2

Step 2 — Rig and Place Unit — Units are mounted

on skids. Leave the unit on the skid until it is in the final posi-

tion. While on the skid, the unit can be rolled, dragged or fork-

lifted; do not apply force to the unit. Use a minimum of 3 roll-

ers when rolling, and raise from above to remove the skid when

unit is in the final position. See Fig. 4 for rigging details.

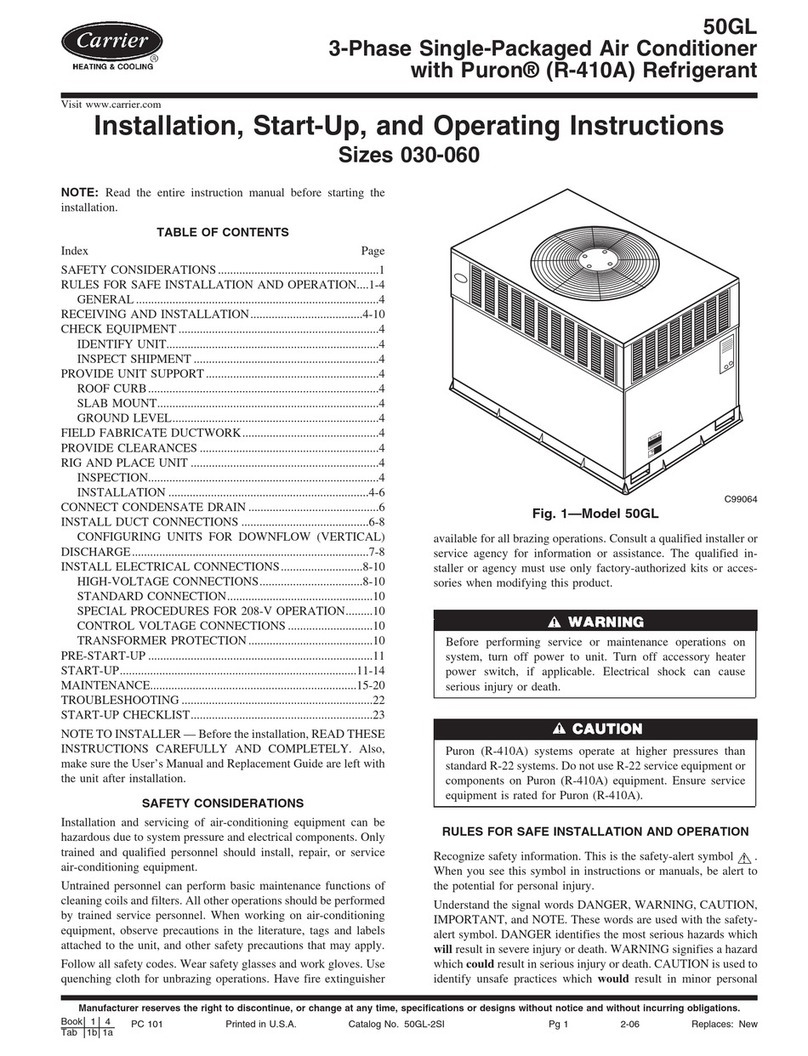

PLACING THE UNIT — The selected unit location should

not be adjacent to an acoustically sensitive space. The best lo-

cations for these units are mechanical rooms, near elevator

shafts, near restrooms, near stairwells or other similar loca-

tions. Position the unit where large supply of outdoor air is

available for the unit inlet. Be sure to leave enough space for

the return air inlet access to the evaporator and condenser coils

for cleaning and maintenance. Units located on the same floor

should have a minimum of 6 ft of clearance between condenser

air openings. Units located floor-to-floor should have a mini-

mum of 10 ft between units to prevent recirculation of condi-

tioned air. DO NOT locate units where they will recirculate

conditioned air. This will cause increased head pressure which

can cause units to trip on high pressure. See Fig. 1-3 for recom-

mended unit clearances and locations.

Either provide inlet filters to protect the coils, or locate the

unit in an area free from airborne dirt or other foreign material

which could clog the coils.

The units are designed to pass through most 36-in. door

openings. The filter rack and duct mounting flanges may also

be removed for additional clearance.

Splitting a 50BYN024 — The size 024 unit height

exceeds 80 in. and may not clear all door openings. It may be

necessary to split the unit in order to move it into the desired

installation location. Refer to the following instructions to split

the unit:

NOTE: This unit and its 2 sections are heavy. Three people

are required to move the sections safely. You will also need

safety goggles, gloves and a dolly.

1. Move the unit to a work area close to the final installation

location.

2. Be certain the service valves for all 3 circuits are in the

“OFF” position. See Fig. 5. If any valves have been

opened, the system must be evacuated.

3. Undo the suction line at the threaded fitting between the

upper and lower sections of the unit. See Fig. 6.

4. Mark and undo each of the liquid lines for all 3 circuits at

the threaded connections to the expansion valve and the

connection to the filter drier. See Fig. 6.

5. Carefully move the liquid lines to the side, keeping them

inside the unit.

6. You can now separate the upper and lower sections of

the unit. Remove the 8 bolts that hold the two sections

together. See Fig. 7. Once the bolts are removed, save the

nuts, bolts and washers for use in re-assembly.

7. Carefully lift the fan/coil section from the base section

and separate.

8. Move the separate sections to the installation location.

9. Place the bottom section first and then place the top sec-

tion on top of it.

10. Bolt the sections together.

11. Reconnect the suction lines with the threaded fittings.

12. Reconnect the liquid lines to the expansion valve and

filter drier. DO NOT mix circuits; be certain each line is

returned to its original location.

13. Connect a vacuum pump to the service port by the com-

pressor, on the suction line.

14. Pull a vacuum to 30 microns.

15. Pull the unit down and check to make sure all joints are

tight and leak free. Open the discharge line service valve.

See Fig. 6.

16. Open the liquid line service valve. See Fig. 6.

17. Follow the unit's start-up instructions.

NOTE: Accessory items need to be installed before the

ducts are attached.

Unit Discharge — Units are shipped from the factory

configured for vertical discharge. The units (except the

50BYN014) can be converted to front or horizontal discharge

by following these instructions:

1. Remove the screws (8) from the top front access panel to

gain access to the fan section.

2. Loosen the supply fan mounting bolts (4) and slide the

fan motor back until the belts (3) are loose.

3. Remove the belts (3).

4. Remove the screws (8) from the unit top panel that holds

the fan.

5. Remove the top cover and fan.

6. Position fan where the top front access panel was mounted.

7. Secure the fan with the screws removed in Step 1.

8. Re-mount the belts.

NOTE: Some units require different belts for different fan

set ups. If this is the case, new belts are provided inside the

fan enclosure.

9. Slide the fan motor back until the proper belt tension is

obtained. Secure the motor with the mounting bolts (4).

10. Mount front access cover on top of the unit (where the top

cover was originally) and secure with the screws (8) re-

moved in Step 4.

Vibration Isolation — Unit compressors are internally

isolated and the compressor compartment is lined with acousti-

cal insulation. If additional vibration isolation is desired, rubber

pads may be located under each unit corner or unit may be

mounted on rubber shear isolators. Spring isolators are not nor-

mally required. Ductwork attached to the unit should be isolated

from the unit with a flexible collar on the inlet and outlet ducts.

Step 3 — Install Accessories (If Required) —

Refer to the following and the instructions provided with the

individual accessory. Refer to Fig. 8 for typical system set up.

HEATING COILS — Accessory steam or hot water heating

coils are mounted in the unit return air before the cooling coil.

1. Remove the filter rack provided with the unit.

2. Mount the filter rack on the coil.

3. Mount the coil in the position where the filter rack was.

NOTE: The filter rack may be used with either ducted or

free air return set ups. Make sure adequate air mixing occurs

to prevent coil freeze-up. A 50BB900---001 freeze protec-

tion thermostat is recommended.

LOW AMBIENT KIT — If the unit will be operated with

inlet air to the condenser below 50 F, a head pressure control

low-ambient damper may be required. The low-ambient kit

controls head pressure by discharge dampers on the condenser

fan. The dampers are actuated by a refrigerant-operated piston

connected to the discharge line of the condenser. If a low-

ambient accessory will be used, install it at this time (before

final ductwork connections are made).

INLET FILTER KIT — An accessory filter rack may also be

installed on the air inlet to help keep the coil clean. This filter

rack should be installed before the ductwork is attached to the

unit (if required in your specific application).

Refer to installation instructions provided with the accesso-

ries for installation details.