C.ITOH 1550S EP User manual

DOT

MATRIX

SERIAL

IMPACT

PRINTER

MODEL

1550S/SC

EP

USERS

MANUAL

<€P

c.

aTOH

&

co.,

LTD.

e.p.o.

Box

136

Tokyo

100-91

Japan

U.S.A.:

C.ITOH ELECTRONICS, INC.

5301

Beethoven Street,

Los Angeles, Calif.

90066 U.S.A.

EUROPE:

C.ITOH ELECTRONICS CO.,

LTD.

Beacon House 26128

Worple Road, Wimbledon,

London SW19 4EE

United Kingdom

C. ITOH ELECTRONICS CORP.

Toho Seimei Bldg. 27th,

2-15-1

Shibuya, Shibuya-ku,

Tokyo

150

Japan

C.ITOH ELECTRONICS

GmbH

RoBstraBe 96

4000 Dusseldorf 30

West Germany

Thank

you for purchasing the model 1550S/SC EP.

"This equipment generates

and

uses radio frequency energy

and

if

not

installed

and

us-

ed properly,

that

is, in strict accordance with the manufacturer's instructions, may cause

interference to radio

and

television reception.

It

has been type tested

and

found to com-

ply with-the limits for a Class B computing device in accordance with

the

specifications

in

Subpart J

of

Part

·15

of

FCC Rules; which are designed

to

provide reasonable protec-

tionagainst such interference in a residential installation. However, there is no guarantee

that

interference will

not

occur

in

a particular installation.

If

this equipment does cause

interference

to

radio

or

television reception, which can be determined by turning the

equipment

off

and

on, the user

is

encouraged

to

try to correct

the

interference by one

or

more ·of

the

following measures:

• reorient

the

receiving antenna

• relocate

the

computer with respect

to

the

receiver

• move the computer away from the receiver

• plug the computer into a different outlet so

that

computer

and

receiver are

on

clif-

ferent branch circuits

If

necessary, the user should consult the dealer

or

an

experienced radio/televisiontechni-

cian for additional suggestions.

The

user may find the following booklet prepared by

the Federal Communications Commission helpful:

"Howto Identify and Resolve Radio-TV Interference Problems". This booklet is available

from the US Government Printing Office, Washington, D.C., 20402, Stock No.

004-000-00345-4~'

Note:

In

order to comply with the limits for a Class B computing device pursuant to Subpart

J

of

Part

15

of

FCC

Rules, please use the Shield cable for interfacing with

the

host com-

puter. (US. VERSION ONLY)

This equipment is manufactured

to

comply with VDE-871/875. However there is no

guarantee that the fault

wave

to other equipments will

not

occur in a paticular connection.

"All of the features and specifications are

subject to change without prior notice"

TABLE OF CONTENTS

Page

INTRODUCTION

................................................................

1

1.1

Features.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

I

1.2 Printer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4

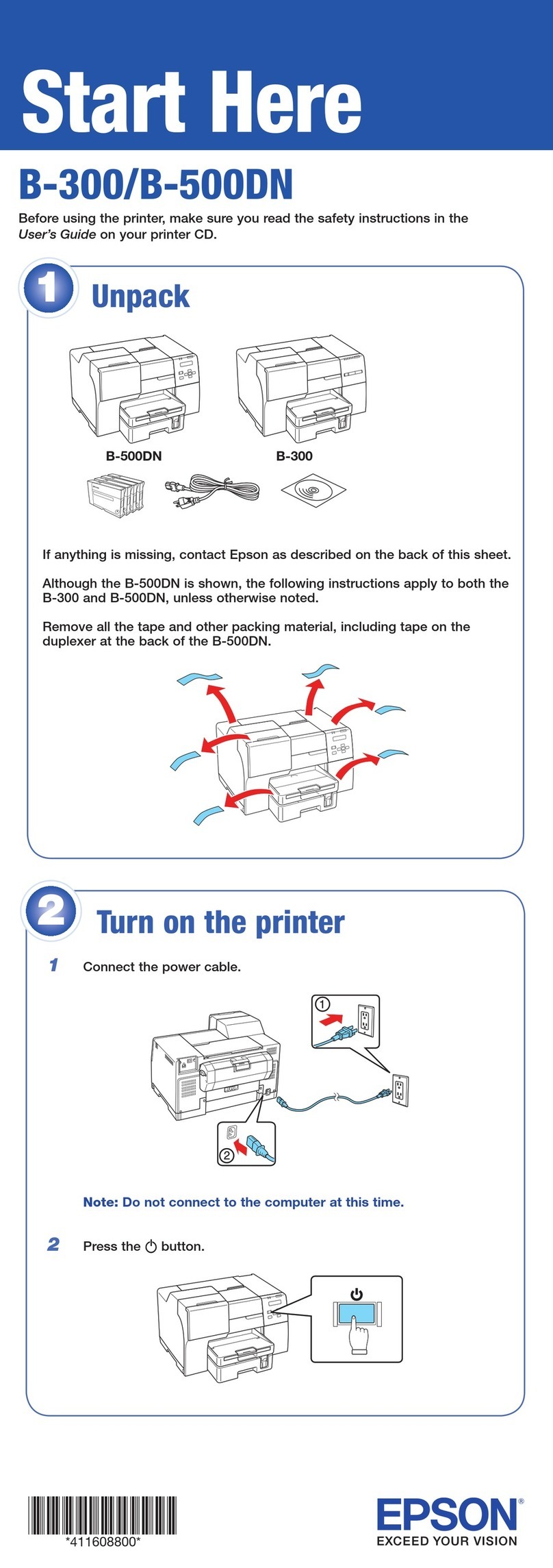

2.1

Unpacking Instmctions

...................................................

4

2.2 Ribbon Cassette Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

6

2.3 Paper Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7

2.3.1 Pin Feed (fan-folded paper)

.........................................

7

2.3.2 Friction Feed (roll paper and sheet paper)

..............................

10

2.4

Use

of

the Paper Guide Separator (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

11

2.5 Print Position Adjustment

.................................................

12

2.6 Adjustment

of

Gap between Dot Head and Platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

13

2.7 Power Cord Connection

...................................................

13

OPERATION

....................................................................

14

3.1 Appearance and Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

14

3.2 Power Switch and Control Panel

............................................

15

3.3 Operating Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

16

3.3.1 SEL (Select) Switch

...............................................

16

3.3.2 LF (Line Feed) Switch

.............................................

16

3.3.3 TOF (Top

of

Form) Switch

.........................................

16

3.4 Alert Switches

..........................................................

16

3.4.1

PE

(Paper Empty) Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

16

3.4.2 Cover Interlock Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

16

3.5 Indicator Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

17

3.5.1 SEL Lamp (Green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

17

3.5.2 PE Lamp (Red)

..................................................

17

3.5.3 Power on Lamp (Green)

............................................

17

3.6 Other Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

17

3.6.1 Self-Test Function

................................................

17

3.6.2 Print Start Conditions

.............................................

17

3.6.3 PE Over Ride Function

............................................

18

3.6.4 Print Stop Function in Case

of

Emergency

..............................

18

3.6.5 Received Data Hexadecimal Print

Out

Function

.........................

18

3.7 DIP Switches Setting

.........................................

,

...........

19

3.8 Connecting the Interface Cable

.............................................

21

3.9 Specification

of

Parallel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

23

3.10 Parallel Interface Timing Chart

..............................................

23

3.11 Connector Pin Assignment and Descriptions

....................................

24

3.12 Print Modes

.............................................................

27

3.13 Control Codes for Printing

....................................

,

.............

27

3.14 List

of

ESC Commands and Print Samples

......................................

31

3.15 General Operating Notes

...................................................

40

-3.16 Periodic Maintenance

......................................................

40

3.17 Print Paper Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

. .

..

43

3.17.1

FanfoldComputerForms

............................................

43

3.17.2 Single Sheet Paper

........................................

,

........

46

3.17.3 Roll Paper

.......................................................

47

APPENDIX

1 Specification

of

Color

Print

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

48

ii

INTRODUCTION

MODEL l550S/SC EP PRINTER

1.1

Features

The l550S/SC EP

is

a sophisticated compact dot matrix printer which can greatly enhance

the

printout

capability and control flexibility for your computer system.

It

is

designed for high compatibility, fast printing (180 characters per second).

A precision 9-wire print head will produce high resolution characters in a variety

of

printing modes: 132

characters per line in the standard mode, 218 characters per line in the compressed mode, 66

or

109 double-

width characters per line in

the

standard mode

or

compressed mode respectively.

Main

features

of

the printer also include:

* Full 96 ASCII characters with descenders.

* Extended character sets

of

international languages.

* Subscript, superscript, and underline.

* Programmable graphics.

* Double-size characters.

* Double-strike (enhanced) printing.

* Extensive line feed control.

* Standard 2K buffer, optionally expandable.

* Hex Dump Function.

* SelfTest Function.

* Color print capability (M-1550SC EP only)

In the case

of

an

IBM

PC

(XT),

or

its equivalent, the printer

is

to be connected to the computer through

a printer adapter card

or

through another adapter card which

is

good for connecting the printer and a

monochrome display

as

well. The interface cable, in that case, should have a 25-pin D-shell connector on

its end toward

the

computer and a 36-pin connector on its end toward the printer.

IBM

is

a trademark

of

International Business Machines Corp.

-1-

1.2 Printer Specifications

(1)

Type

(2) PrintSpeed

(3) Print Direction

(4) Pin Number in Print Head

(5) Line Space

(6) Character Format

Dot Matrix

Double-size characters

Other characters

(ASCII, European, etc.)

Character Set

Print Characteristics

Extra Character Set

Graphics

(7)

Character Pitch

Normal

Double Width

Compressed

Double Width-Compressed

Subscript

Superscript

Serial Impact Dot Matrix

180

CPS

(Draft)

120 CPS (Normal)

Bidirectional with Logic Seek

9

1/6"

(4.23mm)

or

programmable

(H

xW)

2 types

Draft

12Xl2

9X12

Refer

to

Figure 21, 22

Double-size characters

176-223, 244 and 245

No.1

Normal

12X8

9X8

Type

1:

Draft

Type

2:

Normal

Additional ASCII numbers from 160

to

175 for European

chars.; numbers from 176 to 223 for Graphic chars.; numbers

from 224

to

239 for selected Greek chars.; number from

240

to

255 for math. and extra symbols.

No.2

The differences between

No.1

and

No.2

are ASCII numbers 3,

4, 5, 6 and 21; ASCII numbers from 128 to 159 for European

chars

..

Including 50 block chars. and Programmable Graphics.

Characters Maximum number

per inch

of

characters/line

10 132

5 66

16.5 218

8.25 109

10 132

10 132

-2-

(8) Media Handling

Paper Feed

(9)

(10)

(11)

(12)

Paper Width

Number

of

Copies

Paper Loading

Interface

Inked Ribbon

Color

Type

Life Expectancy

Environmental Conditions

Operating Temperature

Operating Humidity

Power Requirement

Voltage

Power Consumption

(13) Dimensions and Weight

Height

Width

Depth

Weight

Sprocket pin feed and friction feed (Selectable)

4.25"

(l08mm)

to

15"

(38lmm)

Original plus two carbon copies (Total thickness must not

exceed 0.011" (0.28mm); Minimum paper thickness is 0.002"

(0.05mm)

From Rear-Top

8-bit Parallel

Black .

Cartridge

2 million characters

41

to

104°F

(5

to 40°C)

10

to

85%

RH

non-condensing

115 VAC, 60Hz

220 V

AC,

50Hz

240 VAC, 50Hz

180 Wmax

5.7" (144.Smm)

21.7" (SSOmm)

12.4"

(3l4mm)

25 Alb (11.5kg)

-3-

2.1

Unpacking Instructions

Paper Guide

Separator

(OPtion)

Aibbon Cassette

Side Pad

(L)

SECTION II

INSTALLATION

Paper

Stand

.dI"""---TopPad

Power Supply Cord

Printer

Side Pad (A)

Outer Carton

Fig. 1 Unpacking (1)

-'-4-

1.

After opening the outer carton,

take

out

the top pad in which

the ribbon cassette, the power

supply cord and the paper stand

are packed. (The paper guide

separator is optional.)

2.

Hold the left and right pads with

both hands and carefully draw

out

the printer from the outer carton.

3. Remove the left and right side pads

from the printer.

Packing

Bag

Fig.2

Unpacking (2)

Filament Tapes

5. Carefully remove clear plastic pack-

ing bag from printer. (See Fig. 2.)

6. Remove the filament tapes.

7.

Open the carrier cover.

Then remove the corrugated tube

that

is provided

to

retain the head.

(See Fig. 3.)

Top

Cover

Fig.3

Unpacking (3)

-5-

2.2 Ribbon Cassette Installation

To install the ribbon cassette

onthe

printer, proceed

as

follows:

(1)

. Open the carrier cover.

(2) Gently move the printer head carrier assembly to a position where no roller

is

fitted on

the

roller

shaft.

(3) To install the ribbon cassette, turn the Cassette Drive Knob in the direction

of

the arrow (clockwise)

to

tension the ribbon. (See Fig. 4.) Holding the cassette, carefully insert the ribbon end between

the ribbon guide plate and ribbon guide, and push the

casset~e

down on the ribbon deck. At this

time, align the two guide projections at the cassette bottom with the cassette guide

~oles.

Make

sure that

th~

notches on both sides

of

the cassette are supported completely by the two cassette

supporters.

If

not supported by the cassette supporters (the cassette

is

raised), push down on the

cassette while turning the ribbon drive gear clockwise. (See Fig. 5.)

After the Ribbon Cassette

is

firmly

in

place, turn the Cassette Drive Knob in a clockwise direction

to make sure the Cassette Drive Gear and the Unit Ribbon Drive Gearare locked together properly.

Note: To ease the ribbon cassette installation, set the Gap Adjusting Lever

to

the Gap 4 position.

(Refer

to

section 2.6)

Notch

Print Head

Cassette Supporter

Cassette Guide Holes

Cassette Drive Knob

Fig.4

Ribbon Cassette

Ribbon Drive Gear

Ribbon Deck

Fig. 5 Ribbon Deck

without

Ribbon Cassette

-6-

2.3 Paper Insertion

2.3.1 Pin Feed (fan-folded paper)

(l)

Open the paper cover.

(2) Open the paper cutter, and pull the roller shaft toward the front

of

the printer.

(3) Pull the release lever toward the front. (See Fig. 6.)

Paper Cutter

Fig. 6 Paper Insertion (1)

(4) Lift the paper retainers on the left and right sprocket tractors.

Paper Retainer

Platen

Paper Cover

Sprocket Tractor

Fig. 7 Paper Insertion (2)

-7-

Paper

Paper Cover

Paper Retainer

(5) Fit the paper sprocket holes onto the right and left sprocket tractor pins.

If

the paper width

ne-

cessitates adjusting the distance between the sprocket tractors, push back therightorleftsprocket

lever (allowing the sprocket tractor(s)

to

move freely) and move the sprocket tractor(s) right or

left

~

needed

to

match paper width. Then pull the sprocket lever(s) forward

to

lock the position

of

the sprocket tractor(s). (Refer

to

Fig. 8.)

Sprocket Lever

Paper Retainer

Fig.8

Paper Insertion (3)

(6) Now push down the paper retainer

of

the sprocket tractors. Turn the platen knob clockwise,

bringing the paper

to

the front side

of

the platen. Return the roller shaft

to

hold the paperagainst

the platen and the Release lever

to

the rear for pin feed operation.

(See

Fig. 9.)

Platen Knob

Fig. 9 Paper Insertion (4)

-8-

(7)

How

to

install paper stand.

Install the paper stand

as

shown below.

•

t

Fig. 10

Paper

Insertion (5)

(8) Positions

of

Bail Rollers.

When inserting paper, set

the

bail rollers

as

shown below.

~

-----

0 0

0 0

0 0

~

E!!'!!!!

-'"

0

~

~

--

0

0 0

0 0

~

-

--

0..-

A A

2XA

A A

L

Fig.

11

Positions

of

Bail

Rollers

L =Paper width

Example: L IS

In

case

of

IS-inch paper: A =6=

(5

=2.5 inches (63.5 mm)

-9-

2.3.2 Friction Feed (ron paperand sheet paper)

(1)

Open

the

print cover, and pull the roller shaft toward

the

front

of

the

printer.

(2) Move the print head carrier assembly

to

the left side

of

the printer.

(3) Push the release lever

to

the rear

of

the printer.

(4) Insert the paper

into

the paper inlet on the paper cover (behind the

pal;>er

cover for roll paper).

When the paper end appears on the platen, set the paper properly, pull the release lever toward

the front

(to

the "friction feed" position), and reposition the roller shaft and print cover. (See

Fig. 12.)

Paper End

Paper

Roll

Paper Inlet

"7""-+-_

Paper Cutter

Release Lever

·+------""~rv/

Fig.

12 Friction Feed Set-up

-10-

2.4

Use

of

the Paper Guide Separator (option)

Install the optional paper guide separator on the printer

as

follows:

(I)

Insert the

legs

of

the paper guide separator into the square

hol~s

on

the rear

of

the printer

top

cover.

'idJ._--

Paper Guide Separator (Option)

~Topcover

Notes:

• Connect the ground wire from the paper guide separator

as

follows:

Remove the screw at top left

of

the power supply unit plate, pass the screw through the hole at

the end

of

the ground wire, and reposition and tighten the screw together with the ground wire.

Do

not

remove these

two

screws.

• To remove the paper guide separator from the printer, pull the ground wire on its paper guide

separator side.

Fig. 13 Mounting the Paper Guide Separator

-11-

(2)

Pass

thepaperthrough thepaper guide separator, andinto the printer. (See 2.3 "Paper Insertion".)

When

the paper end comes

on

the platen, draw

it

over the top

of

the paper guide separator, and

drop it

from

the rear. (See Fig. 14.)

Paper Guide Separator

Platen Knob

Fig. 14 Example

of

Paper Guide Separator Application

2.S

Print

Position

Adjustment

After the paper

is

properly installed,

tum

the platen knob clockwise

to

adjust the print position.

-12-

2.6 Adjustment

of

Gap between Dot Head and Platen

The gap between the Print head and the platen

is

adjustable in 4 steps.

(a) When

the

gap adjusting lever

is

moved fully counterclockwise, the gap between the Print head

and the platen will be narrowed to the limit. The lever

is

usually set at this position when a

single sheet paper

is

used.

(b) To obtain high printing quality, move the gap adjusting lever to adjust the gap.

Platen

Print Head

Platen-to-head gap with gap

adjusting lever pushed fully

to

rear.

'-----Gap

1

(Single paper)

Fig. 15 Gap Adjustment between

Dot

Head and Platen

2.7 Power Cord Connection

Connect the attached power cord to the printer, and insert the plug into the

AC

outlet.

-13-

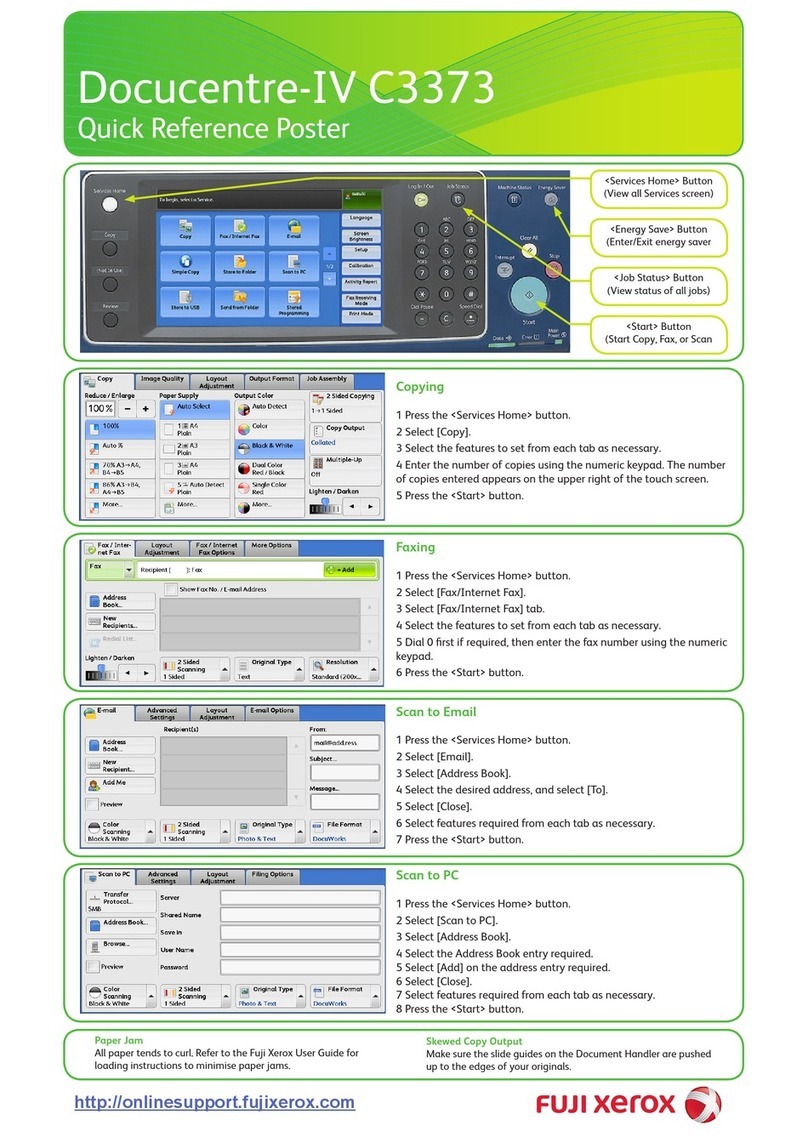

3.1 Appearance

and

Nomenclature

Paper

Cutter

Top

Cover.

Release Lever

-I---~-i."

Power Switch

Carrier Cover

(B)

SECTION III

OPERATION

Fig.

16 Front Exterior View

Platen Knob

/'o.---Carrier

Cover

(B)

~~~"'--_

Front

Control Panel

Bottom

enclosure

Paper Cover

Paper Inlet

Fuse

Interface Connector

Fig.

17

Rear

Exterior View

-14-

3.2

Power

Switch

and

Control

Panel

(1

) Power Switch

The power ON-OFF switch

is

located on the

left side

of

the printer.

Its • mark side should be pushed to turn it

ON.

(2) Control Panel

Power Switch

(ON)

Fig. 18 Power Switch

The control panel

is

located at the right front

of

the printer.

As

shown in Fig. 19, the panel has 3

push switches, 2 green LEDs, and one red LED.

POWeR P.E SEL

L.F

TOF

LED

(green) Push Switches

LED

(red)

Fig.

19

Control Panel

-15-

3.3 Operating Switches

The 3 operating switches are

of

the push type and are located

in

the right hand section

of

the control

panel.

3.3.1 SEL (Select) Switch

(a) SELECT and DESELECI' states alternate with every push.

(b) When power

is

applied, the printer will become SELECT.

Data transmission and printing

of

data in the DATA BUFFER can be stopped temporarily. To

perfonn this operation, press the SEL switch with the LF switch already depressed. To resume

printing and data transmission, press the SEL switch.

3.3.2 LF (Line Feed) Switch

(a) One line feed occurs with every push.

(b)

When

the switch

is

kept depressed, paper

is

fed

one line

as

far

as

4 lines. Thereafter, continuous

forward line feed takes place until the switch

is

turned off.

(c) Line feed can be performed only when the printer

is

in a DESELECT state.

3.3.3 TOF (Top

of

Form) Switch

(a) When this switch

is

pressed, the paper feeds to the next TOF position.

(b) TOF can be performed only when the printer

is

in a DESELECT state.

(c) Paper advance

is

done only once even

if

this switch

is

kept depressed.

3.4 Alert Switches

3.4.1 PE (Paper Empty) Switch

(a) This

is

a microswitch located near the bottom

of

paper feed platen which detects the end

of

paper or absence

of

paper.

(b) When the

end

of

paper

is

detected, printing

is

stopped. When the SEL switch

is

pressed

to

con-

tinue printing, the printer prits one line and then stops.

Upon detection

of

paper empty

by

this switch, the

PE

lamp lights, and the printer

is

deselected.

The printer

is

deselected immediately when the printer power

is

turned on or if

PE

status has

been detected when an INPUT PRIME

is

entered.

3.4~2

Cover Interlock Switch

(a) This

is

an

interlock switch which detects that the top cover

is

opened.

(b) Upon detection

of

cover opening during printing, the printer automatically stops and

is

deselect-

ed

·after printing one line.

If

not during printing, the printer

is

immediately deselected.

(c) To select the printer again, it

is

necessary that the SEL switch

is

depressed after closing the top

cover.

-16-

This manual suits for next models

1

Table of contents

Other C.ITOH Printer manuals