Small Packaged Products

Accessory Crankcase Heaters

Cancels: IlK 582A-18-4 IlK 582A-18-12

5-01

Installation Instructions

PIN CPCRKHTR003A00, CPCRKHTR004A00

CPCRKHTR005A00, CPCRKHTR007A00

NOTE: Read the entire instruction manual before starting the

installation.

This symbol _ indicates a change since the last issue.

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment can be hazard-

ous due to system pressures, electrical components, and fuel gases.

Only trained and qualified personnel should install, service, or

repair air conditioning equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning coils, or cleaning and replacing filters. All other

operations should be performed by trained service personnel.

When working on air conditioning equipment, observe precautions

in the literature, on tags, and on labels attached to the unit.

Recognize safety information. This is the safety-alert symbol z_ -

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAU

TION. These words are used with the safety alert symbol DAN-

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property danlage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

Follow all safety codes. Wear safety glasses and work gloves.

Have a fire extinguisher available.

Table 1--Accessory Crankcase Heater Usage

See Below for Units Applicable

48GXJ583A/PY2P-S

50GX/702A/PA2P-S

50JXJ602A/PH2P-B

50JZ/602B (FACTORY INSTALLED ON 042-_0)

48GP/583B

50GL/702B

UNIT SIZE 240 V 460 V

024 CPCRKHTR004A00 NA

030 CPCRKHTR004A00 NA

036 CPCRKHTROO4AO0 CPCRKHTROO5AO0

042 CPCRKHTROO4AO0 CPCRKHTROOSAO0

048 CPCRKHTR004A00 CPCRKHTR005A00

060 CPCRKHTROO4AO0 CPCRKHTROO5AO0

Table 2--Accessory Crankcase Heater Usage

See Below for Units Applicable

UNIT SIZE

018

024

030

036

O42

O48

060

48GS/582A/PY1 P-S

50GS/701 A/PAt P-B

240 V

CPCRKHTR007A00

CPCRKHTR007A00

CPCRKHTR007A00

CPCRKHTR007A00

CPCRKHTR007A00

CPCRKHTROCAA00

CPCRKHTR007A00

460 V

NA

NA

NA

CPCRKHTROO3AO0

CPCRKHTROO3AO0

CPCRKHTROO5AO0

CPCRKHTR003A00

INTRODUCTION

These instructions cover the installation of an Accessory Crank-

case Heater on Electric Cooling, Heat Pump and Electric

Cooling/Gas Ideating units.

_) DESCRIPTION AND USAGE

The accessory crankcase heater warms the compressor crankcase

oil to reduce refrigerant migration in the crankcase and ensure

proper compressor lubrication. Refer to Tables 1, 2 and 3.

INSTALLATION

Table 3--Accessory Crankcase Heater Usage

See Below for Units Applicable

50JSi601A/PHIP-B (FACTORY INSTALLED ON 036)

UNIT SIZE 240 V 460V

018 CPCRKRTR007A00 HA

024 CPCRKHTR007A00 NA

030 CPCRKHTR007A00 NA

036 CPCRKHTR007A00 CPCRKHTR003A00

042 CPCRKHTR004A00 CPCRKHTR005A00

048 CPCRKHTR004A00 CPCRKHTR005A00

060 CPCRKHTR004A00 CPCRKHTR005A00

1. Turn off gas supply (if applicable) first, then disconnect

electric power supply.

2. Install Lockout Tag,

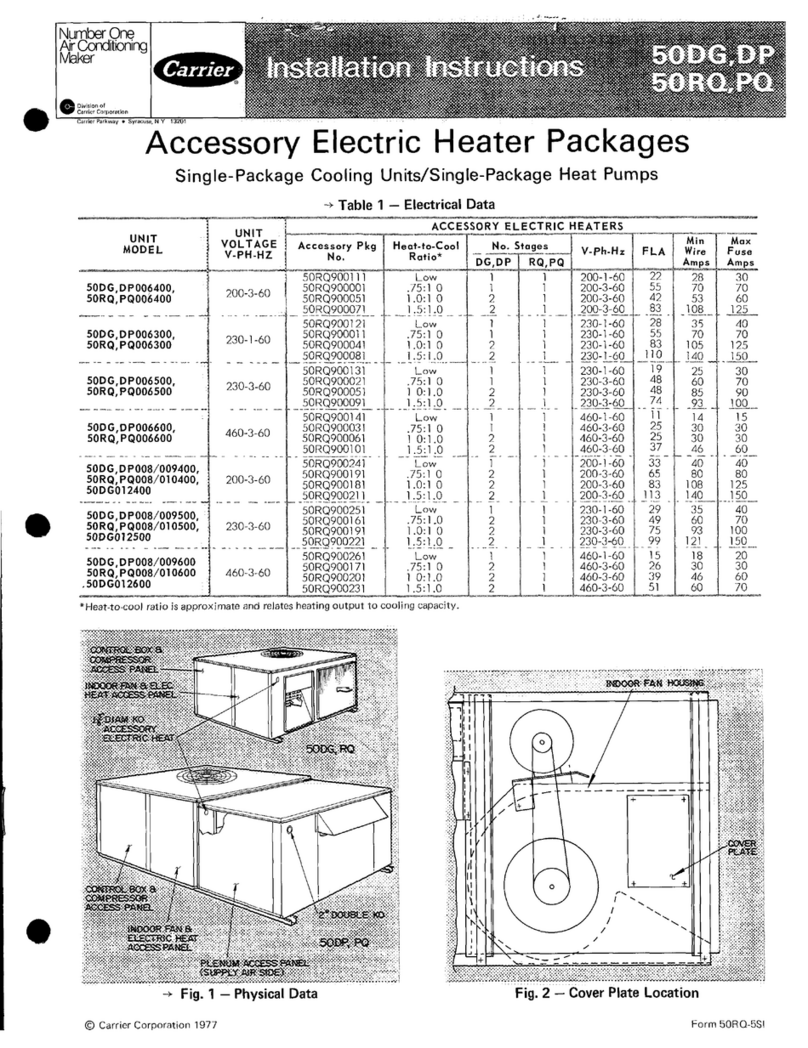

3. Remove access panel for compressor and control box. (See

Fig. 1.)

4. Spread crankcase heater arms and wrap heater around com-

pressor base approximately 2-in. above compressor mounting

plate. (See Fig. l.I

5. Fasten heater firmly in place with fastening clip provided with

the crankcase heater. (See Fig. 1.1

6. Route crankcase heater leads into unit control box, following

the path of the compressor leads. (See Fig. 1.)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4 PC 101 Catalog No. 534-80055 PrintedinU.S.A. Form 48/50-102SI Pg 1 501 Replaces: 48GS,GX-3SI