7

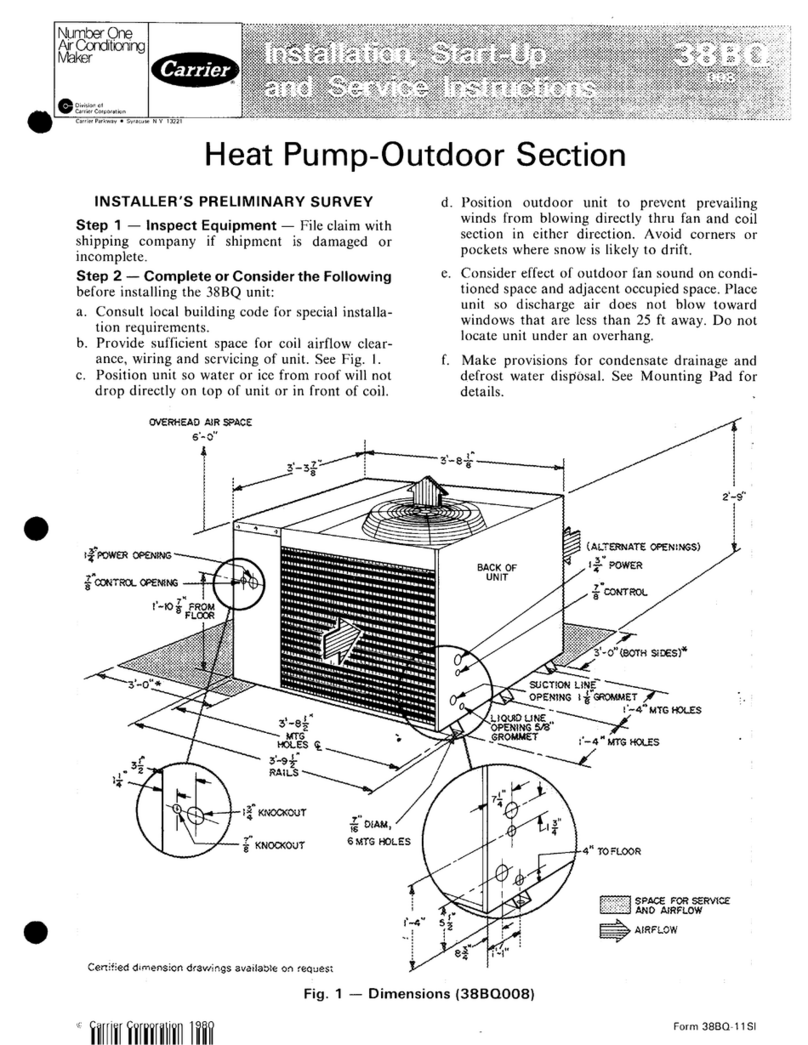

INSTALLATION GUIDELINES (ALL UNITS)

1. Be sure that the location chosen for unit installation provides

ambient temperatures maintained above freezing.

2. Be sure the installation location is isolated from sleeping

areas, private offices and other acoustically sensitive spaces.

3. Be sure unit is mounted at a height sufficient to provide an

adequate slope of the condensate lines. If an appropriate slope

cannot be achieved, a field-supplied condensate pump may

be required.

4. On horizontal units, allow adequate room below the unit for

condensate drain trap and do not locate the unit above supply

piping.

5. Provide sufficient space for duct connection. Do not allow the

weight of the ductwork to rest on the unit.

6. Provide adequate clearance for filter replacement and drain

pan cleaning. Do not allow piping, conduit, etc. to block filter

access.

7. Provide sufficient access to allow maintenance and servic-

ing of the blower and blower motor, compressor, refrigerant

circuit, controls, and coils.

8. For units with free return (non-ducted), provide adequate

space for proper return airflow. For units installed in closets

or mechanical rooms, provide sufficient return grill area for

proper airflow.

9. Provide ready access to water valves and fittings, and screw-

driver access to unit side panels, discharge collar, and all elec-

trical connections.

10. Where access to side panels is limited, pre-removal of the

control box side mounting screws may be necessary for

future servicing.

11. For units that are installed in enclosed spaces (such as furred

in closets or behind finished ceilings), provide access panels

to allow for the installation, maintenance, service, and

removal of the unit.

Step 2 — Check Unit

Upon receipt of equipment at the jobsite, inspect the carton or

crating of each unit, and inspect each unit for damage on both the

interior and exterior. Note any damage and contact your local

equipment sales office.

INSPECT UNIT

To prepare the unit for installation, complete the procedures listed

below:

1. Verify that the correct unit has been received. Check the unit

capacity (tonnage), voltage, orientation, and configuration.

2. Compare the electrical data on the unit nameplate with to ver-

ify the jobsite power feed (voltage, amperage, MCA) and

power protection (MOCP).

3. Verify that the unit is the correct model for the entering water

temperature of the job (standard or extended range)

4. Remove the unit packaging, keeping the unit attached to the

shipping pallet. Do not destroy packaging. Save for re-instal-

lation on the unit if the unit will not be fully installed.

5. Open a unit access panel. Verify that the refrigerant tubing is

free of kinks or dents, and that it does not touch other unit

components.

6. Check the water piping and piping connections to make sure

they are free from defects, kinks, dents, and appear to be

water tight. Verify system operating water pressure.

7. Inspect the blower assembly. Verify that the blower has not

come lose during shipping. Verify clearance between the

blower wheel and the blower housing. Verify free blower

rotation.

8. Inspect all electrical connections. Be sure connections are

clean and tight at the terminals.

9. Check unit controls. If Complete C or Deluxe D, verify field

provided thermostat is available. If WSHP Open, verify

proper sensor has been provided and a commissioning inter-

face will be available.

10. 50PSH Only - Locate the hanging bracket kit located in

the compressor compartment.

11. Remove the foam blower shipping support from underneath

the blower section.

12. Remove any shipping brackets from the unit.

Step 3 — Locate Unit

Locate the unit in an indoor area that allows easy removal of the

filter and access panels, and has enough room for service person-

nel to perform maintenance or repair. Provide sufficient room to

make fluid, electrical, and duct connection(s). If the unit is located

in a confined space such as a closet, provisions must be made for

return air to freely enter the space.

Unit condensate drains are not internally trapped. Allow room be-

low the unit base for horizontal models for an adequate conden-

sate trap.

These units are not approved for outdoor installation; therefore,

they must be installed inside the structure being conditioned. Do

not locate units in areas that are subject to freezing. Units must be

installed in conditioned space that is not subject to extremes of

temperature or humidity to avoid cabinet sweating and/or equip-

ment damage.

Do not use units for temporary heating, air conditioning or ventila-

tion during construction or remodeling, especially when plaster-

ing, sanding or painting or when replacing carpet or flooring. Dust

and debris can clog the coil and blower. Chemical vapors can lead

to formicary corrosion and damage the coil. Ensure adequate ven-

tilation and debris collection during construction or remodeling.

IMPORTANT: It is the installing contractor’s responsibility to

ensure that all equipment is installed with proper access for ser-

vice, start-up, installation of accessories, configuration of control

and other components, and equipment removal in accordance

with Carrier’s recommended service clearances and installation

instructions. Please refer to the Carrier Commercial WSHP War-

ranty Statement (document number 04-570008-01) for details on

warranty exclusions regarding equipment, access, removal and

clearances.

CAUTION

EQUIPMENT DAMAGE HAZARD

DO NOT store or install units in corrosive environments or in

locations subject to temperature or humidity extremes (e.g., at-

tics, garages, rooftops, etc.). Corrosive conditions and high

temperature or humidity can significantly reduce performance,

reliability, and service life. Always move units in an upright

position. Tilting units on their sides may cause equipment

damage.

IMPORTANT: Care must be taken to prevent the introduction of

dust, pain, debris, or chemicals into the unit, which can cause

damage to the unit, delay start-up, and may impact unit

longevity.