ProDAQ 3411 24-Ch. ADC Function Card User Manual 3411-XX-UM

Copyright, 1998-2009 Bustec Production Ltd. Page 3 of 40

Table of Contents

1. Introduction _______________________________________________________7

2. Installation ________________________________________________________9

2.1.

Unpacking and Inspection _______________________________________________ 9

2.2.

Reshipment Instructions ________________________________________________ 9

2.3.

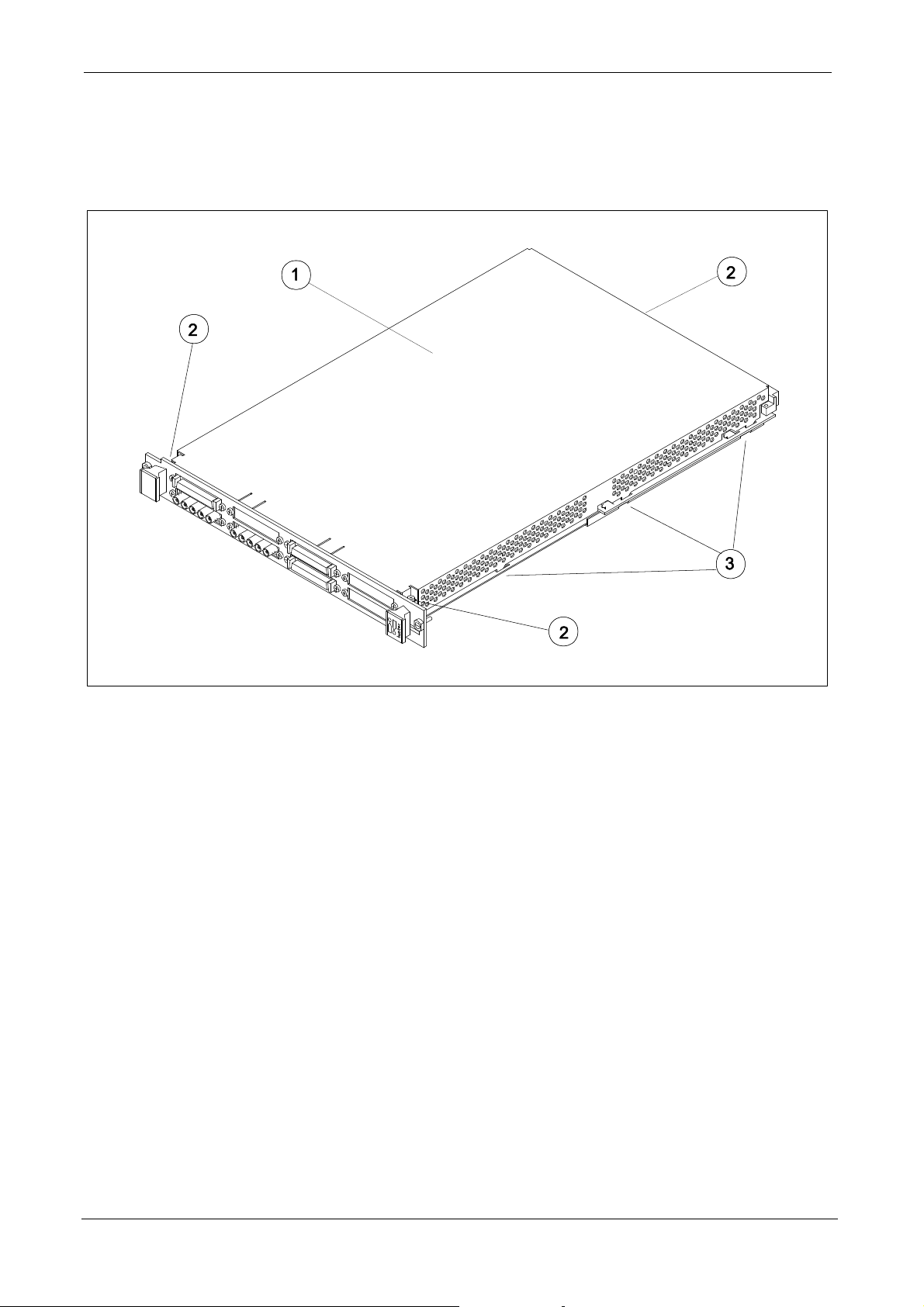

Preparing the ProDAQ Module___________________________________________ 10

2.4.

Installing a ProDAQ Function Card _______________________________________ 11

2.5.

Removing a ProDAQ Function Card ______________________________________ 13

3. Theory of Operation________________________________________________15

3.1.

General Description ___________________________________________________ 15

3.2.

Programmed Conversion _______________________________________________ 15

3.3.

Multiplexed Conversion ________________________________________________ 16

3.3.1.

Channel Mask _____________________________________________________ 16

3.3.2.

Scanning _________________________________________________________ 16

3.3.3.

Data Conversion____________________________________________________ 16

3.3.4.

The on-board FIFO _________________________________________________ 18

3.4.

Trigger ______________________________________________________________ 18

4. The VXIplug&play Driver____________________________________________19

4.1.

Installation ___________________________________________________________ 19

4.2.

The Soft Front Panel ___________________________________________________ 19

4.2.1.

Configuration ______________________________________________________ 20

4.2.2.

Data Acquisition ____________________________________________________ 21

4.2.3.

The Graph Controls _________________________________________________ 22

5. Programming the ProDAQ 3411 ______________________________________23

5.1.

Connecting to the Function Card ________________________________________ 23

5.2.

Setting Gain and Filter _________________________________________________ 24

5.3.

Acquiring single Samples_______________________________________________ 24

5.4.

Acquiring a Waveform _________________________________________________ 25

5.5.

Asynchronous Acquisition______________________________________________ 26

5.6.

Calibration ___________________________________________________________ 27

Appendix A: Front Panel Connector _____________________________________29

Appendix B: Register Description _______________________________________31

A.1

Address Map _________________________________________________________ 31

A.2

Detailed Register Description ___________________________________________ 32

A.1.1

FCID Register _____________________________________________________ 32

A.1.2

GCSR Register ____________________________________________________ 32

A.1.3

FCLEN Register ____________________________________________________ 33

A.1.4

OTRI Register _____________________________________________________ 33

A.1.5

ITRI Register ______________________________________________________ 34

A.1.6

DIVCLK Register ___________________________________________________ 34

A.1.7

MODE Register ____________________________________________________ 35