lines / Pipes .................................................................................................. 12

5.2.1 Gas Flow Variants.................................................................................................. 12

5.2.2 Suction Connection ............................................................................................... 12

5.2.3 Discharge Connection ........................................................................................... 13

5.2.4 Pneumatic Connection (with Active Bypass Valve only) ......................................... 13

5.3 Earth Connection ............................................................................................................. 14

5.4 Filling Oil.......................................................................................................................... 14

5.5 Fitting the Coupling ......................................................................................................... 16

5.6 Electrical Connection ........................................................................................................ 17

5.6.1 Wiring Diagram Three-Phase Motor...................................................................... 17

5.7 Electrical Connection of the Monitoring Devices............................................................... 19

5.7.1 Wiring Diagram Resistance Thermometer.............................................................. 19

5.7.2 Wiring Diagram Limit Switch ................................................................................. 20

5.8 Flowchart ......................................................................................................................... 22

6 Commissioning.........................................................................................................................23

6.1 Compression Chamber Flushing ....................................................................................... 24

7 Maintenance.............................................................................................................................25

7.1 Maintenance Schedule ..................................................................................................... 25

7.2 Oil Level Inspection.......................................................................................................... 26

7.3 Oil Colour Inspection ....................................................................................................... 26

7.4 Oil Change....................................................................................................................... 27

7.5 Coupling Maintenance ..................................................................................................... 30

7.6 Calibration Procedure of the Electrical Devices ................................................................. 30

7.6.1 Procedure A ..........................................................................................................30

7.6.2 Procedure I............................................................................................................30

8 Overhaul...................................................................................................................................31

9 Decommissioning.....................................................................................................................31

9.1 Dismantling and Disposal ................................................................................................. 31

10 Spare Parts................................................................................................................................32