Page 3

MD24 and MD30

MD24 and MD30

1-2 #824820 - Revision A - November, 2013

TABLE OF CONTENTS

Section 1 - General Information

Introduction ........................................................................1-1

Important Safety Information ............................................1-1

Technical Assistance ........................................................1-1

Table of Contents ..............................................................1-2

Warranty Information ........................................................1-3

Model Warranty Tag Information ......................................1-3

Model Warranty Tag Location ............................................1-3

Microwave Drawer Features ..............................................1-4

Microwave Drawer Layout..................................................1-4

Touch Control Panel Layout ..............................................1-4

Cookware Suggestions ......................................................1-5

Radio and TV Interference ................................................1-5

Care and Cleaning ............................................................1-5

Section 2 - Installation Information

Installation Information ......................................................2-2

Electrical Requirements ....................................................2-2

Installation Requirements ..................................................2-2

Clearances and Dimensions MD24....................................2-3

Clearances and Dimensions MD30....................................2-4

MD24 and MD30 Specifications ........................................2-4

Section 3 -Theory and Operation

Control Lock ......................................................................3-2

Open/Close ........................................................................3-2

Clock ................................................................................3-2

Timer ................................................................................3-2

Audible Signal ..................................................................3-2

Cook Time Completion Reminder ....................................3-2

Demonstration Mode ........................................................3-3

Power Level ......................................................................3-3

Multiple Sequence Cooking ..............................................3-3

Auto Start ..........................................................................3-4

Add Minute ........................................................................3-4

Keep Warm ........................................................................3-4

Popcorn ............................................................................3-4

Melt ................................................................................3-4

Soften ................................................................................3-4

Beverage ..........................................................................3-5

Wolf Gourmet ....................................................................3-5

Sensor Reheat ..................................................................3-5

Time Adjustment (sensor cooking) ....................................3-5

Auto Defrost ......................................................................3-5

Manual Defrost ..................................................................3-5

Off Condition ......................................................................3-6

Cooking Condition ............................................................3-6

Power Level ......................................................................3-6

Sensor Cooking Condition ................................................3-7

Section 4 - Component Access and Removal

Warnings and Cautions ....................................................4-2

Microwave Measurement Procedure ................................4-3

Before Operating Oven after Service ................................4-3

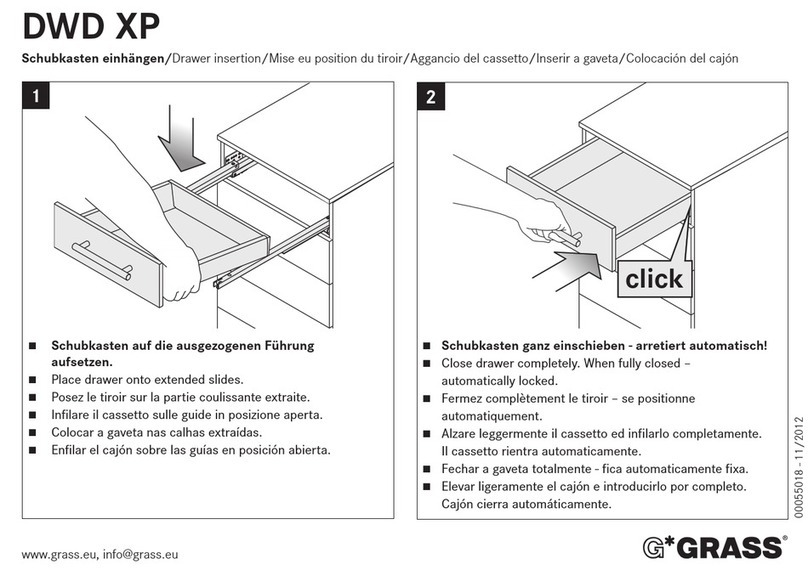

Emergency Opening of Drawer ........................................4-4

Un-installing the Microwave Drawer ..................................4-4

Removing Cord and Outer Case ......................................4-4

Accessing Rear Components ............................................4-4

Metal Key Unit Frame Assembly ........................................4-4

Noise Filter Board Replacement ......................................4-5

Latch Hook and Microswitch Removal ..............................4-5

Adjusting Monitor, Stop and Secondary Interlock ............4-5

After Adjusting Latch Hook ................................................4-6

Drawer Assembly and Choke Removal..............................4-6

Drawer Support Angle Removal ........................................4-6

Drawer Latch Removal ......................................................4-7

Auto Drawer Gear Removal ..............................................4-7

Auto Drawer Gear Installation ..........................................4-7

Rack Gear/Oil Damper Removal........................................4-8

After Reassembly ..............................................................4-8

Section 5 - Troubleshooting Guide

Warnings and Cautions ....................................................5-2

Troubleshooting Chart ......................................................5-3

Control Panel Assembly Test ............................................5-4

CPU-Drawer Board & Display Harness Test ....................5-4

PSU-Drawer Board and Relay Test ..................................5-5

Defrost Test ......................................................................5-6

PSU-Drawer Board Fuse is Open ....................................5-6

AH Sensor Test ................................................................5-8

Magnetron Assembly Test (includes Power Output) ......5-10

Thermal Cut-Out Test ....................................................5-11

Secondary Interlock Switch Test ......................................5-11

Stop Switch Test ..............................................................5-11

Monitor Switch Test ........................................................5-12

Blown Monitor Fuse Test ................................................5-12

MD Transformer Test ......................................................5-13

Noise Filter Test ..............................................................5-13

High Voltage Rectifier Test ..............................................5-14

Relay Diode Test ............................................................5-14

High Voltage Capacitor Test ............................................5-15

PSU-Drawer Board Picture ............................................5-15

CPU-Drawer Board Picture ............................................5-16

SW PSU-Drawer Board Picture ......................................5-16

Noise Filter Board Picture ..............................................5-16

Section 6 - Wiring Diagrams

MD Wiring Schematic (off condition) ................................6-2

MD Wiring Diagram ..........................................................6-3

Control Unit Circuit ............................................................6-4