User’s manual - F640 9

SAFETY REGULATIONS

The equipment is intended for professional use only.

WARNING

Only one operator may work on the equipment at a time.

WARNING

Failure to comply with the instructions and danger warnings may seriously injure operators

and any other person present near the machine. Do not operate the machine until you have

read and understood all the danger, warning and caution notices in this manual.

This machine must be used only by qualied and authorized personnel. A qualied operator is construed

as a person who has read and understood the manufacturer’s instructions, is suitably trained, and

is conversant with safety and adjustment procedures to be adhered to during operations. Operators

must not use the machine under the inuence of alcohol or drugs which may affect their capacity.

The operator must, in all cases:

- Be able to read and understand all the information in this manual.

- Have a thorough knowledge of the capabilities of this machine.

- Keep unauthorized persons well clear of the area of operation.

- Make sure the machine has been installed in compliance with all relevant regulations and legislation.

- Make sure that all machine operators are suitably trained, that they are capable of using the

equipment correctly and that they are adequately supervised.

- Never leave nuts, bolts, tools or any other equipment on the tyre changer as they may become

entrapped between moving parts.

- Not touch power lines or the inside of electric motors or any other electrical equipment before

making sure the power supply has been disconnected.

- Read this manual carefully and learn how to use the machine correctly and safely.

- Always keep this user and maintenance manual in an easily accessible place and consult it

whenever necessary.

WARNING

Do not remove or deface the Danger, Warning or Instruction decals. Replace any missing or

illegible decals. If one or more decals have been detached or damaged, replacements can be

obtained from your nearest dealer.

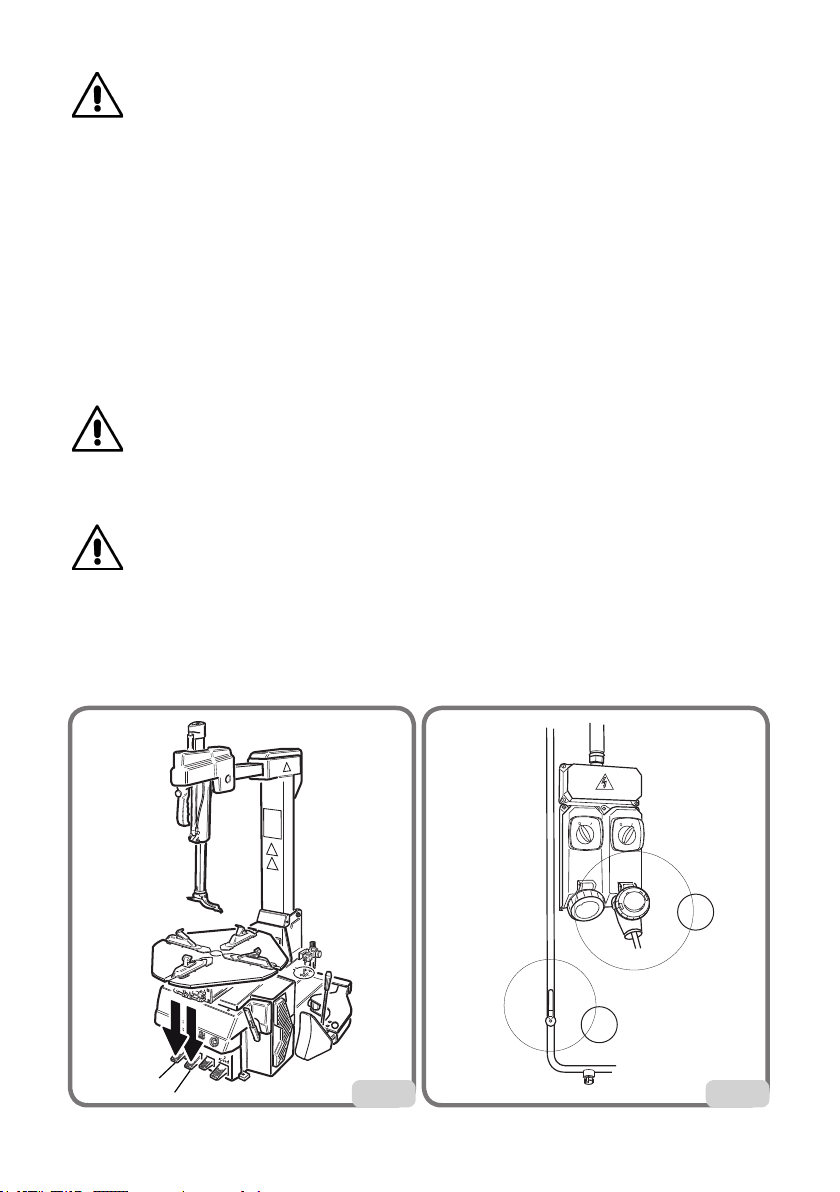

- When using and servicing the machine, observe the standardized industrial accident

prevention regulations for high voltages.

- Any unauthorized alterations or changes made to the machine shall automatically release the

manufacturer from any liability for damage or accidents attributable to such modications.

Specically,tampering with or removing the safety devices is a breach of the regulations for Safety

in the workplace.

- User must wear personal protective equipment such as gloves, safety footwear and goggles.

WARNING

When operating or servicing the equipment, tie back long hair and do not wear loose-tting clothes,

ties, necklaces, rings or wristwatches which could become entrapped by moving parts.