CALIFORNIA ACCENT LIGHTING, INC.

2034 E. Lincoln Ave. #431, Anaheim, CA 92806

ph. 800.921.CALI (2254) or 714.535-7900 \ fx. 714.535.7902

© CALI. All rights reserved. CALI reserves the right to make changes or withdraw specications without prior notice.

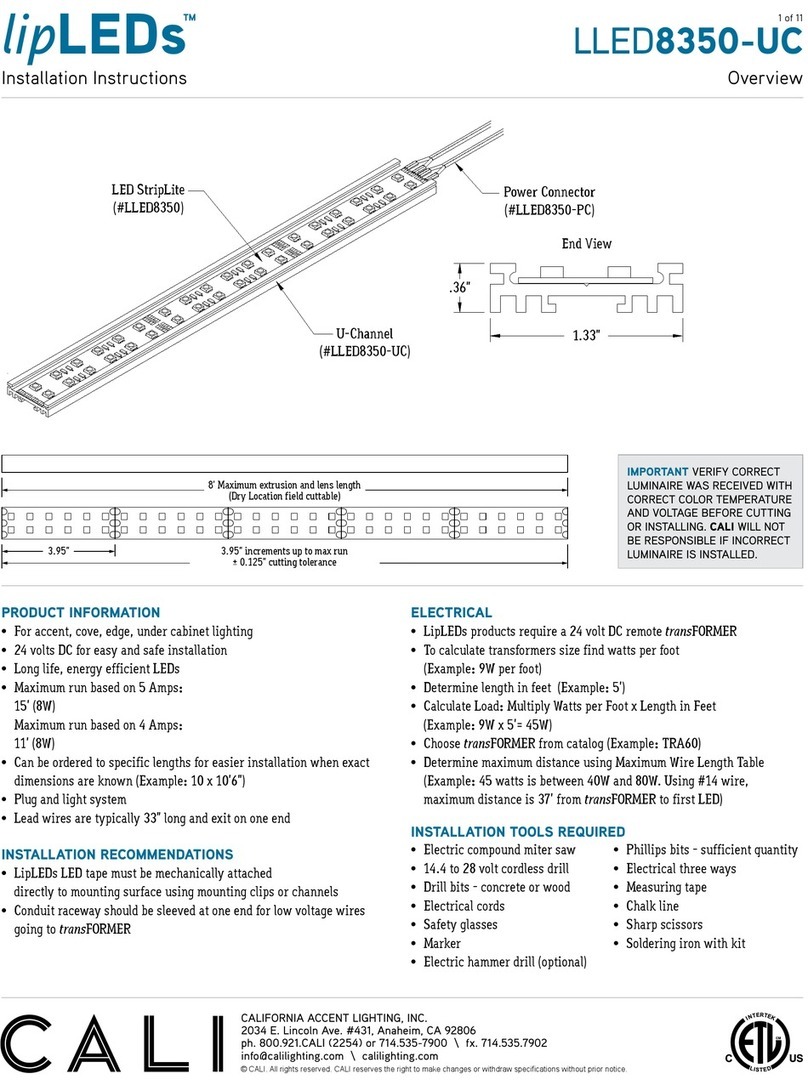

Installation Instructions Overview

lipLED™LLED8200-ST

2 of 11

Symmetric Forward Phase-Control

DIMMING PROTOCOL (Forward Phase Dimming)

Technical Requirements for Control Equipment (Forward Phase Dimming)

• Magnetic Low Voltage (MLV) - Magnetic (core and coil, toroidal)

transformer-supplied low voltage lighting.

• Electrical Characteristics - Inductive

• Special Requirements - Symmetric cycles

(VDC≤2), smooth turn off (positive and negative

periods are equal for safe MLV transformer operation)

• Order transformer with TRA prefix.

DIMMING PROTOCOL (0-10V)

LipLEDs are available in 120 or 277 volts with a dimmable remote driver.

The remote driver is available with 0-10V dimming capabilities.

The following applies to 0-10V dimming interfaces. A 0-10v fluorescent

dimmer will not dim the LEDs.

Technical Requirements for Control Equipment (0-10V Protocol)

• The output current level of the dimmable driver is controlled by DC

voltage (0-10V) applied to the control terminals (blue and white).

The light output of LEDs is controlled by the amount of output current

from the dimmable driver.

• The control device must be capable of sinking a DC current flow from

the driver. The maximum amount under any condition is 500

microamps (uA) per driver.

• The control terminals of the dimmable driver are isolated from the

power lines and are suitable for use as Class 2 wiring. Multiple drivers

are desired for use with same control device, the control terminals may

be connected in parallel in a bus configuration.

• Since the control bus is Class 2 wiring, all control devices that are

connected to the power line must have proper isolation between the

power line and the control terminals/bus.

• The control device, which intends to control more than one dimmable

driver, must be capable of sinking the total current supplied to control

bus by the drivers.

• If the control terminals/bus is shorted in any case, the current on the

control terminals/bus will be 500 microamps (uA) per driver maximum.

• If the control terminals are opened, the voltage on the control terminals

will then be 10V ± 0.5 volt. As a result, dimmable driver supplies

maximum output current to LEDs under this condition.

• The driver is intended for use with control voltages between 0 and 10VDC.

The control equipment must not impose a voltage greater than 11 V peak

maximum on the driver control terminals.

• Order transformer with TRA-E prefix.

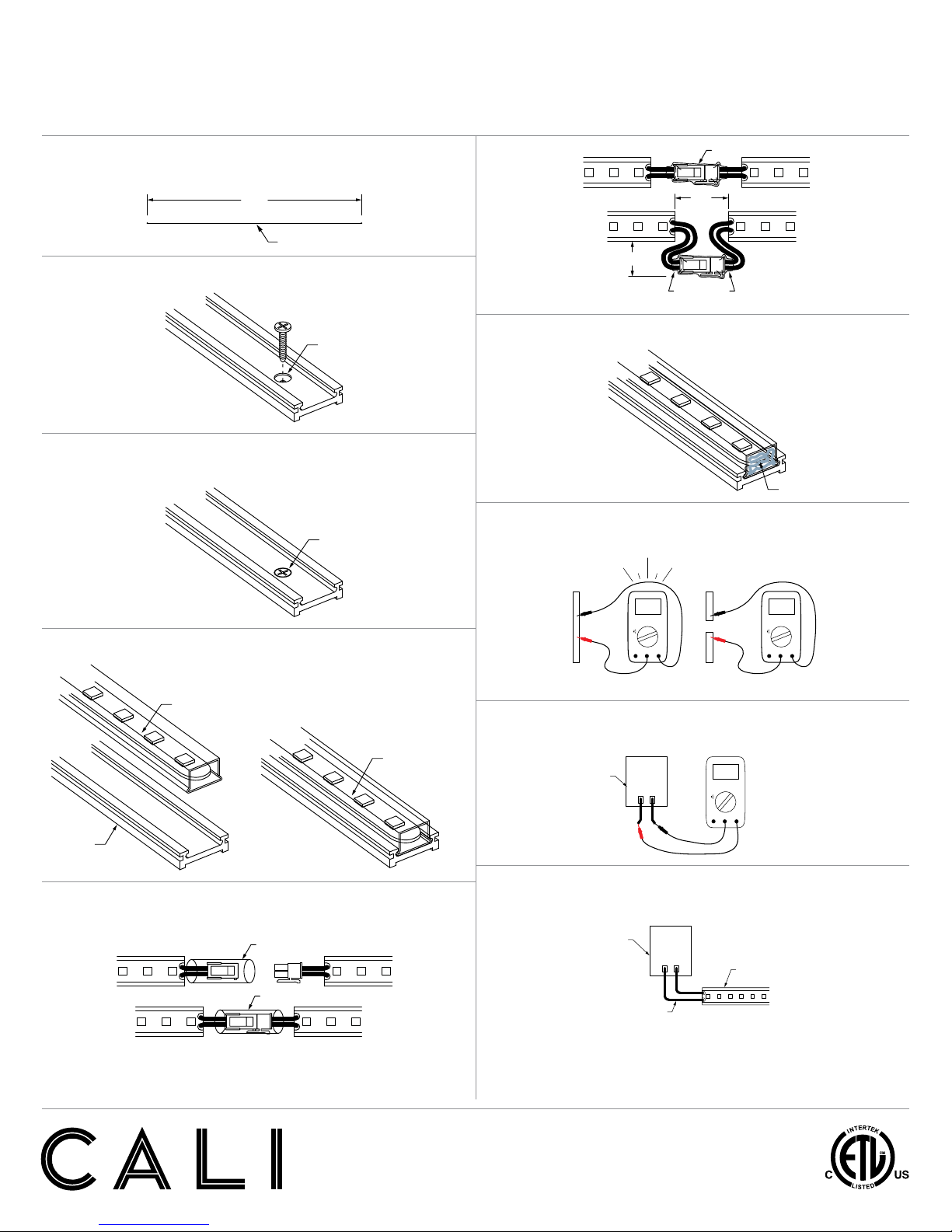

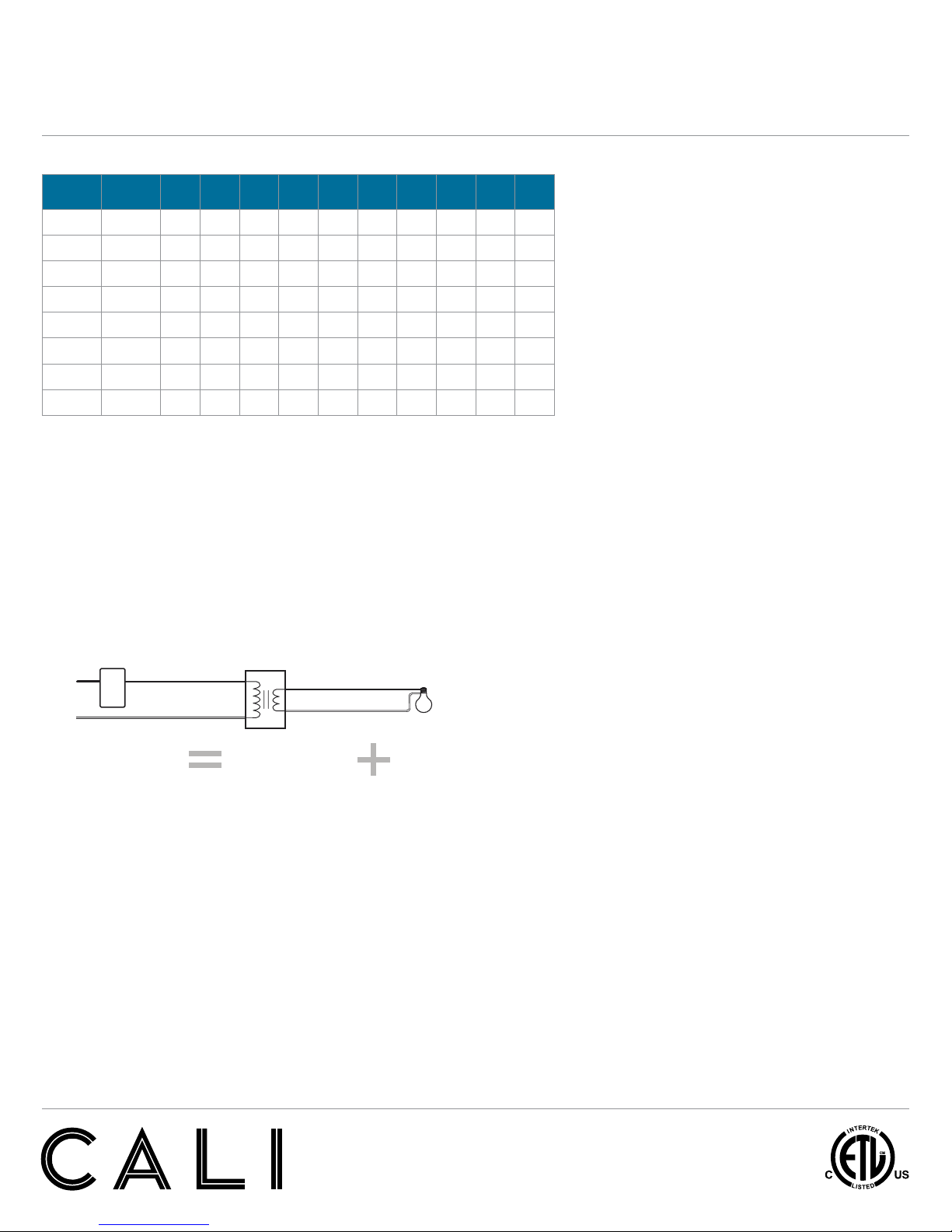

(TRA-E) 0-10V Dimming

(TRA) Forward Phase Dimming

*Maximum run is based on 5 Amps: 20’ (6W), 30’ (4W), 36’ (2W)

For class II applications: 14’ (6W), 24’ (4W), 36’ (2W)

FEATURES

APPLICATIONS Accent, Decorative Lighting

VOLTAGE 24VDC

LAMP TYPE Modular LEDs

DIMMING Forward Phase (TRA)

0-10V (TRA-E)

Hi-Lume 1% A Series (2 Wire)

Hi-Lume 1% (3 Wire)

LENGTH Built to Order

CONSTRUCTION LED Modules

(Field Cuttable - Dry Location Only)

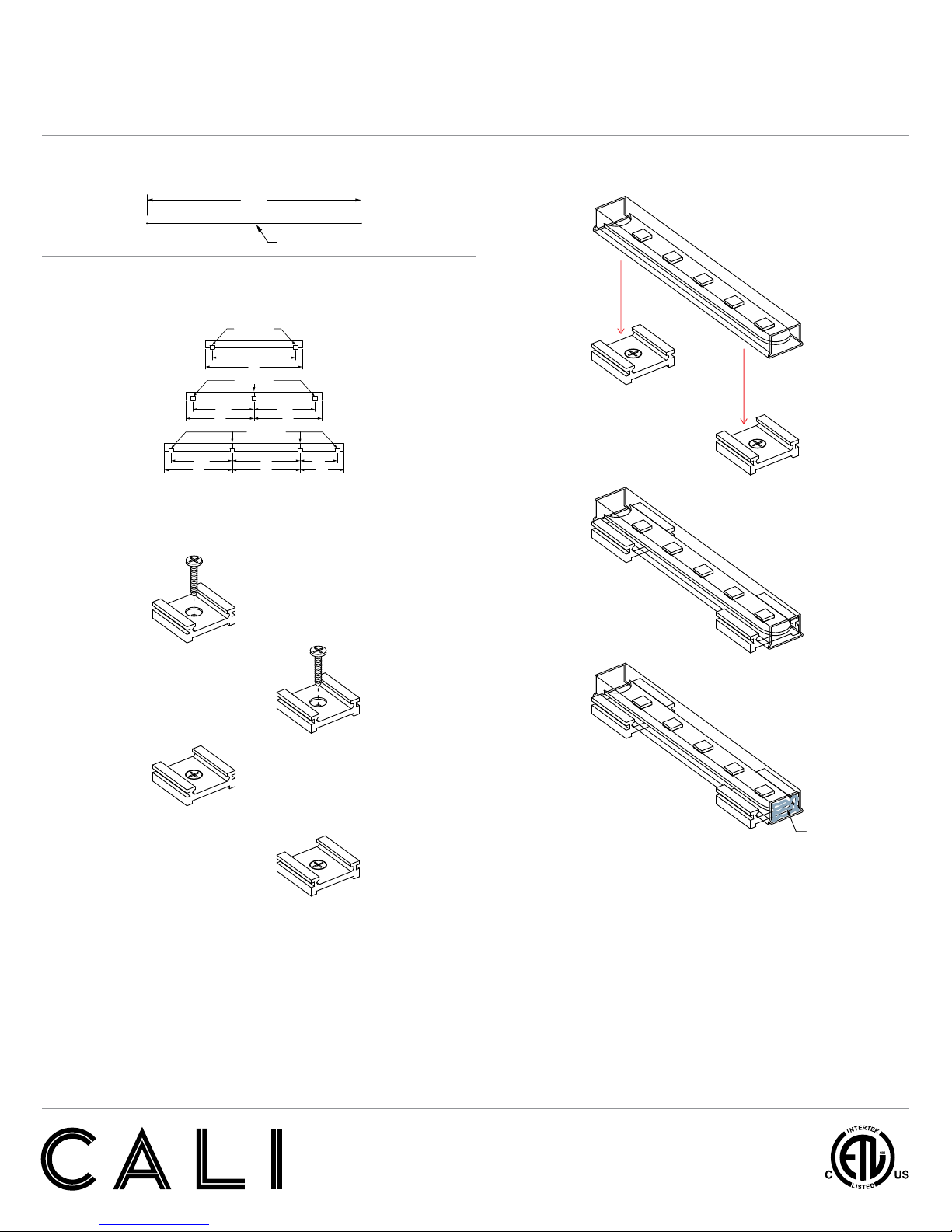

MOUNTING Mounting Clips or Mounting Channel

CRI >90

EFFICACY 108 Lumens per Watt

VIEWING ANGLE 120 Degrees

L70 LED LIFE 60,000 hrs.

MAXIMUM RUN* 20’ (6W), 30’ (4W), 36’ (2W)

LISTING Dry or Wet (IP65 or IP67) Location

UL2108, CSA C22.2#9

UL8750, CSA250

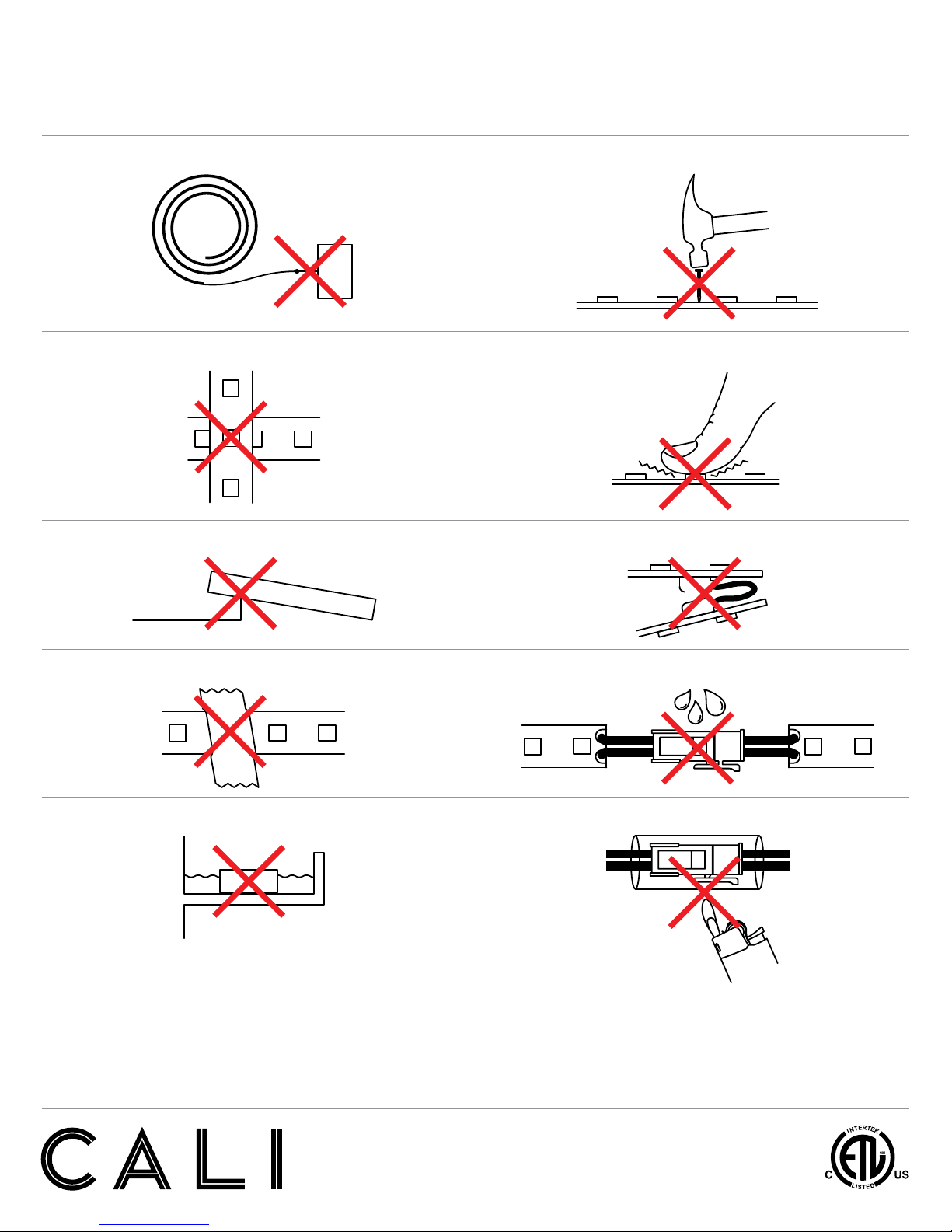

WARNING

When using lipLEDs for any application, basic safety precautions

should always be followed to reduce the risk of fire, electric shock,

and personal injury. lipLEDs must be installed in accordance with

the NEC or CEC as applicable. CALI will not be responsible for any

damage or malfunction caused by the following:

• Do not exceed maximum length per circuit. Each maximum run requires

additional power feed from the transformer

• Do not cover lipLEDs as the covering may cause it to overheat, melt, or ignite.

• Do not install lipLEDs in hazardous locations or closer than 6 inches

from any curtain or similar combustible material.

• Do not use lipLEDs if damaged, such as broken outer jacket, loose

connections, or frayed wire insulation. Inspect periodically.

• Do not submerge lipLEDs in liquid.

• Do not mount lipLEDs with staples, nails, or like means that might

damage the insulation. Mount with double-sided tape and mounting clips.

• Do not install lipLEDs in places where it is subject to continuous flexing.

• Do not mount lipLEDs inside tanks or enclosures of any kind without

sufficient ventilation.

• Ground Fault Circuit Interrupter (GFCI) protections are required

on circuits or outlets.

• Surge protector must be set up for electrical power system to avoid

damaging lipLEDs lighting system.

• Do not install in an environment where excessive heat may exist.

Ambient temperature -40°F - 122°F (-20°C - 50°C).

• Only wet location models are intended for outdoors. See package label

for environmental details.

• Do not install wet location model in areas where water will collect.

• Do not modify wet location extrusion, end caps, or power connectors.