correct steam generator model and size are as critical as design of the steam room itself. The power

supply and circuit protector should be carefully checked to match the parameters of the generator.

Please referring to the table below and select the suitable model for your specification.

Table 3

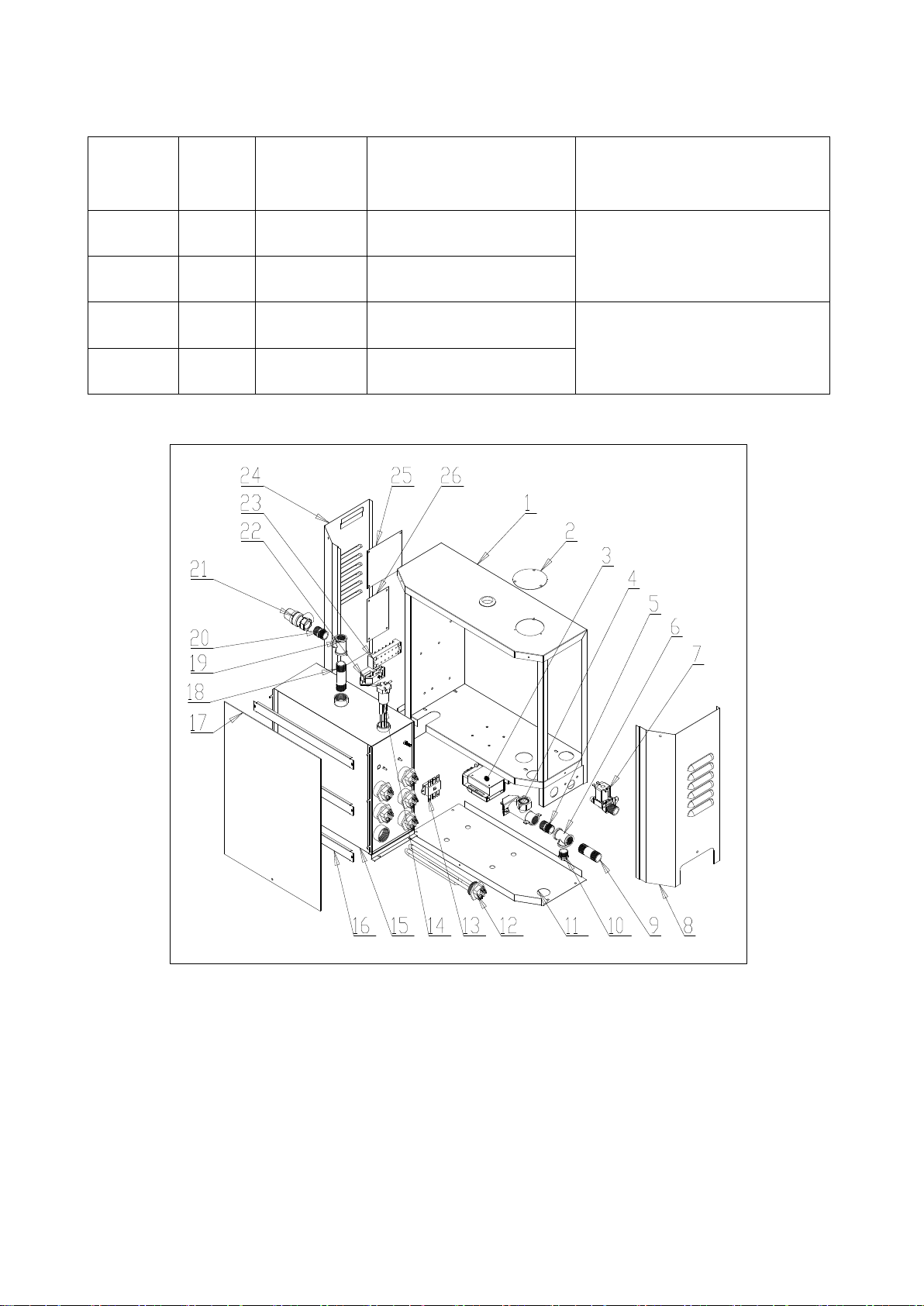

2. Installation of steam generator

Switch off all power supply before installation, and check whether you have the correct model

for your steam room according to table 3.

Do not install the generator outdoors, in wet/moist place, freezing, or corrosive place. Do not

install the generator near to inflammables such oil paint, diluents and fuel. Be alert to the steam

pipeline and safety valve since the high temperature of steam is dangerous to customers.

Generator must be level installed.

The generator should be installed in a dry and well-ventilated place. It can be installed either on

the wall or on the ground, but must be well-fixed. Install the generator as close to steam room as

possible, such as in the closet, under the washing basin or in the basement. (Refer to figure 4).

i. Install the generator on the wall: drill two small holes on the wall, insert the expansion

screws and then hang the generator on those screws.

ii. Install the generator on the ground or deck: Install the frame on the site and then screw the

generator into the frame.

iii. For better service and maintenance, please install the generator with the nameplate face to

front and leave more than 10"space around the generator.

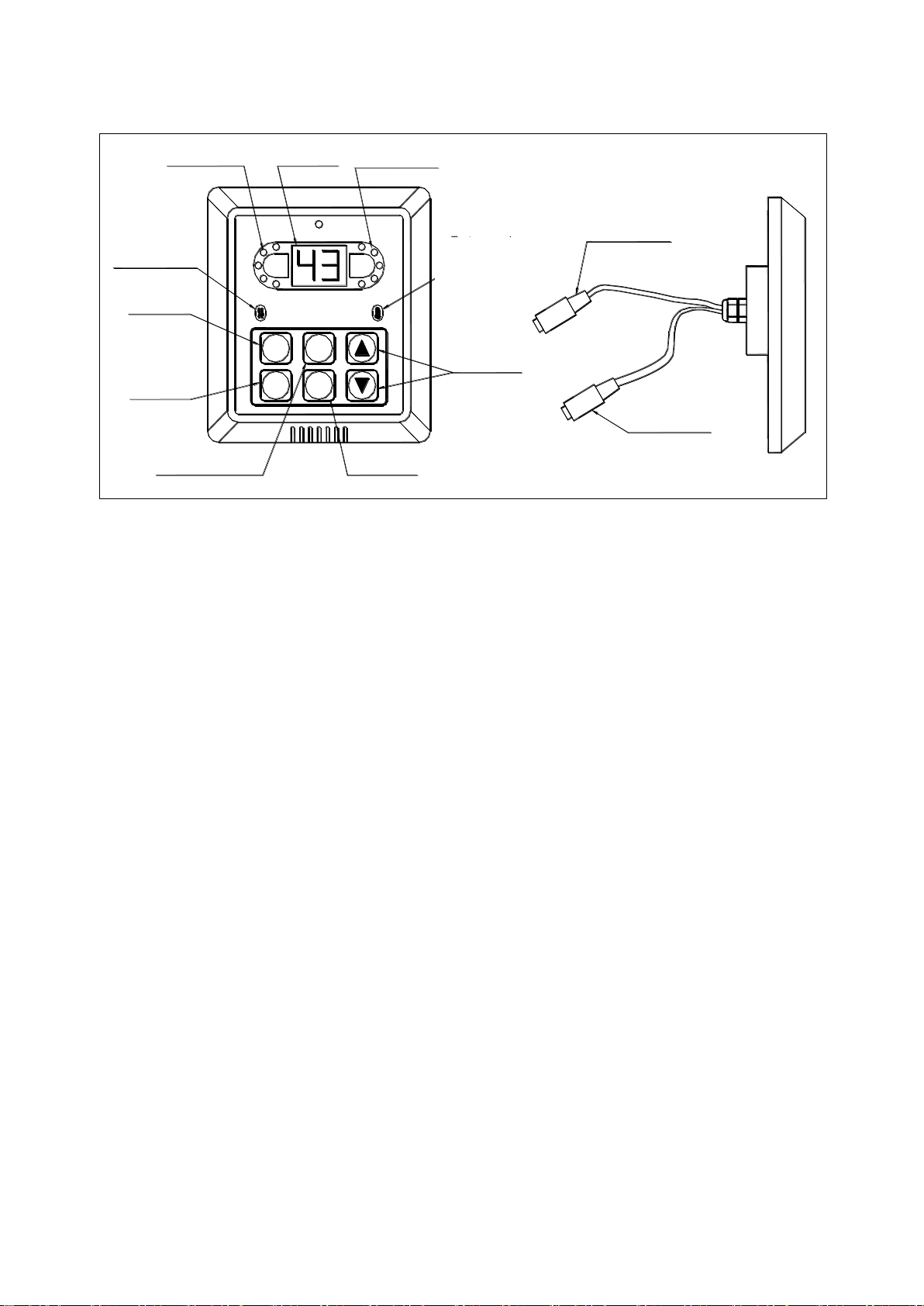

3. Installation of controller and temperature sensor

The controller should be installed with height of 47"outside the steam room but nearby or

other place where easy to operate. Firstly drill a hole with diameter 50mm (2 inch) on the

installation site, pull the control wire and temperature sensor wire through the conduit, then connect

the control wire to the black connector(6P) while connect the temperature sensor wire to the black

connector(2P). Finally the controller panel can be glued to wall by the double sided adhesive on the

back of the panel (Refer to figure 5).

The temperature sensor is used to measure the temperature inside the steam room, so that the

generator can work automatically according to the pre-set temperature and maintain the room

temperature constant. The installation height of the sensor should be about 47-59"from ground.

Please drill a ¢16mm (diameter 5/8‟‟ ) hole, and then nail down the sensor in the steam room

(Refer to figure6),, and pull the sensor wire through the conduit then connect to the black

connector(2P) of the controller.