6

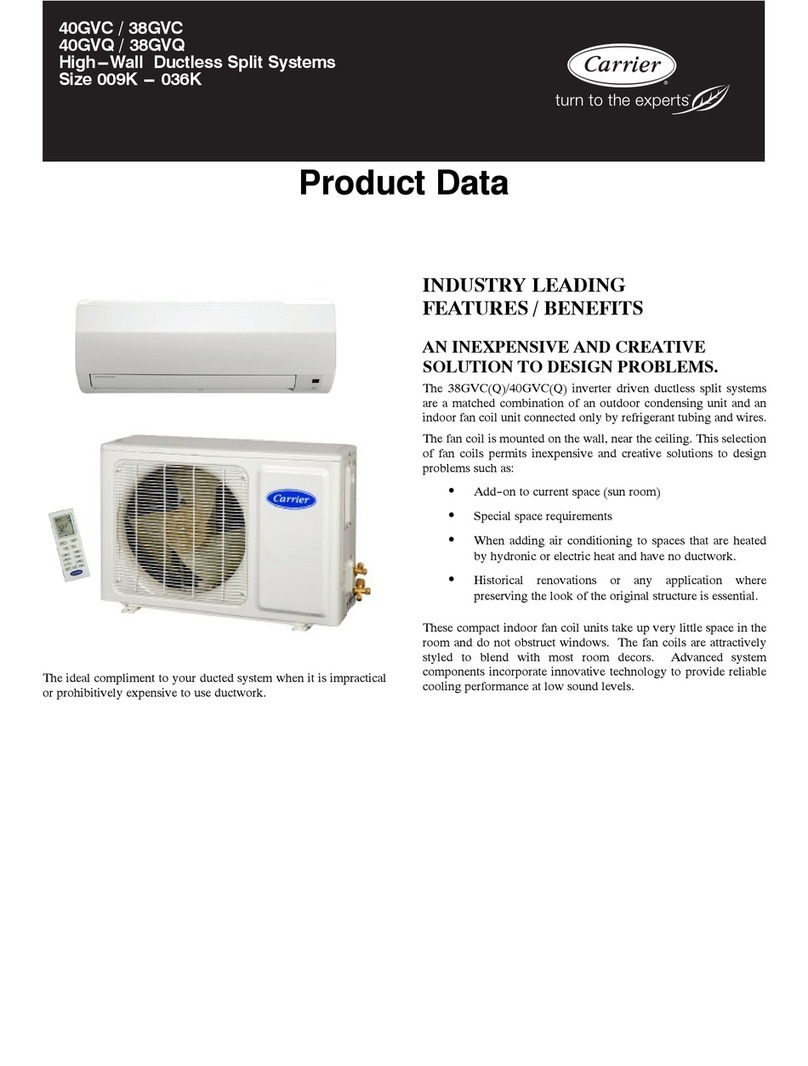

Vertical package air conditionners

Location designation

Before moving the unit, make sure that all panels are fastened in

place. Lift and lower with care. When choosing the location, in any

way the selected fashion, the following precautions have to be taken

into consideration:

- It is mandatory to comply with norm EN 378-3 on Safety and

Environmental Requirements. Part 3: “In situ” installation and

protection to people.

- It is necessary to check that the structure supports the unit’s weigh

(please see weighs in technical characteristics sheet).

- The area where the unit will be located must be perfectly accessible

for cleaning and maintenance operations. Leave enough space so

that air can circulate around the unit (please check minimum free

space for maintenance).

- Foresee appropriate bumping devices in all the installation so that

noise and vibration transmission is avoided.

For being a unit designed to operate indoor, with ducted discharge

and return, both in the internal circuit as in the external circuit, the

following aspects should be taken into account:

• All models can be installed on the floor or over a mount or steel

profile (in order to avoid the transmission of vibrations, it is

recommended to mount anti-vibratory supports).

• Important: In any case, check that the unit remains perfectly

levelled.

• Ifintheinternaland/or external circuit the air return is not ducted, it

isnecessaryto provide forgrillesofappropriate sizes intheplenum

formedbytheroof,forgedandwallsinorderthatthecircuitmakes

the aspiration of the return air.

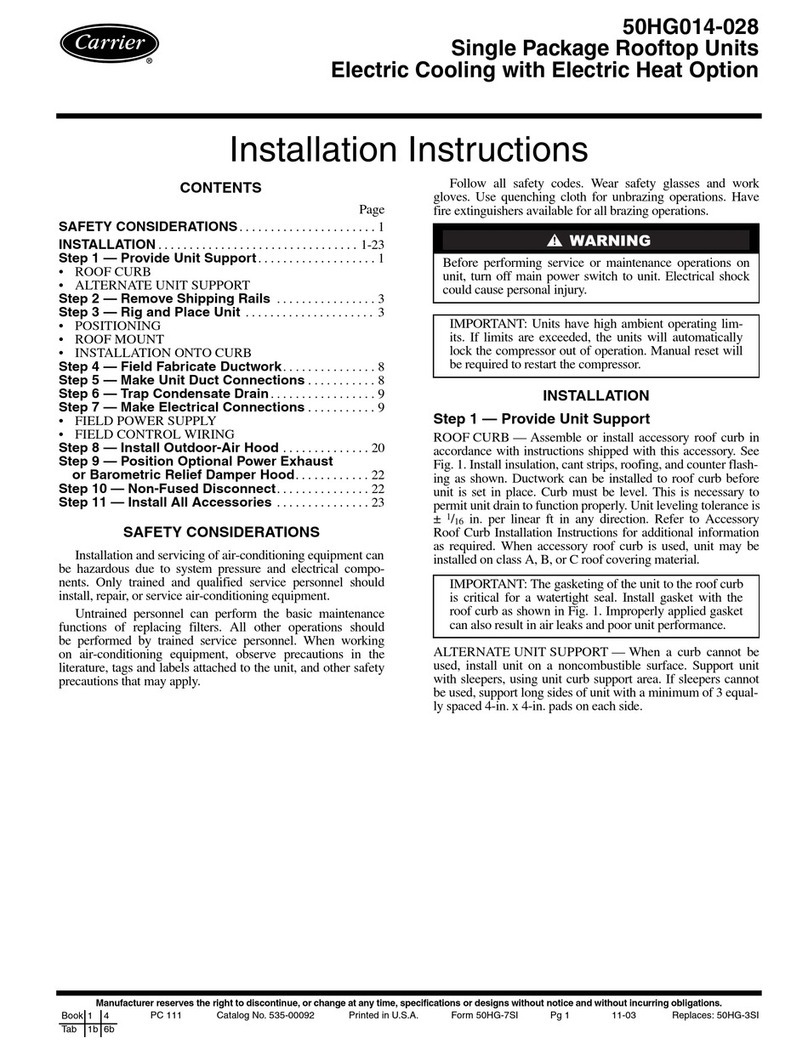

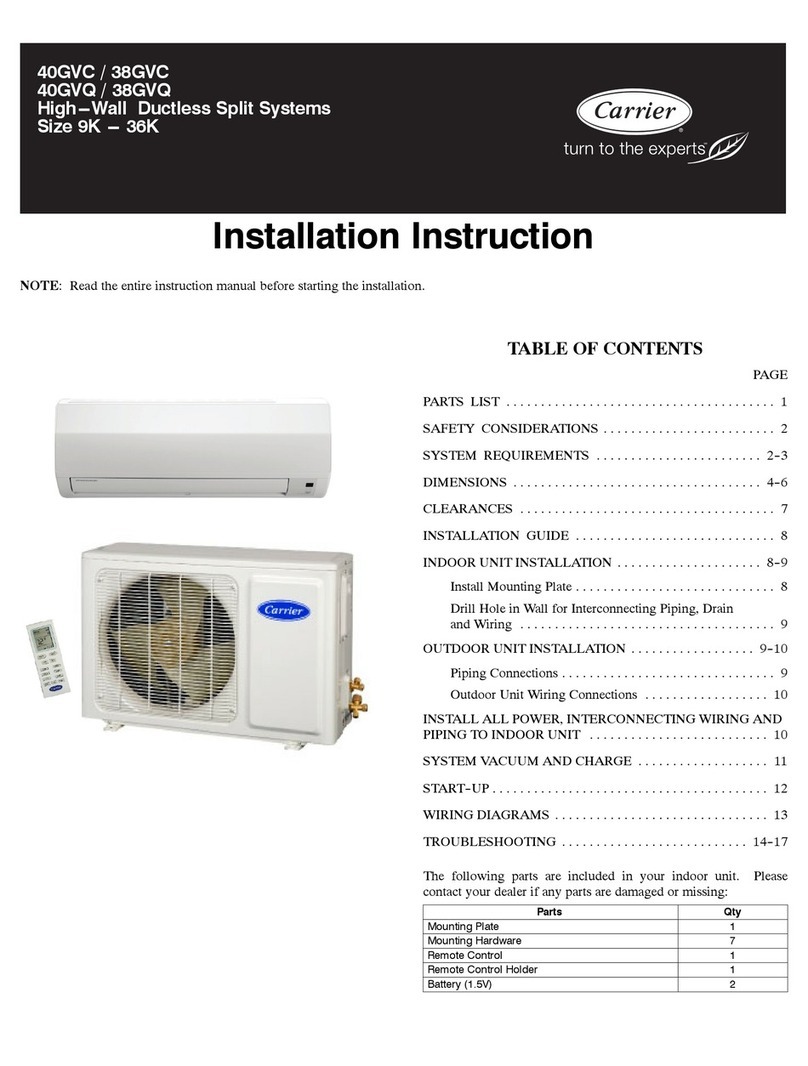

7. LOCATION AND ASSEMBLING

Anchorage for antivibrators

A

B

Minimum free space for commissioning and

maintenance operations

E

D

A

B

C

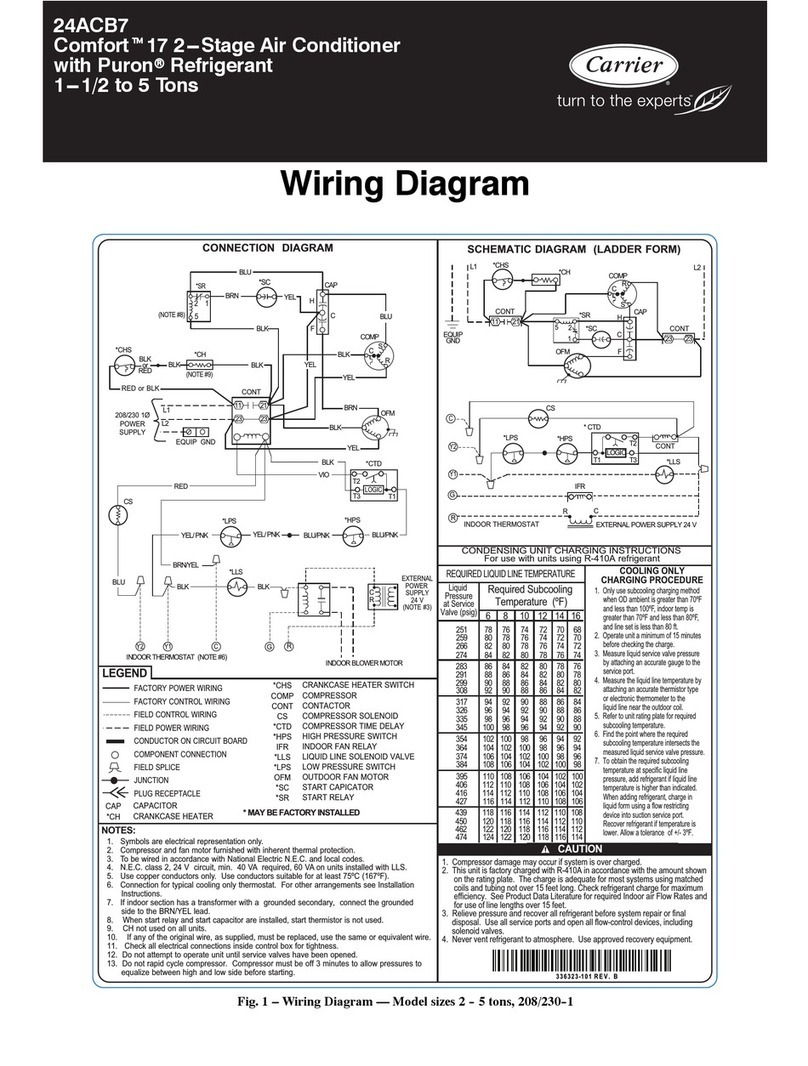

Sound level

These units are designed to work with a low acoustic level. In any

case, the design of the installation the outer environment, the kind

of building for the noise transmitted in the air and the solid elements

for the vibration transmission must be taken into consideration for the

acoustic radiation.

If necessary, commission a study to an acoustic technician.

C) The sound pressure level of the unit, with the ducted return and

supply connections, measured at a distance of 5 metres, in open field,

directivity at 2 and 1.5 metres from the ground is:

B) The sound power level in the indoor fan outlet to be taken into

account for the silencer calculation:

A) The sound power level in the outdoor fan outlet to be taken into

account for the silencer calculation:

Note: The sound pressure level depends on the installation conditions

and, as such, is only indicated as a guide.

50NZ/NF A (mm) B (mm)

080 / 090 1.116 695

120 / 160 1.382 744

180 2.103 695

240 / 320 2.646 744

50NZ/NF A (mm) B (mm) C (mm) D (mm) E (mm)

080 1.000 600 900 600 1.500

090 1.200 600 900 600 1.500

120 1.100 750 900 750 1.500

160 1.100 750 900 750 1.500

180 1.200 600 900 600 1.500

240 1.200 750 900 750 2.000

320 1.500 750 900 750 2.000

50NZ/NF 080 090 120 160 180 240 320

dB(A) 74,4 76,3 81,9 83,6 79,3 84,9 86,6

50NZ/NF 080 090 120 160 180 240 320

dB(A) 79,4 75,1 77,5 80,2 77,8 83,1 79,0

50NZ/NF 080 090 120 160 180 240 320

dB(A) 65,7 67,9 71,4 74,0 70,8 75,2 76,0

Note: Diameter antivibration anchoring: 18 mm.