3

Safety Instructions

Electrical safety

• Use only grounded outlet or GFCI outlet.

All electrical cords must either be securely

grounded, connected to a surge protected

outlet, or preferably, connected to a GFCI

(Ground Fault Circuit Interrupter) outlet.

A GFCI is highly recommended to prevent

electric shock. Do NOT use an extension cord.

• Don’t abuse the cord. Never carry the

machine by the cord or yank it to disconnect

from receptacle. Keep cord away from heat,

oil and sharp edges.

Usage safety

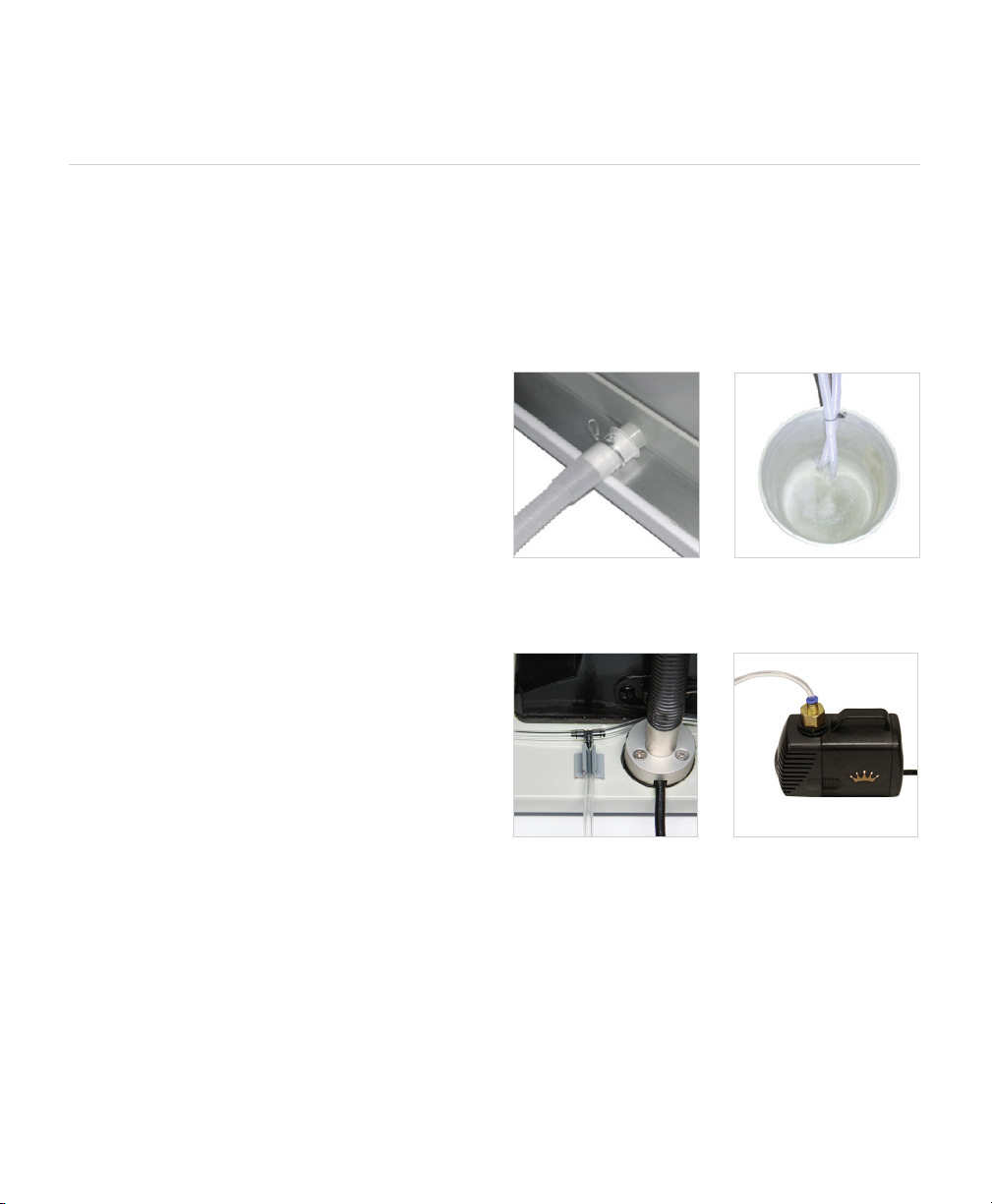

• Never disconnect motor, lamp or pump

with wet hands. Though the motor is sealed,

you must make sure to keep all electrical

connections dry. Avoid touching the pump

when connected to the power.

• Always wear proper eye protection. Enclosed

are safety goggles to protect you from any

debris that may y out while grinding. We

recommend wearing the enclosed goggles

or safety glasses with side shields. Everyday

eyeglasses are NOT safety glasses. If anyone

is around the machine while it is in use, they

must wear safety glasses.

• Wear proper apparel. Do not wear any loose

clothing, gloves, neckties or jewelry that can

get caught in the machine’s moving parts.

Long hair must be secured with a rubber band

or hair tie.

• Keep work area well lit, clean, and

uncluttered.

• Adult supervision is required at all times.

Never leave the machine running unattended.

•Do not touch motor housing. Avoid contact

with the motor housing when in use. The

motor is totally enclosed and non-ventilated

so it produces high temperatures. The

running temperature can reach around 220°F.

• Do not operate this machine while under the

inuence of drugs, alcohol or any medication.

• Never run wheels dry. Make sure there

is adequate water used while grinding so

that rock dust is not formed. This dust may

contain chemicals that can be hazardous to

your lungs if inhaled and is known to cause

cancer, birth defects or other reproductive

harm. To reduce your exposure to these

chemicals, work in a well ventilated area and

wear a dust mask if the grinding operation is

dusty.

• Use only water as coolant.

• Some rocks contain poisonous elements.

Avoid grinding rocks that contain uranium,

mercury, lead, arsenic, etc. Know the material

you are grinding.

• Do not force the tool or attachment to do a

job it is not designed to do.

• Direction of feed. Be aware of the wheel

rotation direction before use.