5

Suggestions for Headend Racking and Maintenance

For prolonged equipment life and operating stability,

CADCO

makes the following

recommendations:

All headends should be installed in an environmentally controlled dust-free room

having a nominal temperature of 80 F (26 C) and 60% humidity. The room

should be protected from rodents and insect pests.

All equipment should be mounted in standard equipment racks or cabinets

All equipment should be rack spaced at one panel height, 1.75 inches (4.44cm).

There should be nothing between the equipment preventing air circulation.

Please make certain headend wiring and current capacity has adequate safety

margins. Never cascade AC powering strips. Use separate outlets. If AC power

is subject to fluctuation we recommend a constant voltage transformer be used.

Beware of ground loops and be certain all wiring is bonded and properly

grounded. Consult a codebook as needed.

All equipment racks should be electrically bonded together and earth grounded

All equipment interconnecting RF cables should be a minimum of double

shielded and quad shielded is recommended. Poorly shielded cable causes cross-

modulation picture degradation between equipment.

Always use the coax connector intended for the coaxial cable used. Be certain it

is installed as recommended by the manufacturer. Connectors should be RFI

shielded.

RF Input and RF Output cables should be on opposite sides of the equipment

rack. Never bundle input and output RF cables together.

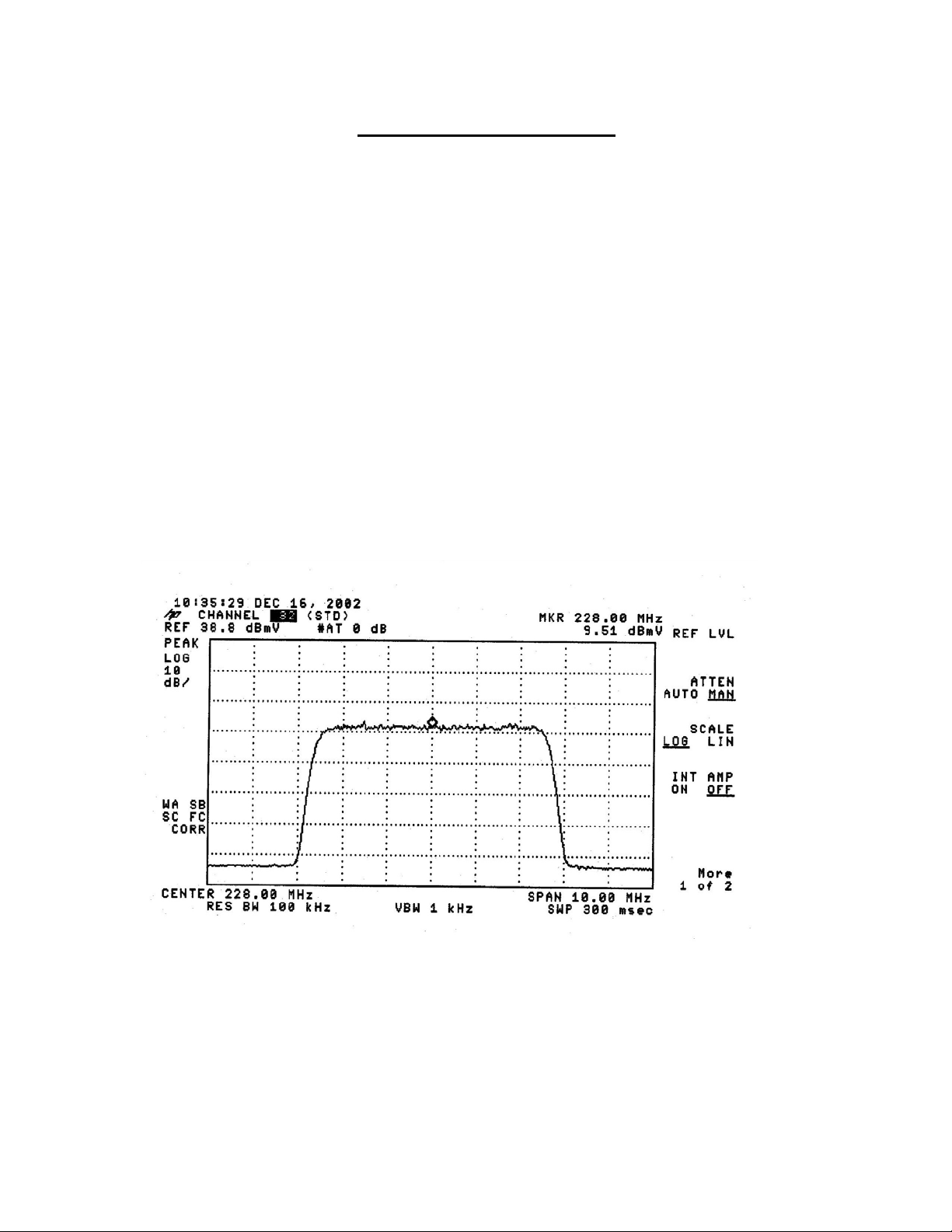

Operate each up-converter at the RF output level recommended. If it is

necessary to reduce the RF Output level, always operate the equipment as

recommended and reduce the RF

Equipment RF test points are only relative indicators of the actual RF output

level. All RF operating level measurements should be made at the RF Output of

each unit.

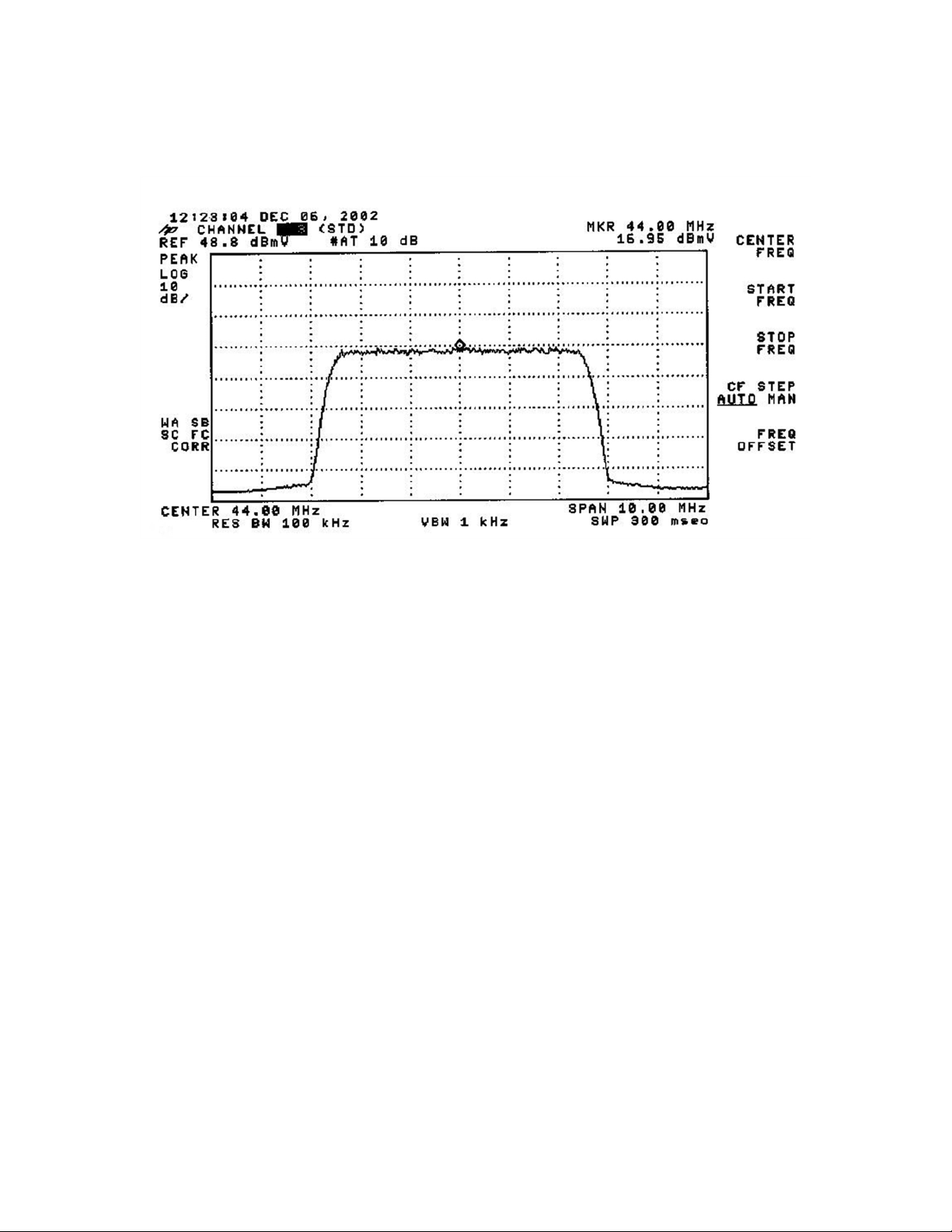

When the headend is initially placed in service, create a record of all operating

parameters for each channel’s equipment. Referring to these records during

routine maintenance provides a helpful record of operating changes.