Directions for Use

Alaris®SE Pump

Models 7130/7131, 7230/7231

iii

Table of Contents

GENERAL INFORMATION

WARNINGS AND CAUTIONS...................................................................................................................................................................... 105

General......................................................................................................................................................................................................... 105

Guardrails®Suite MX ............................................................................................................................................................................. 106

Administration Sets................................................................................................................................................................................. 107

Epidural Administration ......................................................................................................................................................................... 107

Electromagnetic Compatibility............................................................................................................................................................ 108

BATTERY MANAGEMENT SYSTEM........................................................................................................................................................ 109

Battery Power Gauge and Indicator ................................................................................................................................................ 110

Battery Recharge..................................................................................................................................................................................... 110

FLOW SENSOR .................................................................................................................................................................................................. 110

ALERTS COUNTER.......................................................................................................................................................................................... 112

Definitions ................................................................................................................................................................................................... 112

Viewing Alerts Counter ......................................................................................................................................................................... 113

NURSE CALL (7130/7230 ONLY)............................................................................................................................................................... 114

Activating Nurse Call Feature............................................................................................................................................................. 114

If an Alarm Occurs .................................................................................................................................................................................. 114

POLE CLAMP ...................................................................................................................................................................................................... 115

Changing Pole Clamp Orientation.................................................................................................................................................... 115

RS-232 COMPUTER LINK............................................................................................................................................................................. 116

Connecting to a Computer................................................................................................................................................................... 116

Disconnecting from a Computer ....................................................................................................................................................... 117

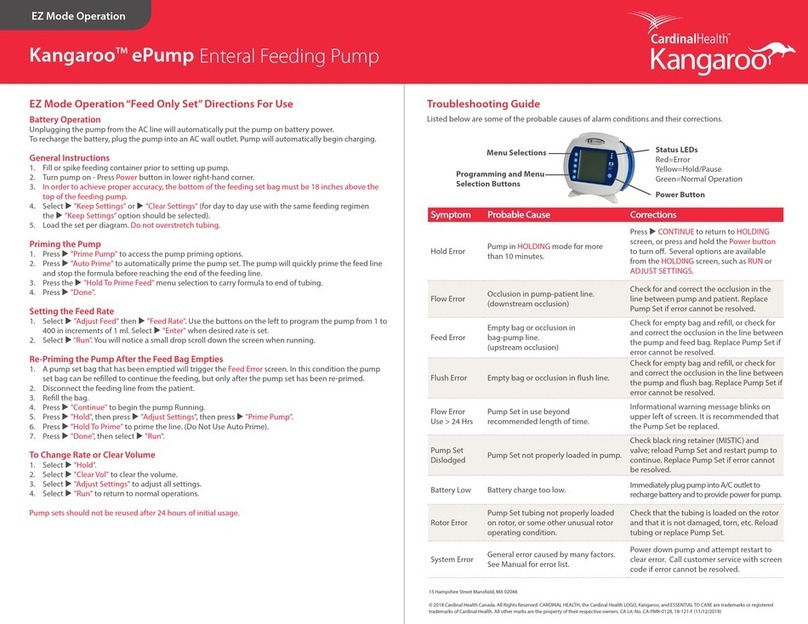

FEATURES AND DISPLAYS......................................................................................................................................................................... 118

Operating Features, Controls, Indicators ...................................................................................................................................... 118

Displays........................................................................................................................................................................................................ 121

Feature Definitions .................................................................................................................................................................................. 122

CONFIGURABLE SETTINGS ...................................................................................................................................................................... 123

Configurable Option Definitions-General...................................................................................................................................... 124

Configurable Option Definitions-Guardrails®Suite MX........................................................................................................... 128

Configurable Options ............................................................................................................................................................................. 129

System Configurable Options ............................................................................................................................................................ 130

SPECIFICATIONS.............................................................................................................................................................................................. 130

SYMBOLS AND TERMS................................................................................................................................................................................. 134

TRUMPET AND START-UP CURVES ..................................................................................................................................................... 137

Pressure Mode.......................................................................................................................................................................................... 138

Resistance Mode ..................................................................................................................................................................................... 140

High Resistance Mode .......................................................................................................................................................................... 142

TROUBLESHOOTING AND MAINTENANCE

GENERAL.............................................................................................................................................................................................................. 143

AIR IN LINE ASSEMBLY................................................................................................................................................................................. 143

SINGLE OR ACCUMULATED AIR BUBBLE DETECTION (NO RESET FEATURE).......................................................... 144

ALARMS, ALERTS, PROMPTS .................................................................................................................................................................. 145

Alarms........................................................................................................................................................................................................... 146

Alerts............................................................................................................................................................................................................. 150

Prompts........................................................................................................................................................................................................ 151

INSPECTION REQUIREMENTS................................................................................................................................................................. 156

CLEANING ............................................................................................................................................................................................................ 156

SERVICE INFORMATION.............................................................................................................................................................................. 158

Technical Support.................................................................................................................................................................................... 158

WARRANTY ......................................................................................................................................................................................................... 159