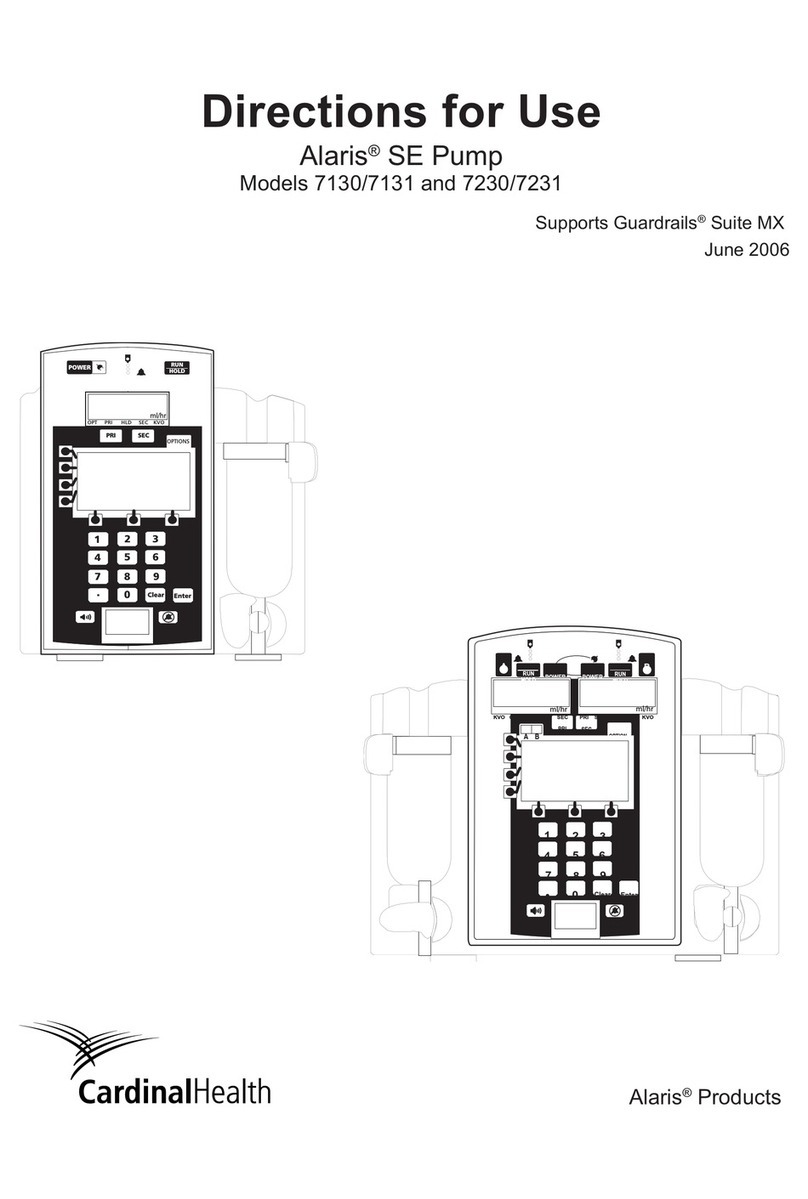

IVAC® Volumetric Pump (Models 571 & 572) 10/104 1000SM00018 Issue 2

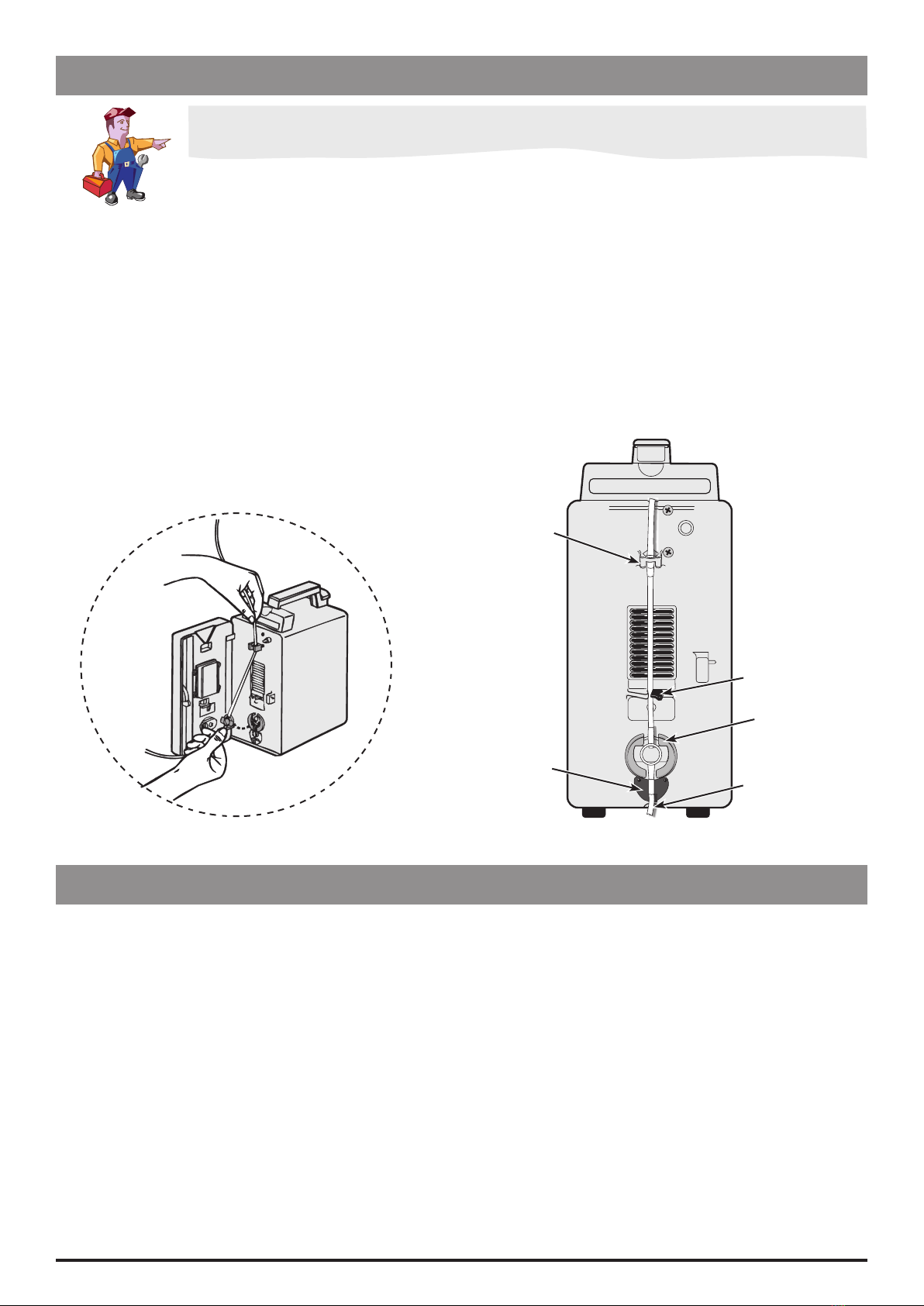

Introduction and Start Up

Changing the infusion rate

1. Press the RUN/HOLD switch to place the pump on hold.

2. Press the RATE switch.

3. Use the JK switches to set the new rate.

4. Restart the pump at the new rate by pressing the RUN/

HOLD switch.

Clearing the total Volume Infused

1. Press the RUN/HOLD switch to place the pump on hold.

2. Press and hold the TOT VOL INF switch and the K

switch directly above simultaneously for 2 seconds until

display shows 000.0.

3. Resume infusion by pressing the RUN/HOLD switch.

Changing the Volume To Be Infused

1. Press the RUN/HOLD switch to place the pump on hold.

2. Press the VOL TO BE INF switch.

3. Set new volume by pressing the JK switches. OFF can

also be selected when a flow sensor is in use, see Notes

below.

4. Restart the pump by pressing the RUN/HOLD switch.

Notes:

1) Without a flow sensor in use, a VTBI value must be entered,

otherwise, the pump will be unable to operate.

2) With a flow sensor in use, a VTBI value isn't required and

OFF can be selected if required.

Programming

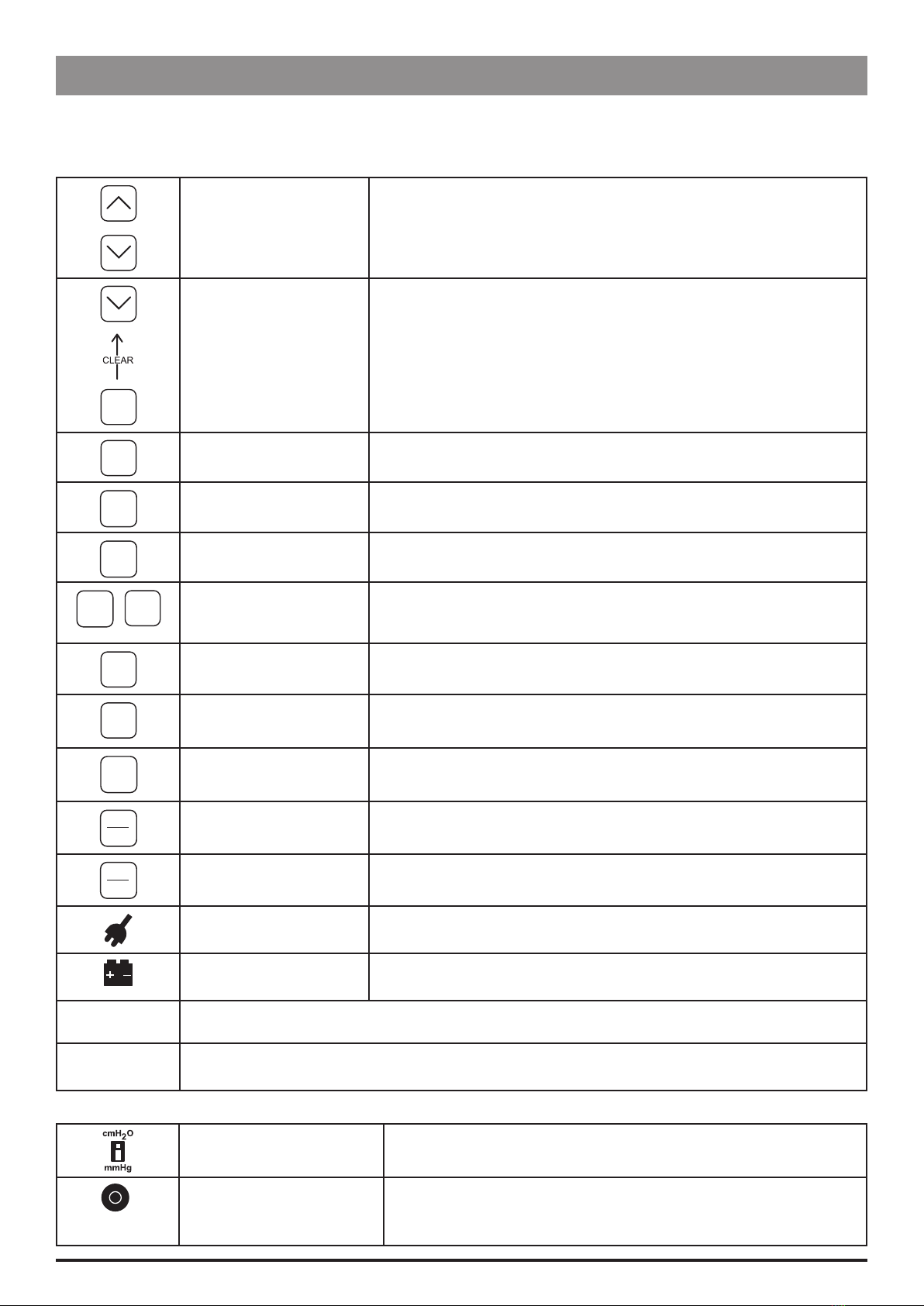

Adjusting the maximum pressure limit

(Occlusion pressure alarm level)

1. Simultaneously press and hold the LIMIT PRES

switch whilst using the JK switches to adjust

the pressure limit.

2. Release the LIMIT PRES switch.

Note: Pressure value will be displayed in mmHg or in

cmH20 depending on unit selected. See 'Pressure

Unit Selector'.

Reading the pressure

1. Press and hold the READ PRES switch. Wait at least

10 seconds to allow reading to stabilize.

Note: Pressure value will be displayed in mmHg or

in cmH20 depending on unit selected. See 'Pressure

Unit Selector'.

Selecting alternating display of total

volume infused

1. Press and release the TOT VOL INF switch three

times within 2 seconds while the pump is infusing or

on hold.

On Model 572, the display will alternate between

primary or secondary infusion and total volume

infused.

On Model 571, the display will continuously

show the total volume infused.

Selecting alternating display of infusion

pressure

1. Press and release the READ PRES switch three times

within 2 seconds while the pump is infusing or on

hold.

On Model 572, the display will alternate between

primary or secondary infusion and infusion

pressure.

On Model 571, the display will continuously

show the infusion pressure.

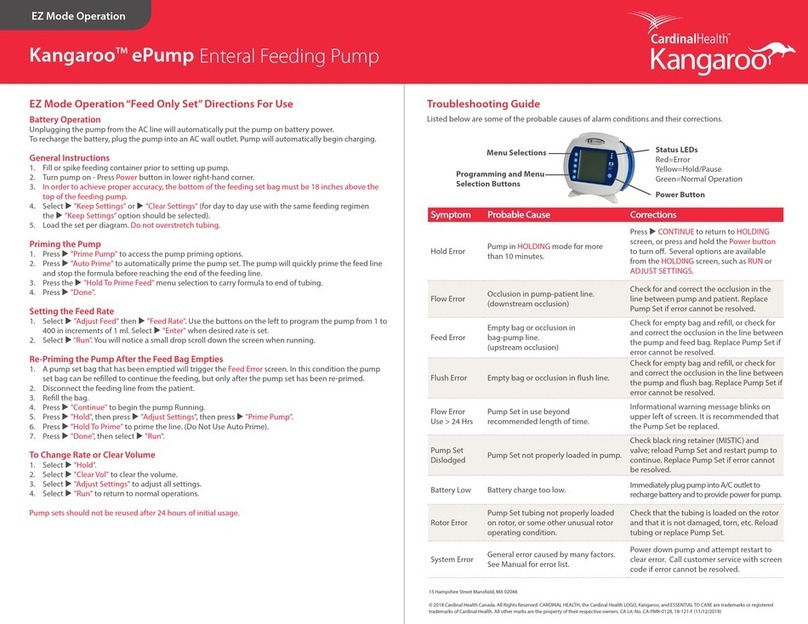

Operating on Battery Power

The pump operates on battery power when it is disconnected from the AC power. The battery power indicator, the

Information and Numeric Displays will flash whenever the pump is on battery power. In the event of a power failure, the

pump will automatically continue to operate on battery power.

Two alarms indicate the condition of the pump's battery:

LOW BATT alternating with the selected volume or pressure status. This indicates that approximately 30 minutes of

operating time remains on battery power

LOW BATT (constant). This indicates that the battery is discharged. Connect the pump to an AC power supply to

recharge the battery.

Note: The pump's battery is designed for limited duration use. Wherever possible, the pump should be used connected

to an AC power supply. If the pump is to be taken out of service for an extended period, it is good practice to charge the

battery periodically to ensure full capacity.