2. Installation Requirements

3

2.1 Related Documents

The installation of the heater must be in accordance with the

relevant requirements of the Gas Safety (Installation and Use)

Regulations, Building Regulations and the Byelaws of the local

Water Undertaking. It should be in accordance also with any

relevant requirements of British Gas and local authority, and

the relevant recommendations of the following current British

Standard Codes of Practice :

BS 6891 : Specification for installation of low pressure

gas pipework up to 28 mm (Rl) in domestic

premises (2nd family gases).

BS 5546 : Installation of gas hot water supplies for

domestic purposes (second family gases).

BS 5440 : Flues and air supply for gas appliances of

rated input not exceeding 60 kW (1st, 2nd

and 3rd family gases).

Part 1 Flues

Part 2 Air Supply

2.2 Air Supply

IMPORTANT :This heater should be used in a well ventilated

room. An air vent direct to outside is required where the room

volume is less that 20 m3size in accordance with the following

table. In addition an openable window is required.

This heater must not be installed in a space less than 5 m3in

total volume.

This water heater is fitted with an atmospheric sensing device

which will turn off the gas supply to the pilot and burner, when

the oxygen in the atmosphere in the locality of the heater is

diminished and will not support safe combustion. It also pro-

tects the user if the heat exchanger fins become blocked.

It is therefore important that the heater is not located over a

cooker or in a position where the air supply is restricted or

contaminated.

The location must also permit space for servicing and air cir-

culation around the appliance.

2.3 Gas Supply

An adequate sized gas meter must be connected to the servi-

ce pipe. Where necessary British Gas will arrange for the exis-

ting meter to be checked or for a suitable meter to be installed.

On no account must any work be carried out on the gas meter

other than by British Gas or their specifically authorised

contractor.

Installation pipes should be fitted in accordance with BS 6891:

Pipework from the meter must be of adequate size. Pipes of a

smaller size than the gas connection should be not used,

The complete installation must be tested for gas soundness

and purged in accordance with BS 6891.

In addition to any other gas appliance installed in the pre-

mises, the meter should be capable of passing : 40 cu, ft/h of

natural gas.

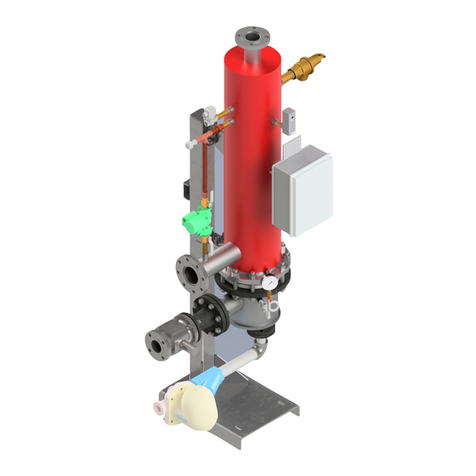

2.4 Description of Operation of Special Components

2.4.1 Atmospheric Sensing Device

The thermoelectric circuit is fitted with a thermal switch located

on the front of the combustion chamber of the heater. When the

oxygen in the atmosphere in the locality of the heater becomes

diminished and is unable to support safe combustion, the pro-

ducts of combustion pass through an orifice in the front panel

and the increase in temperature is detected by the thermal

switch. When the switch is activated it interrupts the thermoe-

lectric circuit and the pilot and main burner are extinguished.

2.4.2 Scale Reducer

The scale reducer is a diaphragm vessel forming part of the

water section. At the termination of a demand cycle the

contens of the heat exchanger are displaced into the vessel

and replaced with cold water.

2.5 Flue

These appliances are flueless. Protection is provided in the

form of the atmospheric sensing device (see Section 2.5.1).

They must not be operated continuously for more than five

minutes.

CONTROL OF SUBSTANCES HARMFUL TO HEALTH

IMPORTANT

To comply with the Control of Substances Harmful to Health

Regulations 1988 we are required to provide information on the

following substance that is contained in this appliance.

Description

Combustion Chamber

Material

Alumino Silicone Fibre

Precautions

During servicing, keep the dust generation to a minimum and

avoid inhaling any dust and contact with the skin and eyes.

Normal handling and use will not present any discomfort,

although some people with a history of skin complaints may be

susceptible to irritation.

When disposing of the lining ensure that it is securely wrapped

and wash hands after contact.

Room Permanent Openable

Volume Air vent Window

0 - 5 m3Installation

not permitted

5 m3- 10 m3100 cm2YES

11 m3- 20 m350 cm2YES

over 20 m3NIL YES