Carrier Weathermaster 38HQ Dimensions and installation guide

Other Carrier Heat Pump manuals

Carrier

Carrier AQUAZONE 50PCH Dimensions and installation guide

Carrier

Carrier Aquasnap plus 30AW Manual

Carrier

Carrier 25VNA8 infinity 18VS User manual

Carrier

Carrier 48EZN User manual

Carrier

Carrier GT-PW (50YEW) User manual

Carrier

Carrier 50ZHA Guide User manual

Carrier

Carrier 38EYX Instructions and recipes

Carrier

Carrier GW Series User manual

Carrier

Carrier COMFORT SERIES 25HCB3 Operation manual

Carrier

Carrier 50FF 020-093 Manual

Carrier

Carrier WeatherMaster 50GC 04-06 Series User manual

Carrier

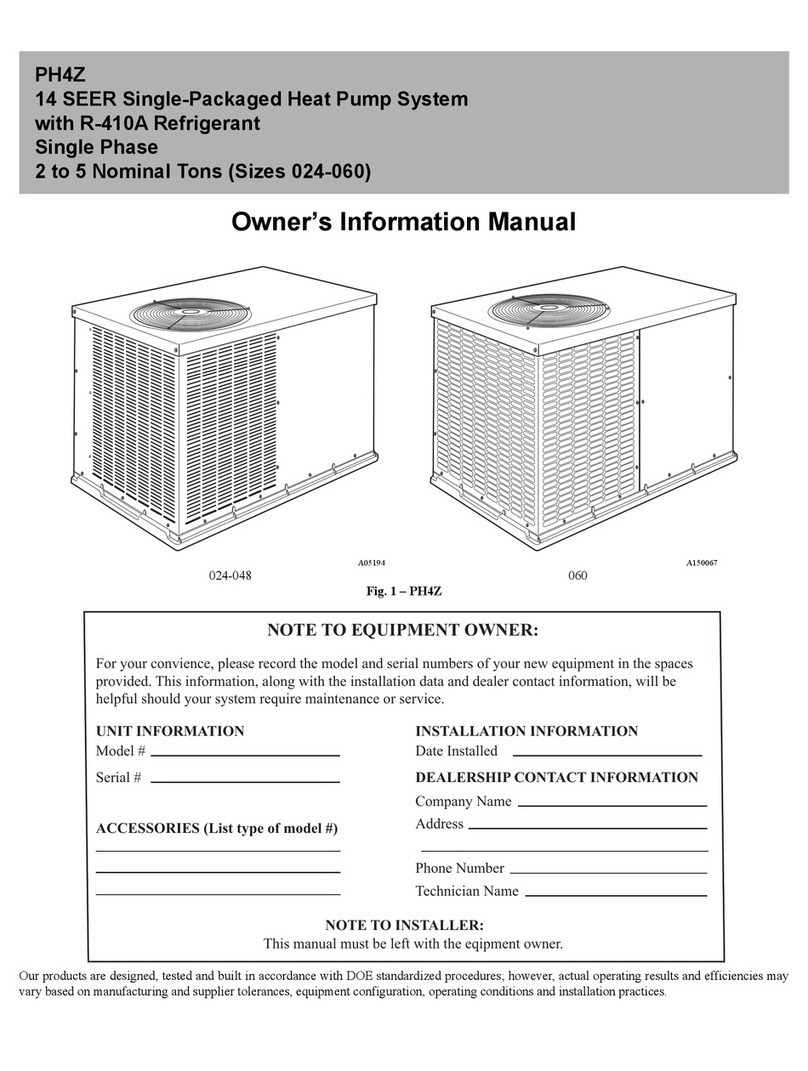

Carrier PH4Z Instruction Manual

Carrier

Carrier AQUAZONE 50KQE Series Manual

Carrier

Carrier 50QT Dimensions and installation guide

Carrier

Carrier WeatherMaker 38YDB Instructions and recipes

Carrier

Carrier 38MARBQ12AA1 User manual

Carrier

Carrier 38BYC Series Instructions and recipes

Carrier

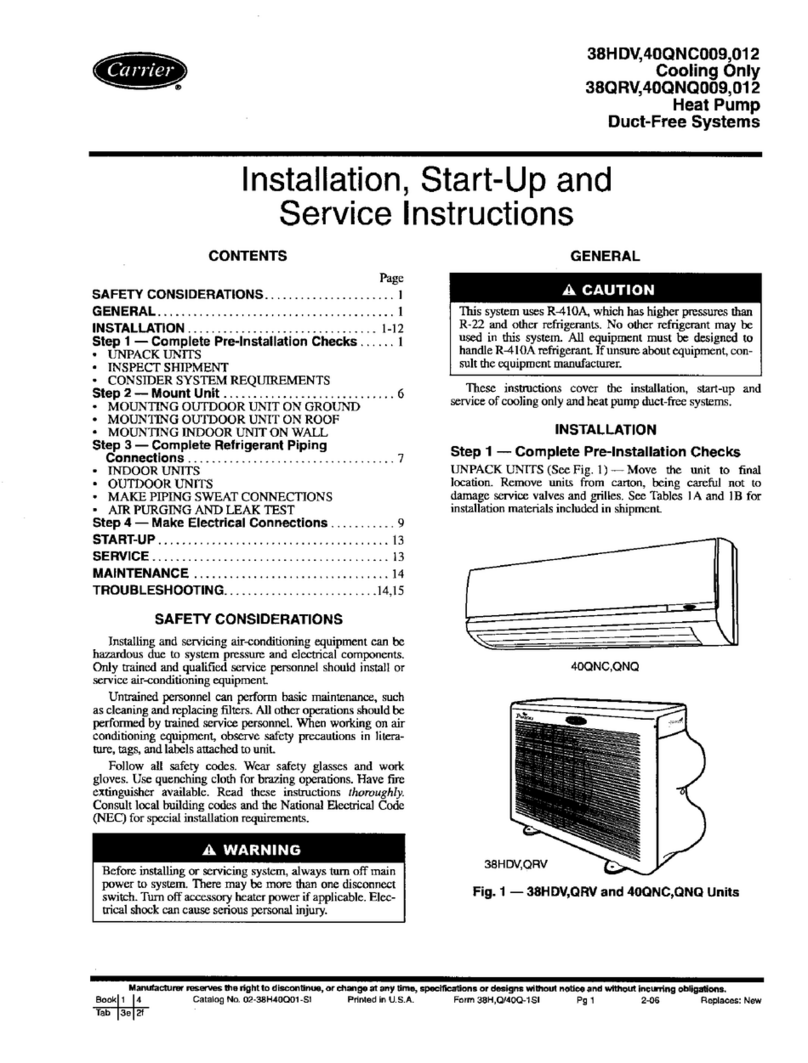

Carrier 38HDV009 Dimensions and installation guide

Carrier

Carrier COMFORT SERIES 25HCR User manual

Carrier

Carrier 10 SEER SPLIT-SYSTEM 38YCW Instructions and recipes

Popular Heat Pump manuals by other brands

Mitsubishi Electric

Mitsubishi Electric PUZ-SWM60VAA Service manual

Dimplex

Dimplex LI 16I-TUR Installation and operating instruction

TGM

TGM CTV14CN018A Technical manual

Kokido

Kokido K2O K880BX/EU Owner's manual & installation guide

Viessmann

Viessmann VITOCAL 300-G PRO Type BW 2150 Installation and service instructions

Viessmann

Viessmann KWT Vitocal 350-G Pro Series Installation and service instructions for contractors

Ariston

Ariston NIMBUS user manual

Weishaupt

Weishaupt WWP L 7 Installation and operating instruction

GE

GE Zoneline AZ85H09EAC datasheet

Bryant

Bryant Preferred Series installation instructions

Daikin

Daikin altherma EJHA04AAV3 installation manual

Bryant

Bryant 549B Series Installation, Start-Up and Service Instructions