Doc150313-01

Installation and maintenance manual

www.cadexair.com 9 1010, Boulevard Lionel Boulet

1-800-461-0668 Varennes, Québec, Canada J3X 1P7

To get rid of water stains, rinse with clear hot water.

You can also avoid water stains by wiping the surface

with a soft and dry cloth. A non-abrasive cream

product or a cleaning product can be used for light

superficial stains. Products specifically designed for

stainless steel cleaning and containing citric acid can

be used. Nylons scouring pads are recommended to

remove the majority of food premises. If a more severe

treatment is required to get rid of stripes and surface

scratches, it is recommended to use a very thin

abrasive to avoid damaging the surface. If stainless

steel has a direction or a special pattern, repairs must

be aligned with the direction of the original finish to

obtain a more esthetic result. If a metallic brush is

used, it should be made of stainless steel from the

same steel gauge then the exhaust hood material. It

is important to verify that the abrasive used are exempt

of all contamination like chloride and iron. If you need

to clean the surface with a chemical product or an

abrasive, we recommend making a test first on a non-

showing surface to verify the results.

If the above advice does not provide a satisfying result,

remember that stainless steel can be polished on site

by specialists, manually or mechanically. Stainless

steel is solid and not plated; therefore, it doesn’t lose

its corrosion resistance properties following a

polishing.

Daily maintenance

•Wipe the visible inner and outer parts of the

exhaust hood.

•Verify the control panel display to ensure good

functioning of the system.

•Wipe the visible parts of the Geo-Vary grease

extractor.

Weekly maintenance

•Remove baffle filters and clean or soak with a hot

water and degreaser solution.

•Empty all grease cups located under modular

extraction baffles.

Monthly maintenance

•Remove and clean all filters.

•Clean the grease gutter.

•Verify the exhaust fan motor belt.

•Verity the filters from you air supply system.

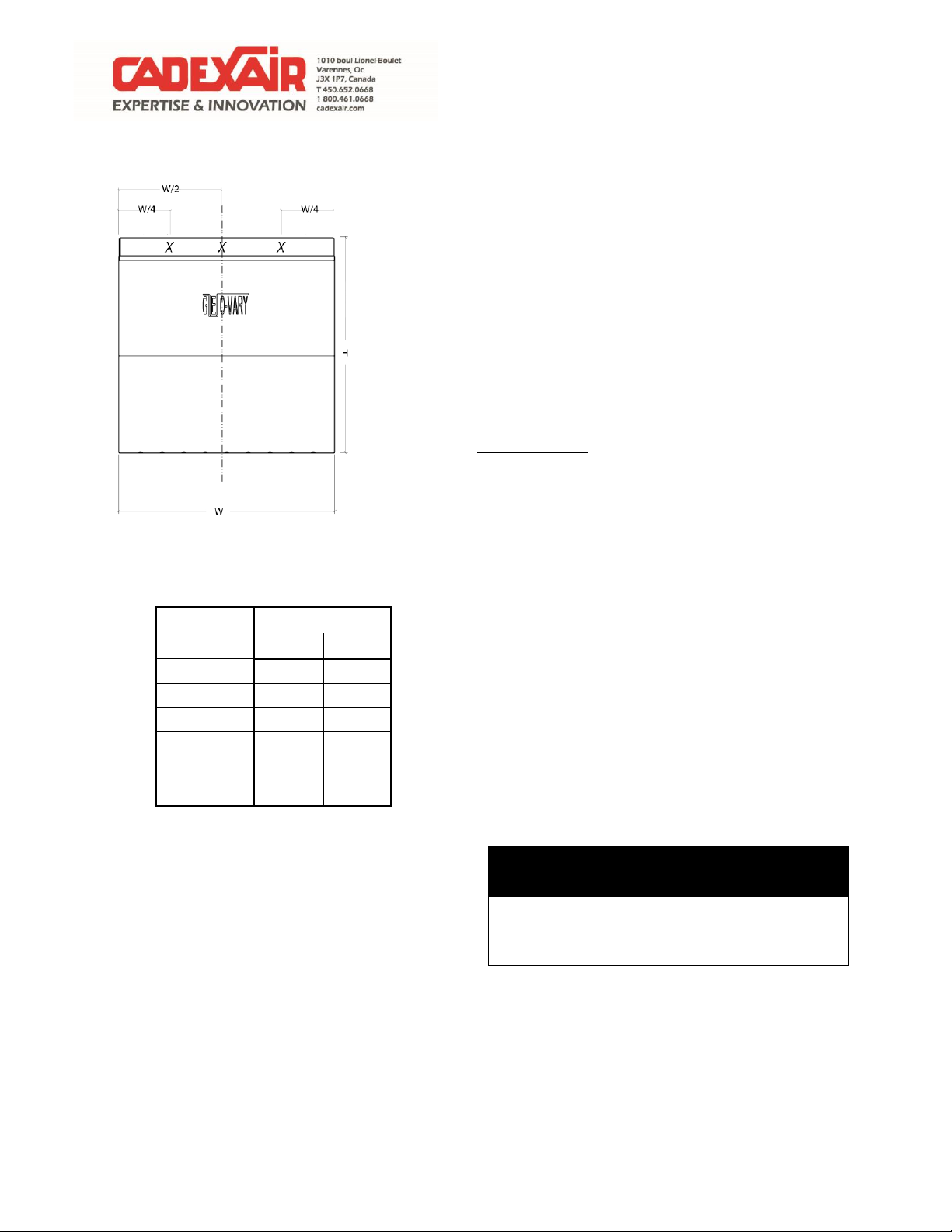

Geo-Vary grease extractor maintenance

When necessary:

•Remove the Geo-Vary grease extractor from the

exhaust hood filter cage. Remove the guillotine

from the extractor by removing the wing nut

located inside the extractor, in the back.

•Put the guillotine and extractor upside down in a

dishwasher or simply wipe the inside surfaces

with detergent and hot water.

•Put back the guillotine in the extractor according

to hit initial setting and screw back the wing nut.

•Install the Geo-Vary grease extractor according to

indications of Annex 3.

Inspection and cleaning of the commercial kitchen

exhaust system

Inspection of the commercial kitchen exhaust system

is mandatory.

Owner of commercial kitchen are obligated to regularly

have their exhaust system inspected in order to ensure

the security of their employees and the public in

general. The system includes: exhaust hoods,

filtration units, exhaust ducts and exhaust fans.

Make an inquiry to your insurance provider about the

required inspection by local standards for your type of

establishment. Refer to annex 4 for more information

about the required inspection schedule according to

the NPFA96 standards.