8

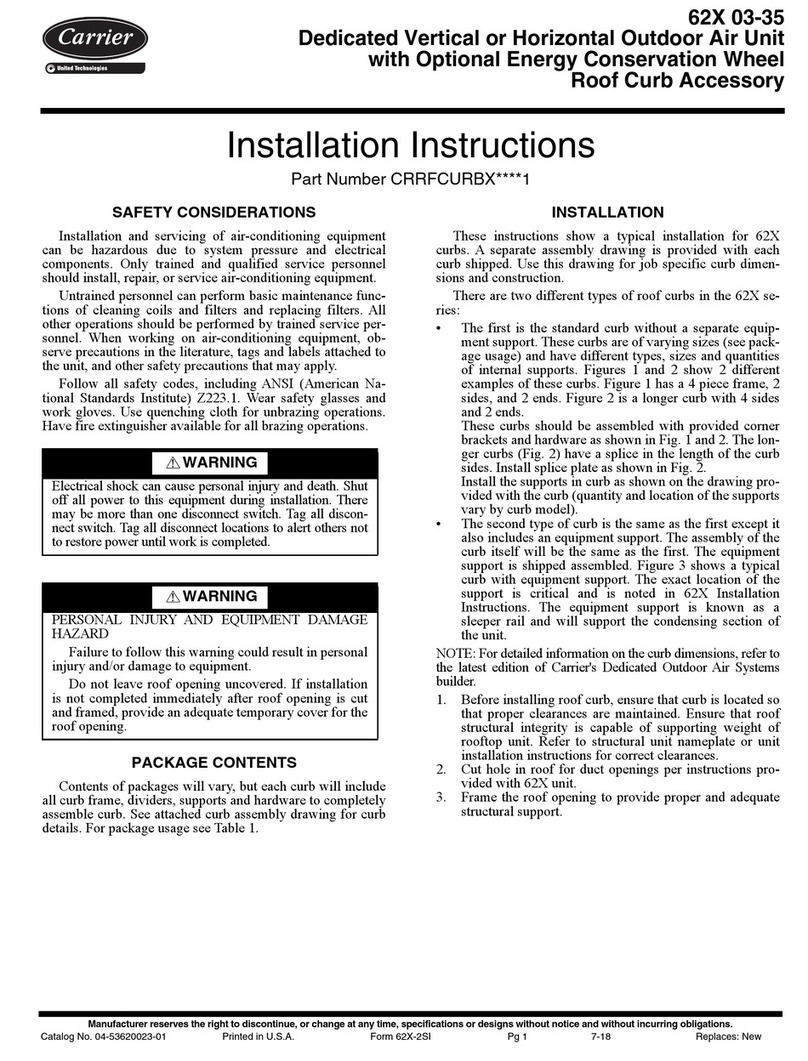

27. Tighten the four bolts securing the motor mounting

brackets to the unit. Torque bolts to 120 ±12 in-lbs

(14 ±1.4 Nm).

28. Remove the cover on the motor connection box.

29. Re-connect all electrical leads to the motor and re

place the connection box cover.

30. Re-connect all electrical power to the unit. Remove

lockout tags on all electrical power sources.

31. Start the unit and allow to run for a designated period.

32. Shut off the unit and make any necessary adjustments

to the V-belt tension or the motor and blower wheel

pulley alignment.

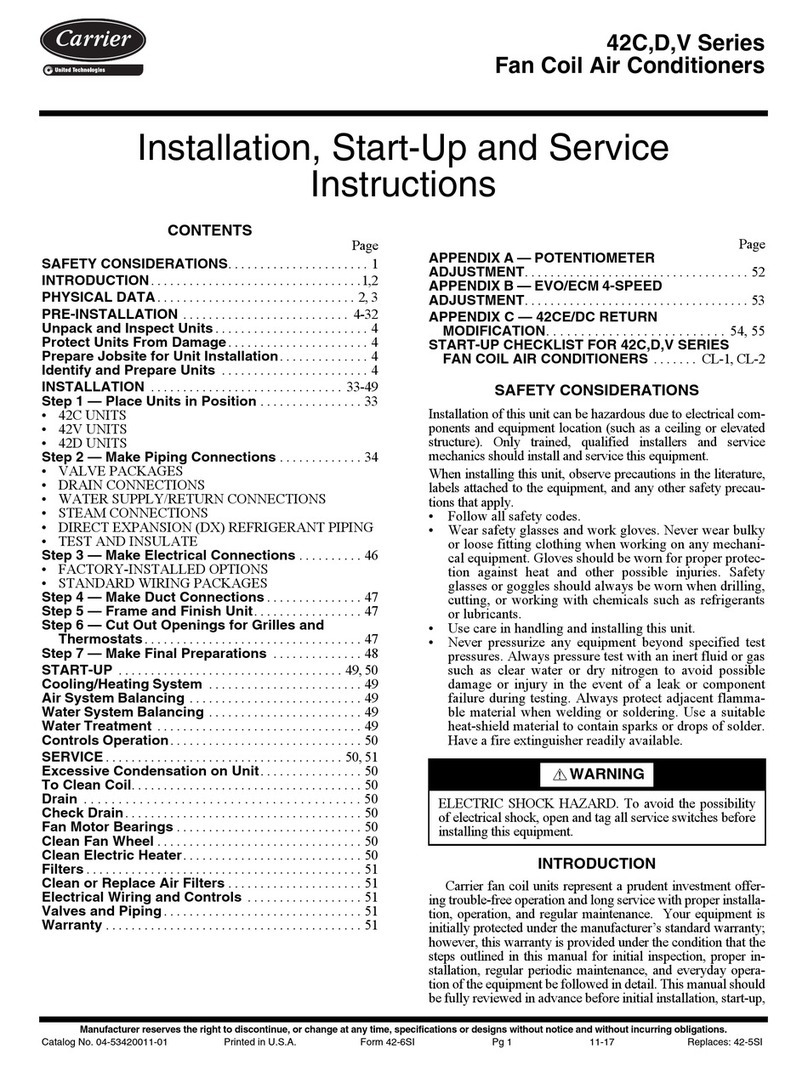

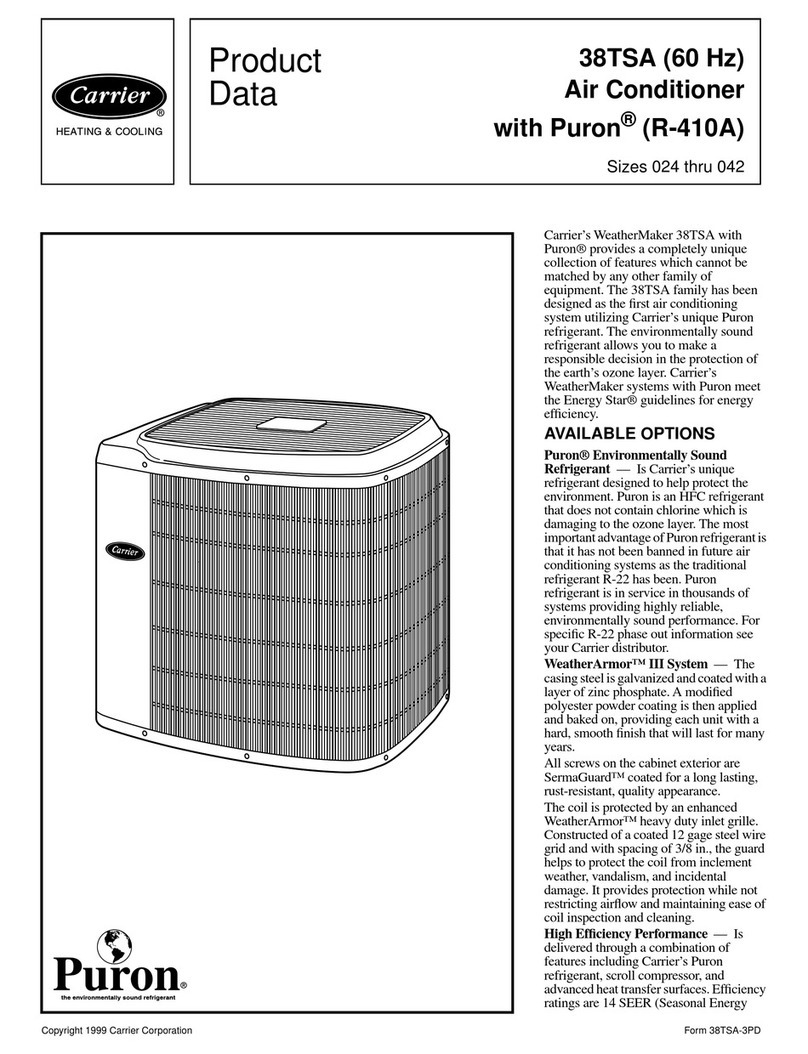

BROWNING BELT

TENSION CHECKER

STRAIGHTEDGE

1/2”

(1.3 cm)

BELT

DEFLECTION

C12093

Fig. 11 −Adjusting V−belt Tension

Changing Fan Wheel Speed by Changing Pulleys

The horsepower rating of the belt is primarily dictated by

the pitch diameter of the smaller pulley in the drive

system (typically the motor pulley in these units). Do not

install a replacement motor pulley with a smaller pitch

diameter than provided on the original factory pulley.

Change fan wheel speed by changing the fixed fan pulley

(larger pitch diameter to reduce wheel speed, smaller

pitch diameter to increase wheel speed) or select a new

system with both pulleys and matching belt(s).

Before changing pulleys to increase fan wheel speed,

check the fan performance at the target speed and airflow

rate to determine new motor loading (bhp). Use the fan

performance tables or use the Packaged Rooftop Builder

software program. Confirm that the motor in this unit is

capable of operating at the new operating condition. Fan

shaft loading increases dramatically as wheel speed is

increased.

EQUIPMENT DAMAGE HAZARD

Failure to follow this CAUTION can result in equipment

damage.

Drive packages cannot be changed in the field. For

example: a standard drive cannot be changed to a high

static drive. This type of change will alter the unit’s

certification and could require heavier wiring to support

the higher amperage draw of the drive package.

CAUTION

!

To reduce vibration, replace the motor’s adjustable pitch

pulley with a fixed pitch pulley (after the final airflow

balance adjustment). This will reduce the amount of

vibration generated by the motor/belt-drive system.

To determine variable pitch pulley diameter, perform the

following calculation:

1. Determine full open and full closed pulley diameter.

2. Subtract the full open diameter from the full closed

diameter.

3. Divide that number by the number of pulley turns

open from full closed

This number is the change in pitch datum per turn

open.

EXAMPLE:

– Pulley dimensions 2.9 to 3.9 (full close to full open)

– 3.9 - 2.9 = 1

– 1 divided by 5 (turns from full close to full open)

– 0.2 change in pulley diameter per turn open

– 2.9 + 0.2 = 3.1″pulley diameter when pulley closed

one turn from full open

COOLING

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal

injury, death and/or equipment damage.

This system uses Puronrefrigerant which has

higher pressures than R−22 and other refrigerants. No

other refrigerant can be used in this system. Gauge

set, hoses, and recovery system must be designed to

handle Puron refrigerant. If unsure about equipment,

consult the equipment manufacturer.

!WARNING

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in death,

serious personal injury and/or property damage.

Never use non−certified refrigerants in this product.

Non−certified refrigerants could contain contaminates

that could lead to unsafe operating conditions. Use

ONLY refrigerants that conform to AHRI Standard

700.

!WARNING

ROUND TUBE PLATE FIN (RTPF)

CONDENSER COIL

The condenser coil is fabricated with round tube copper

hairpins and plate fins of various materials and/or

coatings, and are also available with optional

all−aluminum NOVATION coil construction. Check

position 11 on the unit’s informative data plate for coil

construction code, then refer to the Model Number

Nomenclature in Appendix 1 to identify the materials

provided in this unit. The coil may be one−row or