2

Precauciones en Español

PARA SU SEGURIDAD

Lea y cumpla con todas las ADVERTENCIAS y PRECAUCIONES que figuran

en estas instrucciones.

IMPORTANTE – Cumpla con todos los códigos y ordenanzas gubernamentales.

ŶNota para el Instalador – Asegúrese de entregar estas instrucciones al consumidor

y al inspector local.

ŶNota para el Consumidor – Guarde estas instrucciones con su Manual del

Propietario para referencia futura.

ŶNivel de habilidad – La instalación de este lavavajillas requiere un nivel básico

de habilidades mecánicas, eléctricas y de plomería. La correcta instalación

del producto es responsabilidad del instalador. Si se producen fallas en el

producto debido a una instalación inadecuada, la Garantía del Producto de

GE Appliances no cubrirá las mismas. Consulte la información de la Garantía.

ŶTiempo de instalación – 1 y 3 Horas. Las instalaciones nuevas requieren más

tiempo que las instalaciones de reemplazo.

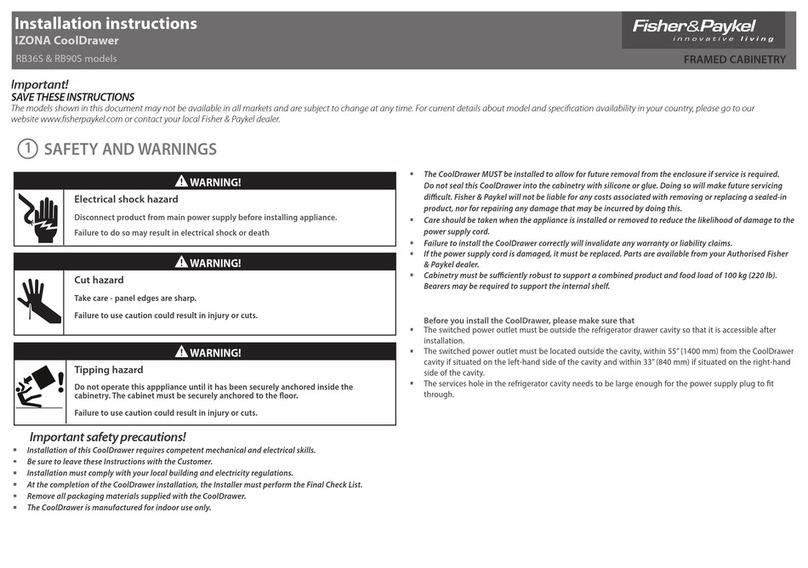

IMPORTANTE – El lavavajillas DEBE ser instalado para permitir el retiro futuro de

su ubicación, si se requiere realizar el servicio técnico.

Se deberá tener cuidado cuando el electrodoméstico sea instalado o retirado, a fin

de reducir la posibilidad de daños sobre el cable de suministro eléctrico.

Si el lavavajillas que recibió está dañado, se debería comunicar de inmediato con

su vendedor o fabricante.

Su lavavajillas es un electrodoméstico donde se calienta agua.

ANTES DE COMENZAR - Lea estas instrucciones en su totalidad y atentamente.

ŶPara reducir el riesgo de descarga eléctrica, incendio o lesiones a personas, el

instalador debe asegurarse de que el lavaplatos esté completamente cerrado en el

momento de la instalación.

ŶPARA SEGURIDAD PERSONAL: Quite el fusible o abra el interruptor de

circuitos antes de comenzar la instalación. No utilice un cable de extensión o un

enchufe adaptador con este artefacto.

ŶLa conexión inadecuada del conductor de conexión a tierra del equipamiento

puede provocar un riesgo de descarga eléctrica. Consulte a un electricista

FDOL¿FDGRRUHSUHVHQWDQWHGHVHUYLFLRWpFQLFRVLWLHQHGXGDVVREUHODFRUUHFWD

conexión a tierra del aparato.

Ŷ

Si el cableado doméstico no cuenta con un cable de 2 hilos con conexión a

tierra, un instalador debe realizar una conexión a tierra. Cuando el cableado

doméstico es de aluminio, asegúrese de usar un compuesto antioxidante y

conectores de aluminio a cobre aprobados por UL.

Ŷ

Para reducir el riesgo de descarga eléctrica, incendio o

lesiones a personas,

el instalador deberá realizar un

control para asegurar que los cables no estén

pellizcados

ni dañados, que el cableado del hogar esté conectado a la ficha de la caja

de empalmes a través de un amortiguador

de refuerzo, y que todas las conexiones

eléctricas

realizadas en el momento de la instalación (tuercas para

cables) estén

dentro de la tapa de la caja de empalmes.

While performing installations described in this booklet, gloves, safety glasses

or goggles should be worn.

ADVERTENCIA

PRECAUCIÓN

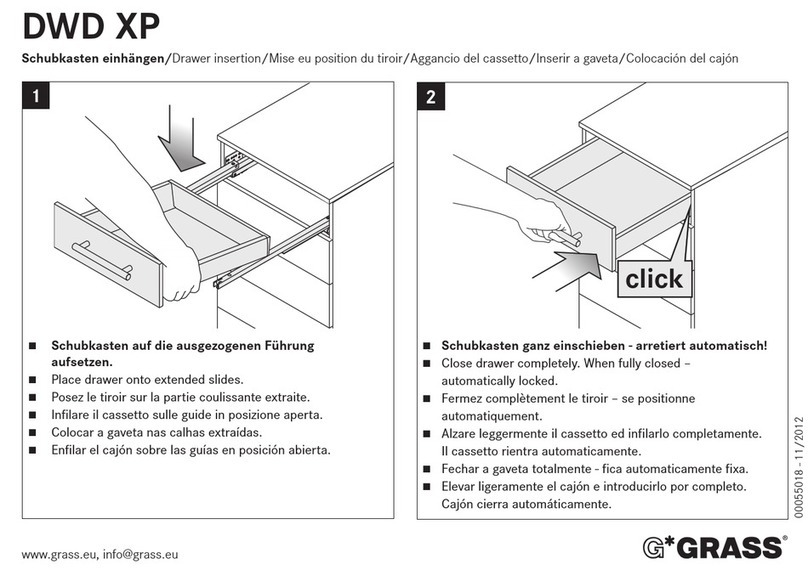

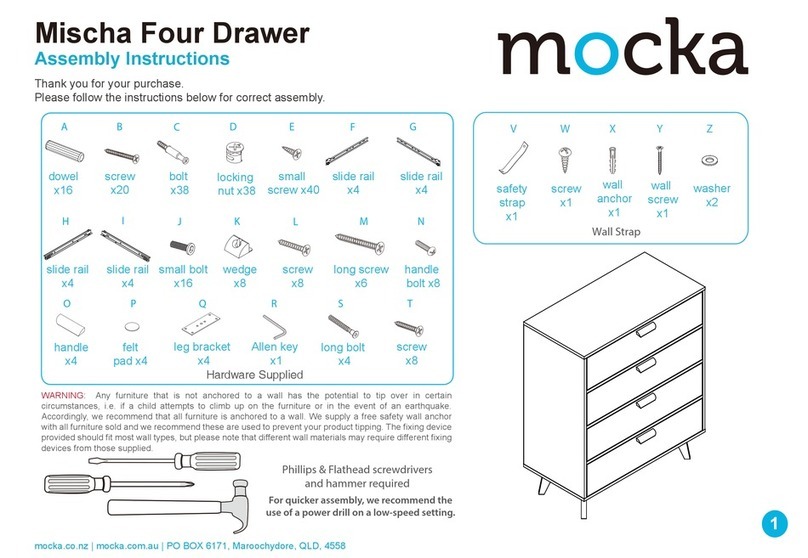

Abrir un cajón hará que el lavavajillas se incline hacia adelante

cuando no esté completamente instalado. Cuando abra un

cajón antes de que el lavavajillas esté completamente instalado,

sostenga la manija del cajón firmemente con una mano y la parte

superior del lavavajillas con la otra mano. Deben usarse guantes.

PRECAUCIÓN

LEA DETENIDAMENTE

CONSERVE ESTAS INSTRUCCIONES