10) Rotate the power unit to the necessary angle, un-

screwing or screwing in the pivot in order to align it

to the column tub and to any encumbrances inside

the frame (for example, be careful of the bottle holder

rivets).

Lock the power unit into defined position tightening

the nut with a 7 mm wrench all the way onto the power

unit to a torque of 2 Nm (18 in.lbs).

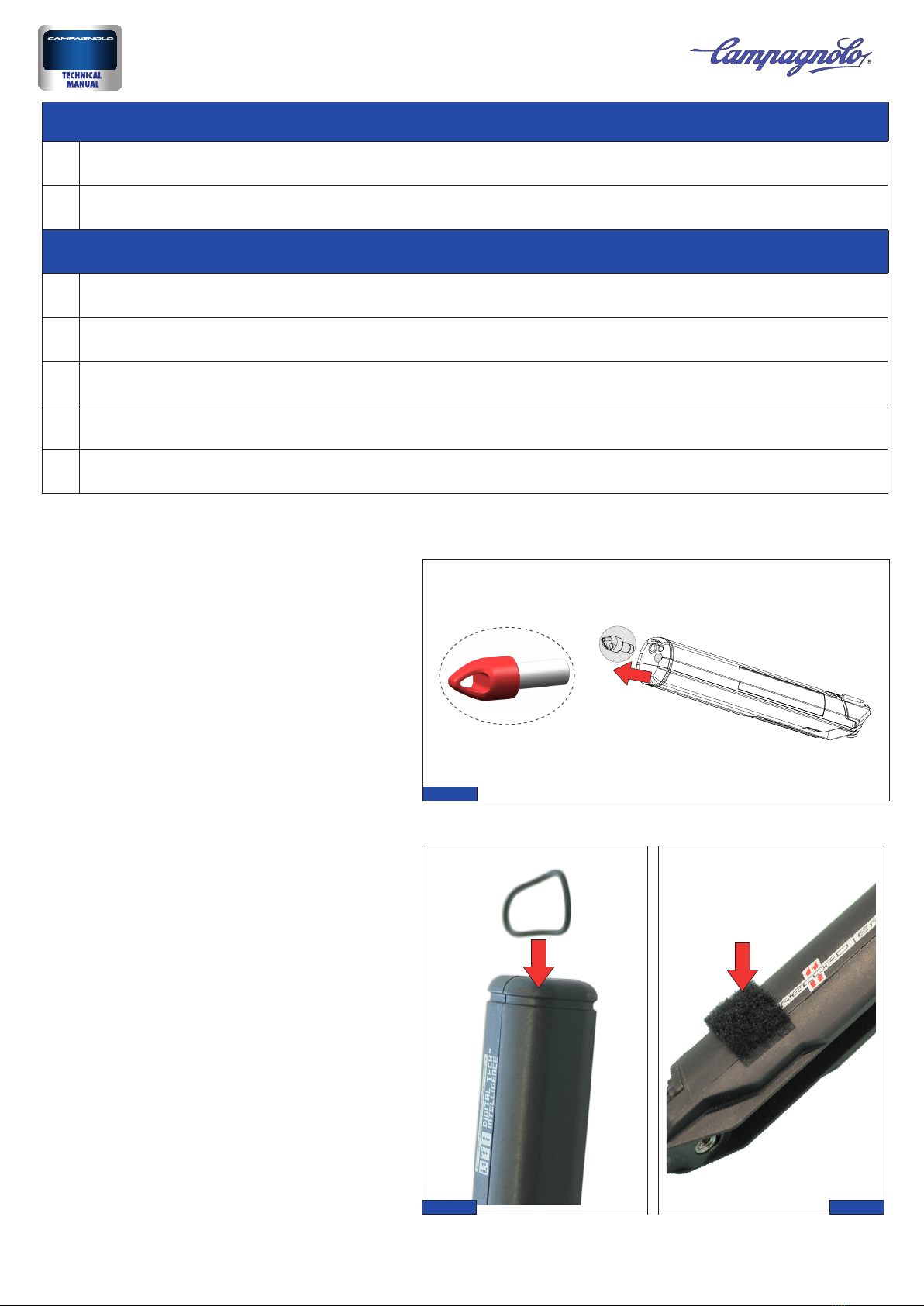

11) To hold the 4 cables of the power unit together

and facilitate routing of the cables through frame, fit

one of the two spiral wraps: near the front derailleur

connectors and the battery charger connector, and fit

the other near the rear derailleur connector (Fig. 17).

Bring the cables out from the bottom bracket shell.

If it is not easy to get the cables out from the bottom

bracket shell, use the grommet magnet kit, putting

the long cable in from the bottom bracket and making

it come out of the seat tube. Fit the short wire on the

red connector, connect the two magnets and pull the

long cable, pulling the ends of the cables out from the

bottom bracket.

• Remove the spiral wraps holding the cables toge-

ther (Fig. 18).

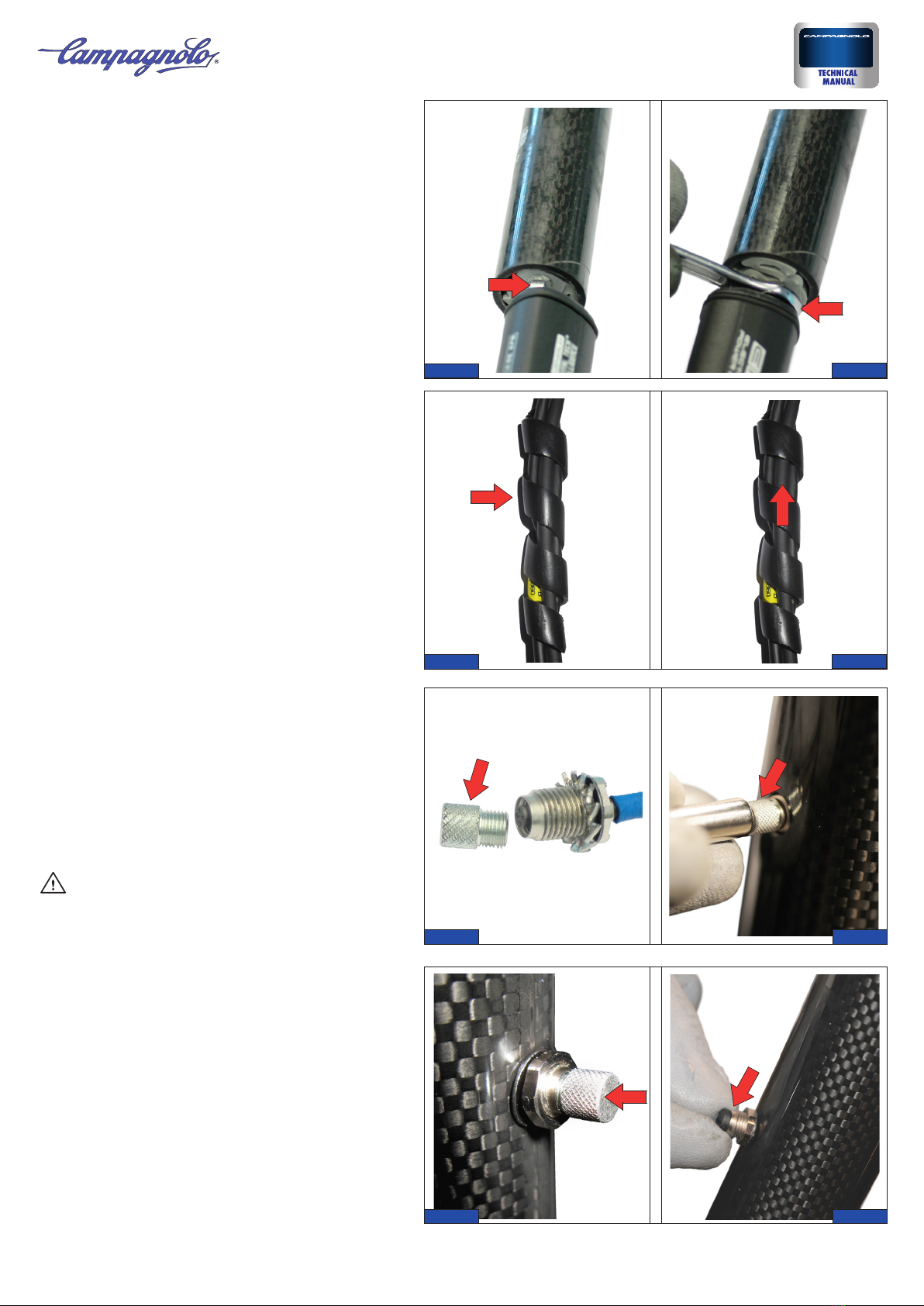

12) Fit the threaded metal insert onto the battery

charger connector (Fig. 19), leaving the knurled wa-

sher on the connector.

- Insert the long cable of the cable guide magnet kit

into the exit hole for the battery charger connector,

then connect it to the battery charger connector with

the magnet.

- Partially bring the connector out through the hole in

the frame and leave the cable with magnet to prevent

the connector from sliding back inside it (Fig. 20)

- Put the washer and nut on and tighten to a torque of

1.5 Nm (13 in.lbs)

(Fig. 21).

WARNING!

If you have a carbon fibre frame contact the frame

manufacturer in order to ensure that it will not be

damaged after tightening to a torque of 1.5 Nm (13

in.lbs) or to define the actions to be taken in order to

prevent damage.

Even the slightest damage caused to a carbon fibre

frame can cause damages which may lead to acci-

dents, injuries or even death.

13) Remove the threaded metal insert (Fig. 22) and fit

the connector cover cap, screwing correctly into place.

EPS

5Rev. 01 /10-2016

15 16

17 18

19 20

21 22