U200 Series-A

3

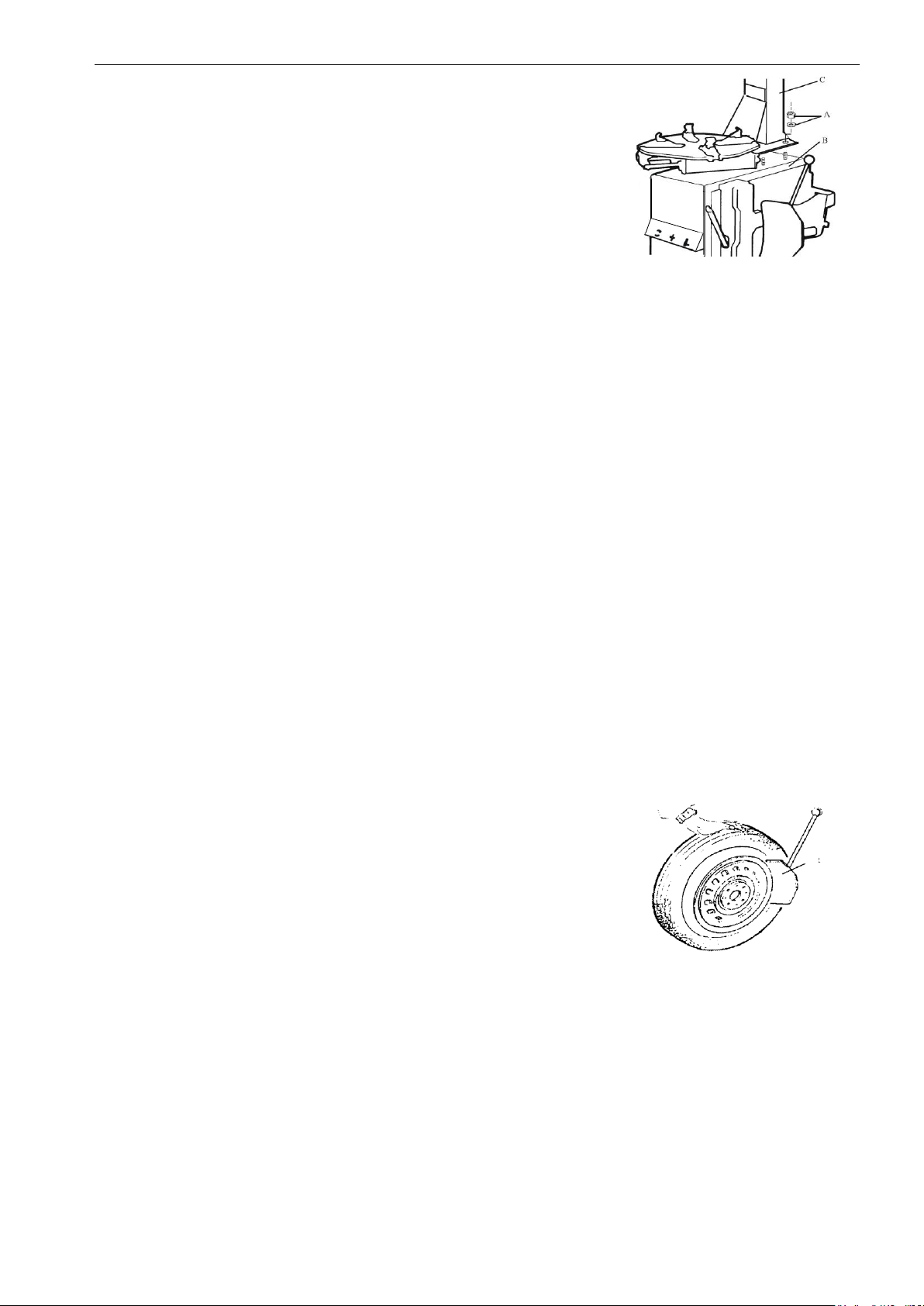

2) Connect the inflation gun to its connector. (Fig 3)

3) Connect tyre changer to compressed air network with air hose of inside

diameter of 7-8 mm, air pressure of 8~10 bar is recommended.

4) Air pressure is not permitted to surpass 10 bar, otherwise, manufacturer

can cancel the warranty coverage.

Caution: the pressure of compressed air network is not permitted to

surpass 10 bar. Please install pressure-adjusting valve when it is more than

10 bar. Before making any electric link up, check to be sure that the main

voltage correspond to what is stamped on the voltage tag. It is essential that

the system is equipped with a good grounding circuit. The machine must be

connected to a power supply line circuit bracket set for 30A.

Caution: The rated power supply of tyre changer is given on rear panel, please check the voltage.

However minor, any operations on electrics must be done only by professional persons.Manufacturer shall

not be liable for any damage caused by failure to comply with the regulations.

Warning: Keep hands and your body away from moving parts of tyre changer. Do not wear necklace,

bracelet or loose clothing. Unreadable and missing labels must be replaced at once. Don't use this machine if

any warning labels missed. Keep labels clear for operator.

10. To perform preliminary operation tests:

Check whether the tyre changer runs well or not after connection finished:

Depress the reverse pedal to turn the turntable in clockwise direction.

Push the reverse pedal up to turn the turntable in anti-clockwise direction.

Depress the bead breaker pedal to open the bead breaker arm. Loosen it to turn the bead breaker arm back.

Depress the jaw clamping pedal completely to open the jaws on the turntable, depress it once again to close the

jaws. When the pedal is in the middle position, the jaws are in the static status.

Tyre changer operation is consisted of three parts:

1)Demounting the tyre bead

2)Demounting the tyre

3)Mounting the tyre

Caution: Before any operations, don’t wear loose clothing and wear protective hat, gloves, and

skid-proof shoes. Take off all the weights on both sides of wheel rim before operation. Ensure to exhaust the

air in the tyre completely, and remove all the wheel weights from the rim.

10.1. To loosen the tyre bead:

Be careful when loosening tyre. Bead breaker arm will move rapidly with

powerful force when depressing the bead breaker pedal, it may crash things in

its working area.

1) Deflate the tyre completely take off the core of valve stem;

2) Close the four jaws on the turntable to avoid conflict. If jaws open, it

may scratch hands, so don't touch the bead when loosening.

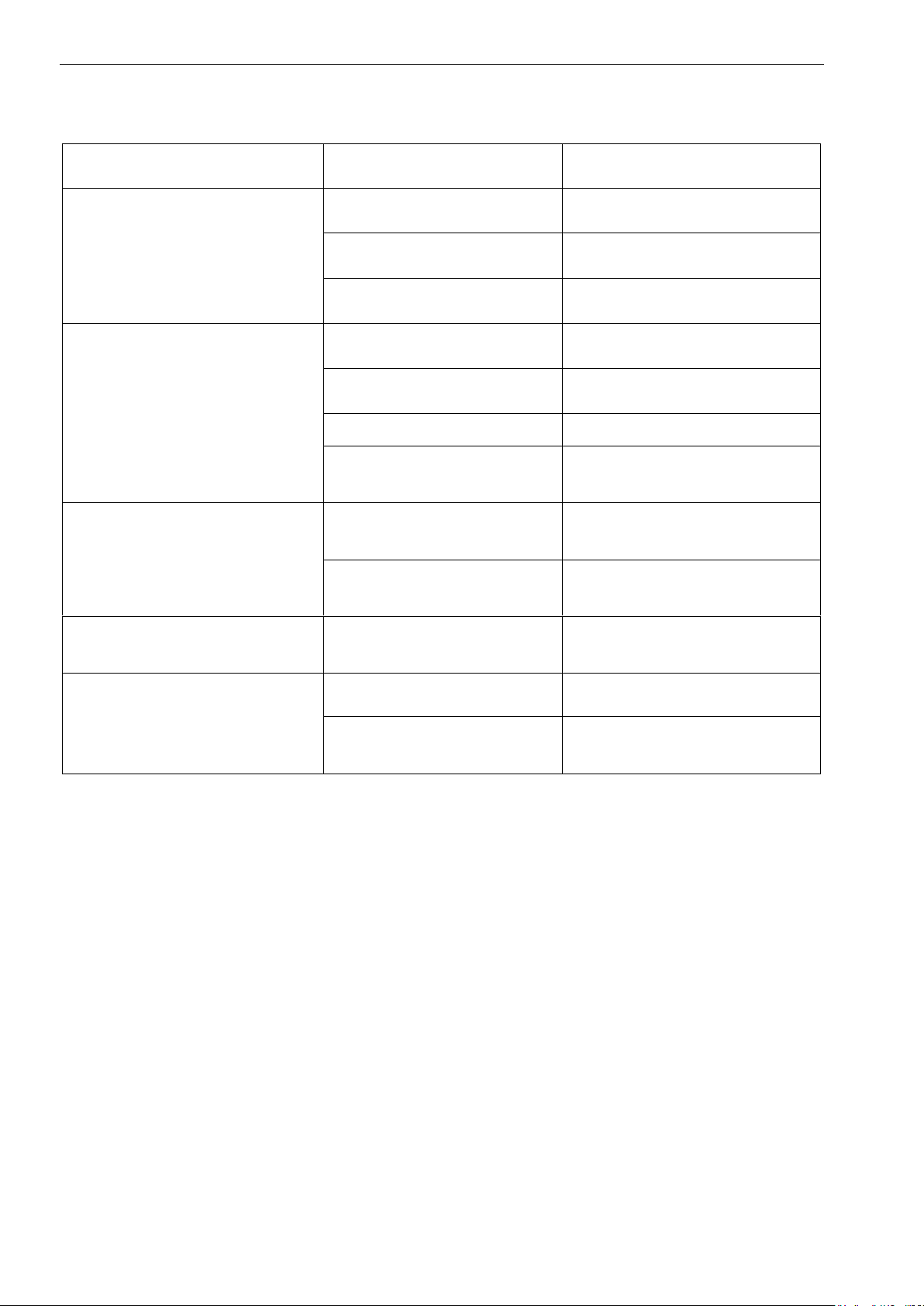

3) Open the bead breaker arm by hands by pushing it towards the outside,

place the tyre against the rubber buffer. Bring the paddle against the bead about

10mm from the edge of the rim shown as Fig 5.

Caution: Place the paddle against the tyre bead.

4) Depress pedal (H, Fig 3) to push paddle into tyre. Repeat the above operations on different positions around

the tyre and both sides of tyre until tyre is released completely.

10.2. Clamping the tyre:

1) Remove all the weights on the wheel rim;

2) Lubricate the tyre bead;

3) Swing the swing arm to non-working position.

4) Secure the wheel rim on the turntable from inside or outside.

Don't put your hands under the wheel while clamping the wheel rim.

Put the tyre on the center of the turntable.