9

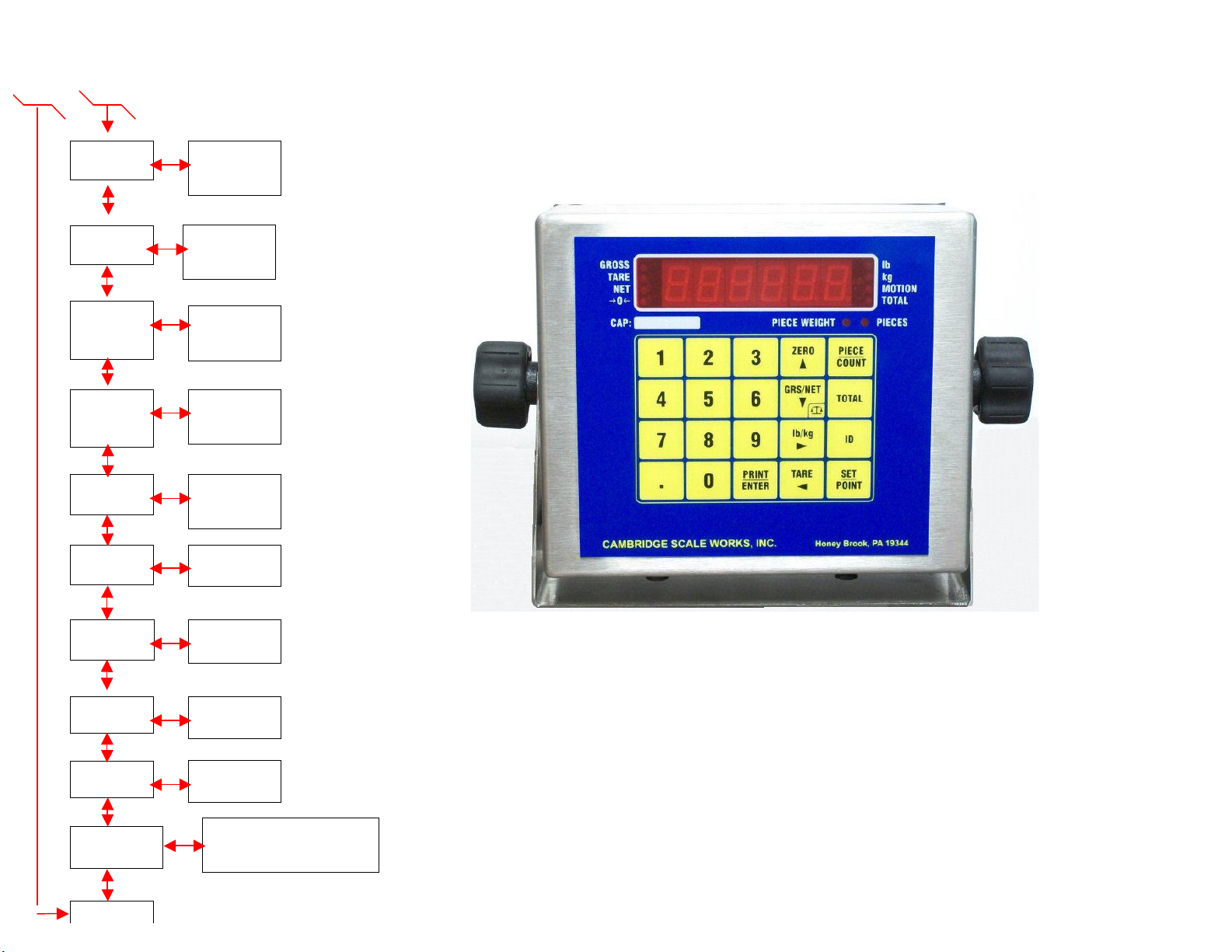

2.2 Scale Menu Definitions

Enter Calibration / Setup mode by pressing and holding the GRS/NET key until Parameter and calibration

event counters are displayed, then release the key. When code is displayed, enter in sequence TARE,

lb/kg, GRS/NET, and PRINT/ENTER. ScAlE will be displayed. Press the down arrow key to enter the

scale menu. Press the right arrow key to enter each sub menu.

-P xxx, C xxx are event counters that will increment each time one or more changes are made

to the Scale or Calibration Parameters.

S1 Ntep 0 Non-Ntep mode 20,000 maximum division limit and no scale negative tests.

1NTEP mode (Default)

2Angle mode. Press the right arrow key to enter. Use the numeric keypad

to enter the desired selection (0,1, or 2), then press the PRINT/ENTER key to

save and exit. S1 will be displayed.

S2 Capacity 1 to 950,000 pounds. 5000 (Default) Press the right arrow key to enter. Use the

numeric keypad to enter the desired capacity then press the PRINT/ENTER key to

save and exit. S2 will be displayed.

S3 Count By .001, .01, .1, 1, .002, .02, .2, 2, .005, .05, .5, 5. 1(default) Use the up and down

arrow keys to choose the count by. Use the left and right arrow keys to choose the

decimal place, then press the PRINT/ENTER key to save and exit. S3 will be

displayed.

S4 Overload (105%) of the scale capacity. Press the right arrow key to enter. Use the numeric

keypad to enter the desired safe overload then press the PRINT/ENTER key to save

and exit. S4 will be displayed.

S5 Zero Limit 0 1.9%

1100% (Default) Press the right arrow key to enter. Use the numeric keypad

to enter the desired selection (0 or 1), then press the PRINT/ENTER key to

save and exit. S5 will be displayed.

S6 Filter 0 to 7, Where 0 is the fastest response and least filtering and 7 is the slowest

response or most filtering. 3 (Default) Press the right arrow key to enter. Use the

numeric keypad to enter the value, then Press the PRINT/ENTER key to save and

exit. S6 will be displayed.

S7 Motion Band 1 to 99 divisions. The weight display must be stable within the selected number of

divisions for the motion indicator to be turned off. 2 (Default) Press the right arrow

key to enter. Use the numeric keypad to enter the value, then press the

PRINT/ENTER key to and exit. S7 will be displayed.

S8 Motion Delay 0 to 99 updates. The weight display must be within the motion band for the

selected number of updates in order to turn off the motion indicator. 4 (Default)

Press the right arrow key to enter. Use the numeric keypad enter the value, then

press the PRINT/ENTER key to save and exit. S7 will be displayed.