haze-gard plus is a stationary

instrument designed to measure the

appearance of glass and of films,

packaging and parts made of plastic

and other transparent materials.

The specimen surface is illuminated

perpendicularly, and the transmitted

light is measured photoelectrically,

using an integrating sphere

(0°/diffuse geometry). The spectral

sensitivity conforms to CIE standard

spectral value function y, under

standard light C resp. A.

Three parameters:

• total transmittance

• haze

• clarity

permit visual appearance to be

characterized fully and objectively.

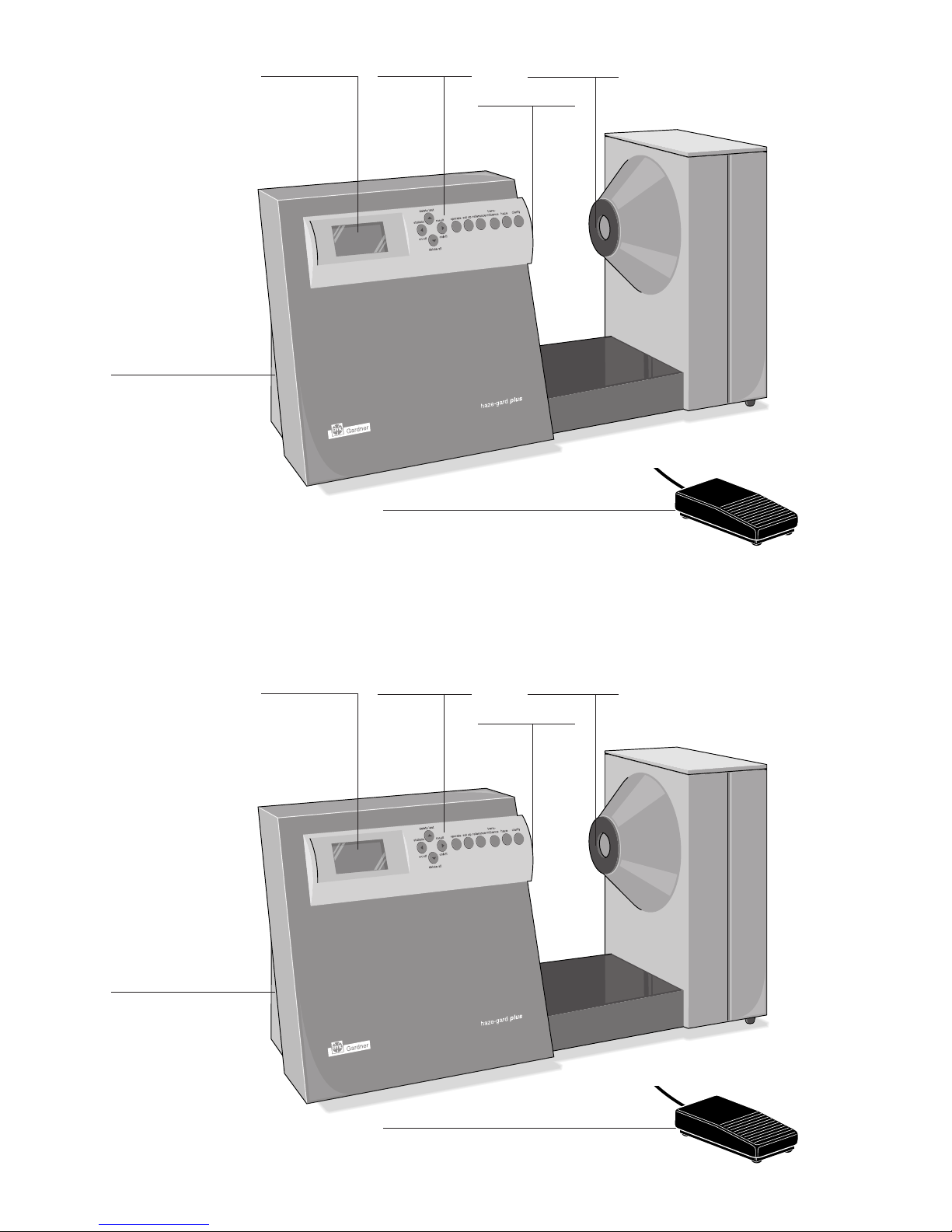

haze-gard plus sets new standards

in transparency measurement

instruments. Aside from its speed

and ease of operation, it also offers

the following features:

• pen specimen area for small

and large products

• Automatic calibration and menu-

driven operation

• High accuracy and reliability

thanks to reference-beam optics

• Longterm calibration and self-

diagnosis

• Closed optics and electronics

• Ready to operate immediately

no lengthy warm-up needed

• Foot switch

• Internal statistics functions

• Memory to store readings,

PC interface, printer outlet

haze-gard plus conforms to the

standards ASTM D-1003 and

ASTM D-1044.

2. System Description

haze-gard plus is a stationary

instrument designed to measure the

appearance of glass and of films,

packaging and parts made of plastic

and other transparent materials.

The specimen surface is illuminated

perpendicularly, and the transmitted

light is measured photoelectrically,

using an integrating sphere

(0°/diffuse geometry). The spectral

sensitivity conforms to CIE standard

spectral value function y, under

standard light C resp. A.

Three parameters:

• total transmittance

• haze

• clarity

permit visual appearance to be

characterized fully and objectively.

haze-gard plus sets new standards

in transparency measurement

instruments. Aside from its speed

and ease of operation, it also offers

the following features:

• pen specimen area for small

and large products

• Automatic calibration and menu-

driven operation

• High accuracy and reliability

thanks to reference-beam optics

• Longterm calibration and self-

diagnosis

• Closed optics and electronics

• Ready to operate immediately

no lengthy warm-up needed

• Foot switch

• Internal statistics functions

• Memory to store readings,

PC interface, printer outlet

haze-gard plus conforms to the

standards ASTM D-1003 and

ASTM D-1044.

2. System Description