vent-captor Typ 3202.30 (3205.30)

Installation and Adjustment Instructions

Please read carefully! No iabiIity can be accepted for damage

caused by improper use of the captor!

Sensors Ltd . · Strohdeich 32 · D-25377 Kollmar Tel.: +49 4128-591

Technical data subject to alteration! Rev. AB / 20.08.15

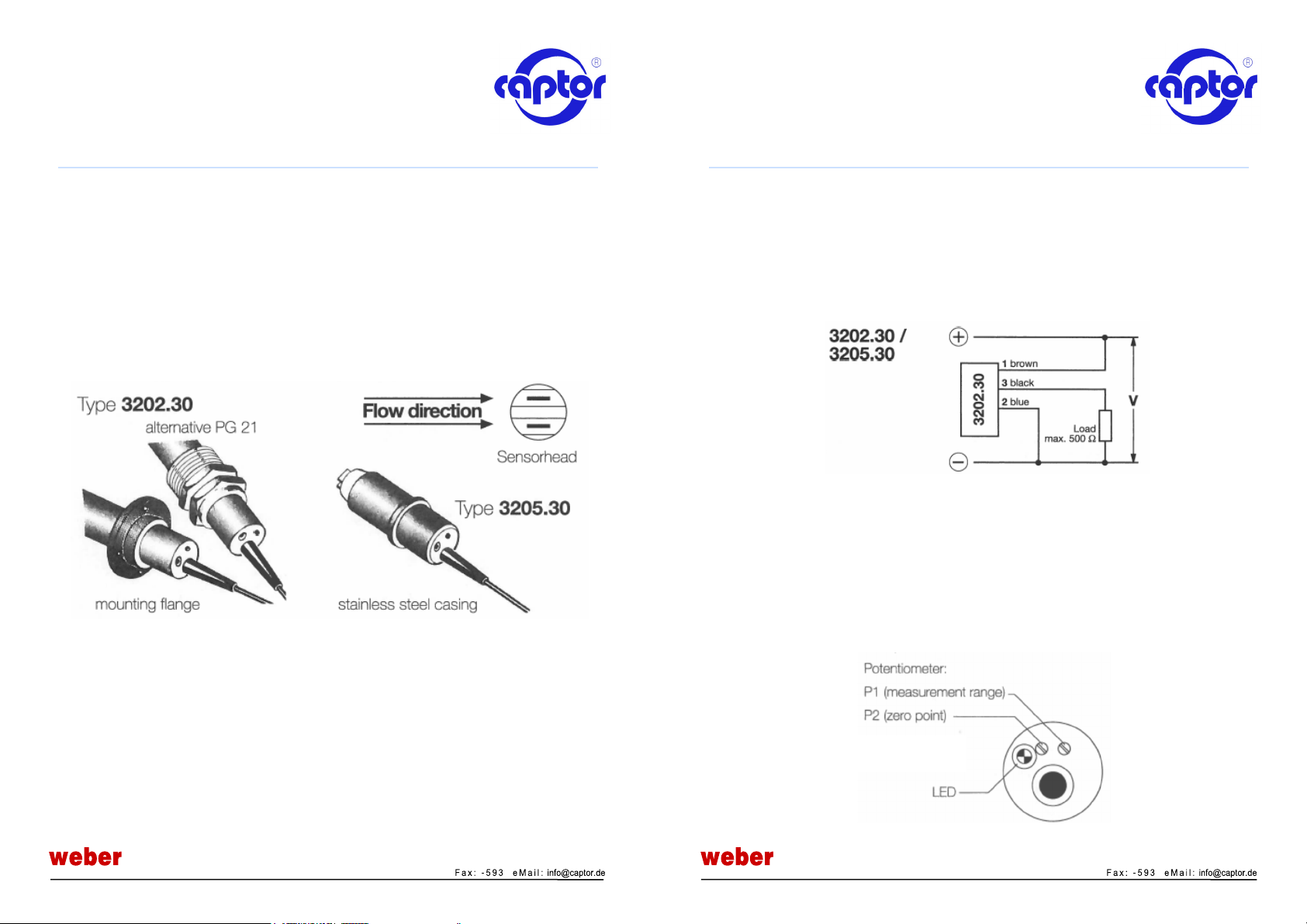

1.0 vent-captor Type Number

1.1Type 3202.30: type number printed on housng

1.2 Type 3205.30: type number indicated on adhesive label

1.3 Measurement range: stamped on cable (eg. 0 - 20 m/s)

1.4 ldentfication ot special version: stamped on cable (eg. S100)

2.0 Installation Instructions

2.1 Installation Depth

Dependent upon duct diameter, min15 mm,

2.2 Orientation

Position the ceramic sensor elements so that they are parallel

to the direction of flow, as illustrated below.

2.3 Installation Site

Optimal installation is with a straight free run of 5-7 x ID diameter upstream

and 3-5 x ID diameter downstream ot the vent-captor.

2.4 Installation of Type 3202.30 with Mounting Flange

Drill 21 mm hole and 4 screw holes in wall of air-duct. Secure the mounting

flange with the 4 screws provided. Push vent-captor into duct and secure by

tightening the locking screw on the side of the flange. Sealing hp on flange

provides secure tiffing. Alternatively a PC 21 connector may be used

(see “items delivered“) Metal PC 21 tiffings are modified by the manufacturer.

ModiFication is indicated by a ‘1 on the fiffing‘s hexagon nut.

Sensors Ltd . · Strohdeich 32 · D-25377 Kollmar Tel.: +49 4128-591

Technical data subject to alteration! Rev. AB / 20.08.15

vent-captor Typ 3202.30 (3205.30)

Installation and Adjustment Instructions

Please read carefully! No iabiIity can be accepted for damage

caused by improper use of the captor!

2.5 Installation of Type 3205.30

Fit the 0-ring over the front of the vent-captor and push back to the flange.

lnsert the vent-captor into the previously mounted 1“-flifing and secure with the

union nut provided. The fitting (available as separate accessory) is designed to

ensure the optimal insertion depth of the vent-captor.

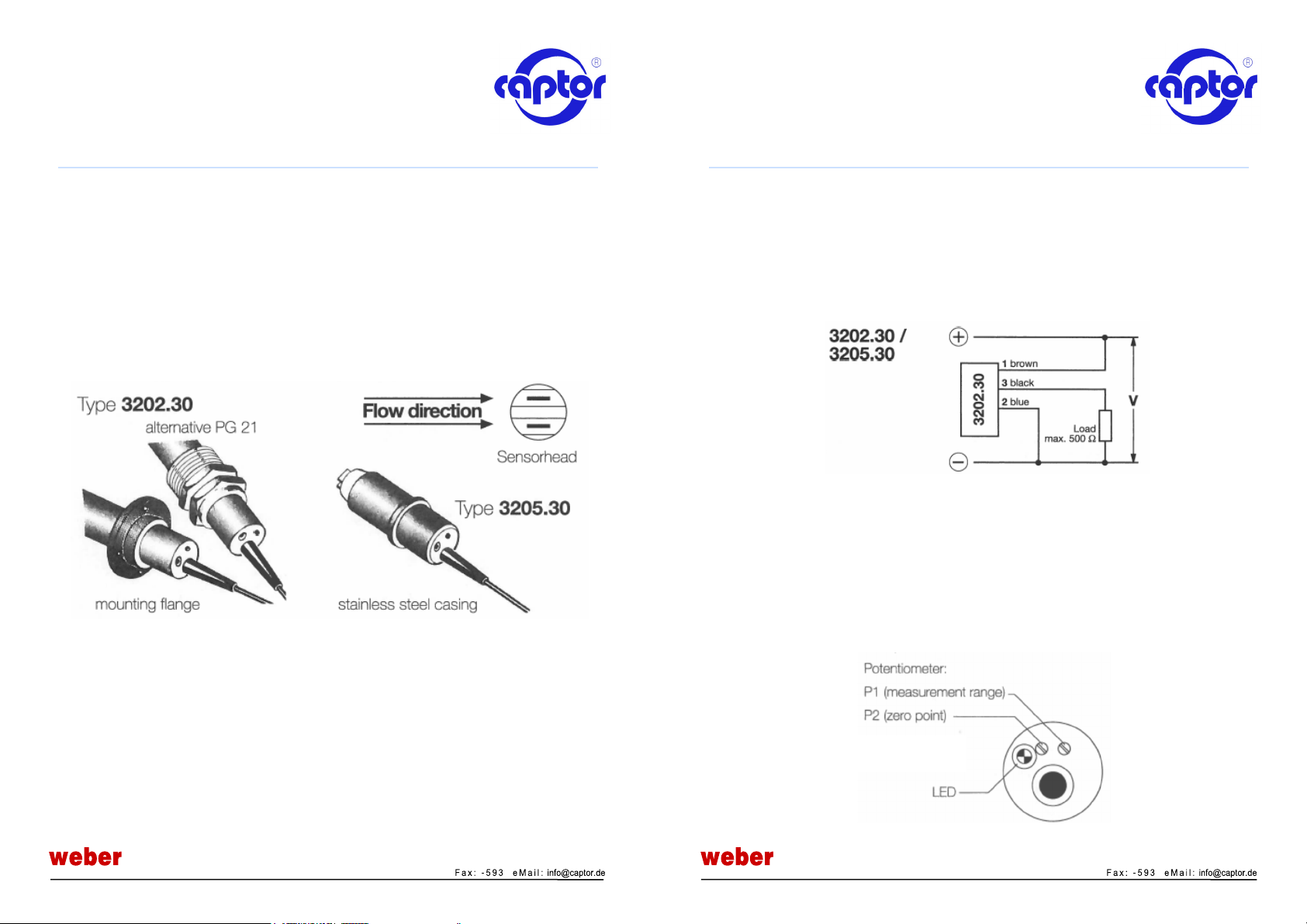

2.6 Powering Up

Connect the vent-captor to 24 V DC as in connection diagram and wait approx.

5 minutes before commencing adjustment.

3.0 Initial State

3.1 The zero point potentiometer P2 s adjusted ex works to 4 mA.

3.2 The range potentiometer Pl is adjusted to the extreme clockwise position.

3.3 Where ex works adjustment of measurement range has been requested,

both potentiometers are seated with silicone. Adjustment is carried out under

manufacturer‘s test rig conditions. Under different installation conditions on

site, deviations in output signal may be possible.

N.B. 18-turn potentiometers are employed with no mechanical end point.