C.ITOH 8510A User manual

DOT

MATRIX

SERIAL

IMPACT

PRINTER

MODEL

8510A

USERS

MANUAL

U.S.A.:

C. ITOH ELECTRONICS, INC.

5301

Beethoven Street,

Los Angeles, Calif.

90066 U.S.A.

{J>c. ITOH &

co.,

LTD.

EUROPE:

5-1, Kita-Aoyama 2-chome,

Minato-ku, Tokyo, Japan

C.P.O.

Box

136 Tokyo 100-91 JAPAN

South-East ASIA:

C. ITOH

&.

CO.,

(WNDON)

LTD.

76 Shoe Lane, C. ITOH

&.

CO.,

(HONG KONG) LTD.

38th Floor

London, EC4A 3JB,

England Connaught Centre

Connaught Road Central

Hong Kong

"This equipment generates and uses radio frequency energy and

if

not

installed and

used properly,

that

is, in strict accordance with the manufacturer's instructions, may

cause interference

to

radio and television reception. It has been type tested and

found

to

comply with the limits for a Class B computing device in accordance with

the specifications in Subpart J

of

Part

15

of

FCC Rules, which are designed

to

provide

reasonable protection against such interference in a residential installation. However,

there is

no

grarantee that interference will

not

occur in a particular installation. If

this equipment does cause interference to radio or television reception, which can

be determined by turning the equipment

off

and on; the user

is

encouraged to try

to

correct the interference by one or more

of

the following measures:

• reorient the receiving antenna

• relocate the computer with respect

to

the receiver

• move the computer away from the receiver

• plug the computer into a different outlet so that computer and receiver are on

different branch circuits

If

necessary, the user should consult the dealer

or

an experienced radio/television

technician for additional suggestions. The user may find the following booklet pre-

pared by

the

Federal Communications Commission helpful:

"How

to

Identify and Resolve Radio-TV Interference Problems". This booklet

is

available from the

US

Government Printing Office, Washington, D.C., 20402, Stock

No. 004-000-00345-4."

(U.S. VERSION ONLY)

"All

of

the features and specifications are

subject

to

change

without

prior notice"

TABLE

OF

CONTENTS

INTRODUCTION

..................................................................

2

PREPARATION

FOR

USE

..........................................................

3

1.

Unpacking Instructions

........................................................

3

2.

Ribbon Cassette Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

5

3. Paper Setting

................................................................

6

4. How

to

Use the Paper Guide Separator

............................................

9

5.

Prjnt Position Adjustment

......................................................

10

6. Gap between Dot Head and

Platen.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

11

7.

Power Cord Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

11

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

12

1.

Appearance and Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

12

2. Power Switch and Control Panel

.................................................

13

3.

Operating Switches

............................................................

14

4.

Alert Switches

...............................................................

14

5.

Indicator Lamps

.............................................................

, 14

6.

Self-Test Function

...........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

15

7.

Dip-Switch Setting

...........................................................

, 16

8. Specification

by

Jumper

................................

: . . . . . . . . . . . . . . . . . . . . .

..

20

9. Connecting the Interface Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

21

10. Parallel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

21

11. Serial

Interface.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

27

12. Function Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

41

13. Special Functions

of

the

M8510A

.................................................

46

14. Character Sets/ASCII Tables

.....................................................

54

15. General Operating Notes

........................................................

57

16. Periodic Maintenance

..........................................................

57

17.

Specifications................................................................

60

18. Print

Sample.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

62

19. Print Paper Specification

........................................................

63

-1-

INTRODUCTION

General Description

The Model 8510A

is

a compact desk-top dot matrix ,serial impact printer used for data communication

terminals, hardcopy

of

CRT displays, peripheral terminals for minicomputers and microcomputers, and

small-sized business systems.

The character format

is

a

dot

matrix

of

7(H) x 9(V),

or

8(H) x 8(V).

Print speed

is

120 characters/second.

Up

to

80 characters can be printed per line in 10 CPI.

Its main features are:

1.

Compact desk-top dot matrix printer

2.

Eighty-column print

3. Light-weight

4.

Low power-consumption

5.

High-quality print

6. Bit image graphics

7.

Graphic symbols

8. Prints in six different languages

9.

High reliability

10. Low cost

-2-

PREPARATION

FOR

USE

1.

Unpacking Instructions

t

Outer

Carton

Power Supply Cord

Fig. 1 Unpacking Instruction (1)

-3-

1.

After opening

outer

carton, take

the

ribbon cassette and power

supply cord out

of

the

pocket

in

the

top

pad.

(Take out the paper guide separator

if

packed together with

the

printer.)

Paper Guide Separator

(Option)

2.

Draw the

top

pad

out

of

the

outer

carton slowly with

both

of

your

hands.

3. Draw

the

printer

out

of

the

outer

carton slowly with

both

of

your

hands.

Caution: Please, do

not

hold

the

knob when drawing

out

the

printer.

(See Fig. 1.)

<9,---

Ribbon Cassette

Packing

Bag

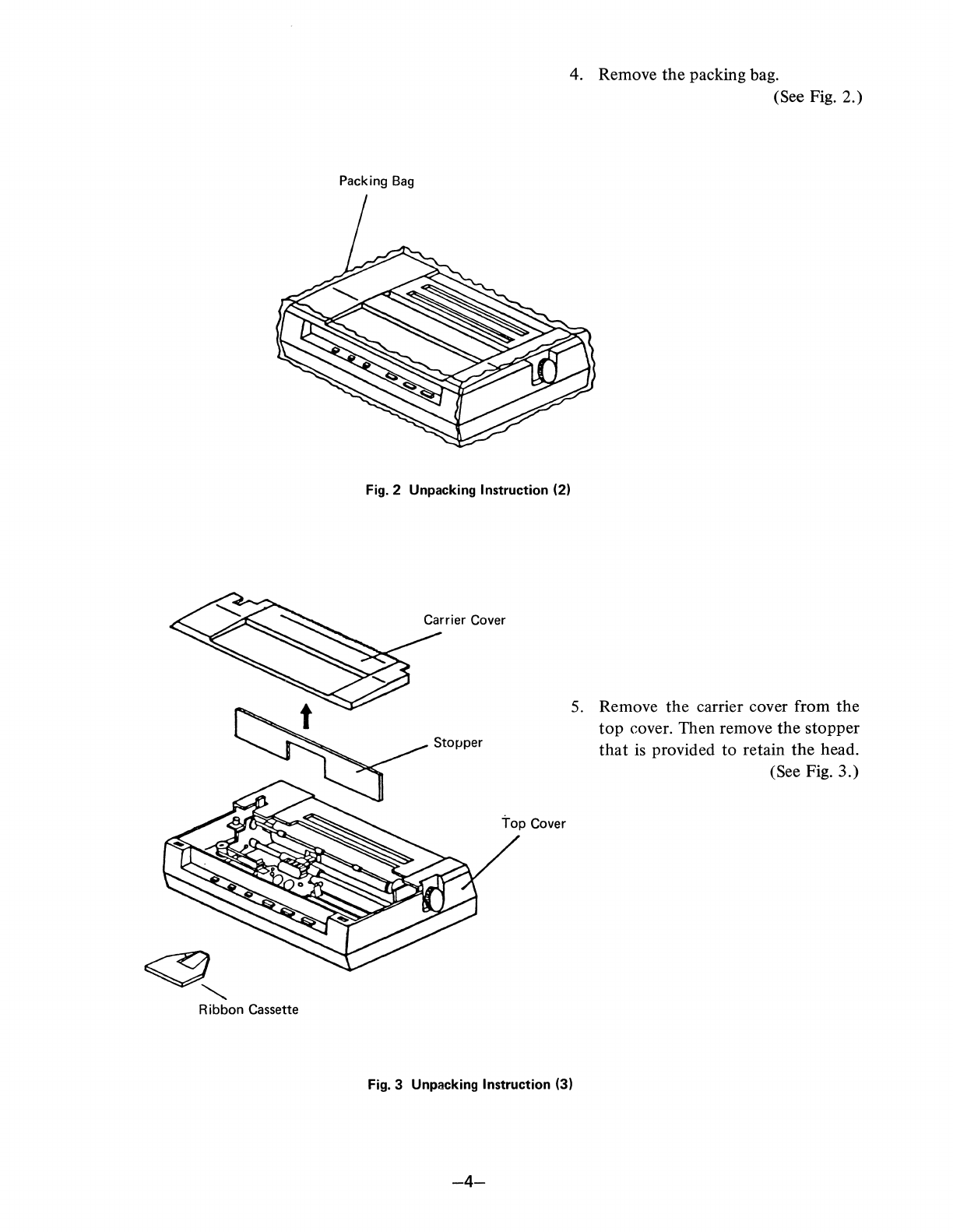

Fig. 2 Unpacking Instruction (2)

4. Remove

the

packing bag.

(See Fig. 2.)

5.

Remove

the

carrier cover from the

top

cover. Then remove

the

stopper

that

is provided to retain the head.

(See Fig. 3.)

Fig. 3 Unpacking Instruction (3)

-4-

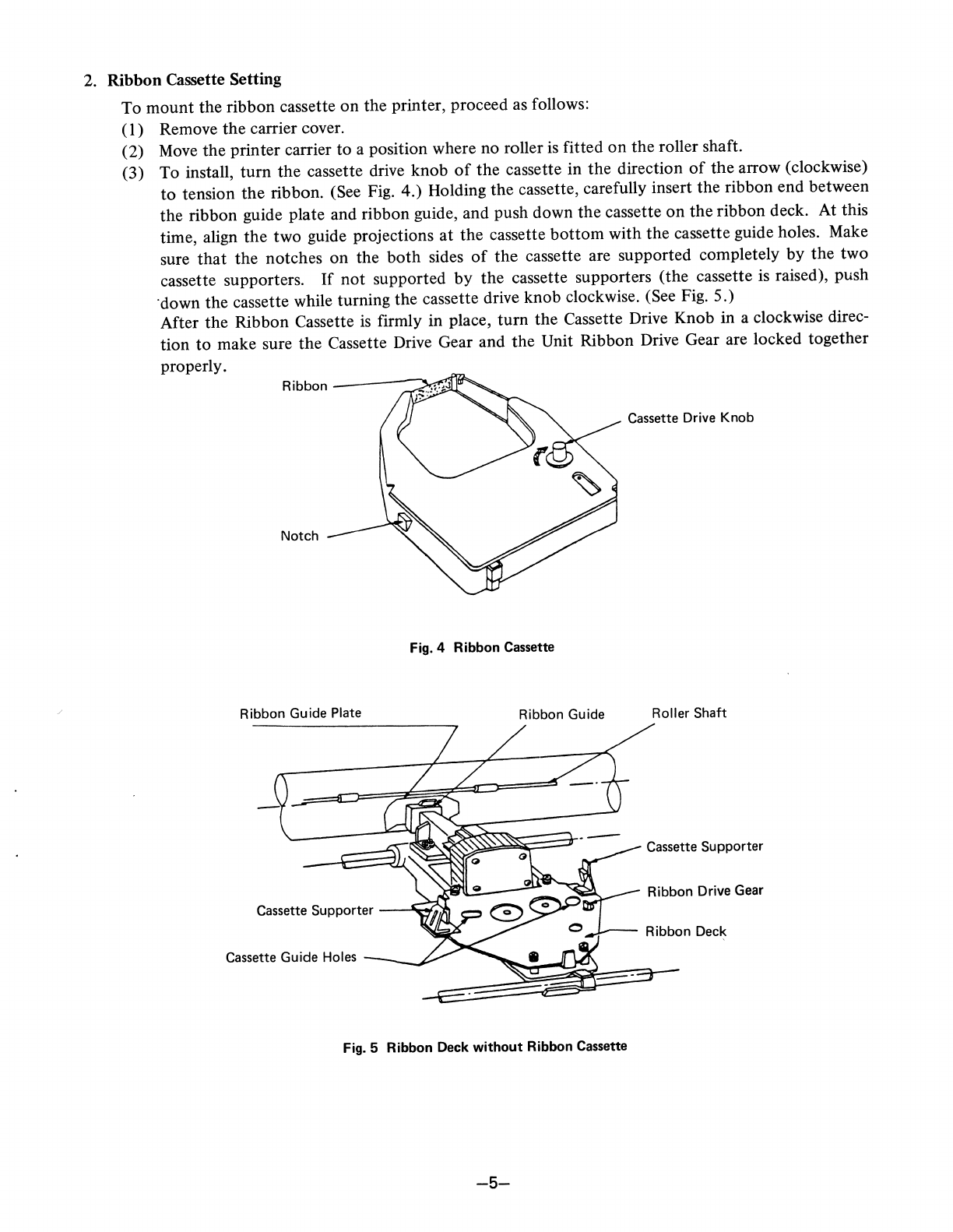

2. Ribbon Cassette Setting

To mount the ribbon cassette

on

the printer, proceed as follows:

(I)

Remove

the

carrier cover.

(2)

Move

the

printer carrier to a position where no roller is fitted

on

the roller shaft.

(3) To install, turn the cassette drive knob

of

the cassette in

the

direction

of

the

arrow (clockwise)

to

tension

the

ribbon. (See Fig. 4.) Holding

the

cassette, carefully insert the ribbon end between

the ribbon guide plate and ribbon guide, and push down

the

cassette

on

the

ribbon deck. At this

time, align

the

two guide projections at

the

cassette

bottom

with the cassette guide holes. Make

sure

that

the

notches on the

both

sides

of

the

cassette are supported completely by

the

two

cassette supporters.

If

not

supported

by

the cassette supporters (the cassette

is

raised), push

·down the cassette while turning the cassette drive knob clockwise. (See Fig. 5.)

After the Ribbon Cassette

is

firmly in place, turn the Cassette Drive Knob

in

a clockwise direc-

tion to make sure

the

Cassette Drive Gear and

the

Unit Ribbon Drive Gear are locked together

properly.

Cassette Drive Knob

Fig. 4 Ribbon Cassette

Ribbon Guide Plate Ribbon Guide Roller Shaft

Cassette Supporter

Ribbon Drive Gear

Cassette Supporter

--"\.,.r.

Cassette Guide Holes

Fig. 5 Ribbon Deck

without

Ribbon Cassette

-5-

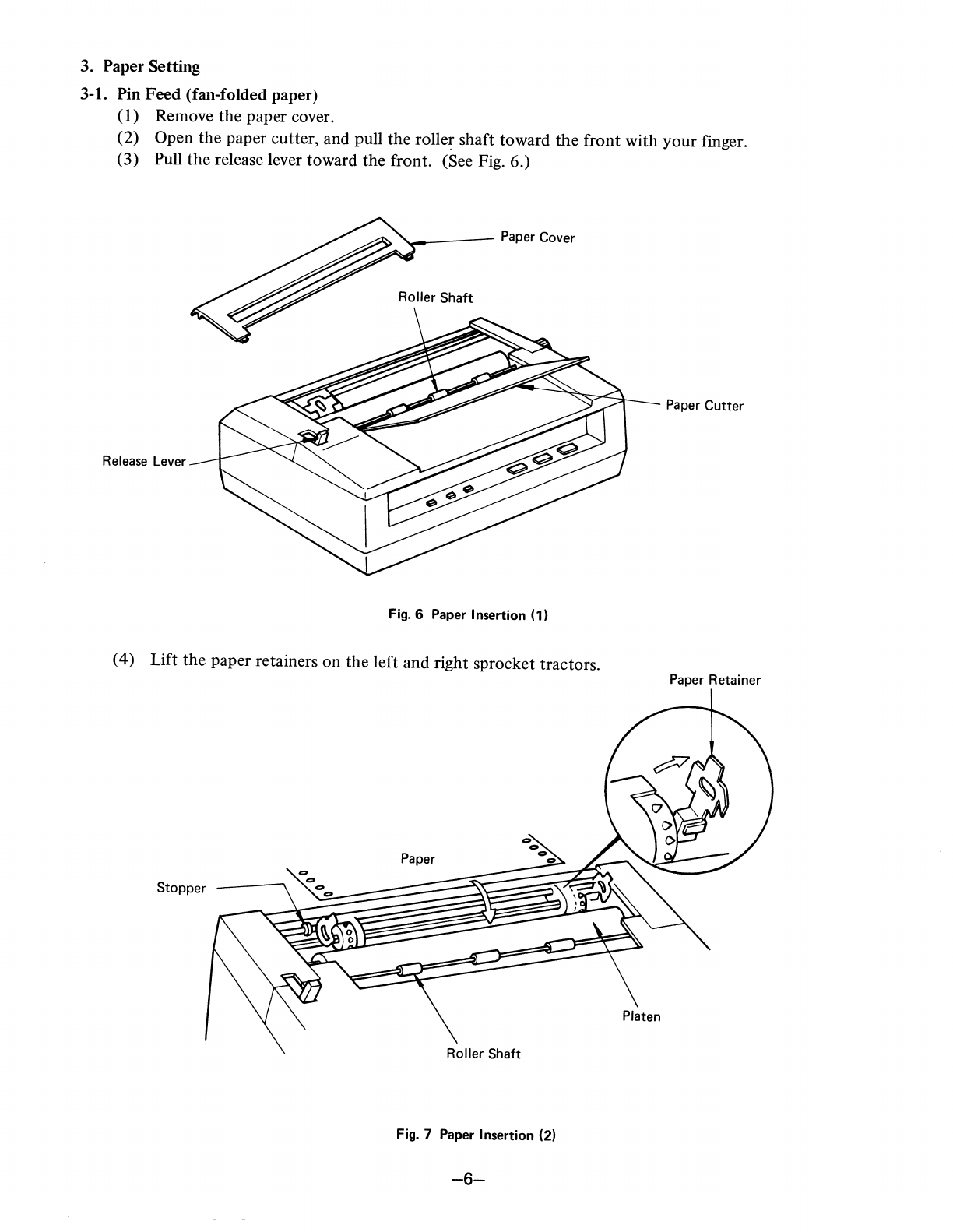

3. Paper Setting

3-1.

Pin

Feed

(fan-folded!>aper)

(1) Remove

the

Paper caver.

(2)

Open the Paper Cutter,

and

PUll the

roller

shaft

tOWard

the

front

With y u

f:

(3)

Pull

the release

le.er

tOWard

the

front.

(See Fig. 6.)

0

r mger.

'--------

Paper

Cover

ROller

Shaft

Release

Lever

Paper

CUtter

Fig. 6

Paper

Insertion

(l)

(4)

Lift the paperretainers

On

the

left

and

right

sprOCket

tractors.

Paper Retainer

Stopper \

'\

....

_

_--..,\.00

......

Paper

ROller

Shaft

Platen

Fig.

7 Paper

Insertion (2)

-6-

(5) Take

the

end

of

the

paper and fit

the

paper sprocket holes

onto

the

right and left sprocket pins.

If

the

paper width necessitates adjusting

the

distance between

the

sprocket

tractor,

push back

the

right

or

left sprocket lever (allowing

the

sprocket tractor(s)

to

move freely) and move

the

sprocket tractor(s) right

or

left

as

needed

to

match

paper width. Then pull

the

sprocket lever(s)

forward

to

lock

the

position

of

the

sprocket

tractor(s). (Refer

to

Fig. 8.)

Sprocket

Lever

Fig. 8 Paper Insertion (3)

(6) Now push down

the

paper clamps

of

the

sprocket tractors.

Turn

the

platen

knob

clockwise,

bringing

the

paper

out

on

the

front side

of

the

platen. Return

the

roller shaft and release lever

to

their previous positions. (Refer

to

Fig.

9.)

Paper

End Platen

Knob

Release Lever

..L~-....f';?~r

Fig. 9 Paper Insertion (4)

(7)

Reposition

the

roller shaft.

(8) Turn

the

release lever

to

the

"pin

feed" position.

-7-

3-2. Frinction Feed (roll paper and sheet paper)

(1)

Open

the

paper cutter, and pull

the

roller shaft toward

the

front.

(2)

Move the head carrier

to

the

left end.

(3)

Turn

the

release lever toward

the

rear.

(4)

Insert

the

paper

into

the

paper inlet

on

the paper cover (behind

the

paper cover for roll paper).

When

the

paper end appears

on

the

platen, set

the

paper properly, turn

the

release lever toward

the front

(to

the "friction feed" position), and reposition

the

roller shaft and paper cutter.

(See Fig. 10.)

Paper

Roller

Shaft

Roller Paper Inlet

-:;;::~~Icl--"..4-_

Paper

Cutter

Release Lever

Fig.

10

-8-

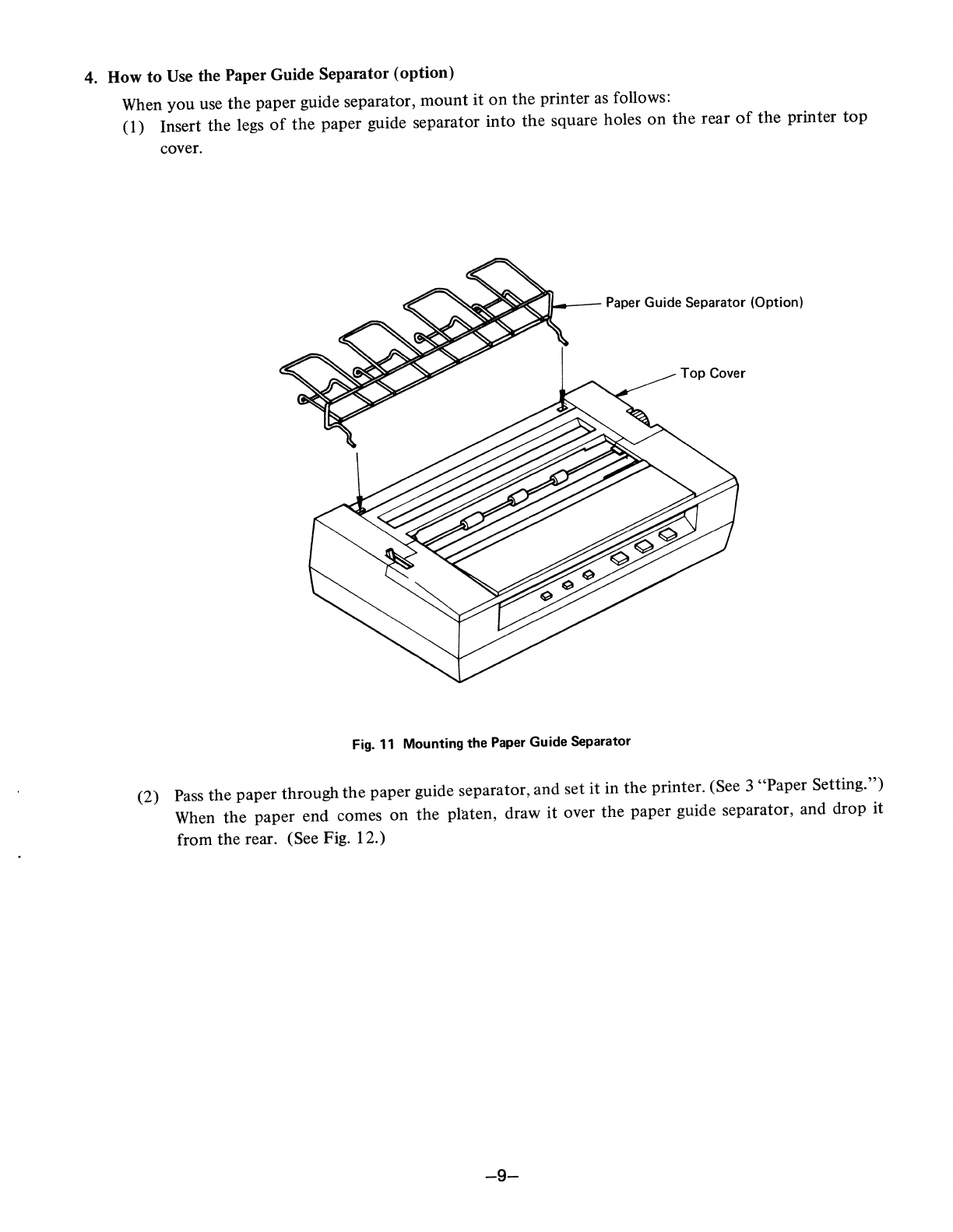

4. How

to

Use the Paper Guide Separator (option)

When

you

use

the

paper guide separator,

mount

it

on

the

printer

as

follows:

(1) Insert

the

legs

of

the

paper guide separator

into

the

square holes

on

the

rear

of

the

printer

top

cover.

1"-"--

Paper Guide Separator (Option)

Top Cover

Fig.

11

Mounting

the

Paper Guide Separator

(2) Pass

the

paper through

the

paper guide separator,

and

set

it

in

the

printer. (See 3 "Paper Setting.")

When

the

paper end comes

on

the

platen, draw

it

over

the

paper guide separator, and drop it

from

the

rear. (See Fig. 12.)

-9-

j

/

Fig.

12 Example of Paper Guide Separator Application

5.

Print Position Adjustment

After

the

paper

is

properly set, turn the right platen knob clockwise

to

adjust the print position.

-10-

6. Gap between

Dot

Head and Platen

The gap between

the

head needle end and the platen is adjustable in 4 steps.

(a) When

the

gap adjusting lever is pushed fully away from you,

the

gap between

the

head needle

end and the platen will

be

0.5

to

0.55. The lever is usually set

at

this position when a single

sheet

of

paper

is

used.

(b) Depending

on

the

number

of

sheets

of

paper, pull

the

gap adjusting lever toward you

to

adjust

the gap.

Head

Platen·to-head

gap

with

adjusting lever

fully

pushed away

from

you.

Head

Adjusting Lever

Fig. 13 Gap Adjustment between

Dot

Head and Platen

7. Power Cord Connection

..

~-""7"C--

Gap

of

0.8

to

0.85

Gap

of

0.7

to

0.75

Gap

of

0.6

to

0.65

Gap

of

0.5

to

0.55

(Single paper)

Connect

the

attached power cord

to

the printer, and insert

the

plug into the

AC

outlet.

-11-

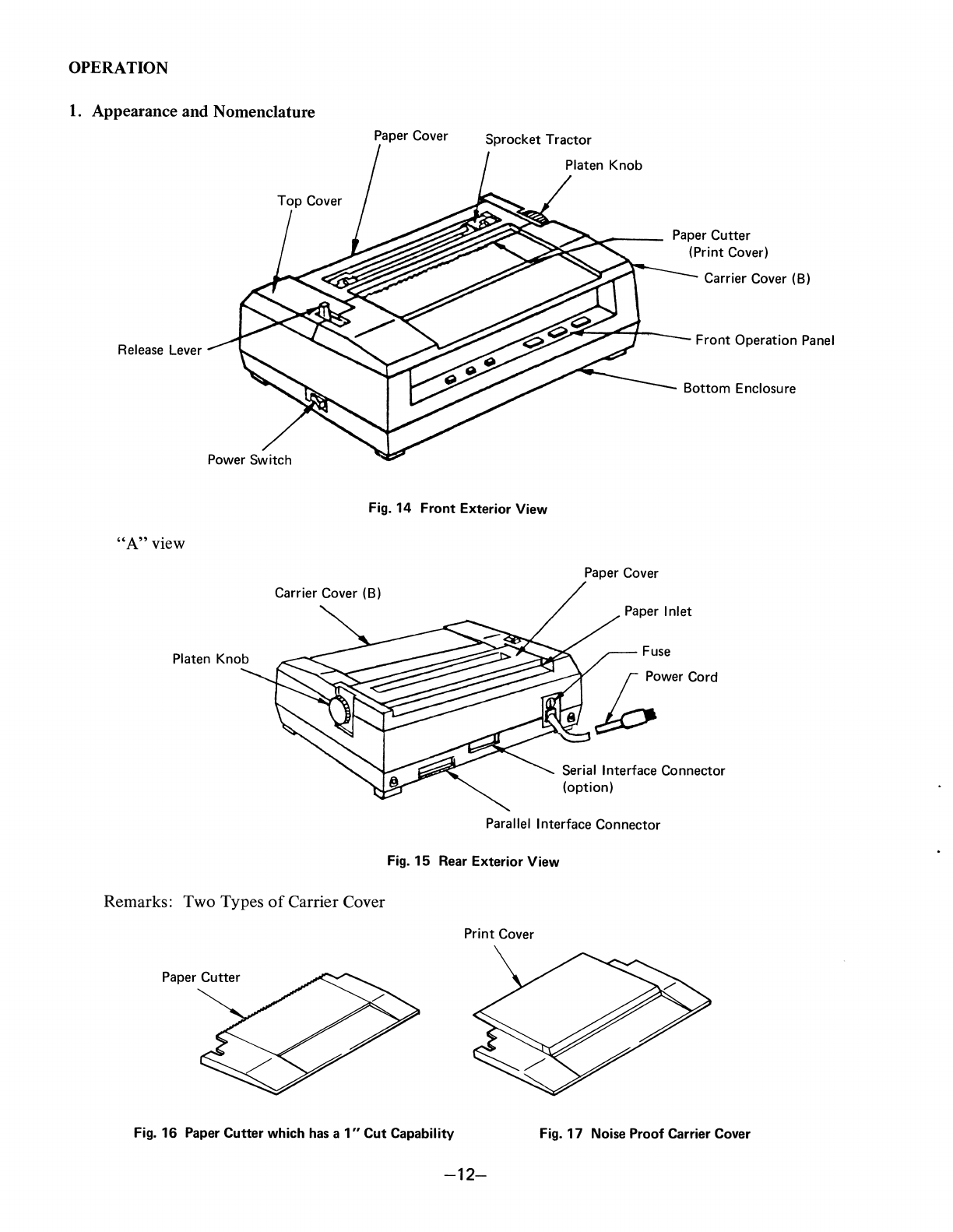

OPERATION

1.

Appearance and Nomenclature

Paper Cover Sprocket Tractor

Paper Cutter

(Print Cover)

Carrier Cover

(B)

Release Lever Front Operation Panel

Bottom Enclosure

Fig.

14

Front

Exterior View

"A"

view

Carrier Cover

(B)

Platen Knob

Remarks: Two Types

of

Carrier Cover

Paper Cutter

Paper Cover

Fuse

~""'''''--1b

Powe, Co,d

Serial Interface Connector

(option)

Parallel Interface Connector

Fig.

15

Rear Exterior View

Print Cover

Fig.

16

Paper Cutter which has a

1"

Cut Capability Fig.

17

Noise Proof Carrier Cover

-12-

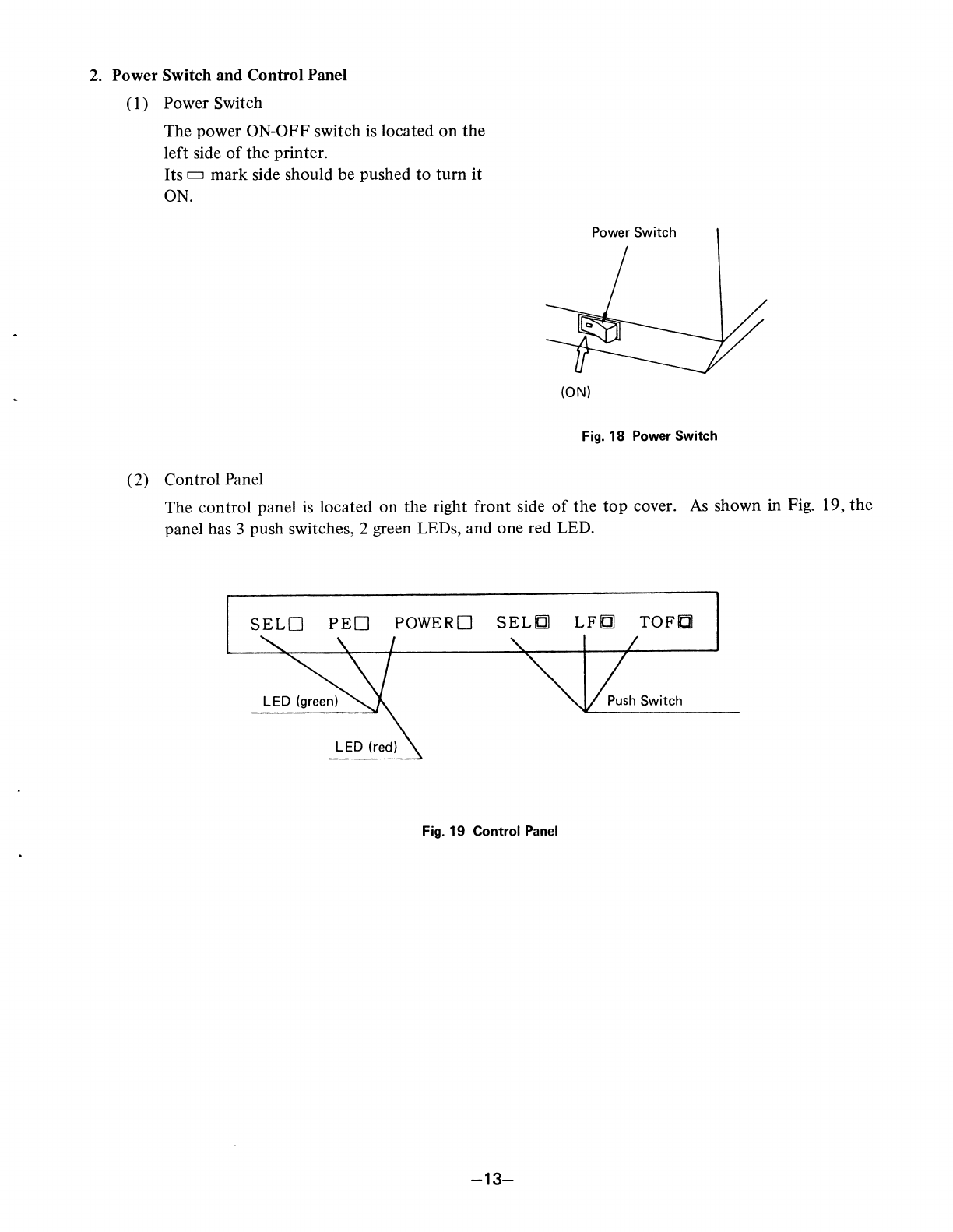

2. Power Switch and Control Panel

(I)

Power Switch

The power ON-OFF switch is located

on

the

left side

of

the

printer.

Its c:::J mark side should be pushed

to

turn

it

ON.

(2) Control Panel

Power Switch

(ON)

Fig.

18

Power Switch

The control panel

is

located

on

the right front side

of

the

top

cover.

As

shown in Fig. 19,

the

panel has 3 push switches, 2 green LEDs, and one red LED.

SELO

PEO

POWERO

SELfJ]

LFfJ]

TOFIl

Fig.

19 Control Panel

-13-

3. Operating Switches

3-1. SEL (Select) Switch

(a) This is a push switch located

on

the

control panel.

(b) SELECT and DESELECT states alternate with every push.

(c) When power

is

applied,

the

printer will become either SELECT

or

DESELECT, depending

on

DIP switch selection. (Refer

to

section 7-10.)

(d) Data transmission and printing

of

data in

the

DATA

BUFFER

can be stopped temporarily.

To

perform this operation, press

the

SEL switch with

the

LF

switch already depressed. To resume

printing and data transmission, press the SEL switch.

3-2.

LF

(Line Feed) Switch

(a) This is a push switch located on the operating panel.

(b) One line feed occurs with every push.

(c) Line feed can be performed only when the printer is in a DESELECT state.

(d) Data transmission and printing

of

data in

the

DATA BUFFER can be stopped temporarily. To

perform this operation, press

the

SEL switch with

the

LF

switch already depressed. To resume

printing and data transmission, press the SEL switch.

3-3.

TOF

(Top

of

Form)

Switch

(a) This is a push switch located on

the

operating panel.

(b) When this switch is pressed, the paper feeds

to

the

next

TOF

position as set in

the

VFU.

(c)

TOF

can be performed only when the

printer

is in a DESELECT state.

4. Alert Switches

4-1. PE (Paper

Empty)

Switch

(a) This is a microswitch installed beneath

the

platen.

(b) When this sensor detects

that

the paper end is near (25

mm

from the end),

the

PE lamp is lit.

The printer enters the DESELECT state, data reception ceases and print operation stops. The

printer

enters a FAULT state.

4-2. Cover Interlock Switch

(a) When

the

top

cover

is

open, printing will stop

and

the printer will

enter

the

DESELECT and

FAULT states.

(b) To resume printer operation, close

the

cover and press

the

SEL switch.

5. Indicator Lamps

The following lamps are located

on

the

control panel.

5-1. SEL Lamp (Green)

This lamp is Iit when

the

printer is in the SELECT state.

5-2. PE Lamp (Red)

This lamp is Iit when

the

PE microswitch is activated.

5-3. Power Lamp (Green)

The lamp is Iit when

the

printer power is on.

-14-

6. Self-Test

Function

M8510A has a Self-Test function

to

check printing operation.

To

activate Self-Test, perform

the

following steps:

(1)

Turn power ON. Check to see

that

the carriage

is

returned

to

the

left home position. Turn

power OFF.

(2) Set the paper.

(3) With the

TOF

button

depressed, turn power ON,

then

release

the

button. The printer will auto-

matically print

the

preprogrammed test pattern, perform line feed, and print again. The Self-

Test function will continue, providing a sample

of

the

print capabilities.

(4) To stop Self-Test,

turn

power OFF.

-15-

7. DIP Switch Setting

DIP switch setting allows various selections

to

be made

as

described below.

DIP

SW-l

and

SW-2

are mounted on the main

PC

board. They are visible

at

right and accessible when

the carrier cover

is

opened.

"ST"

denotes the setting made

at

the time

of

shipment from the factory.

SW1

SW2

&r~/C/t

~

00000000

OPEN III

00000000

OPEN

National Character

Set

TOF-to-TOF

Processing

of

DCl

and

DC3

LF

or

Non-LF when

DATA

BUFFER

is

Full

Print Command

Code

Function

of

CR

Numeric Display

of

0

Selection

of

3K

Buffer or

Single Line Buffer

No Function (OPEN)

L--________

Selection

of

Character Pitch

at Power-On

Selection

of

7-Bit or 8-Bit

Data

SELECT or DESELECT

at

Power-On

L--

____________

Bidirectional Print or

Unidirectional Print

~

7

-6

)

'f

3

2-

Sw \

C-

D

'0

'0

C 0

0 C

~

1 b

~

~

3

2-

Svft2-

0 0 Q 0 0

0 C G

-16-

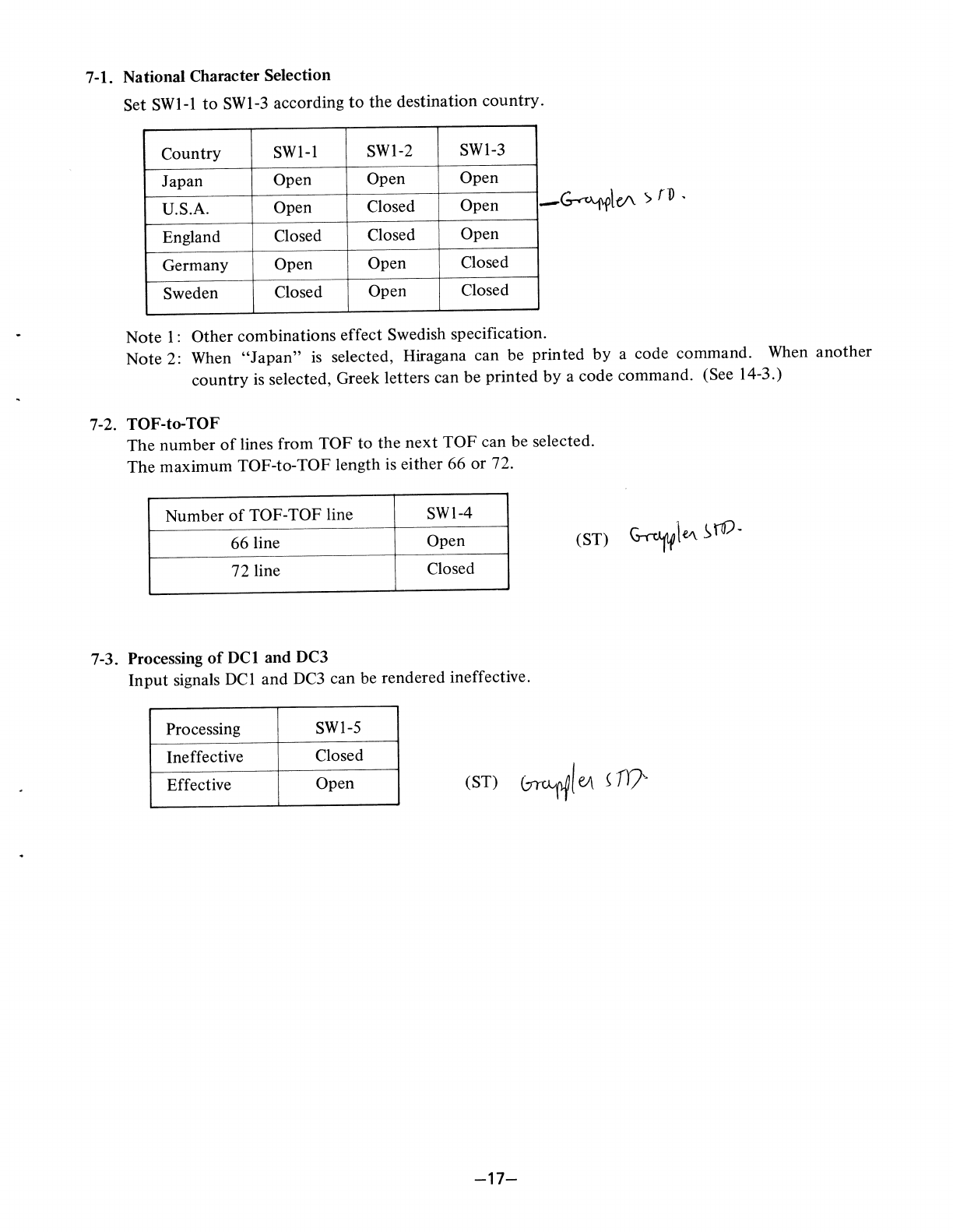

7-1. National Character Selection

Set SWl-l

to

SWl-3 according

to

the destination country.

Country SWl-1 SWl-2 SWl-3

Japan Open Open Open

U.S.A. Open Closed Open

England Closed Closed Open

Germany Open Open Closed

Sweden Closed Open Closed

Note

I:

Other combinations effect Swedish specification.

Note 2: When

"Japan"

is

selected, Hiragana can be printed

by

a code command. When

another

country

is

selected, Greek letters can be printed

by

a code command. (See 14-3.)

7-2. TOF-to-TOF

The number

of

lines from TOF to the next

TOF

can be selected.

The

maximum TOF-to-TOF length is either 66

or

72.

Number

of

TOF-TOF line SWl-4

66 line Open

72 line Closed

7-3. Processing

of

DCI and DC3

Input

signals DCl and

DC3

can be rendered ineffective.

Processing SWl-5

Ineffective Closed

Effective Open (ST)

~I

eJ\

~

Fr}·

-17-

7-4. LF

or

NON-LF when DATA BUFFER

is

Full

When the DATA BUFFER is full, the data will be printed

out

without a print command code. At this

point, one line feed

mayor

may

not

take place, depending

on

the position

of

the DIP switch.

Condition SWI-6

LF Closed

Non-LF Open (ST)

7-5.

Print Command Code

Several command codes in addition

to

CR may serve

as

print command codes. (In incremental print

mode this selection

is

unnecessary because each character

is

printed

as

it

is

received.)

Command Code SWI-7

CR Only Open

CR, LF, VT, FF,

US

Closed

i'--

7-6. Function

of

CR

One line feed

mayor

may

not

take place following a Carriage Return.

Function SWI-S

CR Open (ST)

CR+LF

Closed

7-7. Numeric Display

of

0

The numeral 0 may be printed with or without a slash.

Display

SW2-1

0 Open (ST)

0 Closed

7-S.

Selection

of

Character Pitch

at

Power-On

Characters may be printed 10 CPI

or

proportionally (spacing allowance made depending on the size

of

the character).

These are the options available at Power-On. Other print modes are software selectable. See section

14-2 for details.

Print Mode

SW2-5

10

CPI

character Open (ST)

Proportional character Closed

-18-

Table of contents

Other C.ITOH Printer manuals