76

WARNING!

Potential hazard that could result in serious personal injury to

the tool user or others in the work area.

• Always wear eye and hearing protection when using the air compressor. Failure

to do so may result in sight or hearing loss.

• Do not overload the tool. Allow the tool to operate at its optimum speed for

maximum efficiency.

• Do not point the tool towards yourself or other people, even when the tool has

stopped. Keep hands, feet, and all other parts of the body clear from work area.

• Do not attempt to clear nailer jams while the air hose is connected.

• Do not keep the trigger or the Push Lever pressed while loading nails.

SAFETY GUIDELINES

SAFETY GUIDELINES

NOTE: Some commercial air line drying liquids are harmful to “O” rings and seals—

Do not use these low temperature air dryers without checking compatibility.

SAFETY GUIDELINES

CAUTION!

• DANGER! Potential hazard that could result in serious personal

injury including possible death.

• Do not use oxygen or any other combustible or bottled gas to

power air-powered tools. Failure to observe this warning can

cause explosion and serious personal injury or death.

• Do not use this tool in the presence of flammable liquids, dust or gases. Sparks that

are created during use may ignite these materials.

• Use only compressed air to power air-powered tools. Use an approved air hose with

a minimum length of 25' (7.6 m).

• Do not allow inexperienced or untrained individuals to operate any air-powered tool.

• Keep hands and other parts of the body away from the Outlet (Firing Head) during use.

• Nails or objects in the workpiece can cause serious injury if they are deflected by the

workpiece.

• Keep children away from the work area. Do not allow children to handle power tools.

• Never point nailer toward yourself or anyone else.

• Always assume the nailer contains fasteners. Never point the nailer toward yourself or

anyone else, whether it contains fasteners or not. If fasteners are mistakenly driven, it

can lead to severe injuries. Never engage in horseplay with the nailer. Respect the

nailer as a dangerous working implement.

• Disconnect the tool from the air supply and turn off the

compressor before performing any maintenance, when the

tool is not in use, when it is being handed to another person,

when it is left unattended, or when loading and changing

nails. Failure to comply may result in injury or damage to

equipment.

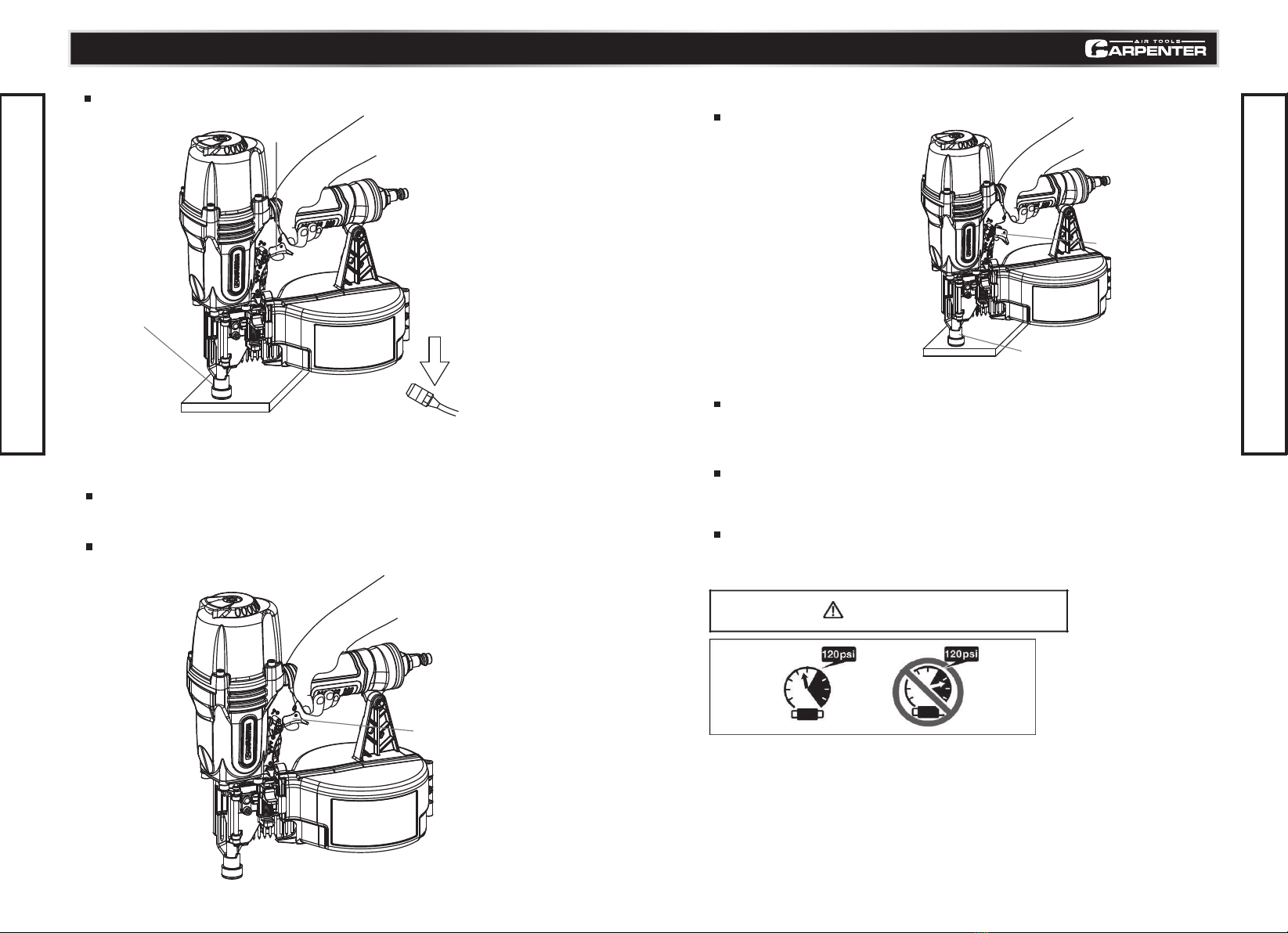

• Do not exceed the maximum or minimum pressures.

Operating the tool at the wrong pressure (too low or

too high) may cause excessive noise or rapid wear.

• Use only Non-Detergent Air Tool Lubricating Oil for this tool.

• Near and below freezing, moisture in the air line may freeze and prevent tool

operation. Do not store in a cold weather environment to prevent frost or ice

formation. Frost and ice on the tools operating valves and mechanisms could

cause tool failure.

Potential hazard that could result in damage to the tool or property.

Model No. CCN65Z contact us 1-888-666-1887