Parts list for DCM1001 Power Amplifier Carvin P/N

Binding Post, 2-way, Red/Black.................................................03-10450

Cover, Black 18GA Steel ............................................................10-82005

Chassis......................................................................................10-07509

Fan, 24VDC 80mm.....................................................................70-02408

Fan Guard, 80x80mm................................................................03-90080

Handle, 2-space rack.................................................................10-11120

Knob, Black, 1.25” DIA..............................................................07-09001

Stand-off, Al, 1.5” Hex, 6-32......................................................03-63315

Toroid insulator pad 3.8” OD.....................................................03-15004

Front cover.............................................................................10-07501-2

Rear label ..................................................................................77-07508

Power cord (120V)....................................................................05-01603

Power cord (230V)....................................................................05-01903

10 Amp Circuit breaker (120V)..................................................70-28110

6 Amp Circuit breaker (230V)....................................................70-28106

Toroid (120V) ............................................................................15-75160

Toroid (230V) ............................................................................15-75260

C1, Capacitor 10KµF 63V, Poly 20%.........................................42-10363

C2B, Capacitor 10KµF 63V, Poly 20%.......................................42-10363

R30, 1/4W Resistor 47K, .35” prep. 5% Carbon......................50-47045

Parts list for Printed Circuit Card

Ref. Des. Description Carvin P/N

A1 IC Op Amp NE5532 Linear Output 60-55320

A2 IC Op Amp MC4558 CP1 Dual HFREQ 60-45580

A3 IC Op Amp NE5532 Linear Output 60-55320

A4 IC Op Amp NE5532 Linear Output 60-55320

A5 IC Op Amp MC4558 CP1 Dual HFREQ 60-45580

A6 IC Op Amp MC4558 CP1 Dual HFREQ 60-45580

A7 IC Op Amp MC4558 CP1 Dual HFREQ 60-45580

A8 IC Op Amp NE5532 Linear Output 60-55320

BP1 Binding Post Red/Black Combo 03-10400

BP2 Binding Post Red/Black Combo 03-10400

BR1 Diode Bridge AC/DC PCB MTG 60-35041

C3 Capacitor 1000µF 35V Electrolytic 20% 47-10235

C4 Capacitor 1000µF 35V Electrolytic 20% 47-10235

C5 Capacitor 0.047µF 100V Poly 10% 46-47312

C6 Capacitor 0.047µF 100V Poly 10% 46-47312

C7 Capacitor 220µF 50V Electrolytic 20% 47-22151

C8 Capacitor 10µF 50V Electrolytic 20% 47-10051

C9 Capacitor 0.047µF 100V Poly 10% 46-47312

C10 Capacitor 0.047µF 100V Poly 10% 46-47312

C11 Capacitor 0.047µF 100V Poly 10% 46-47312

C15 Capacitor 0.047µF 100V Poly 10% 46-47312

C16 Capacitor 0.047µF 100V Poly 10% 46-47312

C17 Capacitor 0.047µF 100V Poly 10% 46-47312

C18 Capacitor 470µF 25V Electrolytic 20% 47-47125

C100 Capacitor 27PF 500V Ceramic 5% 45-27052

C101 Capacitor 27PF 500V Ceramic 5% 45-27052

C102 Capacitor 22µF 50V Electrolytic 20% 47-22051

C104 Capacitor 27PF 500V Ceramic 5% 45-27052

C105 Capacitor 0.047µF 100V Poly 10% 46-47312

C110 Capacitor 0.001µF 100V Poly 10% 46-10212

C111 Capacitor 22µF 50V Electrolytic 20% 47-22051

C115 Capacitor 27PF 500V Ceramic 5% 45-27052

C116 Capacitor 56PF 500V Ceramic 5% 45-56052

C117 Capacitor 120PF 500V Ceramic 5% 45-12052

C118 Capacitor 10µF 63V Electrolytic 20% 47-10061

C119 Capacitor 0.047µF 100V Poly 10% 46-47312

C120 Capacitor 0.001µF 100V Poly 10% 46-10212

C121 Capacitor 0.068µF 100V Poly 10% 46-68312

C200 Capacitor 27PF 500V Ceramic 5% 45-27052

C201 Capacitor 27PF 500V Ceramic 5% 45-27052

C202 Capacitor 22µF 50V Electrolytic 20% 47-22051

C204 Capacitor 27PF 500V Ceramic 5% 45-27052

C205 Capacitor 0.047µF 100V Poly 10% 46-47312

C210 Capacitor 0.001µF 100V Poly 10% 46-10212

C211 Capacitor 22µF 50V Electrolytic 20% 47-22051

C215 Capacitor 27PF 500V Ceramic 5% 45-27052

C216 Capacitor 56PF 500V Ceramic 5% 45-56052

C217 Capacitor 120PF 500V Ceramic 5% 45-12052

C218 Capacitor 0.047µF 100V Poly 10% 46-47312

C219 Capacitor 0.047µF 100V Poly 10% 46-47312

C220 Capacitor 0.001µF 100V Poly 10% 46-10212

C221 Capacitor 0.068µF 100V Poly 10% 46-68312

Ref. Des. Description Carvin P/N

D1 Diode 1N4003 Rect Gen 1A 200V 60-40030

D2 Diode 1N4003 Rect Gen 1A 200V 60-40030

D3 Diode 1N4003 Rect Gen 1A 200V 60-40030

D4 Diode 1N4003 Rect Gen 1A 200V 60-40030

D5 Diode 1N4003 Rect Gen 1A 200V 60-40030

D6 Diode 1N4003 Rect Gen 1A 200V 60-40030

D7 Diode 1N4003 Rect Gen 1A 200V 60-40030

D8 LED Red small #204HD 3mm T-1.0 60-75320

D9 LED Yellow small #204YD 3mm T-1.0 60-75340

D10 Diode 1N4003 Rect Gen 1A 200V 60-40030

D11 Diode 1N4003 Rect Gen 1A 200V 60-40030

D12 Diode 1N4003 Rect Gen 1A 200V 60-40030

D13 Diode 1N4003 Rect Gen 1A 200V 60-40030

D100 Diode 1N4003 Rect Gen 1A 200V 60-40030

D101 Diode 1N4003 Rect Gen 1A 200V 60-40030

D102 LED Green small #204GD 3mm T-1.0 60-75330

D103 LED Red small #204HD 3mm T-1.0 60-75320

D104 LED Red small #204HD 3mm T-1.0 60-75320

D106 Diode 1N4003 Rect Gen 1A 200V 60-40030

D107 Diode 1N4003 Rect Gen 1A 200V 60-40030

D108 Diode 1N4003 Rect Gen 1A 200V 60-40030

D109 Diode 1N4003 Rect Gen 1A 200V 60-40030

D200 Diode 1N4003 Rect Gen 1A 200V 60-40030

D201 Diode 1N4003 Rect Gen 1A 200V 60-40030

D202 LED Green small #204GD 3mm T-1.0 60-75330

D203 LED Red small #204HD 3mm T-1.0 60-75320

D204 LED Red small #204HD 3mm T-1.0 60-75320

D205 Diode 1N4003 Rect Gen 1A 200V 60-40030

D206 Diode 1N4003 Rect Gen 1A 200V 60-40030

D207 Diode 1N4003 Rect Gen 1A 200V 60-40030

D208 Diode 1N4003 Rect Gen 1A 200V 60-40030

D209 Diode 1N4003 Rect Gen 1A 200V 60-40030

H1-A Header 4 Pin AMP 9A 600V PCB MTG 23-08604

H1-B Header 4 Pin AMP 9A 600V PCB MTG 23-08604

H2 Header 2 Pin Vert Panduit PCB MTG 23-10002

H2-A Header 4 Pin Vert SHS 2.5mm PCB MTG 23-11004

H2-B Header 4 Pin Vert SHS 2.5mm PCB MTG 23-11004

H3-A Header 10 Pin Vert SHS 2.5mm PCB MTG 23-11010

H3-B Header 10 Pin Vert SHS 2.5mm PCB MTG 23-11010

H4-A Header 10 Pin Vert SHS 2.5mm PCB MTG 23-11010

H4-B Header 10 Pin Vert SHS 2.5mm PCB MTG 23-11010

H5 Header 2 Pin Vert Panduit PCB MTG 23-10002

H6-A Header 4 Pin AMP 9A 600V PCB MTG 23-08604

H6-B Header 4 Pin AMP 9A 600V PCB MTG 23-08604

H7 Header 9 Pin AMP 9A 600V PCB MTG 23-08609

J100 XLR Jack Female Neutrik Vert PCB MTG 21-40000

J101 Phone Jack, 1/4” 7 Pin Plastic, 24mm Tall 21-06457

J102 Phone Jack, 1/4” 3 Pin Plastic, 24mm Tall 21-06453

J200 XLR Jack Female Neutrik Vert PCB MTG 21-40000

J201 Phone Jack, 1/4” 7 Pin Plastic, 24mm Tall 21-06457

J202 Phone Jack, 1/4” 3 Pin Plastic, 24mm Tall 21-06453

K100 Relay 24V12A SPDT SIEMENS PCB MGT 70-05712

K200 Relay 24V12A SPDT SIEMENS PCB MGT 70-05712

L100 Inductor 3.3µH Air Core Spool 15-00165

L200 Inductor 3.3µH Air CoreSpool 15-00165

OP1 Opto Isolator VTL5C2 60-50253

OP2 Opto Isolator VTL5C2 60-50253

P100 Pot. B10Kx2 41Clk Brkt Rot Knurled 90° 71-10301

P101 Pot. Trimmer 5K Vert PCB MTG 71-25000

P200 Pot. B10Kx2 41Clk Brkt Rot Knurled 90° 71-10301

P201 Pot. Trimmer 5K Vert PCB MTG 71-25000

Q1 Transistor Darlington NPN MPSA14 60-00014

Q2 Transistor 2N5400 PNP AMP TO-92 60-54000

Q100 Transistor Darlington NPN MPSA14 60-00014

Q101 Transistor TIP31C 3A 100V NPN TO-220 60-31000

Q102 Transistor MPSW42 HV 1.0W NPN T0-237 60-00042

Q103 Transistor CENW92 HV PNP 1.0W TO-92 60-00092

Q104 Transistor TIP32C 3A 100V PNP TO-220 60-32000

Q105 Transistor TIP31C 3A 100V NPN TO-220 60-31000

Q106 Transistor TIP31C 3A 100V NPN TO-220 60-31000

Q107 Transistor MJL21194 NPN 16A 250V 200W 60-21194

Q108 Transistor MJL21194 NPN 16A 250V 200W 60-21194

Q109 Transistor MJL21193 PNP 16A 250V 200W 60-21193

Q110 Transistor MJL21193 PNP 16A 250V 200W 60-21193

Ref. Des. Description Carvin P/N

Q200 Transistor Darlington NPN MPSA14 60-00014

Q202 Transistor MPSW42 HV 1.0W NPN T0-237 60-00042

Q203 Transistor CENW92 HV PNP 1.0W TO-92 60-00092

Q204 Transistor TIP32C 3A 100V PNP TO-220 60-32000

Q205 Transistor TIP31C 3A 100V NPN TO-220 60-31000

Q206 Transistor TIP31C 3A 100V NPN TO-220 60-31000

Q207 Transistor MJL21194 NPN 16A 250V 200W 60-21194

Q208 Transistor MJL21194 NPN 16A 250V 200W 60-21194

Q209 Transistor MJL21193 PNP 16A 250V 200W 60-21193

Q210 Transistor MJL21193 PNP 16A 250V 200W 60-21193

R1 1/4W Resistor 2.2K .35” prep. 5% Carbon 50-22035

R2 1/4W Resistor 3.3K .35” prep. 5% Carbon 50-33035

R3 1/4W Resistor 100K .35” prep. 5% Carbon 50-10055

R4 1/4W Resistor 150Ω.35” prep. 5% Carbon 50-15025

R5 1/4W Resistor 39K .35” prep. 5% Carbon 50-39045

R6 1/4W Resistor 39K .35” prep. 5% Carbon 50-39045

R7 1/4W Resistor 470K .35” prep. 5% Carbon 50-47055

R8 1/4W Resistor 470K .35” prep. 5% Carbon 50-47055

R9 1/4W Resistor 22K .35” prep. 5% Carbon 50-22045

R10 1/4W Resistor 22K .35” prep. 5% Carbon 50-22045

R11 1/4W Resistor 20K .35” prep. 5% Carbon 50-20045

R12 1/4W Resistor 6.8K .35” prep. 5% Carbon 50-68035

R13 1/4W Resistor 2.2M .35” prep. 5% Carbon 50-22065

R14 1/4W Resistor 20K .35” prep. 5% Carbon 50-20045

R15 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R16 Not Used

R17 1/4W Resistor 22K .35” prep. 5% Carbon 50-22045

R18 1/4W Resistor 1K .35” prep. 5% Carbon 50-10035

R19 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R20 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R22 1/4W Resistor 5.6K .35” prep. 5% Carbon 50-56035

R23 1/4W Resistor 470K .35” prep. 5% Carbon 50-47055

R24 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R25 1/4W Resistor 1K .35” prep. 5% Carbon 50-10035

R26 1/4W Resistor 4.7K .35” prep. 5% Carbon 50-47035

R28 1/4W Resistor 220Ω.35” prep. 5% Carbon 50-22025

R31 1/4W Resistor 100K .35” prep. 5% Carbon 50-10055

R100 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R101 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R102 1/4W Resistor 22K .35” prep. 5% Carbon 50-22045

R103 1/4W Resistor 22K .35” prep. 5% Carbon 50-22045

R104 1/4W Resistor 2.2K .35” prep. 5% Carbon 50-22035

R105 1/4W Resistor 220Ω.35” prep. 5% Carbon 50-22025

R106 1/4W Resistor 470K .35” prep. 5% Carbon 50-47055

R107 1/4W Resistor 470K .35” prep. 5% Carbon 50-47055

R108 1/4W Resistor 1K .35” prep. 5% Carbon 50-10035

R109 Not Used

R110 1/4W Resistor 470K .35” prep. 5% Carbon 50-47055

R111 1/4W Resistor 470Ω.35” prep. 5% Carbon 50-47025

R112 1/4W Resistor 1.5K .35” prep. 5% Carbon 50-15035

R115 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R116 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R117 1/4W Resistor 2.2K .35” prep. 5% Carbon 50-22035

R118 1/4W Resistor 47K .35” prep. 5% Carbon 50-47045

R119 1/4W Resistor 4.7K .35” prep. 5% Carbon 50-47035

R120 1/4W Resistor 100Ω.35” prep. 5% Carbon 50-10025

R121 1/4W Resistor 100Ω.35” prep. 5% Carbon 50-10025

R122 1/4W Resistor 4.7K .35” prep. 5% Carbon 50-47035

R123 1/4W Resistor 680Ω.35” prep. 5% Carbon 50-68025

R124 1/4W Resistor 4.7K .35” prep. 5% Carbon 50-47035

R125 1/4W Resistor 2.2K .35” prep. 5% Carbon 50-22035

R126 1/4W Resistor 1K .35” prep. 5% Carbon 50-10035

R127 1/4W Resistor 680Ω.35” prep. 5% Carbon 50-68025

R128 1/4W Resistor 2.2K .35” prep. 5% Carbon 50-22035

R129 1/2W Resistor 4.7Ω0.5 prep. 5% Carbon 52-47005

R130 1/4W Resistor 150Ω.35” prep. 5% Carbon 50-15025

R131 1/2W Resistor 4.7Ω0.5 prep. 5% Carbon 52-47005

R132 5W Resistor 0.22ΩVert 5% Sand Bar 55-02205

R133 5W Resistor 0.22ΩVert 5% Sand Bar 55-02205

R134 5W Resistor 0.22ΩVert 5% Sand Bar 55-02205

R135 5W Resistor 0.22ΩVert 5% Sand Bar 55-02205

R136 1/4W Resistor 1K .35” prep. 5% Carbon 50-10035

R137 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R138 1/4W Resistor 100K .35” prep. 5% Carbon 50-10055

Ref. Des. Description Carvin P/N

R139 1/4W Resistor 100K .35” prep. 5% Carbon 50-10055

R140 1/4W Resistor 33K .35” prep. 5% Carbon 50-33045

R144 2W Resistor 10Ω0.8 prep. 5% Metal 54-10015

R150 2W Resistor 10Ω0.8 prep. 5% Metal 54-10015

R200 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R201 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R202 1/4W Resistor 22K .35” prep. 5% Carbon 50-22045

R203 1/4W Resistor 22K .35” prep. 5% Carbon 50-22045

R204 1/4W Resistor 2.2K .35” prep. 5% Carbon 50-22035

R205 1/4W Resistor 220Ω.35” prep. 5% Carbon 50-22025

R206 1/4W Resistor 470K .35” prep. 5% Carbon 50-47055

R207 1/4W Resistor 470K .35” prep. 5% Carbon 50-47055

R208 1/4W Resistor 1K .35” prep. 5% Carbon 50-10035

R209 Not Used

R210 1/4W Resistor 470K .35” prep. 5% Carbon 50-47055

R212 1/4W Resistor 470Ω.35” prep. 5% Carbon 50-47025

R215 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R216 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R217 1/4W Resistor 2.2K .35” prep. 5% Carbon 50-22035

R218 1/4W Resistor 47K .35” prep. 5% Carbon 50-47045

R219 1/4W Resistor 4.7K .35” prep. 5% Carbon 50-47035

R220 1/4W Resistor 100Ω.35” prep. 5% Carbon 50-10025

R221 1/4W Resistor 100Ω.35” prep. 5% Carbon 50-10025

R222 1/4W Resistor 4.7K .35” prep. 5% Carbon 50-47035

R223 1/4W Resistor 680Ω.35” prep. 5% Carbon 50-68025

R224 1/4W Resistor 4.7K .35” prep. 5% Carbon 50-47035

R225 1/4W Resistor 2.2K .35” prep. 5% Carbon 50-22035

R226 1/4W Resistor 1K .35” prep. 5% Carbon 50-10035

R227 1/4W Resistor 680Ω.35” prep. 5% Carbon 50-68025

R228 1/4W Resistor 2.2K .35” prep. 5% Carbon 50-22035

R229 1/2W Resistor 4.7Ω0.5 prep. 5% Carbon 52-47005

R230 1/4W Resistor 150Ω.35” prep. 5% Carbon 50-15025

R231 1/2W Resistor 4.7Ω0.5 prep. 5% Carbon 52-47005

R232 5W Resistor 0.22ΩVert 5% Sand Bar 55-02205

R233 5W Resistor 0.22ΩVert 5% Sand Bar 55-02205

R234 5W Resistor 0.22ΩVert 5% Sand Bar 55-02205

R235 5W Resistor 0.22ΩVert 5% Sand Bar 55-02205

R236 1/4W Resistor 1K .35” prep. 5% Carbon 50-10035

R237 1/4W Resistor 10K .35” prep. 5% Carbon 50-10045

R238 1/4W Resistor 100K .35” prep. 5% Carbon 50-10055

R239 1/4W Resistor 100K .35” prep. 5% Carbon 50-10055

R240 1/4W Resistor 33K .35” prep. 5% Carbon 50-33045

R244 2W Resistor 10Ω0.8 prep. 5% Metal 54-10015

R250 2W Resistor 10Ω0.8 prep. 5% Metal 54-10015

S1 Switch DPDT Push, Vert Small PCB MTG 25-02201

S2 Switch DPDT Push, Vert Small PCB MTG 25-02201

S3 Switch DPDT Push, Vert Small PCB MTG 25-02201

S4 Switch DPDT Push, Vert Small PCB MTG 25-02201

VR1 Voltage Regulator 7815 +15V 2A 60-78150

VR2 Voltage Regulator 7915 -15V 2A 60-79150

VR3 Voltage Regulator 7915 -15V 2A 60-79150

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

SAFETY INSTRUCTIONS (EUROPEAN)

The conductors in theAC power cord are colored in accordance with the following code.

GREEN & YELLOW—Earth BLUE—Neutral BROWN—Live

U.K. MAIN PLUG WARNING: Amolded main plug that has been cut off from the cord is

unsafe. NEVERUNDERANYCIRCUMSTANCESSHOULDYOU INSERTADAMAGED

OR CUT MAIN PLUG INTOAPOWER SOCKET.

IMPORTANT! FOR YOUR PROTECTION, PLEASE READ THE FOLLOWING:

WATER AND MOISTURE: Appliance should not be used near water (near a bathtub, washbowl,

kitchen sink, laundry tub, in a wet basement, or near a swimming pool, etc). Care should be taken

so that objects do not fall and liquids are not spilled into the enclosure through openings.

POWERSOURCES: Theproduct shouldbeconnectedtoapowersupply onlyofthetypedescribed

in the operating instructions or as marked on the appliance.

GROUNDING OR POLARIZATION: Precautions should be taken so that the grounding or polar-

ization is not defeated.

POWER CORD PROTECTION: Power supply cords should be routed so that they are not likely

to be walked on or pinched by items placed upon or against them, paying particular attention

to cords at plugs, convenience receptacles, and the point where they exit from the appliance.

SERVICING: The user should not attempt to service the appliance beyond that described in the

operating instructions. All other servicing should be referred to qualified service personnel.

FUSING: If your unit is equipped with a fuse receptacle, replace only with the same type fuse.

Refer to replacement text on the unit for correct fuse type.

REFER SERVICING TO QUALIFIED SER-

VICE PERSONNEL! THIS UNIT CON-

TAINS HIGH VOLTAGE INSIDE!

CAUTION

RISK OF ELECTRIC SHOCK

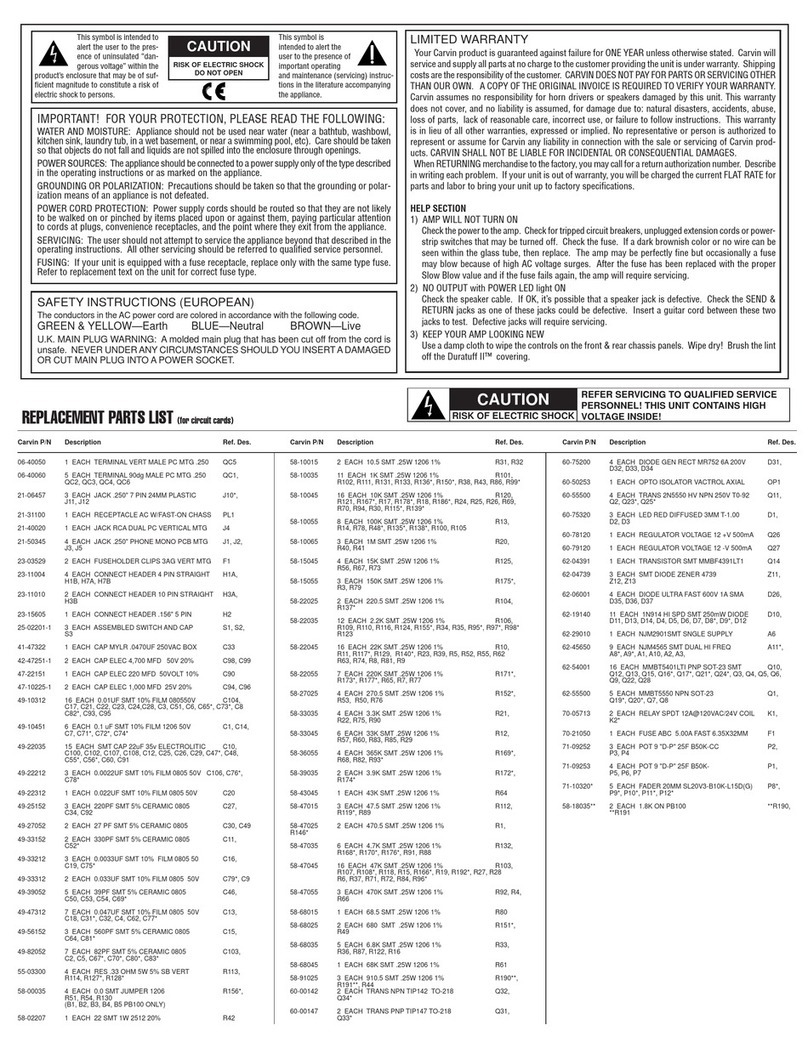

REPLACEMENT PARTS LIST

This symbol is intended to

alert the user to the pres-

ence of uninsulated “dan-

gerous voltage” within the

product’s enclosure that may be of suf-

ficient magnitude to constitute a risk of

electric shock to persons.

This symbol is

intended to alert the

user to the presence of

important operating

and maintenance (servicing) instruc-

tions in the literature accompanying

the appliance.

LIMITED WARRANTY

Your Carvin product is guaranteed against failure for ONE YEAR unless otherwise stated. Carvin

will service and supply all parts at no charge to the customer providing the unit is under warranty.

Shippingcostsaretheresponsibilityofthecustomer. CARVINDOES NOTPAYFORPARTSORSER-

VICING OTHER THAN OUR OWN. A COPY OF THE ORIGINAL INVOICE IS REQUIRED TO VERIFY

YOURWARRANTY. Carvin assumes no responsibilityforhorn drivers orspeakersdamaged by this

unit.Thiswarranty does not cover,andno liability is assumed,fordamage due to: naturaldisasters,

accidents, abuse, loss of parts, lack of reasonable care, incorrect use, or failure to follow instruc-

tions. Thiswarrantyisinlieuofallotherwarranties,expressedorimplied.Norepresentativeorperson

is authorized to represent or assume for Carvin any liability in connection with the sale or servicing

ofCarvinproducts.

CARVINSHALLNOTBELIABLEFORINCIDENTALORCONSEQUENTIALDAMAGES.

When RETURNING merchandise to the factory, you may call for a return authorization number.

Describe in writing each problem. If your unit is out of warranty, you will be charged the current

FLAT RATE for parts and labor to bring your unit up to factory specifications.

HELP SECTION

1) WILL NOT TURN ON

Check the power to the unit. Check for tripped main circuit breakers, unplugged extension cords

or power-strip switches that may be turned off. Check the amps circuit breaker on the rear panel.

If the black curved center button is in the out position, push it in to reset. If the breaker contin-

ues to trip, check your speaker cables and total speaker impedance. If the amps circuit breaker

will not reset, then the amp will require servicing.

2) MAINTAINING YOUR EQUIPMENT

Avoidspilling liquids orallowing any otherforeignmatter inside theunit. Thepanel of yourunitcan

be wiped from time to time with a dry or slightly damp cloth in order to remove dust and bring back

the new look.

As with all pro gear, avoid prolonged use in caustic environments (salt air). When

used in such an environment, be sure the amplifier is adequately protected by rack, covers, etc..