C&M Britony II T User guide

BRITONY II T

Room Sealed Balanced Flue

MULTI POINT WATER HEATER

GGAASSSSAAFFEETTYY((IINNSSTTAALLLLAATTIIOONNAANNDDUUSSEE))RREEGGUULLAATTIIOONNSS..

It is the law that all gas appliances are installed by a competant person

in accordance with the above regulations.

BRITONY II.T NAT G.C. N° 52 980 04

BRITONY II.T LPG G.C. N° 52 980 09

from serial number 999508276-04

C

*

+-

IInnssttaallllaattiioonn

aannddSSeerrvviicciinnggIInnssttrruuccttiioonnss

(leave these instructions with the user)

The model number and serial number of this heater are on the data badge which is found inside the

rear case on the lower left hand side.

These numbers should be used when ordering replacement parts.

CCOONNFFOORRMMSSWWIITTHHEEUURROOPPEEAANNSSTTAANNDDAARRDDEENN..2266

c

2

CCoonntteennttss

PPaaggee33::TTEECCHHNNIICCAALLDDAATTAA

PPaaggeess44,,55aanndd66::IINNSSTTAALLLLAATTIIOONN

PPaaggeess77,,88aanndd99::SSEERRVVIICCIINNGGIINNSSTTRRUUCCTTIIOONNSS

PPaaggeess1100aanndd1111::FFAAUULLTTFFIINNDDIINNGGCCHHAARRTTFFOORRBBRRIITTOONNYYIIIITT

PPaaggee1122::SSHHOORRTTLLIISSTT

15 mm15 mm 15 mm

outlet inlet

gas

395

300

365

300

15

115

450

95

131 253

655

200

750

90

50

610

GGEENNEERRAALL

The BRITONY II T is a cat. II2H3+ appliance

809124535.02 BRITONY II T NAT GC N° 52 980 04

809124525.02 BRITONY II T LPG GC N°52 980 09

The BRITONY II T is a balanced flue instantaneous gas fired multipoint water heater. For direct connection to the mains cold

water supply.

The BRITONY II T does not require any purpose provides ventilation unless installed in a compartment. A compartment enclos-

ing the heater requires high and low level openings communicating with outside air or the room in which the compartment is locat-

ed. The free area of these openings must be :

H

Hi

ig

gh

hL

Le

ev

ve

el

lL

Lo

ow

wL

Le

ev

ve

el

l

Air from room 252 cm2 (40 in2) 252 cm2 (40 in2)

Air from outside 126 cm2 (20 in2) 126 cm2 (20 in2)

The installation of the heater must be in accordance with the relevant requirements of the Gas Safety Regulations, Buildings

Regulations and the Bye-laws of the local Water Undertaking. It should also be in accordance with any relevant requirements of

BRITISH GAS and local authority and the relevant recommendations of the following British Standard Codes of Practice.

BS 5440 Flues and air supply for gas appliances of rated imput not exceeding 60 kW (1st and 2nd family gases)

Part 1 - Flues

Part 2 - Air Supply

BS 5546 Code of practise for installation of gas hot water supplies for domestic purposes (2nd family gases)

BS 6891 Specification for installation of low pressure gas pipework of up to 28 mm

(R1) in domestic premises (2nd family gas)

3

Technical Data

TABLE 1

Heat imput Nominal ...................................................................................... 23 kW - 78,480 Btu/h

Heat output Nominal ..................................................................................... 21 kW - 71,650 Btu/h

Gas rate (maximum) :

• Natural gas (G 20) ................................................................................ 2.43 m3/h - 88.1 ft3/h

• Butan (G 30)......................................................................................... 1.81 kg/h

• Propan (G 31)....................................................................................... 1.79 kg/h

Burner pressure (G 20) .................................................................................. 11.6 mbar - 4.5 in w.g

Main burner injectors marking :

• Natural gas (restrictor ø 5.2) ................................................................. 1.18

• Butan - propan ..................................................................................... 0.70

Pilot injector marking :

• Natural gas ........................................................................................... 0.23

• Butan - propan ..................................................................................... 0.15

Water flow rate - raised 50° C (90° F) ............................................................ 6 l/m - 1.32 g.p.m.

Water flow rate - raised 30° C (54° F) ............................................................ 10.05 l/m - 2.21 g.p.m.

Minimum water pressure............................................................................... 1 Bar - 15 P.S.I.

Maximum water pressure .............................................................................. 10 Bar - 150 P.S.I.

Water inlet - right hand connection................................................................. 15 mm copper

Water outlet - left hand connection................................................................. 15 mm copper

Gas - centre connection ................................................................................. 15 mm copper

Height............................................................................................................ 655 mm

Width ............................................................................................................. 395 mm

Depth............................................................................................................. 253 mm

Weight............................................................................................................ 19 kg

Space for fixing - Top ..................................................................................... 65 mm

Space for fixing - Bottom ............................................................................... 178 mm

Space for fixing - Sides .................................................................................. 25 mm

Space for fixing - Front .................................................................................. 152 mm

HOLE FOR WALL LINER

Width ............................................................................................................. 305 mm

Height............................................................................................................ 205 mm

WALL THICKNESS

Standard flue set............................................................................................ 75 - 355 mm

Optional flue set............................................................................................. 75 - 500 mm

The minimum water pressure is for the correct operation of the heater only. An additional allowance must be made for the resisance

of the pipework and fittings particularly where showers and washing machines are used. This should be the equivalent of 2 m (6.5

ft.) head.

4

IInnssttaallllaattiioonn

The BRITONY II T is supplied in two cartons, on containing

the heater, the other containing the balanced flue set.

I

IN

NS

ST

TA

AL

LL

LI

IN

NG

GT

TH

HE

EB

BA

AL

LA

AN

NC

CE

ED

DF

FL

LU

UE

E

The standard flue set is suitable for walls having a thickness of

75 mm (3 in) to 355 mm (14 in). An optional flue set for wall

thicknesses up to 500 mm (20 in) is available to special order.

Detailed recommandations for flueing are given in BS 5440 :

1. The following notes are for general guidance only.

The heater must be installed so that the flue terminal is exposed

to the external air. The heater must not be installed so that the

terminal discharges into another room or space such as an out-

house or lean-to.

Termination should be on a clear expanse of wall, the terminal

preferably being not less than 300 mm (1 ft.) away from a cor-

nern recess or projection.

D

DO

ON

NO

OT

Tinstall the terminal :

a) within 300 mm (1 ft.) measured vertically from the bottom of

an openable window, air vent or any other ventilation open-

ing.

b) within 300 mm (1ft.) above adjacent ground level.

c) within 600 mm (1 ft.) of any surface facing the terminal.

d) immediately beneath eaves or a balcony.

Where the lowest part of the terminal is less than 2 m ( 6,5 ft.)

above the level of any ground, balcony, flat roof or place to

which any person has access, and which adjoints the wall in

which the terminal is situated, the terminal must be protected by

a guard of durable material. (A terminal guard is available from

QUINNELL BARRETT & QUINNELL, 071 639 1357.

The air inlet, product outlets duct or terminal of the heater must

not be closer than 50 mm (2 in) to any combustible material.

Detailed recommandations on the protection of combustible

material are given in BS 5440 : 1

P

PR

RE

EP

PA

AR

RI

IN

NG

GT

TH

HE

EW

WA

AL

LL

L

The heater should be installed on a wall of flat non- combustible

material that will not reverberate. Whatever the thickness of the

wall, make a hole 305 mm (12 in) wide by 205 mm

(8 in) high. If the hole is cut accurately there is no need to line it

as the wall liner will seal off the cavity.

A minimum clearance of 80 mm (3,2 in) should be left above

the top edge of the wall opening. For dimensions and clearance

see page 2 and Technical Data, page 3.

Slide the wall liner through the wall ensuring that is horizontal

and that the flanged end is flush with the face of the inside wall.

Trim to length if necessary, so that the outer end of the duct is

flush with the face of the outside wall. Make good around the

wall liner if necessary (fig. 1).

N.B. : For walls of between 75-100 mm (3-4 in), turn the wall

liner hooks down through 90°.

F

FI

IT

TT

TI

IN

NG

GT

TH

HE

EF

FL

LU

UE

ET

TE

ER

RM

MI

IN

NA

AL

L

W

Wa

al

ll

lL

Li

in

ne

er

r

- For walls of 14 ins. (355 mm) or less, use only the flanged wall

liner section, measure and cut to length so that the liner extend

1/4 in. from external wall face. Cut “U” cover section to length.

- Assemble by inserting the tabs on the “U” shaped section into

the slots on the cover.

-Turn the tabs over in the direction of the lip on the cover, fit

hooks with nuts and bolts provided.

- Refit liner into hole and cement into position for a weather

proof finish.

- Ensure that the wall liner is horizontal.

- For walls of over 14 in. assemble the telescopic extension

piece in the same manner as the flanged section.

- Insert inside the flanged section and extend until it extends 1/4

in. from external wall face, mark around inside of flanged sec-

tion.

- Remove liner and extension, cut off surplus from extension

leaving a minimum 2 in. overlap making sure extension does

not obscure hooks.

- Re-assemble liner and extension, seal around outside of joint

with tape supplied.

- Re-fit liner into hole.

- Cement in position for a weather-proof finish.

- Ensure that the liner is horizontal.

N

N.

.B

B.

.:

:For walls 3 in. - 4 in. (75 mm - 100 mm) do not use the

hooks but fit the chains into the slots in the bend fixing brack-

ets.

F

Fl

lu

ue

eD

Du

uc

ct

t

For the standard flue set the duct is telescopic and should be

ajusted to length to ensure that is fully engages with the termi-

nal and the flue bend. The joint should be sealed with the tape

supplied.

For walls over 14 in. fit additional telescopic extension piece

(total 3 pieces) ensuring a 2 in. overlap. Seal the joint with the

Fig. 1 Fig. 2 Fig. 3

5

IInnssttaallllaattiioonn

I

IN

NS

ST

TA

AL

LL

LA

AT

TI

IN

NG

GT

TH

HE

EH

HE

EA

AT

TE

ER

R

The heater is attached to the wall by 2 studs at the top and two

screws at the bottom. A further optional top fixing is provided

for installations where the wall adjacent to the top fixing holes is

of less than sound construction. The fixing studs, screws and

optional top bracket are packed with the gas service tap and a

foam gasket and placed in a box which is found inside the car-

ton.

Remove the front case of heater by pulling off gas control/tem-

perature control knobs, slide facia plate upwards to expose case

fixing screw, and unscrewing the three fixing screws at the top

case taking care not to lose the rubber spacer behind the centre

fixing screw.

Remove the flue bend from the top of the heat exchanger by

releasing the fixing clip and removing the two screws.

N

N.

.B

B.

.:

:If the optional top fixing bracket is to be spigot of the

appliance in the wall liner, check that the appliance is vertical

and mark the four or five fixing holes. Drill and plug the wall and

fasten the top studs in position. These studs can be screwed into

the wall by locking two nuts together on the parallel thread and

using a spanner.

Attach the self adhesive foam gasket to the flat surface of the

heater around the air inlet spigot of the rear case. Remove the

protective paper while sticking down the gasket. Lift the heater

into positon on the wall, locating on the studs and the wall liner.

Secure the heater to the wall using the nuts and screws provid-

ed. The hooks fit under the nuts of the top fixing studs (fig. 4).

Transfer the terminal fixing chains from the wall liner to these

hoods. The terminal chains should not be left fixed to the wall

liner hooks.

Slide the flue duct through the rectangular hole in the rear case

and engage into the central spigot of the terminal so that it

touches the two end stops. Refit the flue bend so that the flue

duct engages by at least 25 mm (1 in), it may be necessary to

cut the flue duct to the correct length, and ensure that the flue

bend is seated correctly on the heat exchanger with the gasket

in place. Replace the two screws and clip securing the flue bend.

Do not refit the front cover until the appliance has been com-

missioned.

G

GA

AS

SC

CO

ON

NN

NE

EC

CT

TI

IO

ON

N

Fit the gas service tap provided using the fine filter washer to

seal the connection. Fit the 15 mm dia. copper tail nut and

washer provided to the inlet of the gas service tap and connect

this to the gas supply.

The size of the gas supply pipe from the meter to the heater only

should be as follows.

D

Di

is

st

ta

an

nc

ce

ef

fr

ro

om

mM

Me

et

te

er

rG

Ga

as

sS

Su

up

pp

pl

ly

y

o

ou

ut

tl

le

et

tt

to

oh

he

ea

at

te

er

r

0-3 m (0-10ft.) 15 mm

3-20 m (10-65 ft.) 22 mm

The sizes are for the heater only and do not take account of any

other gas appliances that may be connected to the same gas

service pipework.

W

WA

AT

TE

ER

RC

CO

ON

NN

NE

EC

CT

TI

IO

ON

NS

S

Remove the plastic covers protecting the water inlet and outlet

connections.

Fit the water service tap provided to the right hand connection

at the bottom of heater using the coarse filter washer to seal the

connection.

Fit the washers provided to the inlet of the water service tap and

to the outlet ot the heater (left hand connection).

The water service tap supplied with the heater incorporates a

drain plug.

A

AP

PP

PL

LI

IC

CA

AT

TI

IO

ON

NS

SO

OF

FT

TH

HE

EB

BR

RI

IT

TO

ON

NY

YI

II

IT

T

The heater is designed to serve a variety of hot water draw-off

points including washing machines and showers. The heater

can be connected to all the hot water draw-off points in the

installation. If more than one outlet is open simultaneously the

total flow of water cannot exceed that quoted in the Technical

data.

The heater is compatible with most current automatic washing

machines, but care should be taken to ensure that the machine

is capable of accepting water at the design flow rate of the

heater. Hot and cold fil machines normally require a hot water

temperature of 60° C (140° F), the heater producing approxi-

mately 6,5 l/m (1,44 g.p.m.) at this temperature. The advice of

the washing machine manufacturers should be sought, but gen-

erally it is only necessary to remove the water inlet connection

of the machine to obtain a satisfactory heater operation.

Chaffoteaux do not recommend the use of a bath/shower type

mixing valve with the Britony range of water heaters. It has been

found that the characteristics of these type of fittings are such

that a coarse and unsatisfactory shower results.

TO COLD TAPS

HOT WATER

COLD WATER

Mixing Valve

TO HOT TAPS

Fig. 4

6

IInnssttaallllaattiioonn

Contact Chaffoteaux Limited for details of those machines know

to be compatible with the BRITONY II T.

The heater can be used to supply hot water to a separate show-

er draw-off. The heater should not be used to supply more than

one shower mixing valve, but can supply two shower heads off

a single shower head is shown in fig. 5. Only those fittings

detailed should be used with the heater. Chaffoteaux Limited do

not supply the water governor or any shower fittings. For local

supplies of these please contact :

W

Wa

at

te

er

rg

go

ov

ve

er

rn

no

or

r:

:

Dereve (Flow Controls) Limited

Park Lane

HANDSWORTH

Birmingham B 21 8LE 0121 5537 021

S

Sh

ho

ow

we

er

rA

Ac

cc

ce

es

ss

so

or

ri

ie

es

s:

:

Caradon Mira Ltd B

Ba

ar

rk

ki

in

ng

gG

Gr

ro

oh

he

e:

:

Cromwell Road 1 River Road

Cheltenham Barking

Gloucester GL52 5EP Essex IG11 OHD

Tel : 01242 27953 Tel : 0181-594-8898

M

Me

ey

yn

ne

el

ll

lV

Va

al

lv

ve

es

sL

Lt

td

d:

:

Shaw Road,

Bushbury,

Wolverhampton,

West Midlands WV109LB

Tel : 01902 28621

A

Aq

qu

ua

al

li

is

sa

aP

Pr

ro

od

du

uc

ct

ts

sL

Lt

td

d:

:N

Ne

ew

wT

Te

ea

am

mL

Lt

td

d:

:

Horton’s Way Brunell Road

London Road Earlstree Ind. Estate

Westerham Corby

Kent TN 16 1BT Northants NN17 2 LF

Tel : 01959 63240 Tel : 01536 62822

Do not use the heater with push-on hand showers that fit over

existing hot and cold water taps.

P

PI

IP

PE

EW

WW

WO

OR

RK

K

The following notes are for general guidance only.

(I) The heaters performance may be affected if the installation has old

pipework forming dead-legs or air reservoirs.

Always ensure that any old pipework is either removed or

capped off immediately adjacent to the pipework that wille

be in use.

(II) The size of pipework between the heater and the various

draw-off points should be sized to ensure an adequate flow

at all draw-offs when used individually.

(III) A check should be made of all stop cocks in the incoming

supply and it should be ensured that they are of the fixed

jumper pattern. Loose jumpers can be pinned or soldered

into position.

(IV) If the appliance is installed on a supply or distribution pipe

containing a non-return valve, combinations of check valve,

or any equipment containing such devices, then provision

must be hade to accomodate an expansion of at least 4 %

of the volume of wate contained within the installation.

(V) Expansion vessels must be fitted on the supply pipe

between the non-return valve, combinations of check valve,

or any equipment containing such divices, and the appli-

ance.

P

PU

UT

TT

TI

IN

NG

GI

IN

NT

TO

OS

SE

ER

RV

VI

IC

CE

E

R

Re

em

mo

ov

ve

ep

pr

ro

ot

te

ec

ct

ti

iv

ve

ef

fi

il

lm

mb

be

ef

fo

or

re

eu

us

se

e

Open the gas and water service taps beneath the appliance.

Purge the gas and water supplies. Check for gas and water

soundness at all heater and external pipework connections. Fit

the gas control knob and light the pilot by turning the knob 90°

anti-clockwise. It may be necessary to purge the pilot gas sup-

ply, if so, wait a few moments, return the gas control knob to

the off position and repeat (the pilot supply will only purge when

the gas control knob has been turned 90° anti-clock-wise).

Turn the gas control knob fully anti-clockwise to the main gas

position. If the pilot is now extinguished for any reason, return

the gas control knob to the safety interlock to reset itself. Turn

on an adjacent water draw-off point, the heater will now light.

Check the burner pressure by fitting a suitable gauge to the pres-

sure test point on the end of the burner manifold. The correct

pressure is given in Table 1 page 3. If the burner pressure is not

correct, check that the pressure at the gas tap test point is 20

mbar (8 ins w.g.) with the appliance operating. If the inlet pres-

sure is not correct, check for any possible blockage or restriction

in the corrected contact your local gas region. The heat input to

the heater is preset and non-adjustable.

R

Re

em

mo

ov

ve

et

th

he

eg

ga

as

sc

co

on

nt

tr

ro

ol

lk

kn

no

ob

b

Replace the front cover ensuring that the rubber spacer is in

place behind the centre fixing screwn, slide facia plate down,

replace the gas control knob and temperature control knob

ensuring that the knob indidates «hot» when turned fully clock-

wise.

Hand the User’s Instructions to the consumer and instruct in the

correct and safe operation of the heater.

D

DR

RA

AI

IN

NI

IN

NG

GT

TH

HE

EH

HE

EA

AT

TE

ER

R

If the heater is not to be used for long periods it is recommend-

ed that it be drained. See the Servicing Instructions for how to

drain the heater.

7

SSeerrvviicciinnggIInnssttrruuccttiioonnss

Before commencing any servicing work, turn off the gas and

water at the gas and water inlet taps on the appliance.

Slide the bottom plastic trim forward to improve access

R

RO

OU

UT

TI

IN

NE

ES

SE

ER

RV

VI

IC

CI

IN

NG

G

To ensure continued efficient and safe operation of the appliance

it is recommended that it is checked and serviced as necessary

at regular intervals. The frequency of servicing will depend upon

the particular installation condition and usage, but in general

once a year should be adequate. It is the law that any service

work must be carried out by a competant person such as

Bristish Gas, other C.O.R.G.I. registered personnel or your local

Chaffoteaux Service Centre, in accordance with the Gas Safety

(Installation and Use) Regulations. This routine service will nor-

mally be confined to :

1) Cleaning the burner, and pilot tube.

2) Cleaning the heat exchanger, and thermocouple.

3) Checking the gas controls.

4) Cleaning water filter, and water governor.

5) Chek diaphragm and replace every 3 years.

The following schedules are recommended :

a) Check the function of appliance, burner pressure, gas flow

rate and soundness.

b) Observe flame picture and undertake combustion test.

c) Check, clean or replace components as necessary.

1

1)

)F

FR

RO

ON

NT

TC

CA

AS

SI

IN

NG

G

To remove, pull off the gas control and temperature control

knob.

Slide facia plate upward to allow access to centre fixing screws.

Unscrew the top, centre and bottom fixing screws.

Pul off the case taking care not to lose the rubber spacer behind

the centre fixing point.

2

2)

)B

BU

UR

RN

NE

ER

R

Unscrew the pilot tube clamping screw (A - fig. 7) and remove

the clamp and tube.

Remove the burner manifold by unscrewing the two screws

(B - fig. 7).

Pull burner head assembly forward to remove, taking care not

to trap the thermocouple or ignitor wires.

The burner head should be turned upside down and cleaned by

brushing.

Replace in reverse order making sure that the gasket between

the burner manifold and gas section is in place and that the

burner head assembly is correctly located on the two spigots at

the rear.

3

3)

)H

HE

EA

AT

TI

IN

NG

GB

BO

OD

DY

Y

Remove the flue bend from the top of the heat exchanger by

removing the clip and the two fixing screws. Lift the flue bend

off the heat exchanger taking care not to damage the sealing

gasket. The heating body can be examined in position and if

external cleaning is sufficient, remove the burner and clean the

heat exchanger with a soft brush, detergent and the hot water.

To remove the heating body for further cleaning, the heater

must first be drained.

Turn off the water inlet tap to the appliance as before and open

an adjacent hot water draw-off point. Remove the drain plug

from the side of the water inlet tap (C - fig. 8) and drain the

water from the heater. Alternatively remove the water governor

plug (D - fig. 8) from the base of the water section and drain the

water governor plug before proceeding.

Remove the burner (see section 2).

Remove the screw holding the bottom of the heating bodyskirt

to the rear case.

Release the two union nuts on the heating body legs.

Remove the heating body.

In hard water areas it may be necessary to descale the heating

body. Use a solution consisting of 5 parts water to 1 part

hydrochloric acid. The water should preferably be hot - ADD

ACID TO WATER, NOT WATER TO ACID.

Fill the heating body solution and leave until the solution stops

bubbling. Flush out the heating body thoroughly before refitting

to the heater.

W

WA

AR

RN

NI

IN

NG

G-

-A

AC

CI

ID

D/

/W

WA

AT

TE

ER

RS

SO

OL

LU

UT

TI

IO

ON

NS

SM

MU

US

ST

TB

BE

EU

US

SE

ED

D

W

WI

IT

TH

HE

EX

XT

TR

RE

EM

ME

EC

CA

AU

UT

TI

IO

ON

N.

.T

TA

AK

KE

EC

CA

AR

RE

EN

NO

OT

TT

TO

OS

SP

PL

LA

AS

SH

H

T

TH

HE

ES

SO

OL

LU

UT

TI

IO

ON

NO

ON

NT

TO

OS

SK

KI

IN

NO

OR

RI

IN

NT

TO

OT

TH

HE

EE

EY

YE

ES

S.

.W

WA

AS

SH

H

A

AN

NY

YA

AR

RE

EA

AS

SA

AF

FF

FE

EC

CT

TE

ED

DW

WI

IT

TH

HL

LA

AR

RG

GE

EA

AM

MO

OU

UN

NT

TS

SO

OF

FC

CO

OL

LD

D

W

WA

AT

TE

ER

RA

AN

ND

DS

SE

EE

EK

KM

ME

ED

DI

IC

CA

AL

LA

AD

DV

VI

IC

CE

E.

.

Fig. 7 Fig. 8 Fig. 9

B

A

C

D

E

F

8

SSeerrvviicciinnggiinnssttrruuccttiioonnss

Re-assemble in reverse order ensuring that the skirt fixing screw

and reinforcing strip are in place.

4

4)

)P

PI

IL

LO

OT

T`

`

Unscrew the pilot tube clamping screw (A - fig.7) and remove

the clamp and tube.

Blow through the tube to remove any dust.`

Remove the burner (see section 2)

Unscrew the knurled pilot burner outer ring (E - fig. 9).

Lift off flame retention gauze.

Unscrew the pilot body (F - fig. 9), with a 15 mm spanner.

Clean by blowing or washing in water. Do not clean the holes

with a wire.

Blow any dust out of the gas section.

Re-assemble in reverse order.

5

5)

)T

TH

HE

ER

RM

MO

OC

CO

OU

UP

PL

LE

E

Remove the burner (see section 2).

Remove the pilot (see section 4).

Unscrew the thermocouple nut (G - fig. 10) from the thermo-

electric valve and remove it from the wire.

With a 7 mm box panner, unscrew the nut (H - fig. 11) hold-

ing the termocouple into the gas section.

Thread the thermocouple and wire up through the gas sec-

tion.

Replace in reverse order.

6

6)

)S

SP

PA

AR

RK

KE

EL

LE

EC

CT

TR

RO

OD

DE

E

Remove the burner (see section 2).

Remove the electrode fixing screw (J - fig. 11) with a screw-

driver placed inside the heating body skirt.

Pull off the electrode cable from the piezo cartridge.

Lift the electrode out of the gas section.

Re-assemble in reverse order, and note that the slot in the

connector on the end electrode cable is vertical when pushed

onto the cartridge.

7

7)

)T

TH

HE

ER

RM

MO

O-

-E

EL

LE

EC

CT

TR

RI

IC

CV

VA

AL

LV

VE

E

To replace, remove the thermocouple nut (G - fig. 10).

Unscrew cap from the side of the gas section and widthdraw

the thermo-electric valve.

N

NO

OT

TE

E:

:This heater is fitted with a safety interlock. When the

pilot is turned off, the heater can not be relit until the ther-

mocouple cools down and the lighting sequence is repeated.

8

8)

)M

MA

AI

IN

NG

GA

AS

SV

VA

AL

LV

VE

E

To inspect and clean, remove the burner (see section 2).

Disconnect the thermocouple and ignitor lead (see section 5

and 6).

Remove the four screws fastening the top of the gas section

to the base (K - fig. 12) and the two screws at the back

(L - fig. 12), holding it to the rear case.

Lift the gas section top off the base.

Remove the complete gas valve assembly by unscrewing the

brass cylinder that two flats.

Dismantle the gas valve assembly by unscrewing the hexag-

onal spring retainer from the top of the assembly. Remove

the spring and gas valve and clean the valve seating.

Replace the gas valve facing rubber and gas valve assembly

“O” ring if necessary.

Replace in reverse order, ensuring that the hexagonal spring

retaining nut is screwed fully down and the whole assembly

is screwed fully down into the gas section.

9

9)

)D

DI

IA

AP

PH

HR

RA

AG

GM

M

To replace, turn off the cold water supply and gas.

Drain the heater by removing the water governer plug situat-

ed in the base of the water section.

Unscrew the four water unions (M - fig. 13) on the water sec-

tion.

Unscrew the six screws (N - fig. 13) holding the water section

to the gas section.

Remove the water section complete with the diaphragm.

Replace in reverse order - NOTE - fit the water governor last.

It is easier if the cold water inlet connection is partially

engaged before fitting the screws and reconnecting the union

nuts.

1

10

0)

)W

WA

AT

TE

ER

RG

GO

OV

VE

ER

RN

NO

OR

R

To clean, turn off the cold water supply to the heater.

Remove the governor situated in the base of the water sec-

tion (O - fig. 14).

Clean the components with water.

Check that the spring loaded piston moves freely.

Replace in reverse order.

Fig. 10 Fig. 11 Fig. 12

G

J

H

K

L

9

Fig. 13

Fig. 15

Fig. 16 Fig. 17

Fig. 18

Fig. 14

SSeerrvviicciinnggiinnssttrruuccttiioonnss

1

11

1)

)G

GA

AS

SA

AN

ND

DW

WA

AT

TE

ER

RF

FI

IL

LT

TE

ER

RS

S

Gas and water inlet are fitted

between the inlet taps and the

heater.

To clean, turn off the taps, unscrew

the union nuts attaching the taps to

the heater, and remove the filters.

Clean the filters by blowing or wash-

ing in water. DO NOT use any sol-

vents.

Replace ensuring that the coarse fil-

ter is fitted in the water inlet and the

fine filter in the gas inlet.

1

12

2)

)P

PI

IE

EZ

ZO

OC

CA

AR

RT

TR

RI

ID

DG

GE

E

Pull off the electrode from the piezo

cartridge.

Remove the screw holding the gas

control cam and remove the cam (P

- fig. 15).

Remove the two screws (Q - fig. 15)

holding the retaining plate.

Remove the piezo cartridge and

replace if necessary.

1

13

3)

)H

HE

EA

AT

TI

IN

NP

PU

UT

T

The heat input is pre-set and non-

adjustable. The heat input and burn-

er pressure should be checked

against Table 1.

If the heat input/burner pressure is

not correct, check the working pres-

sure at the pressure test point on

the gas service tap. This should be

20 mbar (8 ins w.g.).

The gas installation should be

examined for any possible blockage

if the pressure is incorrect.

1

14

4)

)W

WA

AT

TE

ER

RS

SE

EC

CT

TI

IO

ON

NV

VE

EN

NT

TU

UR

RI

I

Drain the heater as in Section 3.

Disconnect the right hand heating

body leg at the water section and

remove the venturi.

Clean or replace as necessary and

re-assemble in reverse order.

1

15

5)

)S

SL

LO

OW

WI

IG

GN

NI

IT

TI

IO

ON

ND

DE

EV

VI

IC

CE

E

Burner ignition should be smooth

and quiet. Incorrect adjustment of

the slow ignition screw can cause

explosive ignition or ignition at all.

To adjust the slow ignition device

firstly tighten screw (S - fig. 14) fully

then unscrew 1/4 turn at a time until

the appliance ignites smoothly.

Note : Turning the screw (S) clock-

wise delays ignition.

1

16

6)

)G

GA

AS

SC

CO

ON

NV

VE

ER

RS

SI

IO

ON

N

F

Fr

ro

om

mn

na

at

tu

ur

ra

al

lg

ga

as

st

to

ob

bu

ut

ta

an

n-

-p

pr

ro

op

pa

an

na

an

nd

d

v

vi

ic

ce

e-

-v

ve

er

rs

sa

a(fig. 16, 17, 18).

- Turn off gas at the gas service cock and

remove the front casing (see section 1,

front casing, p. 7).

-Unscrew the pilot tube clamping screw

(52) and remove pilot tube (8).

- Remove the burner manifold (7) by

unscrewing the four screws (53).

-Disconnect at thermo-electric valve by

undoing nut (54) and pull off the elec-

trode cable (55).

-Unscrew the two screws (56) and pull

burner forward to remove.

- Unscrew the four screws (57) and lift

the gas section top off the base.

- Unscrew the complete valve box (58).

- Replace the new complete valve box

fitted inside with a spring and the gas

valve (factory assembled).

- Replace the gas section top on the

base and screw the four screws (57).

- Replace the burner and screw the 2

screws (56).

- Re-assemble the thermo-couple nut

(54) and electrode cable (55).

- Change the pilot gasket (61) change

the pilot injector.

- Replace the new burner manifold with

the appropriate injectors and the man-

ifold restrictor (if planned).

Fasten the four screws (53).

- Replace the pilot tube (8) conform with

the new used gas and gently tighten

the screw (52).

56

57

54

55

M

S

O

P

Q

61 53

7

52

58

10

P

PR

RO

OB

BL

LE

EM

MC

CA

AU

US

SE

ER

RE

EM

ME

ED

DY

Y

L

LO

OW

WW

WA

AT

TE

ER

RI

I)

)Insufficient gas flow Check rate and user’s tap is open

T

TE

EM

MP

PE

ER

RA

AT

TU

UR

RE

E

I

II

I)

)Water governenor sticking Remove and clean or replace

I

II

II

I)

)Incorrect venturi Replace (3.65 mm)

I

IV

V)

)No venturi fitted Fit

B

BU

UR

RN

NE

ER

RS

ST

TA

AY

YS

SO

ON

NI

I)

)Air in pipework Check for “dead-legs”

I

II

I)

)Gas valve stays open Clean and grease gas spindle

I

II

II

I)

)Venturi blocked Remove and clean

I

IV

V)

)Dirt on gas valve facing Strip and clean gas valve

V

V)

)Loose jumper on house stop cock tap Replace water stop tap or pin down jumper

V

VI

I)

)Dirt foreign matter is water section Clean water section

V

VI

II

I)

)Slow ignition device stuck Clean and adjust (see page 4)

Y

YE

EL

LL

LO

OW

WF

FL

LA

AM

ME

ES

SI

I)

)Heating body fins blocked Remove heating body and clean

S

SO

OO

OT

TF

FO

OR

RM

ME

ED

D

I

II

I)

)Primary air supply restricted Check burner manifold and clean

I

II

II

I)

)Wrong injectors Replace manifold

U

UN

NS

ST

TA

AB

BL

LE

EF

FL

LA

AM

ME

ES

SI

I)

)Water in gas line Purge

I

II

I)

)Faulty flue Check terminal position and flue ducts

H

HE

EA

AT

TI

IN

NG

GB

BO

OD

DY

YI

I)

)Scale Descale heating body

N

NO

OI

IS

SE

E

I

II

I)

)Excessive gas Check gas pressure (see page 3)

I

II

II

I)

)Insufficient water flow See below

I

IN

NS

SU

UF

FF

FI

IC

CI

IE

EN

NT

TI

I)

)Water service tap partly closed Check it is fully opened

W

WA

AT

TE

ER

RF

FL

LO

OW

WI

II

I)

)Blocked venturi Remove and clean venturi

I

II

II

I)

)Low water pressure Check water pressure

I

IV

V)

)Water governor faulty Change governor

V

V)

)Water governor sticking Remove and clean or replace

V

VI

I)

)Foreign matter in water section Remove and clean

FAULT FINDING CHART FOR BRITONY II T

11

P

PR

RO

OB

BL

LE

EM

MC

CA

AU

US

SE

ER

RE

EM

ME

ED

DY

Y

P

PI

IL

LO

OT

TF

FL

LA

AM

ME

EI

I)

)Gas service tap closed Open service tap

D

DO

OE

ES

SN

NO

OT

TL

LI

IG

GH

HT

T

I

II

I)

)Air in pipe Purge line

I

II

II

I)

)Pilot injector blocked Clean or change

I

IV

V)

)No ignition spark Check electrode, lead and ignitor

P

PO

OO

OR

RP

PI

IL

LO

OT

TF

FL

LA

AM

ME

EI

I)

)Pilot injector dirty/damaged Clean or change

I

II

I)

)Wrong injector change for correct diameter (seeTable 1)

I

II

II

I)

)Pilot head blocked Clean

I

IV

V)

)Faulty pilot tube Clean or replace

P

PI

IL

LO

OT

TW

WI

IL

LL

LN

NO

OT

TI

I)

)Thermocouple not working Change thermocouple

S

ST

TA

AY

YA

AL

LI

IG

GH

HT

T

I

II

I)

)Thermo-electric valve faulty Change valve

I

II

II

I)

)Gas pressure low/variable Check at inlet to heater (see page 3)

I

IV

V)

)Terminal wrongly positioned Re-position heater (see page 4)

V

V)

)Badly assembled flue Refit-check sealing

V

VI

I)

)Gas pressure too hight Check with British Gas

M

MA

AI

IN

NB

BU

UR

RN

NE

ER

RI

I)

)Gas service tap not open fully Open fully

D

DO

OE

ES

SN

NO

OT

TL

LI

IG

GH

HT

T

I

II

I)

)Gas pressure low Check at manifold and at inlet with heater

I

II

II

I)

)Water rate low Check if water rate is sufficient (see page 3)

I

IV

V)

)Gas valve not opening Check (V) and (VI)

V

V)

)Diaphragm punctured Change diaphragm

V

VI

I)

)Venturi blocked or loose Check venturi

V

VI

II

I)

)Gas control tap faulty Check operation of User’s gas control tap

V

VI

II

II

I)

)Wrong injector Check for correct diameter (see Table 1)

I

IX

X)

)Slow ignition device stuck or wrongly adjusted Clean or adjust (see page 9)

E

EX

XP

PL

LO

OS

SI

IV

VE

EI

I)

)Pilot Check pilot tube and injector

I

IG

GN

NI

IT

TI

IO

ON

N

I

II

I)

)Slow ignition device stuck or wrongly adjusted Clean or adjust (see page 9)

G

GA

AS

SC

CO

ON

NT

TR

RO

OL

LT

TA

AP

PI

I)

)Grease dried Clean and regrease

S

ST

TI

IF

FF

F(

(U

US

SE

ER

R’

’S

S)

)

I

II

I)

)Operating mechanism replaced incorrectly Refit

FAULT FINDING CHART FOR BRITONY II T

Réf 91220174 f- 02/2003

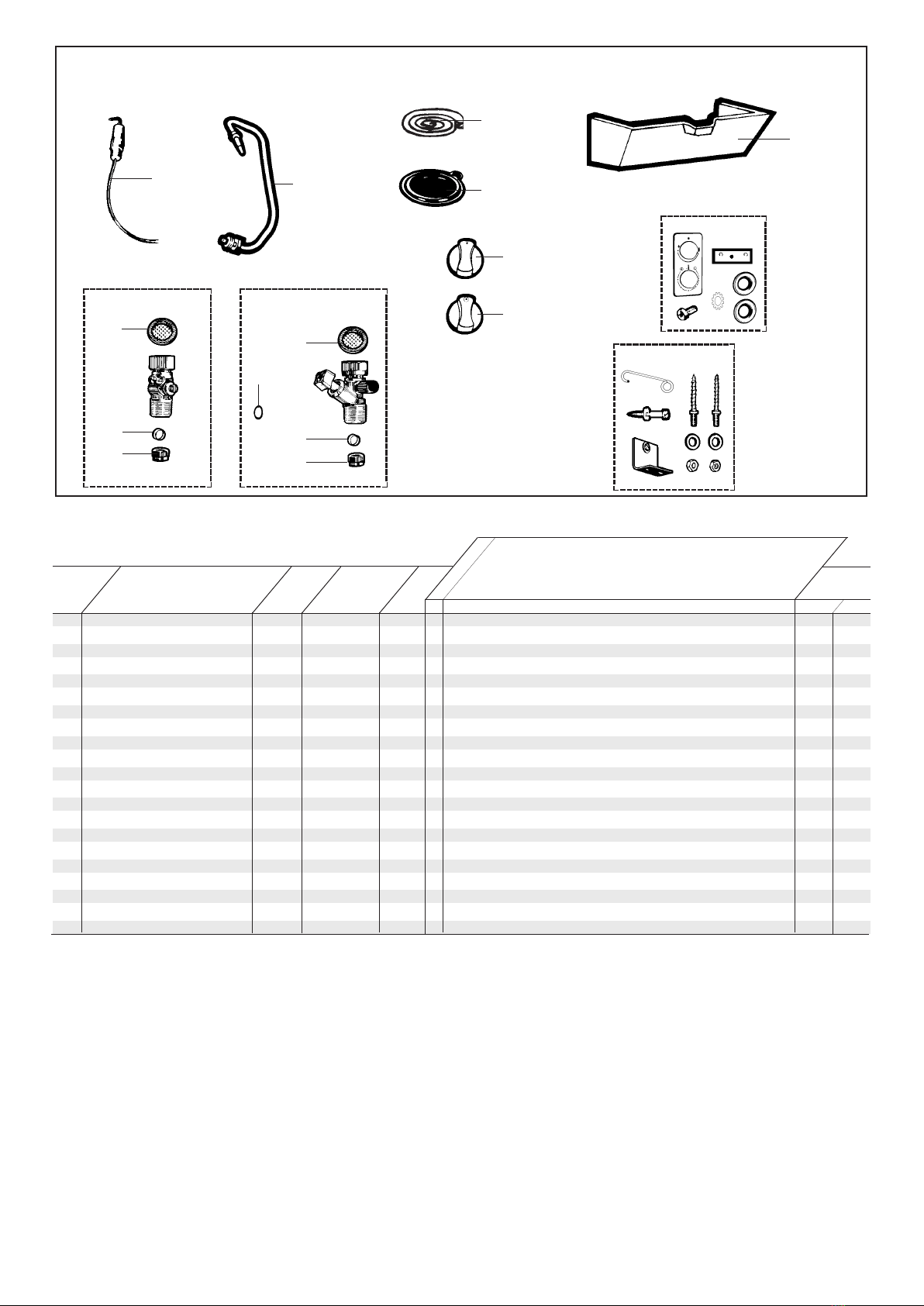

SHORT LIST

503

1038

1036

1019

165

634

930

931

907

1031

920

1006

1036

1043

1006

502

1001 1018

165 FOAM SEAL 25x12 L: 1.030M 366032 26773 .

502 THERMOCOUPLE 387251 35087 .

503 ELECTRODE & LEAD ASSY 387252 60703 .

634 DIAPHRAGM 263432 25809.30 .

907 FACIA KIT 264888 81172 HP .... 09/99

FACIA KIT 61400140 .02/03 ...

920 BOTTOM TRIM 1018809 .... 01/03

BOTTOM TRIM 61312266 .02/03 ...

930 GAS CONTROL KNOB 264487 74469 .... 01/03

GAS CONTROL KNOB 61312271 .02/03 ...

931 TEMPERATURE SELECTOR KNOB 264488 74470 .... 01/03

TEMPERATURE SELECTOR KNOB 61312270 .02/03 ...

1001 GAS SERVICE TAP KIT 265158 81288 NAT .

1006 COMPRESSION OLIVE 263800 56489 .

1018 WATER SERVICE TAP KIT 263794 81289 .

1019 WATER FILTER 277854 1007727 .

1031 FIXING ASSY 265160 81404 .

1036 NUT 1/2" 366642 56490 .

1038 GAS FILTER 263545 37309 .

1043 "O" RING D: 7.2-1.9 262806 24164.12 .

DescriptionKey N°

Manf. Pt. N°

Type

G.C N°

BF

Manf. date

BRITONY II T

from to

Chaffoteaux & Maury are continuously improving their products and therefore reserve the right to change specifications without prior

notice and accepts no liability for any errors or omission in the information contained in this document.

Manufacturer: Chaffoteaux & Maury - France

Commercial subsidiary: MTS (GB) Limited

MTS Building

Hughenden Avenue

High Wycombe

Bucks HP13 5FT

Telephone: (01494) 755600

Fax: (01494) 459775

Internet: www.chaffoteaux.co.uk

E-mail: [email protected]

Technical Support Help Line: 0870 241 8180

Customer Service Help Desk: 0870 600 9888

Table of contents

Other C&M Water Heater manuals

Popular Water Heater manuals by other brands

Rinnai

Rinnai Continuous Flow Water Heaters Operation manual

Giant

Giant RESIDENTIAL ELECTRIC WATER HEATER owner's manual

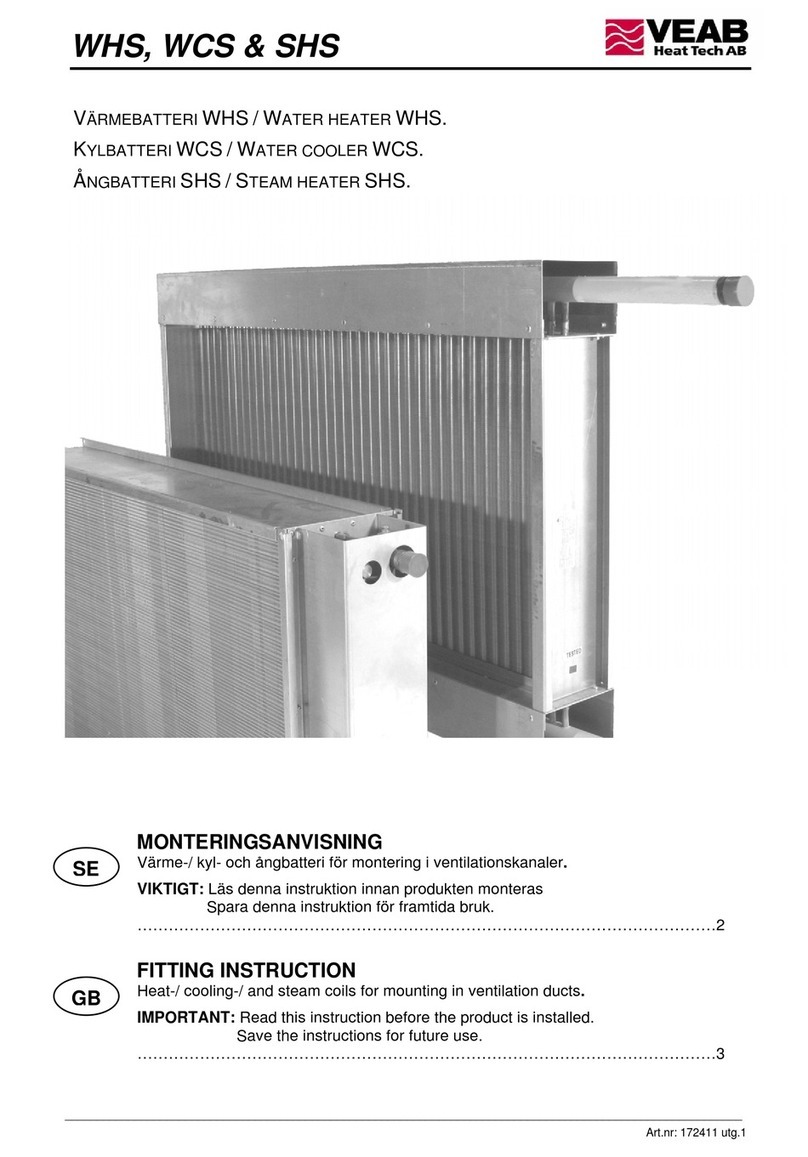

VEAB

VEAB WHS FITTING INSTRUCTION

Kenmore

Kenmore THE ECONOMIZER 153.333315 HA owner's manual

Solahart

Solahart Atmos Eco 180HAV Owner's guide and installation instructions

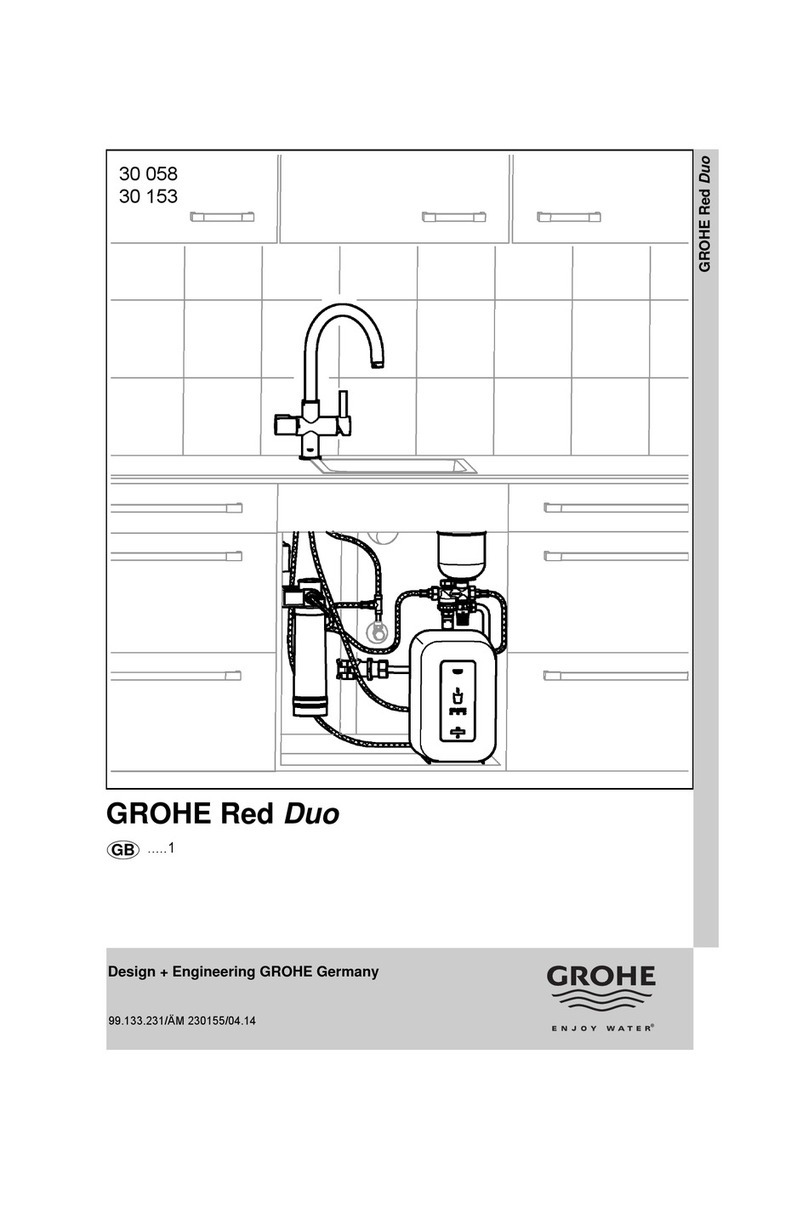

Grohe

Grohe Red Duo 30 058 Technical guide

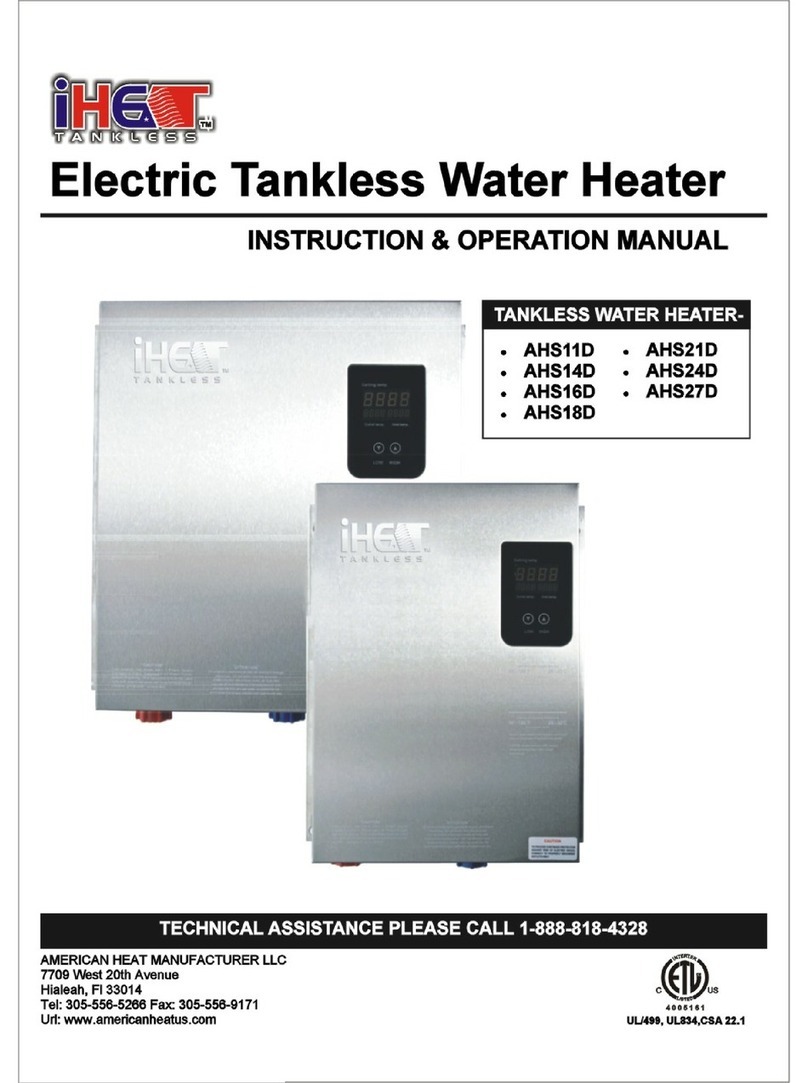

iHeat

iHeat AHS11D Instruction and operation manual

Kenmore

Kenmore POWER MISER 153.336151 owner's manual

Kenmore

Kenmore 153.338003 owner's manual

Watts

Watts Aerco SmartPlate EV Installation, operation & maintenance manual

A.O. Smith

A.O. Smith BTN 120 THRU 400/A Series Installation and operaion manual

Sony

Sony VPL-CX75 Operation instructions