99-0400 Rev.00

Contents

Part 1 - General Information.....................................................................................................................................................1

1.1 –Special Instructions to Owner ........................................................................................................................................................................1

1.2 –Product Overview.............................................................................................................................................................................................2

1.3 –Product Ratings................................................................................................................................................................................................2

1.3.1 –Capacity Ratings ...........................................................................................................................................................................................2

1.3.2 –Electrical Ratings ..........................................................................................................................................................................................2

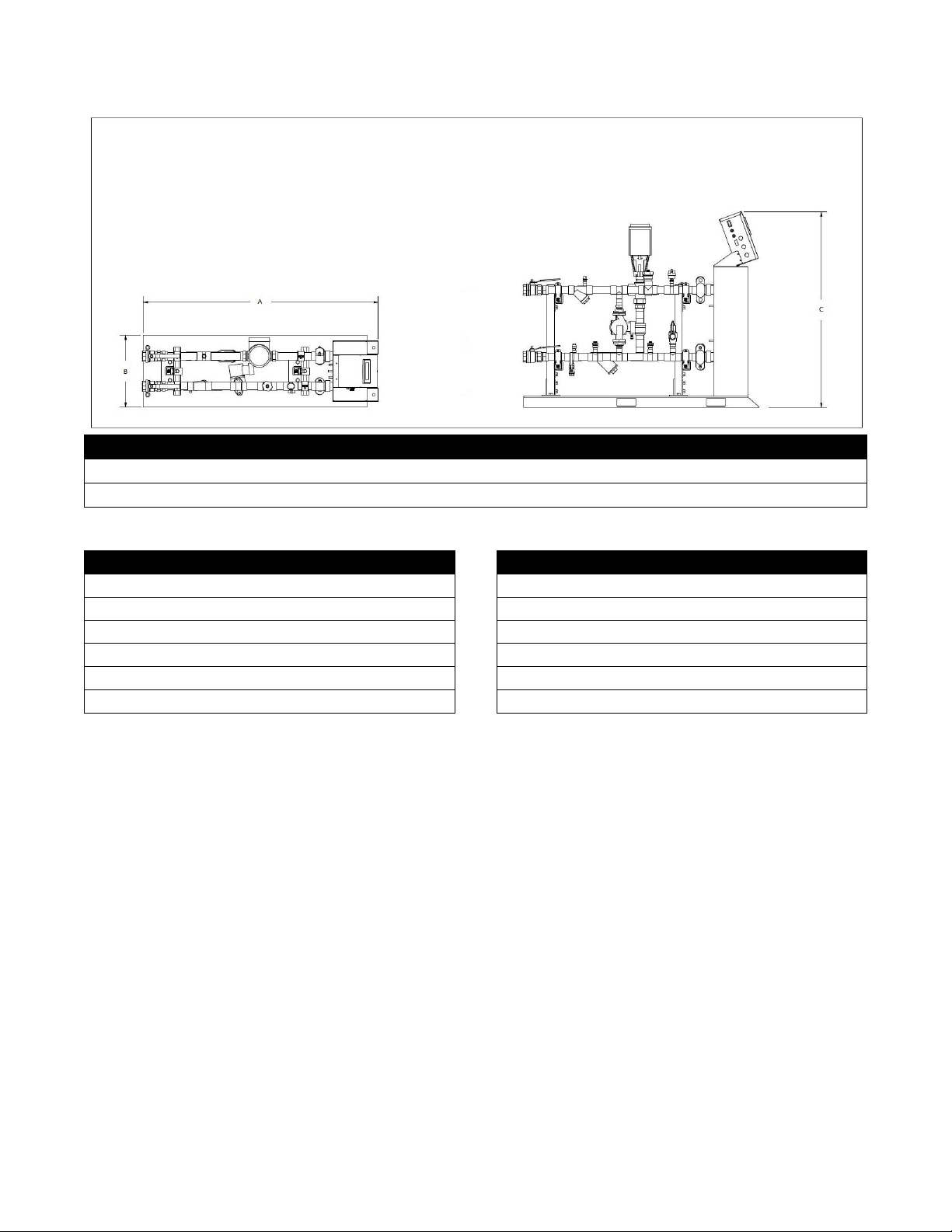

1.3.3 –Dimensions and Connections .....................................................................................................................................................................3

1.4 –Sequence of Operation....................................................................................................................................................................................4

1.5 –Codes .................................................................................................................................................................................................................4

1.6 –Warranty ............................................................................................................................................................................................................4

Part 2 –Installation..................................................................................................................................................................4

2.1 –Checking the Equipment.................................................................................................................................................................................4

2.2 –Mechanical Environment.................................................................................................................................................................................4

2.3 –Locating the Equipment ..................................................................................................................................................................................4

2.4 –Clearances.........................................................................................................................................................................................................4

Part 3 –Heat Exchanger ..........................................................................................................................................................4

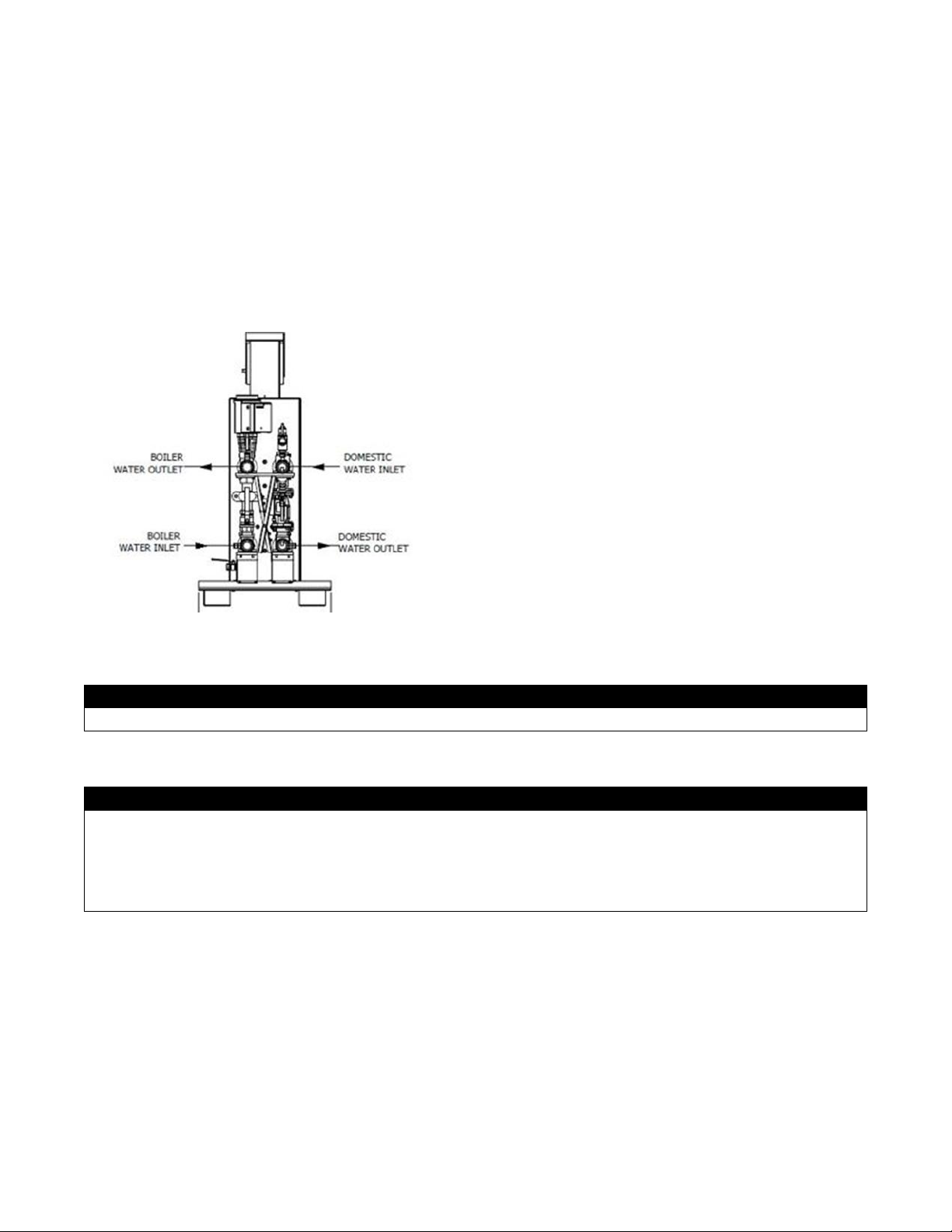

3.1 –Overview............................................................................................................................................................................................................4

3.2 –Double Wall Models..........................................................................................................................................................................................5

3.3 –Cleaning.............................................................................................................................................................................................................5

Part 4 –Electrical.....................................................................................................................................................................5

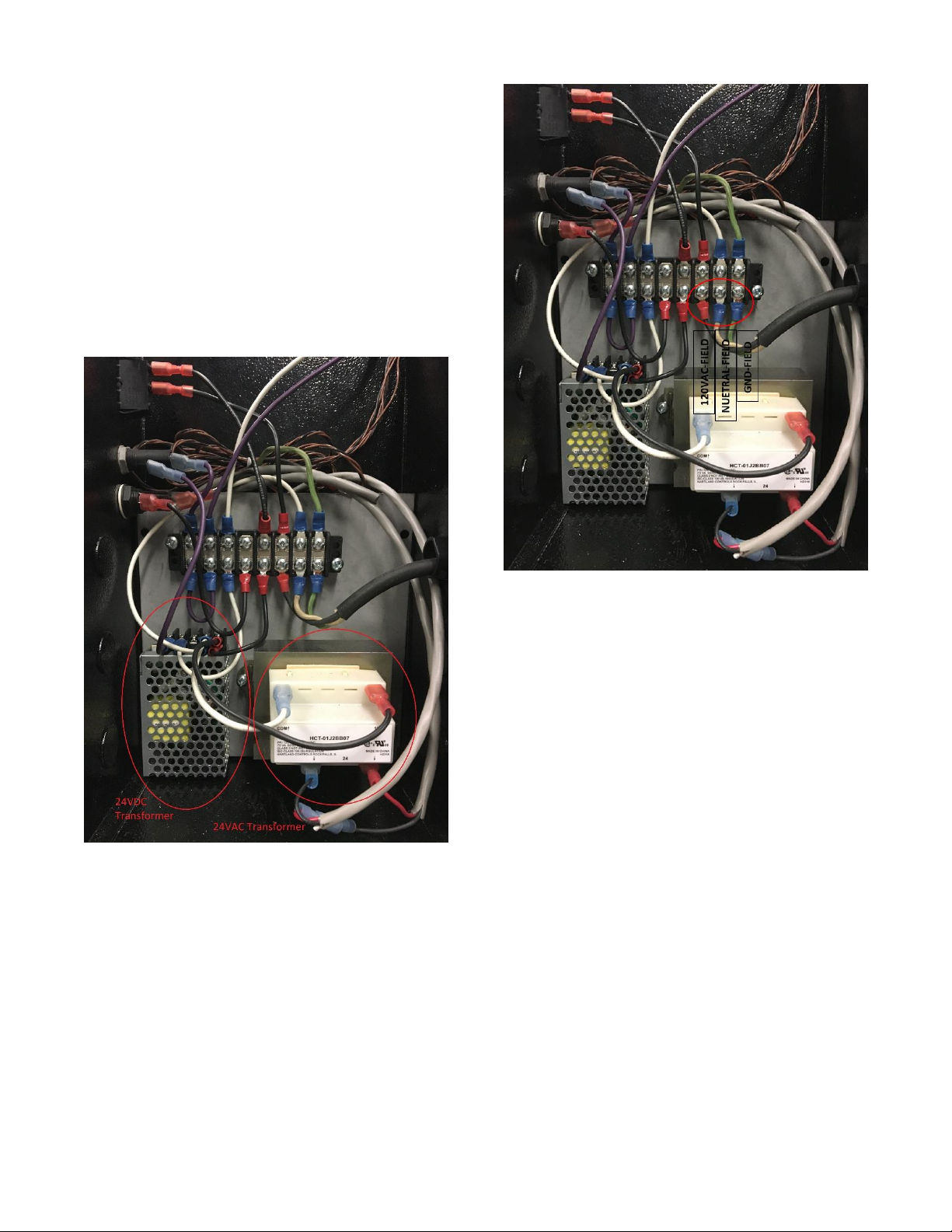

4.1 –Overview............................................................................................................................................................................................................5

4.2 –Field Power Supply ..........................................................................................................................................................................................6

4.3 –Fuses..................................................................................................................................................................................................................6

4.4 –Digital Output Wiring .......................................................................................................................................................................................7

Part 5 –Control........................................................................................................................................................................8

5.1 –Overview............................................................................................................................................................................................................8

5.2 –Screen Navigation ............................................................................................................................................................................................9

5.2.1 –<Control>......................................................................................................................................................................................................11

5.2.2 –<Alarm>.........................................................................................................................................................................................................11

5.2.3 –<Setup> (Installer Level Password: 3232)................................................................................................................................................12

5.2.3.1 –<Alarm Configuration> ............................................................................................................................................................................12

5.2.3.2 –<Data Logging> ........................................................................................................................................................................................13

5.2.3.3 –DataXport...................................................................................................................................................................................................14

5.2.3.3 –<Modbus>..................................................................................................................................................................................................16

5.2.3.4 –<PID Configuration>.................................................................................................................................................................................16

Part 6 –Components .............................................................................................................................................................17

6.1 –Electro-Hydraulic Actuator............................................................................................................................................................................17

6.1.1 –Operation......................................................................................................................................................................................................17

6.1.2 –Stroke Calibration........................................................................................................................................................................................17

6.1.3 –Manual Operation ........................................................................................................................................................................................17

6.2 –Temperature and Pressure Relief Valve (If Supplied) ...............................................................................................................................17

6.2.1 –Overview.......................................................................................................................................................................................................17

6.2.2 –Re-inspection of T&P relief valve..............................................................................................................................................................18

6.3 –Aquastat (Manual Reset) ...............................................................................................................................................................................18

6.4 –Circulator Pump..............................................................................................................................................................................................18

6.4.1 –Overview.......................................................................................................................................................................................................18

6.4.2 –Troubleshooting ..........................................................................................................................................................................................20

Appendix A –Special Considerations for low volume boilers dedicated only to a DHW load.............................................21

Appendix B –Electrical Schematics –DynaFLO...................................................................................................................22

DynaFLO LIMITED WARRANTY.............................................................................................................................................23