10

System Start-Up

1. Plug the power transformer into an ap-

proved power source. Connect the power

cord to the valve.

2. When power is supplied to the control, the

screen will display “INITIALIZING WAIT

PLEASE” while it finds the service position.

3. Manually step the valve past the BRINE

position to the BACKWASH position. If

screen is locked, press SETTINGS for 3

seconds to unlock. Press and hold the

MANUL REGEN. Key for 3 seconds. Press

any key to skip the BRINE cycle.

4. Once in the BACKWASH cycle, open the

inlet on the bypass valve slowly and allow

water to enter the unit. Allow all air to es-

cape from the unit before turning the wa-

ter on fully then allow water to Backwash

for 30 minutes after installing in order to

allow the layers to settle to their appropri-

ate height.

5. Press any button to advance to the RINSE

position. Check the drain line flow. Allow

the water to run for 3-4 minutes or until

the water is clear.

6. Press any button to advance to the REFILL

position. Check that the valve is filling wa-

ter into the brine tank. Allow the valve to

refill for the full amount of time as dis-

played on the screen to insure a proper

brine solution for the next regeneration.

7. The valve will automatically advance to the

SERVICE position. Open the outlet valve

on the bypass, then open the nearest

treated water faucet and allow the water

to run until clear, close the tap and replace

the faucet screen.

8. Add salt into the cabinet / brine tank.

9. Program unit.

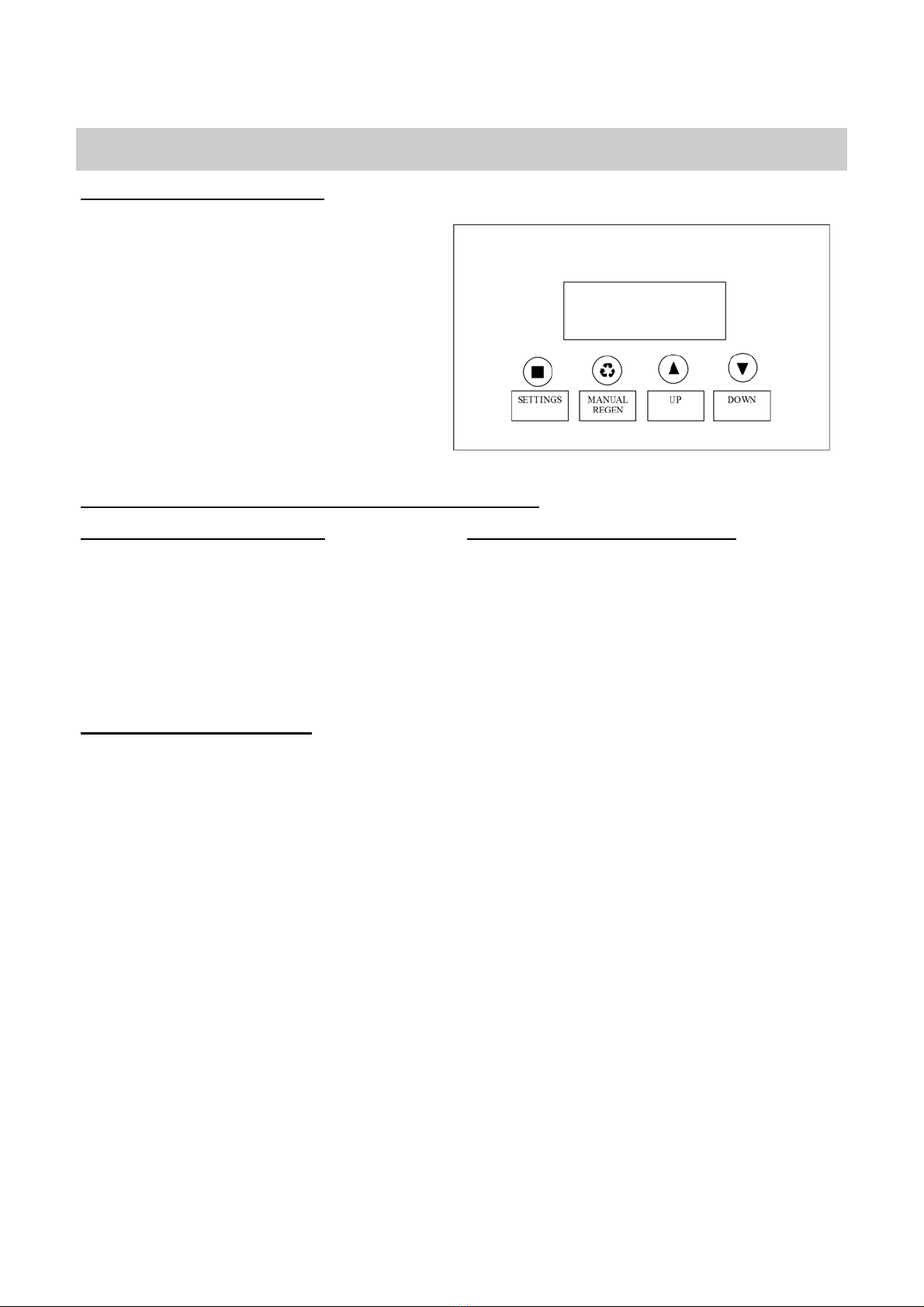

Key Pad Configuration

Start-up Instructions

SETTINGS This funcon is to enter the basic set up infor‐

maon required at the me of installaon.

MANUAL

REGEN

This funcon is to iniate an immediate or

delayed manual regeneraon.

DOWN /

UP

Increase or decrease the value of the sengs

while in the programming mode.

DELAYED REGENERATION

Press and release the MANUAL REGEN. But-

ton to set a delayed regeneration that will

occur at the regeneration time. The main

display page will show DELAYED REGEN ON.

To cancel press and release the MANUAL RE-

GEN. Button. The main display page will

show DELAYED REGEN OFF.

IMMEDIATE REGENERATION

To start an immediate regeneration (or step

valve through each position), press and hold

the MANUAL REGEN. Button for 3 seconds

(until beeps). The valve will start an immedi-

ate regeneration. Press any key to skip to

the next cycle.

Manual Regeneration (Step / Cycle Valve)