www.graf.info

17 / 50

5. Installation and assembly

5.1 Construction site

Under all circumstances, the following points must be clarified prior to installation:

The structural suitability of the ground according to DIN 18196

Maximum groundwater levels which occur and drainage capability of the subsoil

Types of load which occur, e.g. traffic loads

An expert ground report should be requested from the local planning authority to determine the physical

characteristics of the subsoil.

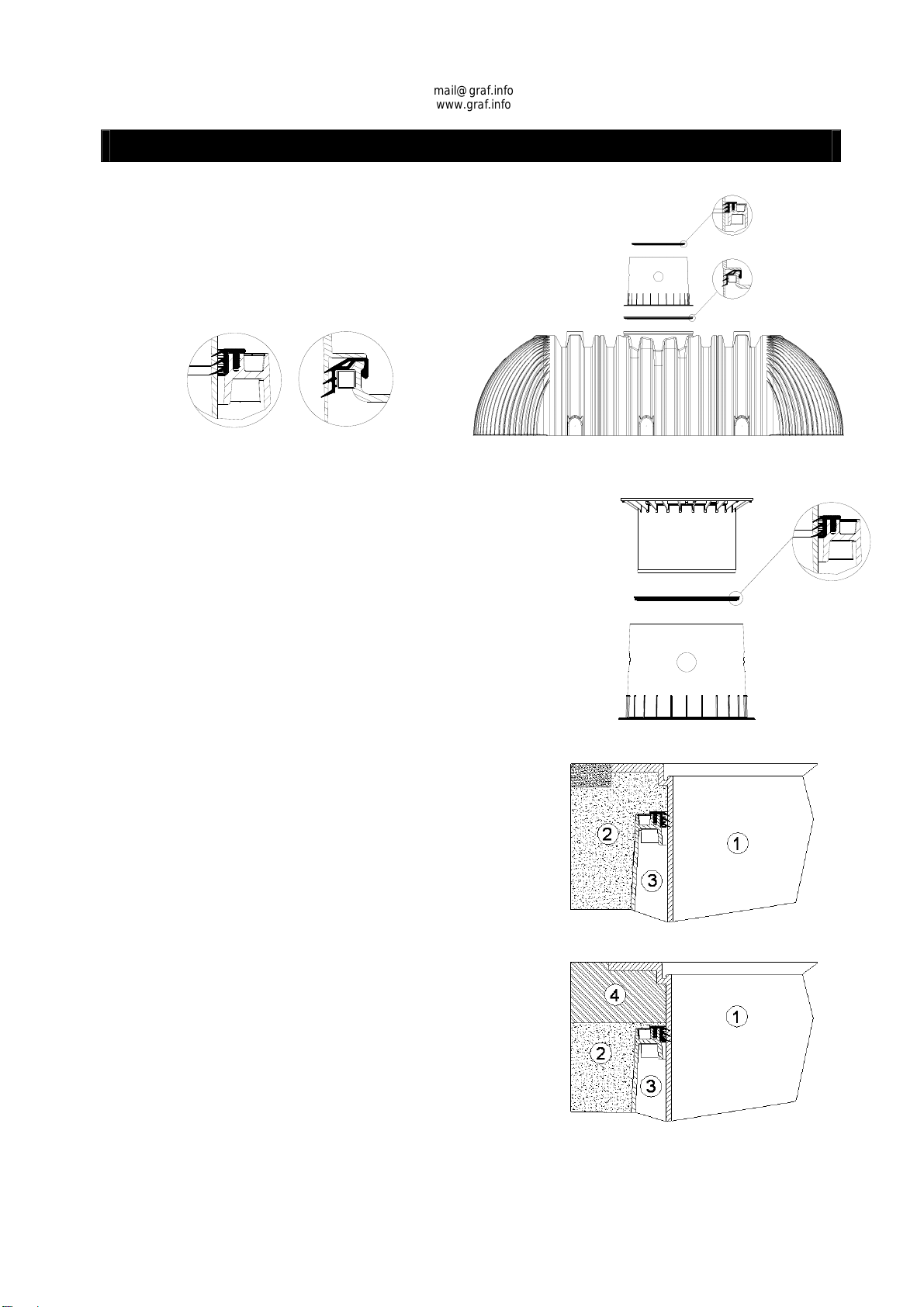

5.2 Trench

To ensure that sufficient space is available for working, the base area of the trench must exceed the di-

mensions of the tank by 500 mm on each side; the distance from solid constructions must be at least

1000 mm.

The embankment must be designed according to DIN 4124. The construction site must be horizontal and

plane and must guarantee sufficient load-bearing capacity.

The depth of the trench must be dimensioned so that the max. earth coverage (see point 2 – installation

conditions) above the tank is not exceeded. To use the system throughout the entire year, it is necessary

to install the tank and those parts of the system which conduct water in the frost-free area. The frost-free

depth is usually approx. 600 mm – 800 mm; precise information in this regard can be obtained from the

responsible authority.

A layer of compacted, round-grain gravel (grain size 8/16, thickness approx. 150 - 200 mm) is applied as

the foundation.

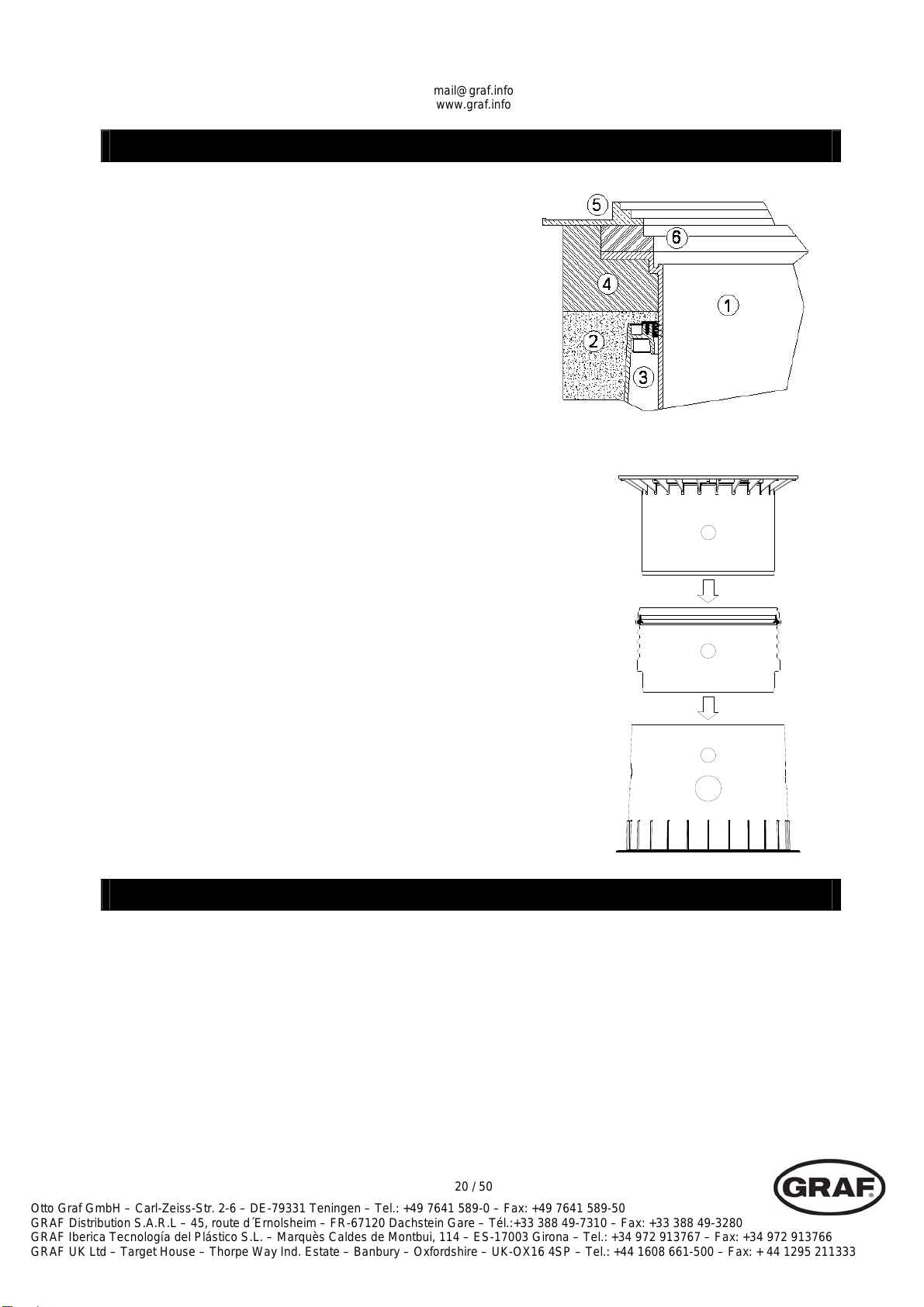

5.2.1 Slope, embankment, etc.

On installation of the tank in the immediate vicinity (< 5 m)

of a slope, earthen mound or slope, a statically calculated

supporting wall must be erected to absorb the soil pressure.

The wall must exceed the dimensions of the tank by at least

500 mm in all directions, and must be located at least

1000 mm away from the tank.

5.2.2 Groundwater and cohesive (water-impermeable)

soils (e.g. clay soil)

With only occasional ground water and cohesive, water-

impermeable soils (e.g. loam), adequate drainage of the

ground water or leakage water must be ensured so that the

tanks never stand deeper in the ground water than indicated

in the table. If necessary, the drainage line must end in a

vertical DN 300 pipe in which an

immersion pressure pump is installed to pump off the exces-

sive water. The pump must be checked at regular intervals.

If it is to be expected that the tanks could sink lower, ade-

quate drainage must be ensured in all cases.

We recommend the general laying of a drainage line, since

in the event of prolonged rainfall the ground water level can

rise unexpectedly.

5.2.3 Installation adjacent to surfaces used by vehicles

If the underground tanks are installed adjacent to surfaces

which are used by heavy vehicles weighing over 12 t, the

minimum distance away from these surfaces is at least the

depth of the trench.

Tank size All tank size

Immersion depth 1275 mm