www.bvmsystems.co.uk

40-0287-12 - 7 -

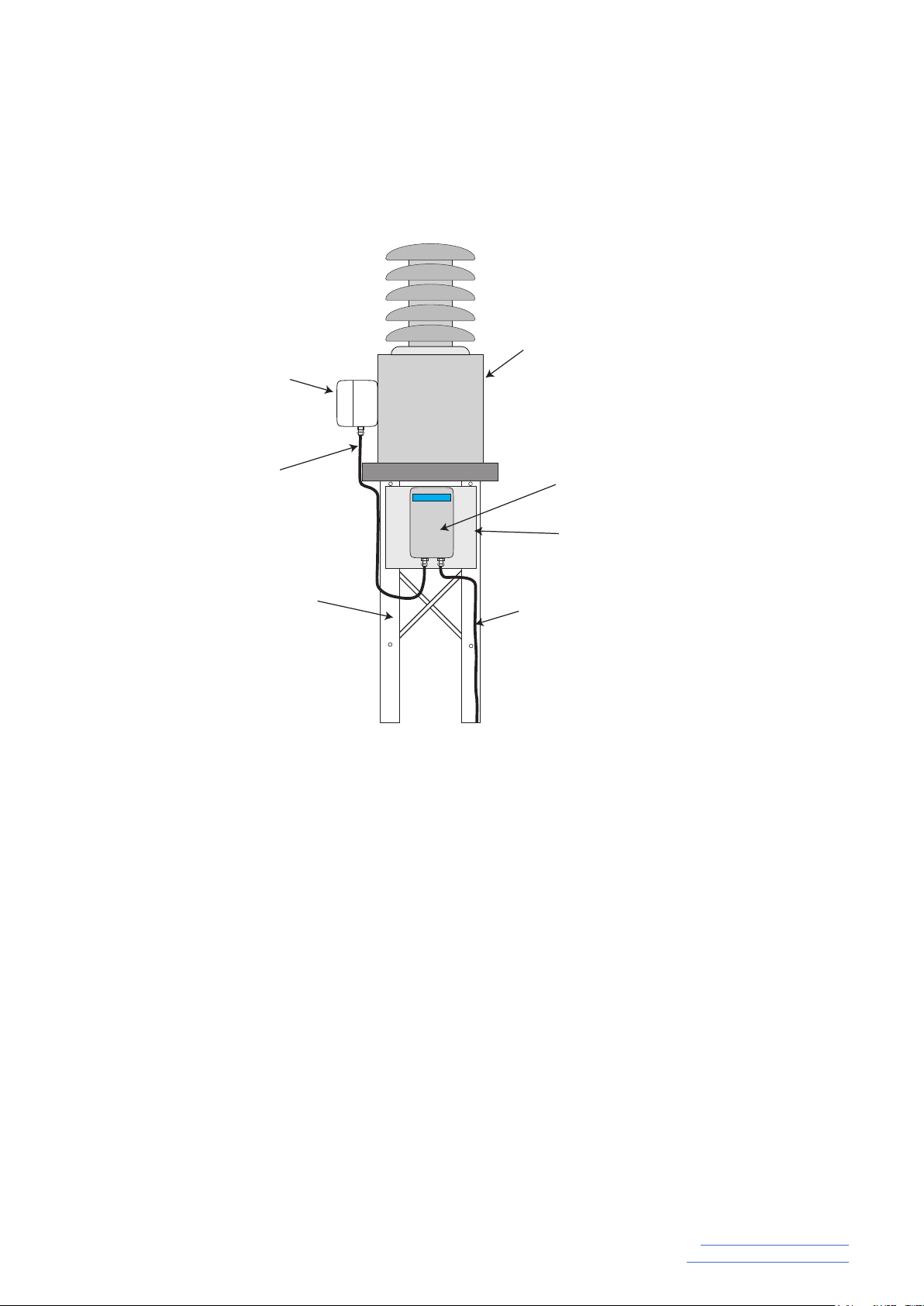

N.B. A mounting plate or bracket will be required

to secure the SCM to the CVT structure. Since

there is a wide variety of support structures used

in substations this bracket is NOT provided with the

PQSensor™ and will normally be sourced locally.

4.2 Installation in Hot Climates

In climates where ambient temperatures can ex-

ceed 40˚C it is highly recommended to mount the

SCM in a location that will afford the maximum

shade from direct sunlight. While the PQSensor™

is rated for temperatures up to 65˚C in warmer cli-

mates it is prudent to limit exposure to direct sun-

light. This is best achieved by using a mounting

plate at least 500mm wide which is fitted on the

shaded side of the CVT structure. A sun shade can

also be provided for such installations.

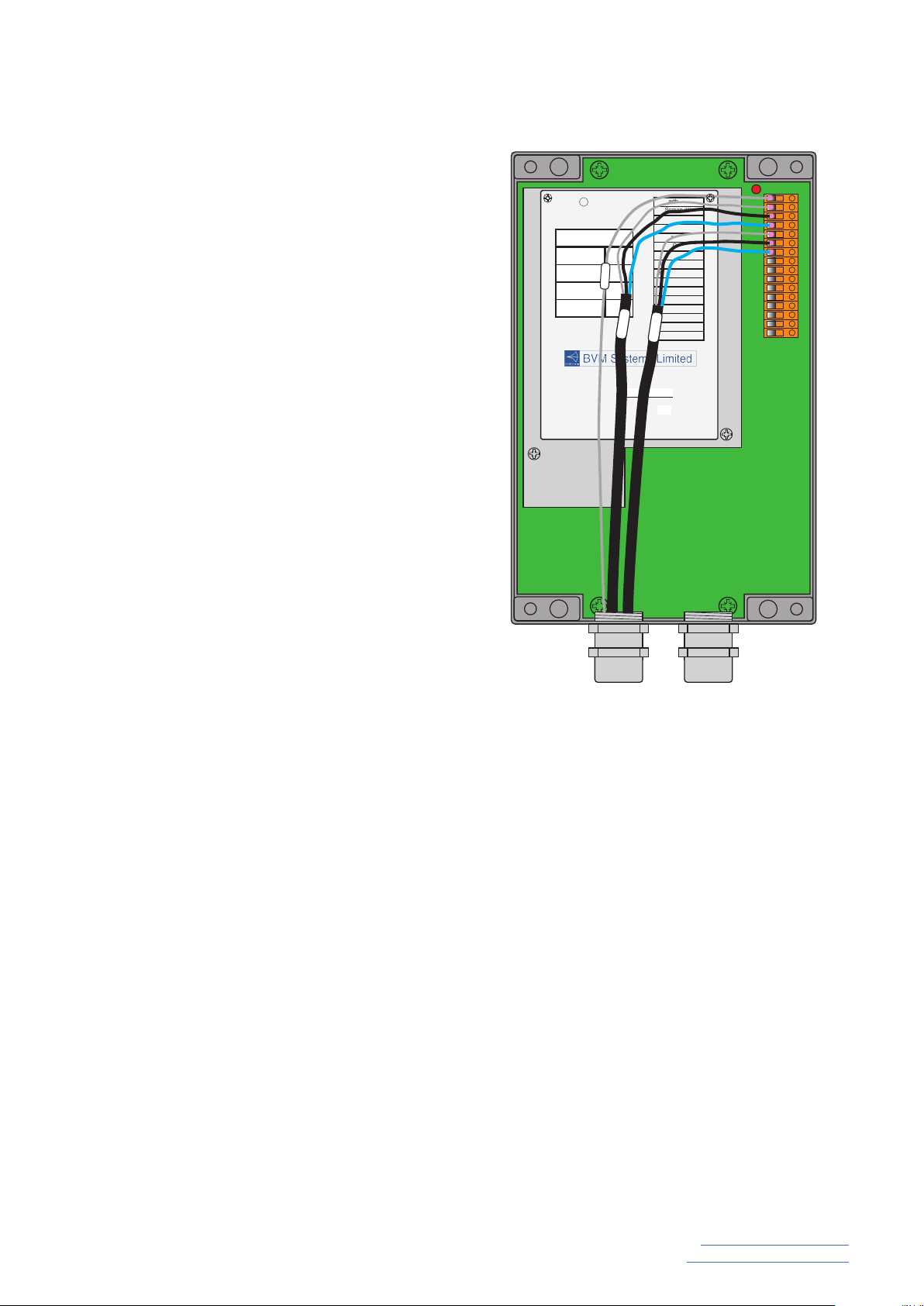

4.3 Installing the Interconnecting Cable

The Interconnecting cable is 3m in length and is

pre-terminated at both ends for connection between

the CVT secondary terminal box and the SCM en-

closure. The interconnecting cable should be wired

between the MU in the CVT secondary terminal

box and the SCM using the SWA cable glands sup-

plied. First terminate the connections in the SCM

as shown in Figure 3 and the drawing in Appendix

IV and then terminate the other end of the cable

on the MU in the CVT terminal box. A full wiring

diagram for the Interconnecting Cable in contained

in Appendix IV. The interconnecting cable should be securely xed to the CVT structure at as

many points as necessary to ensure there are no loose sections of cable.

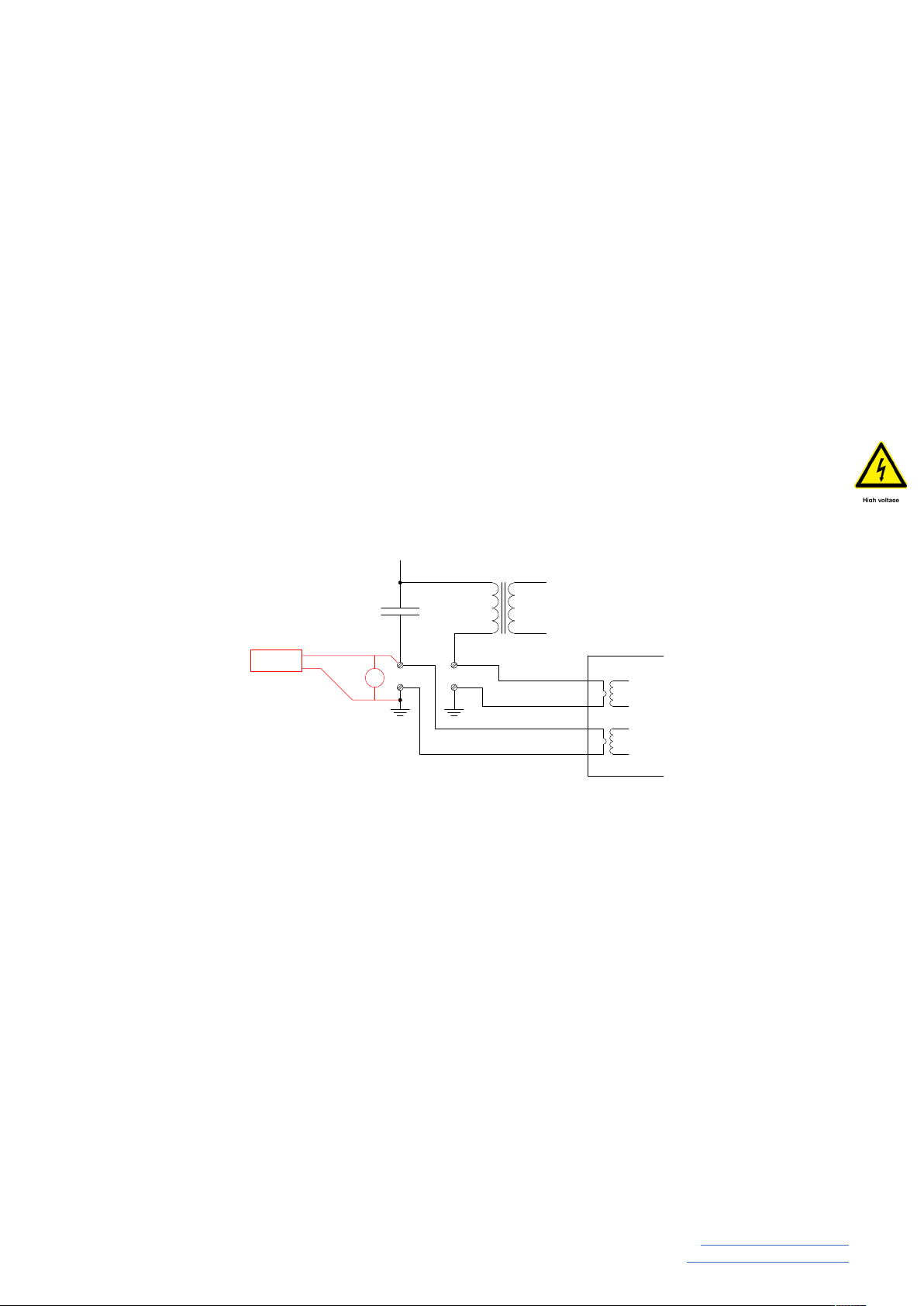

4.4 Supply Voltage and Output Signal connection

In addition to the connections to the Measurement Unit the supply voltage and the output signal

need to be connected. These connections should be made using stranded cable with a mini-

mum size of 1mm2.

The PQSensor™ accepts a universal supply and can be powered from 110V ac, 230V ac or

80 - 250V dc. A ground/earth connection must always be made to pin 3 of the PQSensor™ user

connection terminal block.

The nominal output signal from the PQSensor™ is of the order of 60V ac so appropriate safety

precautions should be taken when working with a voltage of this level. For safety purposes it

should be assumed that when the PQSensor™ is powered on there is always a voltage of 60V

ac present on the output terminals.

The PQSensor™ is intended to be used with recording equipment that has an input impedance

of greater than 1Mohm.

Supply Voltage:- 110/230V ac, 88 - 250Vdc

Part No. 18-0049-

PQSensor™

Serial No.

16. Earth

15. Screen (White)

14. LCCT (Black)

13. LCCT (Blue)

12. Screen (White)

11. HCCT (Black)

10. HCCT (Blue)

9. Earth

8. Aux (Cmn)

7. Aux

6. Earth

5. O/P (Cmn)

4. O/P

3. Earth

2. Neutral / -

1. Live / +

CVT Serial Number

Factory Test Voltage

FieldTest Voltage

Date Sign

Date Sign

Output (V)

Output (V)

O/P Adj.

HCCT

LCCT

EARTH

Figure 3