3

The illustrations in this document are for illustrative purposes only and not part of any offer for sale or contract. The manufacturer

reserves the right to change the design at any time without notice.

1 - TECHNICAL RECOMMENDATIONS/WARRANTY.......................................................................................................................4

2 - OPERATING PRINCIPLE .............................................................................................................................................................4

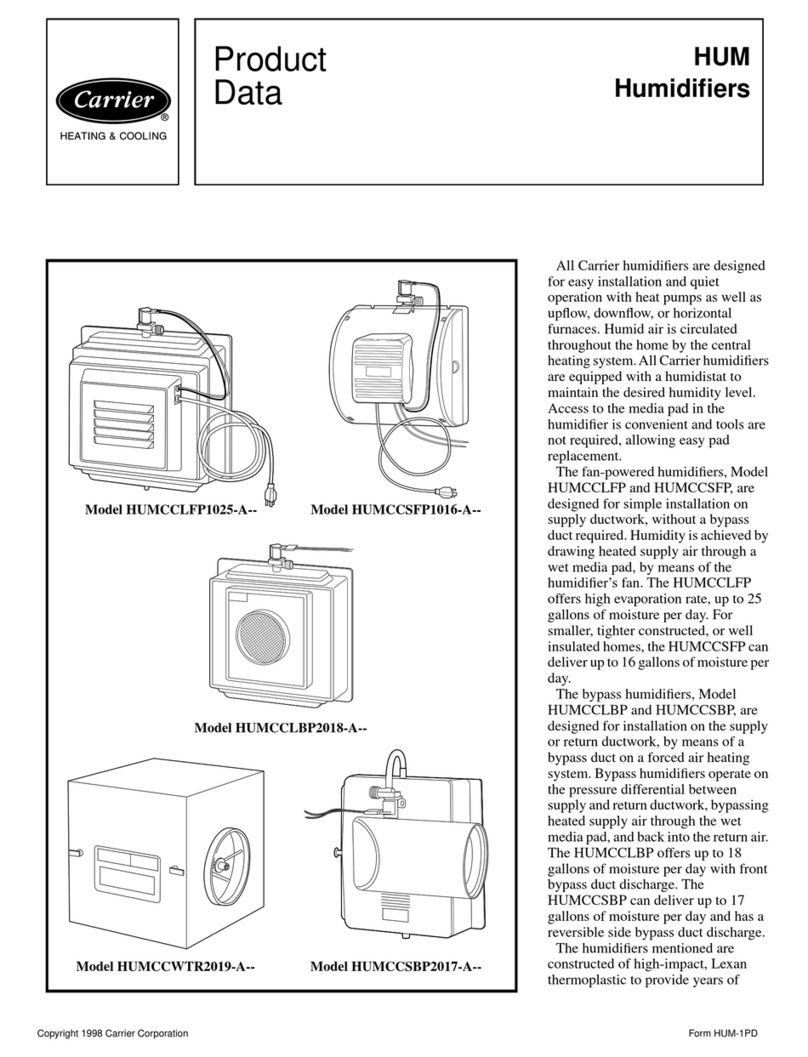

3 - DESCRIPTION...............................................................................................................................................................................5

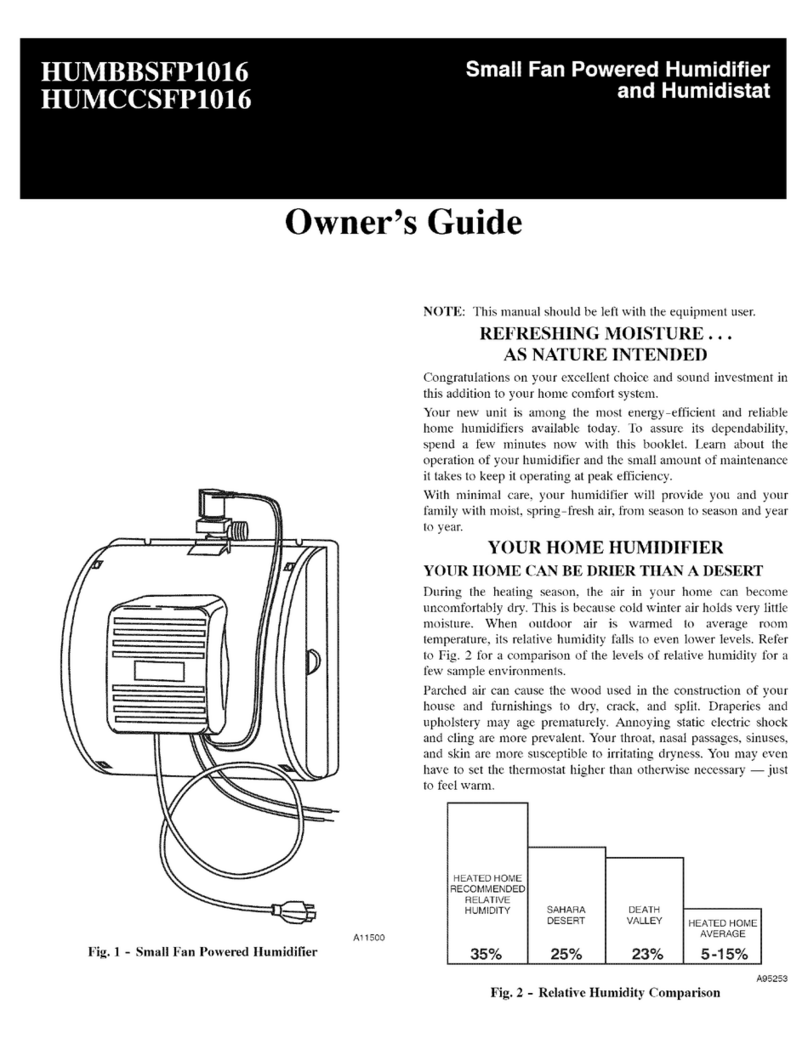

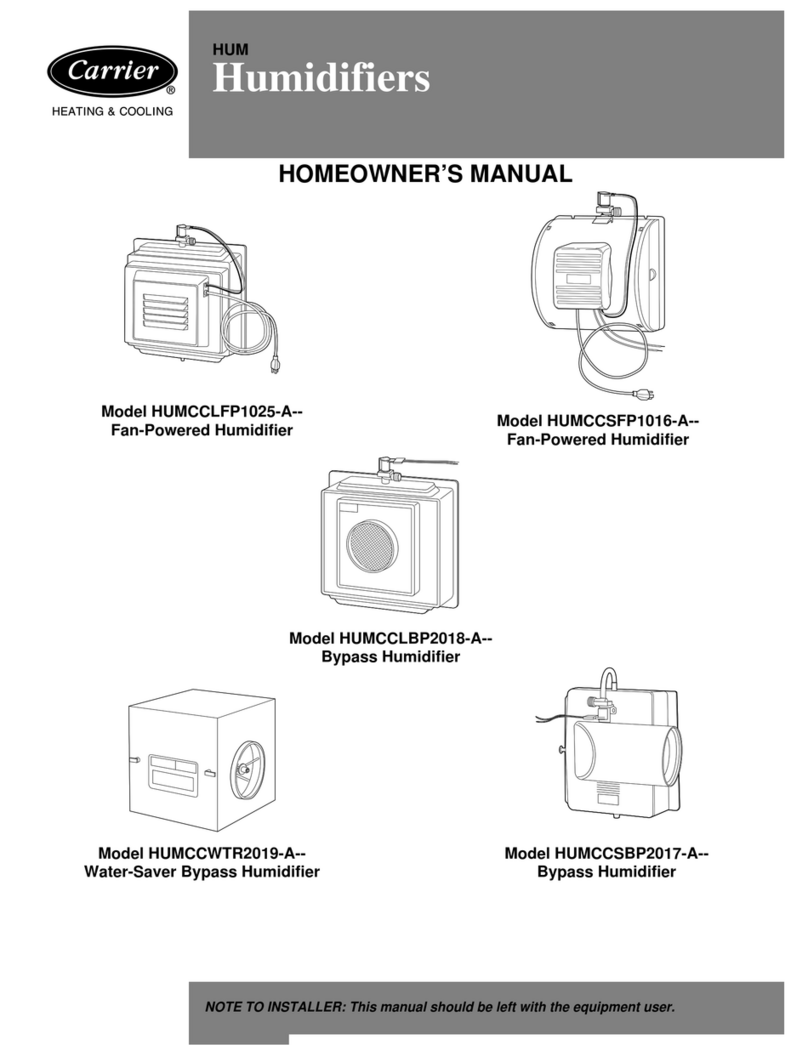

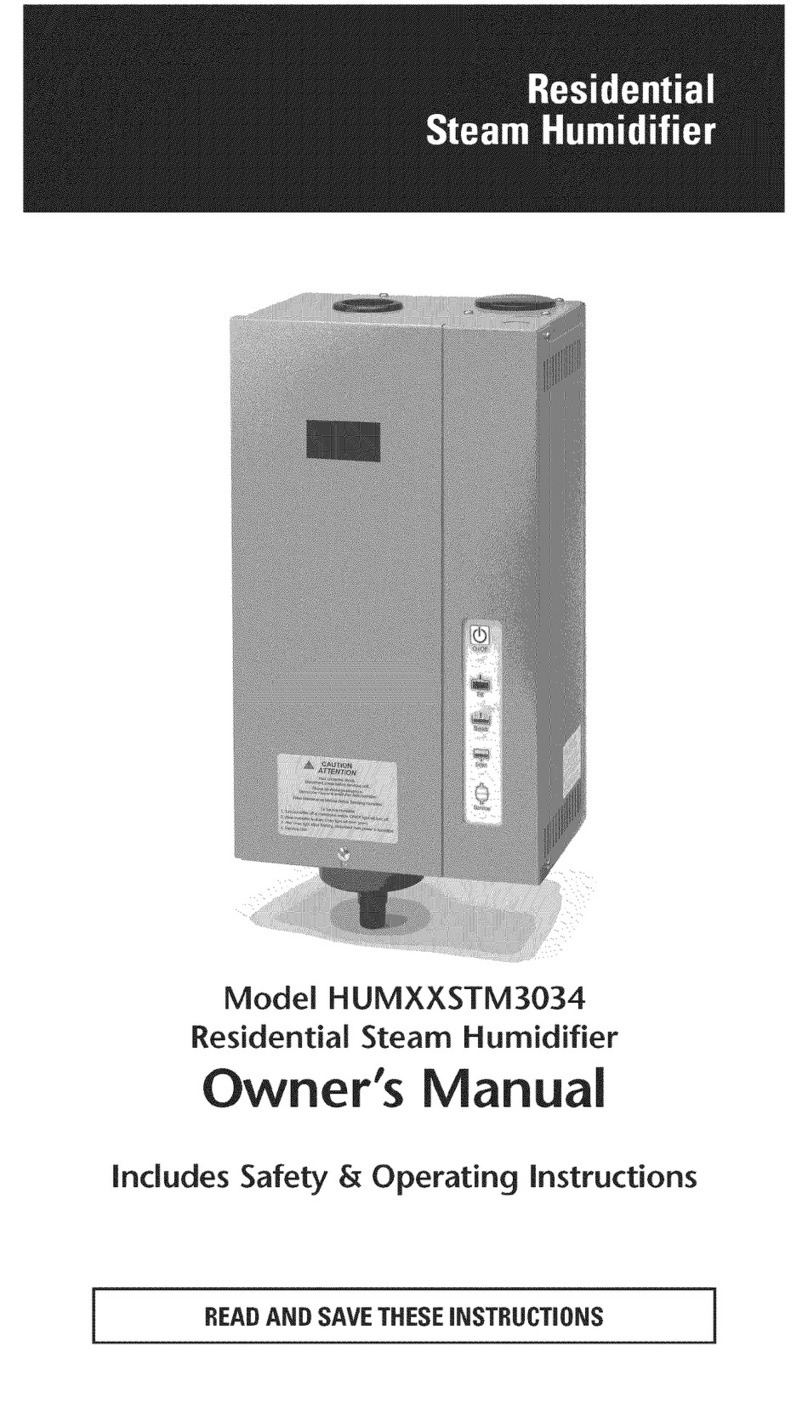

3.1 - General description of the humidier.........................................................................................................................................5

3.2 - General recommendations........................................................................................................................................................6

4 - TECHNICAL CHARACTERISTICS ...............................................................................................................................................7

4.1 - General characteristics of the humidier...................................................................................................................................7

4.2 - Characteristics of the components............................................................................................................................................8

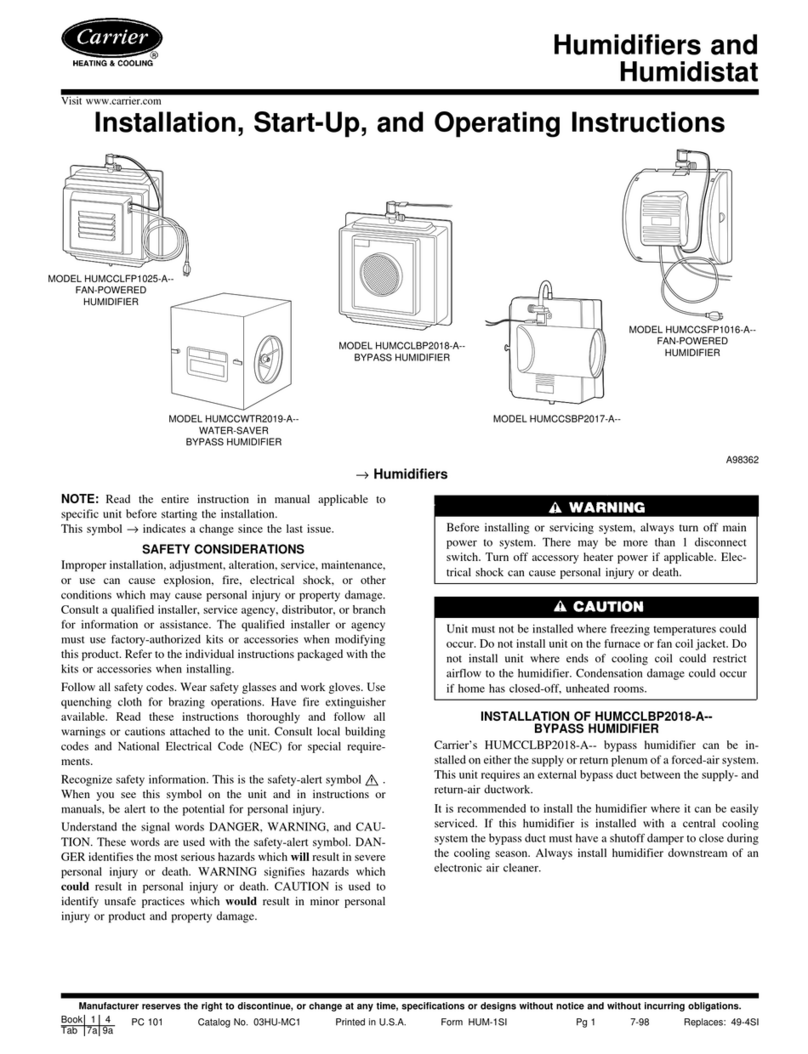

5 - INSTALLATION/START-UP/MAINTENANCE .............................................................................................................................17

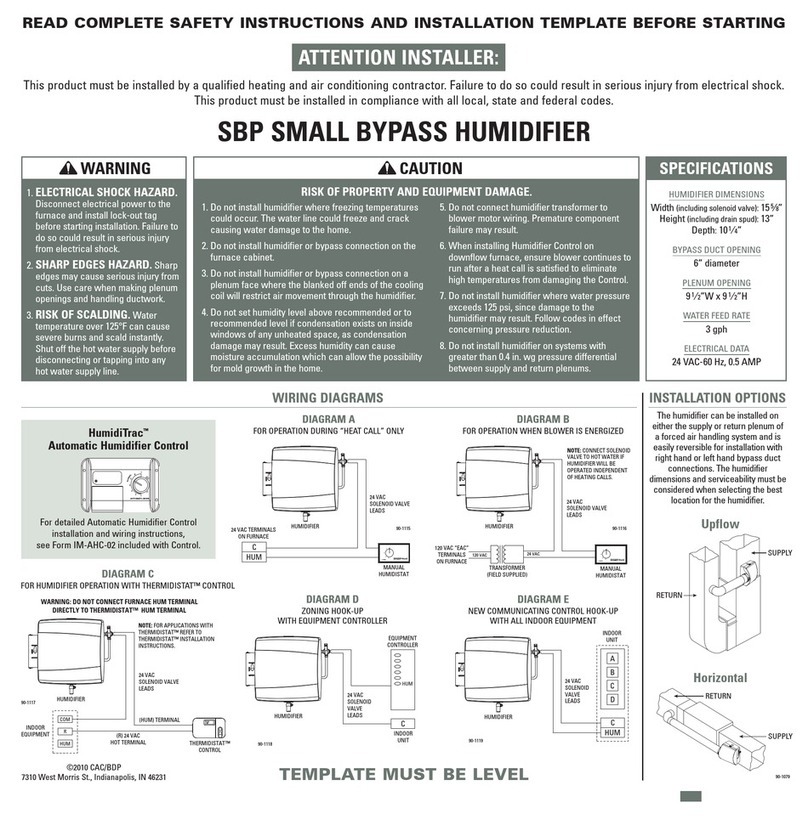

5.1 - Installation ...............................................................................................................................................................................17

5.2 - Start-up....................................................................................................................................................................................17

5.3 - Maintenance............................................................................................................................................................................17

5.4 - Disposal of the product and efuent generated ......................................................................................................................17

5.5 - Cleaning and disinfection ........................................................................................................................................................17

5.6 - Removing the media ...............................................................................................................................................................18

6 - RELATED DOCUMENTS ............................................................................................................................................................ 22

6.1 - CCB control box wiring diagram (option 12)............................................................................................................................22

7 - MCCB MANUAL - HUMIDIFIER CONTROL BOX ......................................................................................................................23

7.1 - General description.................................................................................................................................................................23

7.2 - Installation ...............................................................................................................................................................................24

7.3 - Description of hardware ..........................................................................................................................................................25

7.4 - Connections ............................................................................................................................................................................31

7.5 - Monitoring................................................................................................................................................................................33

7.6 - Conguration...........................................................................................................................................................................34

7.7 - Settings ..................................................................................................................................................................................36

7.8 - Calibration ...............................................................................................................................................................................37

7.9 - Launch.....................................................................................................................................................................................37

7.10 - List of alarms.........................................................................................................................................................................38

8 - AL-UW SUBMERSIBLE UVC LAMP...........................................................................................................................................39

8.1 - Safety ......................................................................................................................................................................................39

8.2 - Operating data and description of the device..........................................................................................................................40

8.3 - Assembly and connection of the unit.......................................................................................................................................41

8.4 - Unit operation..........................................................................................................................................................................42

8.5 - Faults and troubleshooting......................................................................................................................................................42

8.6 - Maintenance and spare parts..................................................................................................................................................43

8.7 - Disposal...................................................................................................................................................................................43

CONTENTS