6

INSTALLATION

Storage

The 09FC free cooling units are designed for outdoor installations.

At times, a delay in construction or other factors require that a unit

be stored for a period of time prior to installation. The following

guidelines should be used for unit storage.

PROVIDE MACHINE PROTECTION

Place and store the unit in an area that will protect it from vandal-

ism, accidental contact with vehicles, falling debris or construction

waste. Ideally, do not remove the shipping protection such as the

coil protectors. This will provide additional protection for the unit.

The unit can be stored outdoors.

INSPECTION DURING STORAGE

To ensure faster installation when the time comes, the following

inspection schedule is recommended:

Every 3 Months

The 09FC units are shipped with a nitrogen holding charge in the

water loop. Check to be sure that there is positive pressure, at least

5 psig (34 kPa) in the water piping. If a circuit is found to be with-

out pressure, contact a qualified refrigeration mechanic. The sys-

tem should be pressurized to find the leak. It should be repaired

and recharged with nitrogen.

Every 6 Months

Check the unit for damage, both physical and from wildlife.

Check the unit for nests from rodents, birds, or insects. Depending

on location, these organisms can cause deterioration of compo-

nents which may result in failure. Consider an exterminator if nec-

essary. If damage is found and it will interfere with the installation,

consider repairing the damage before installation. Check the unit

control box for signs of moisture. If moisture is found, determine

the entry path and seal the leak.

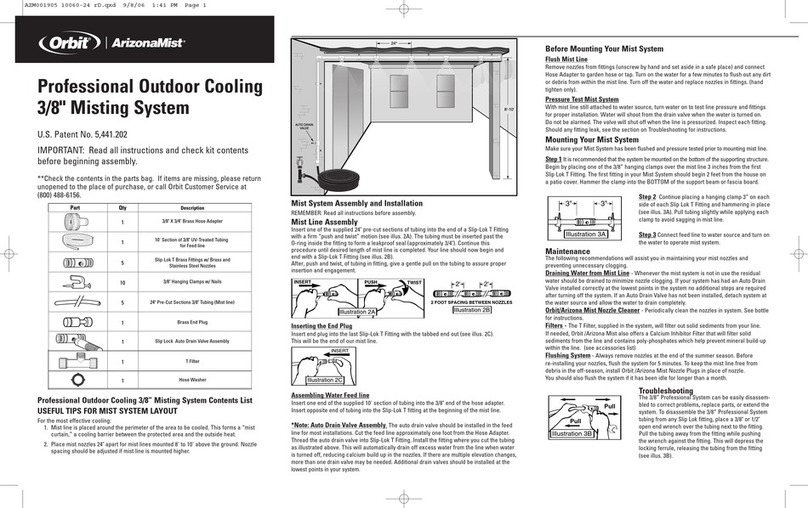

Step 1 — Inspect Shipment

Inspect unit for damage upon arrival. If damage is found,

immediately file a claim with the shipping company. Verify proper

unit delivery by checking unit nameplate data and the model

number nomenclature shown in Fig. 1. See Table 1 for unit

physical data.

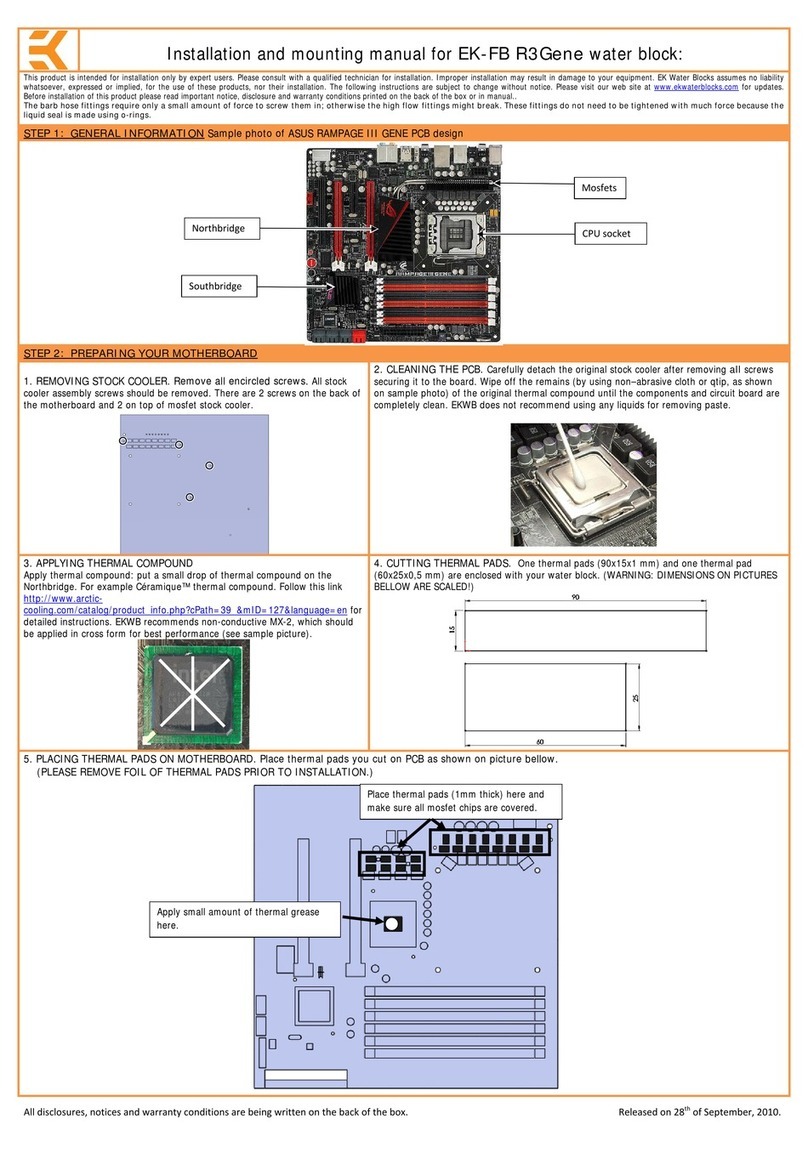

Step 2 — Rig and Place Unit

All units are designed for overhead rigging, it is important that

this method be used. Lifting holes are provided in frame base rails.

It is recommended shackles are used in the lifting holes (see rig-

ging label on unit and Fig. 4 for rigging weights and center of

gravity). All panels must be in place when rigging.

Use spreader bars or frame to keep the cables, chains, and straps

clear of the unit sides. Leave standard coil protection packaging in

place during rigging to provide coil protection. Remove and dis-

card all coil protection after rigging cables are detached.

Standard 09FC unit packaging consists of coil protection only.

Skids are not provided unless selected as a shipping option. If

overhead rigging is not available at the jobsite, the unit should be

placed on a skid or pad before dragging or rolling. Units with ex-

port shipping skid option, cannot be moved using rollers unless

there is a way to remove them first. When rolling, use a minimum

of 3 rollers. When dragging, pull the pad or skid. Do not apply

force to the unit. When in final position, raise from above to lift

unit off the pad or skid.

PLACING UNITS

When considering unit location, be sure to consult National Elec-

trical Code (NEC, U.S.A.) and local code requirements. Allow

sufficient space for airflow, wiring, piping, and service. The place-

ment area must be level and strong enough to support the operat-

ing weight of the unit. (See Tables 2 and 3.)

In areas where snow can be expected, consider the snow depth for

the location. The fan variable frequency drive (VFD) is equipped

with a cooling fan located on the bottom of the device. The unit

should be installed with the inlet of the VFD cooling fan at least

12 in. (304 mm) above the anticipated snow level.

Refer to Fig. 5-11 for airflow clearances. Recommended mini-

mum clearances are 6 ft (1829 mm) for unrestricted airflow and

service on sides of unit, 4 ft (1219 mm) on ends, and unrestricted

clear air space above the unit. Provide ample space to connect flu-

id lines to unit.

For multiple units, allow 10 ft (3048 mm) separation between air-

flow surfaces. See Fig. 3. If walls surround the unit, wall height

should not exceed the top of the unit fan discharge. Installation in

a pit is not recommended.

The unit may be placed at the end (opposite control box) of a

chiller, however assure there is space for piping between water

connections. Some chiller water connections are at the end of the

chiller and may not be accessible if 09FC is too close to it.

Fig. 3 — 09FC Multiple Unit Separation

IMPORTANT: To maintain unit stability while lifting, use a

minimum of 4 cables, chains or straps of equal length.

Attach one end of each cable to shackle attachment point

and the other end of each cable to overhead rigging point.

CAUTION

All panels must be in place when rigging. Failure to comply

could result in equipment damage.

CAUTION

For all unit sizes, do not forklift unit unless unit is attached to a

skid designed for forklifting. Failure to follow this caution

could result in equipment damage or personal injury.

* Minimum for when coils face each other. Less clearance is

required in other configurations.

† Clearance of 3.5 ft is required when a coil faces the wall. When

there is no coil facing the wall, see the certified drawing for the

required service clearance.

10 ft

(3.0 m)

MINIMUM*

3.5 ft (1.1 m)

MINIMUM†