3

WARRANTY ............................................................................. 4

Certifications and Approvals ................................................. 4

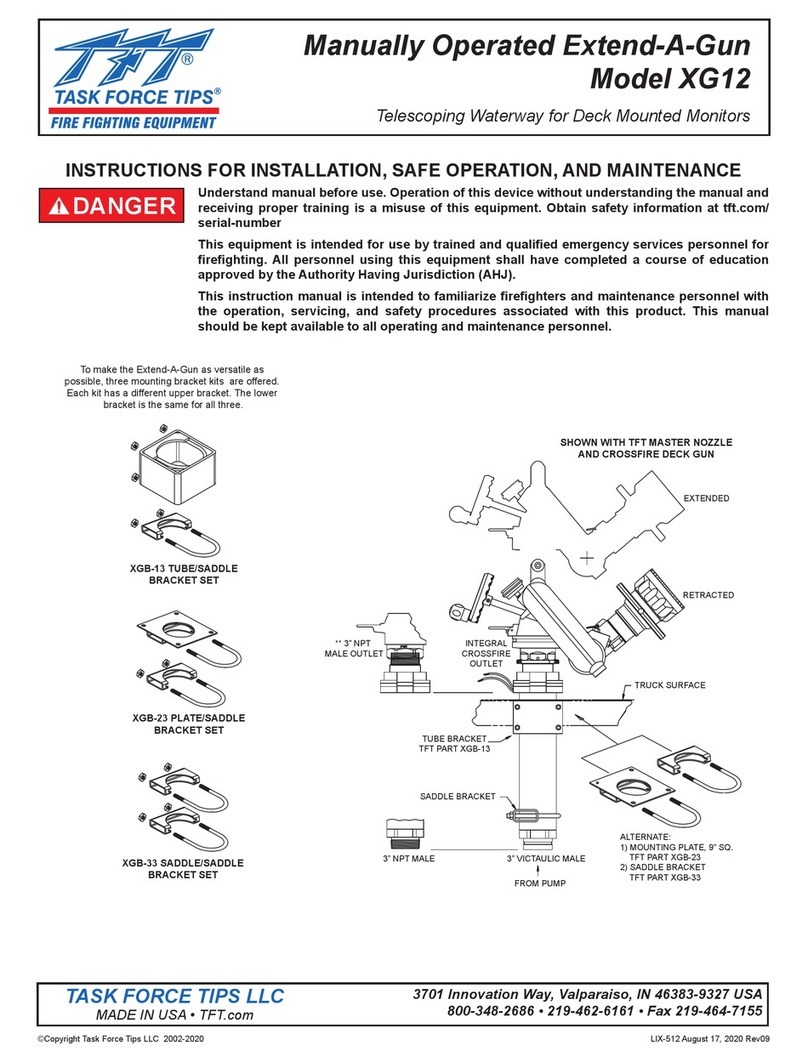

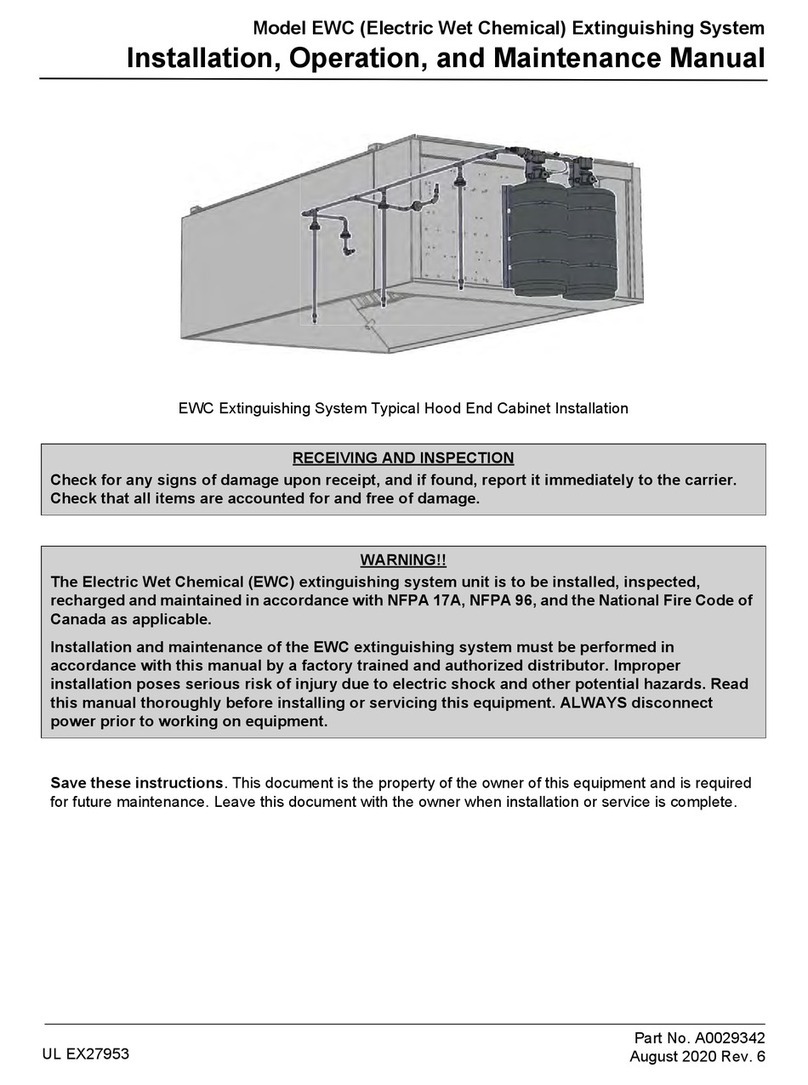

System Overview .................................................................. 4

COMPONENTS ....................................................................... 5

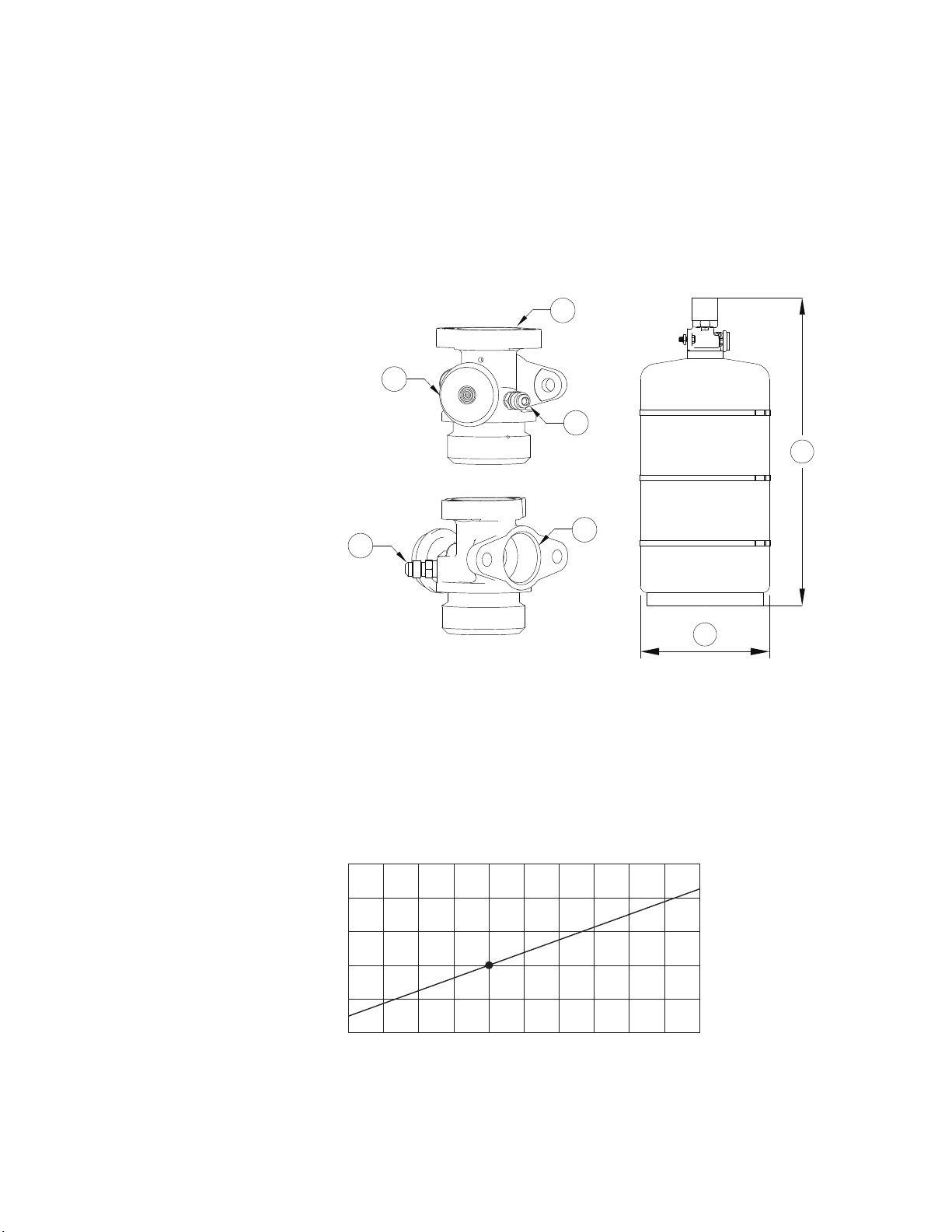

Cylinder Assembly ................................................................ 6

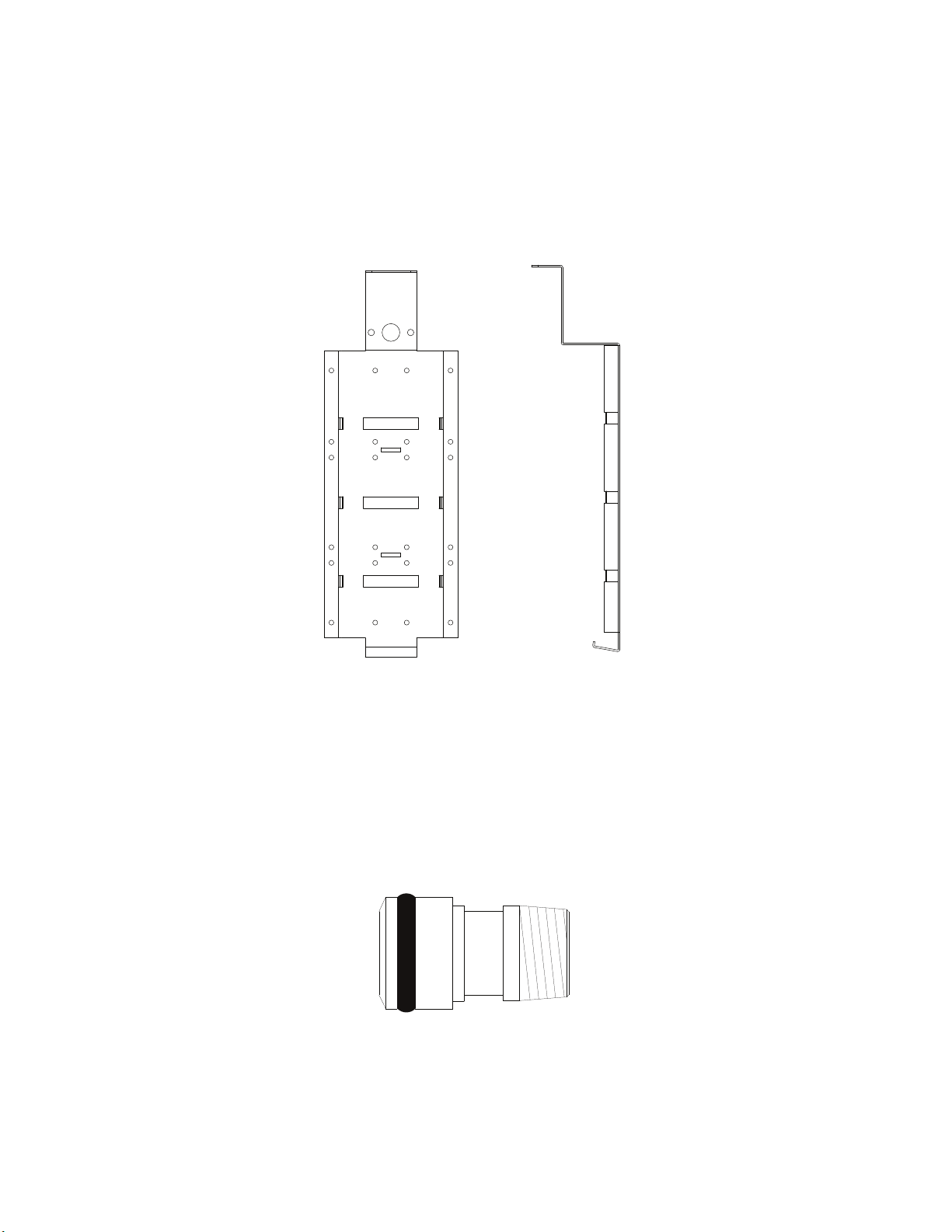

Cylinder and Actuator Bracket .............................................. 7

Discharge Adapter ................................................................ 7

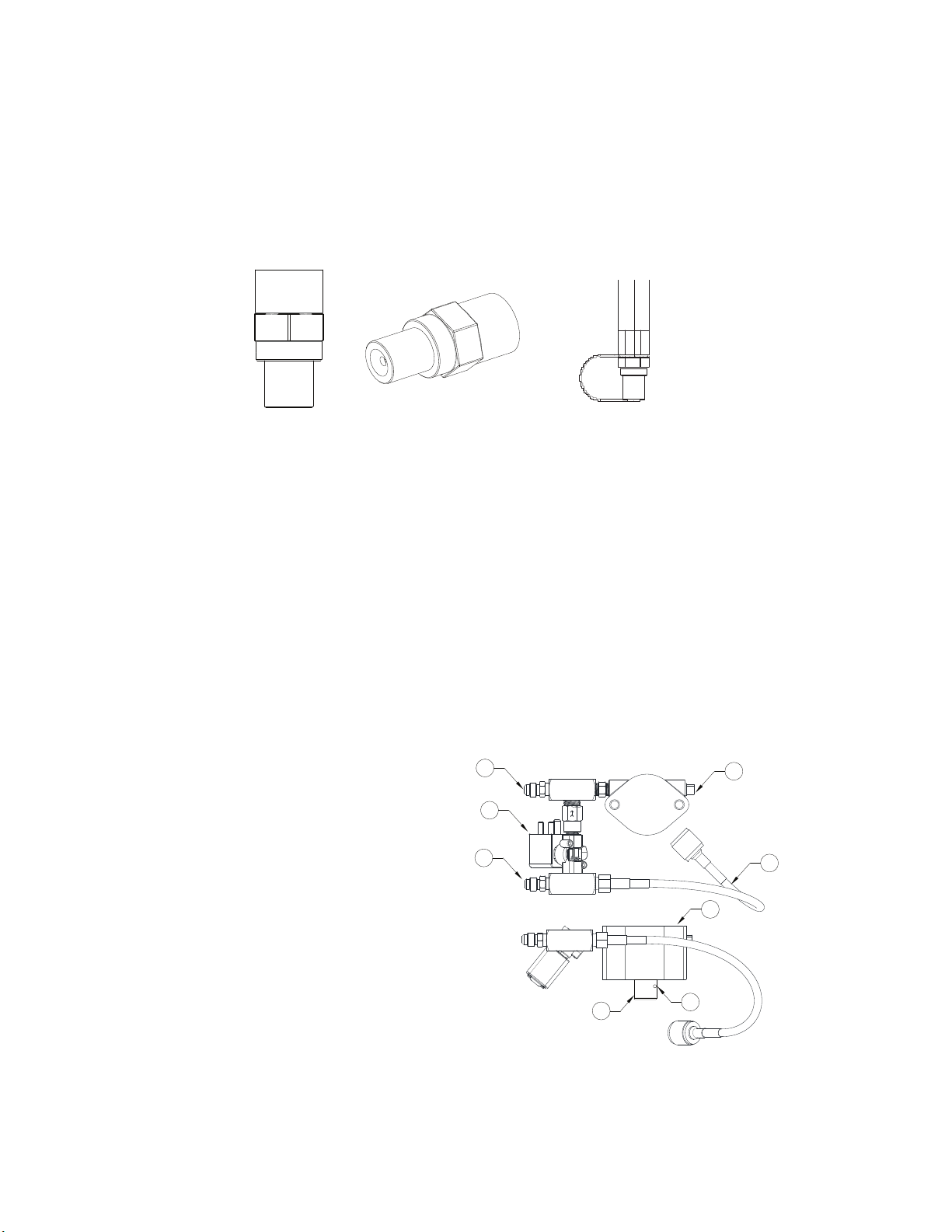

Nozzles ................................................................................. 8

Primary Actuator Kit (PAK) ................................................... 8

Secondary Valve Actuator (SVA) and Hose ......................... 9

Supervisory Pressure Switch ................................................ 9

Gas Shut-Off Valves ........................................................... 10

Electric Remote Manual Release ....................................... 10

Firestat (Heat) Detector ...................................................... 10

INSTALLATION ...................................................................... 11

Cylinders ............................................................................. 11

Primary and Secondary Actuator Installation ...................... 12

Primary Actuator Kit (PAK) ................................................. 12

Secondary Valve Actuator .................................................. 13

Supervisory Pressure Switch .............................................. 14

Duct and Plenum Protection ............................................... 15

Plenum Protection ........................................................... 15

Duct Protection ................................................................ 16

Ventilation Exhaust and Dampers ...................................... 18

Electrostatic Precipitators (ESP) ......................................... 18

Appliance Protection ........................................................... 19

Overlapping Appliance Protection ................................... 19

Appliance Coverage ........................................................... 20

Coverage Exceptions ...................................................... 21

Overlapping Protection .................................................... 23

Overlapping Coverage - Group Protection ...................... 23

Upright Broiler/Salamander Protection ............................ 26

Appliance with Shelf ........................................................ 27

Wok Protection ................................................................ 28

Large Wok Protection ...................................................... 29

Appliance with Upright Obstruction ................................. 30

Appliance with Overhead Salamander ............................ 31

Pizza Ovens .................................................................... 32

Agent Distribution Piping .................................................... 34

Single Cylinder Nozzle and Piping Parameters ............... 35

Dual Cylinder Nozzle and Piping Parameters ................. 35

Nozzle Installation ........................................................... 36

Gas Shut-Off Valves ........................................................ 37

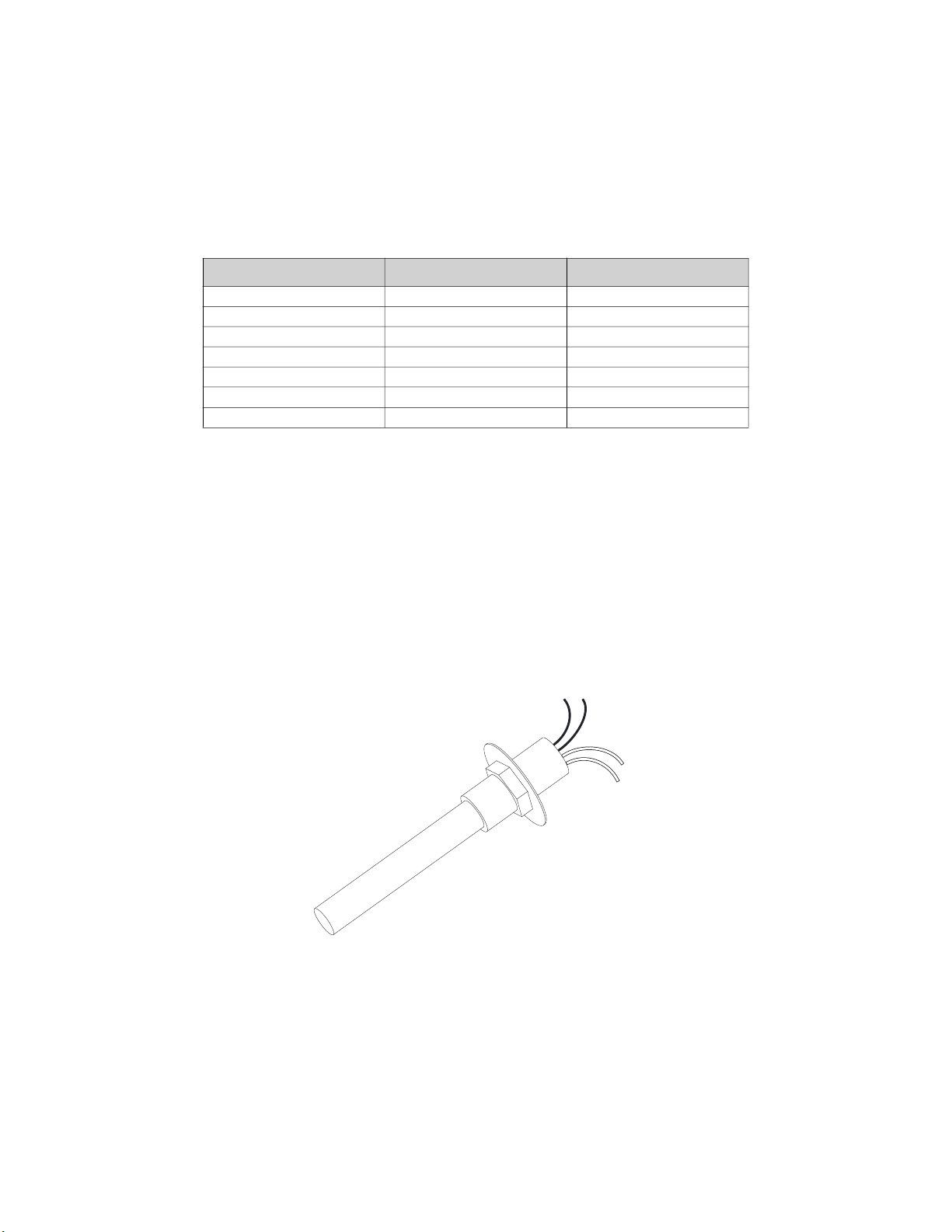

Fire Protection System Firestat .......................................... 38

Non-Solid Fuel Appliances (Rated 450°F) ....................... 38

Non-Solid Fuel Appliances (Rated 600°F) ....................... 38

Solid Fuel Appliances (Rated 700°F) .............................. 38

Hood Riser Sensor Replacement ....................................... 40

Fire Protection Manual Actuation Device ............................ 41

Trouble Input Wiring ........................................................... 41

Battery Backup ................................................................... 42

Power Supply Adjustment ................................................... 42

Fire Protection System Printed Circuit Board .................. 43

ELECTRICAL ......................................................................... 46

Wire Ampacity Rating ......................................................... 47

Distance Limitations ............................................................ 47

Fire Alarm Contacts ............................................................ 47

Fire Group ........................................................................... 48

Fire Protection System Supervised Loops .......................... 49

OPERATION .......................................................................... 50

Test Mode Overview ........................................................... 50

Reset Overview .................................................................. 51

TROUBLESHOOTING ........................................................... 53

Appliance Shutdown in Fault Conditions ............................ 54

Local Alarm Muting .......................................................... 54

Test Mode ....................................................................... 54

Supervised Loop Wiring Troubleshooting ........................... 55

DIP Switch Settings ......................................................... 56

Typical DIP Switch Arrangement ..................................... 57

INSPECTION AND TEST ...................................................... 58

Start-up/Test Procedure ..................................................... 58

Preparing System for Test ............................................... 58

Connecting Service Test Tank to the System ................. 58

Test Procedure ................................................................ 59

Disconnecting Service Tank/Re-arming System ............. 60

MAINTENANCE ..................................................................... 61

Every Month (System Owner) ............................................ 61

Every Six Months (Authorized Distributor) .......................... 62

Every Twelve-Years ........................................................... 62

Agent Cylinders ............................................................... 62

Actuation Hoses .............................................................. 62

Conditional Maintenance .................................................... 63

Replacing A Primary Actuation Kit .................................. 63

Replacing A Secondary Valve Actuator .......................... 63

Mobile Kitchen Decommissioning/Commissioning .......... 64

POST-DISCHARGE MAINTENANCE ................................... 65

General Information ............................................................ 65

Appliance Cleanup ............................................................. 65

Cleaning Distribution System ............................................. 65

Cleaning Nozzles ................................................................ 65

Flushing the Distribution Pipe Network ............................... 66

Flushing Procedure with Spare/Test Cylinder .................... 66

Flushing Procedure with an External Water Supply ........... 67

Cylinder Maintenance ......................................................... 67

Removing a Cylinder .......................................................... 68

Depressurizing a Cylinder ............................................... 69

Installing a Cylinder ......................................................... 70

Rechecking the System ................................................... 70

TANK FIRE SUPPRESSION SYSTEM PARTS .................... 71

Start-Up and Maintenance Documentation ........................ 72

Job Information ................................................................... 72

Table of Contents