CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

SAFETY INSTRUCTIONS (EUROPEAN)

The conductors in the AC power cord are colored in accordance with the following code.

GREEN & YELLOW—Earth BLUE—Neutral BROWN—Live

U.K. MAIN PLUG WARNING: A molded main plug that has been cut off from the cord is

unsafe. NEVER UNDER ANY CIRCUMSTANCES SHOULD YOU INSERTA DAMAGED

OR CUT MAIN PLUG INTO A POWER SOCKET.

IMPORTANT! FOR YOUR PROTECTION, PLEASE READ THE FOLLOWING:

WATER AND MOISTURE: Appliance should not be used near water (near a bathtub, washbowl,

kitchen sink, laundry tub, in a wet basement, or near a swimming pool, etc). Care should be taken

so that objects do not fall and liquids are not spilled into the enclosure through openings.

POWER SOURCES: The product should be connected to a power supply only of the type described

in the operating instructions or as marked on the appliance.

GROUNDING OR POLARIZATION: Precautions should be taken so that the grounding or polar-

ization is not defeated.

POWER CORD PROTECTION: Power supply cords should be routed so that they are not likely

to be walked on or pinched by items placed upon or against them, paying particular attention

to cords at plugs, convenience receptacles, and the point where they exit from the appliance.

SERVICING: The user should not attempt to service the appliance beyond that described in the

operating instructions. All other servicing should be referred to qualified service personnel.

FUSING: If your unit is equipped with a fuse receptacle, replace only with the same type fuse.

Refer to replacement text on the unit for correct fuse type.

REFER SERVICING TO QUALIFIED SER-

VICE PERSONNEL! THIS UNIT CON-

TAINS HIGH VOLTAGE INSIDE!

CAUTION

RISK OF ELECTRIC SHOCK

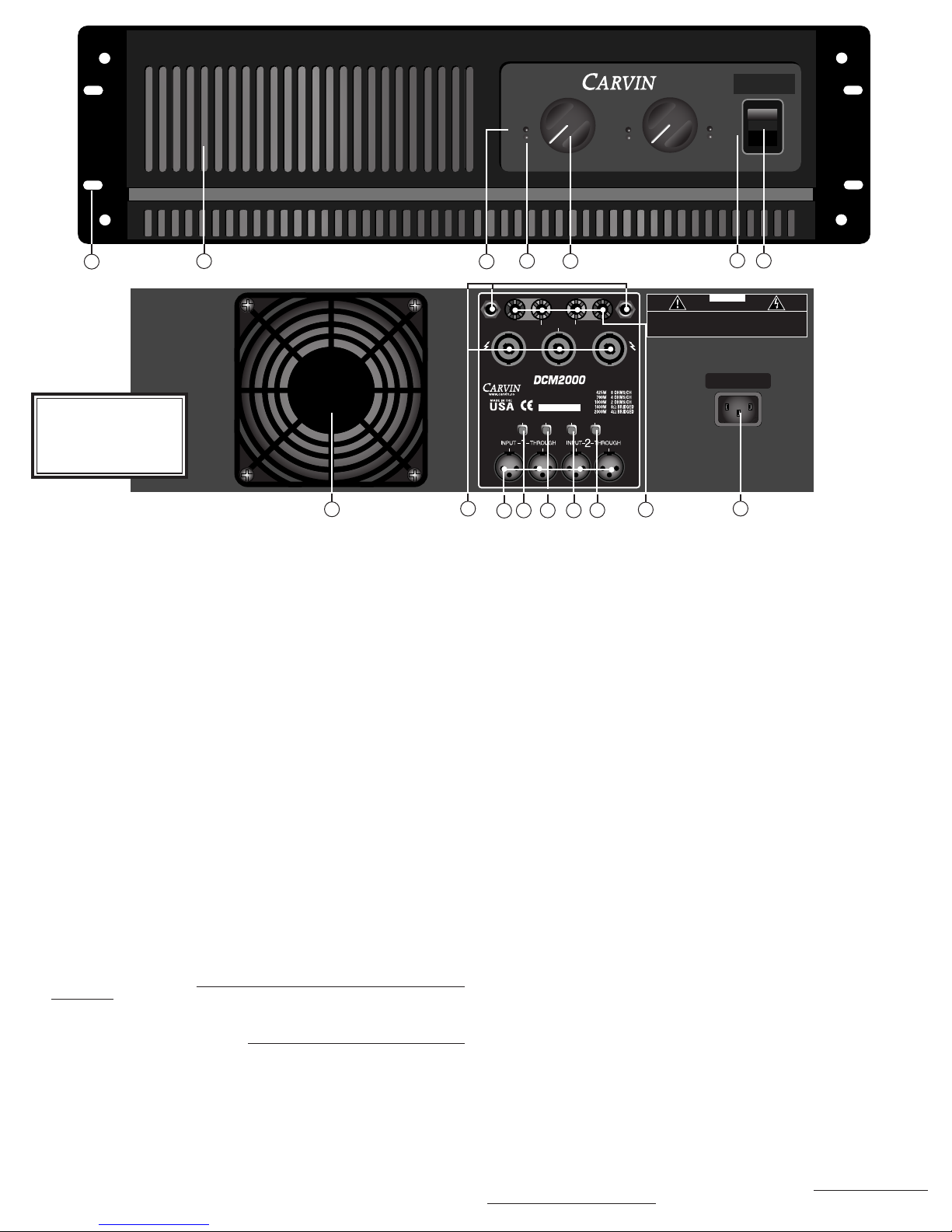

REPLACEMENT PARTS LIST FOR DCM AMPS

This symbol is intended to

alert the user to the pres-

ence of uninsulated “dan-

gerous voltage” within the

product’s enclosure that may be of suf-

ficient magnitude to constitute a risk of

electric shock to persons.

This symbol is

intended to alert the

user to the presence of

important operating

and maintenance (servicing) instruc-

tions in the literature accompanying

the appliance.

LIMITED WARRANTY

Your Carvin product is guaranteed against failure for 3 YEARS unless otherwise stated.

Carvin will service and supply all parts at no charge to the customer providing the unit

is under warranty. Shipping costs are the responsibility of the customer. CARVIN DOES

NOT PAY FOR PARTS OR SERVICING OTHER THAN OUR OWN. A COPY OF THE ORIG-

INAL INVOICE IS REQUIRED TO VERIFY YOUR WARRANTY. Carvin assumes no respon-

sibility for horn drivers or speakers damaged by this unit. This warranty does not cover,

and no liability is assumed, for damage due to: natural disasters, accidents, abuse, loss

of parts, lack of reasonable care, incorrect use, or failure to follow instructions. This war-

ranty is in lieu of all other warranties, expressed or implied. No representative or person

is authorized to represent or assume for Carvin any liability in connection with the sale

or servicing of Carvin products.

CARVIN SHALL NOT BE LIABLE FOR INCIDENTAL OR CON-

SEQUENTIAL DAMAGES.

When RETURNING merchandise to the factory, you may call for a return authoriza-

tion number. Describe in writing each problem. If your unit is out of warranty, you

will be charged the current FLAT RATE for parts and labor to bring your unit up to fac-

tory specifications.

MAINTAINING YOUR EQUIPMENT

Avoid spilling liquids or allowing any other foreign matter inside the unit. The panel of

your unit can be wiped from time to time with a dry or slightly damp cloth in order to

remove dust and bring back the new look.

As with all pro gear, avoid prolonged use in

caustic environments (salt air). When used in such an environment, be sure the ampli-

fier is adequately protected by rack, covers, etc..

03-00220 2 EACH INSLTR MICA .0030".450"X .65"

03-00223 2 EACH INSLTR MICA .0030"1.37"X .65"

03-00450 1 EACH INSLTR 9.125x1.5x.01" SGL ADHV

03-00475 1 EACH SPACER PAD .1X .4X .75 W/ADHSV

03-00503 8 EACH INSULATOR .36X .36X .20" 85deg

03-82061 1 EACH CABLE TIE 14.5Lx .19Wx 2" BNDL

03-92521 6 EACH STANDOFF LED .925 x .215 T1

USE ON D2,D3,D181,D180,D31,D32

05-85622 1 EACH CABLE ASSY, 5C 220MM

06-10028 24 EACH MS PPH 4-40X .500 ZINC TYPE F

06-40050 7 EACH TERMINAL VERT MALE PC MTG .250

QC1,QC2,QC3,QC4,QC5,QC6,QC7

07-01602 1 EACH KNOB "6" 6x6x9.7mm GREY CAP S3

07-01603 3 EACH KNOB "6L" 6x6x17.4mm GREY CAP

S1,S2,S4

12-00880 1 EACH HEATSINK 8"L 1pc FAN MOUNTED

15-00105 2 EACH COIL AIR 1.5uH 14AWG L100,L200

21-31100 1 EACH RECEPTACLE AC W/FAST-ON CHASS PL1

21-40000 2 EACH XLR FEMALE CONNECTOR W/O GRND

J100,J200

21-40001 2 EACH XLR MALE CONNECTOR J1,J2

21-45000 3 EACH SPEAKON 4-POLE PCMTG #NL4MD-V

J3,J103,J203

21-52345 2 EACH JACK .250 PHONE MONO STEEL

J105,J205

23-03529 2 EACH FUSEHOLDER CLIPS 3AG VERT MTG

F1

23-08604 3 EACH CONNECT HEADER .086" 4 PIN H6B H1 H6A

23-08605 1 EACH CONNECT HEADER .086" 5 PIN H5

23-08612 1 EACH CONNECT HEADER .086" 12 PIN H7

23-10002 3 EACH CONNECT HEADER .100" 2 PIN H4,H8,H9

23-11010 6 EACH CONNECT HEADER 10 PIN STRAIGHT

H1A,H1B,H2A,H2B,H3A,H3B

25-02201 4 EACH SWITCH DPDT PUSH PC MTG LOCKNG

S1,S2,S3,S4 30-

02000K 1 EACH PCB CARD MAIN DCM1500/2000

41-47322 3 EACH CAP MYLR .0470UF 250VAC BOX

C19,C20,C21

42-10312 4 EACH CAP ELEC 10,000 MFD 100V 20%

C115,C116,C215,C216

44-13520 2 EACH JUMPER PCB 20AWG .350" X .175" B1,B3

45-25152 4 EACH CAP CERM 250PF 500VOLT 5%

C106,C107,C206,C207

46-10412 2 EACH CAP POLY .1000UF 100VOLT 10%

C117,C217

46-47312-1 2 EACH CAP POLY .0470UF 100V 10%PREP

C127,C227

47-10235 4 EACH CAP ELEC 1,000 MFD 35V 20%

C1,C2,C8,C12

47-22151 1 EACH CAP ELEC 220 MFD 50VOLT 10% C18

47-47125 1 EACH CAP ELEC 470 MFD 25VOLT 20% C7

49-10412 2 EACH 0.1UF SMT 5% CERAMIC 0805 C10,C13

49-22035 13 EACH SMT CAP 22uF 35v ELECTROLITIC

C15,C16,C17,C102,C120,C124,C126,

C181,C202,C220,C224,C226,C281

49-22212 1 EACH 0.0022UF SMT 10% FILM 0805 50V C14

49-27052 9 EACH 27 PF SMT 5% CERAMIC 0805

C100,C101,C103,C104,C200,C201,

C203,C204,C280

49-39052 2 EACH 39PF SMT 5% CERAMIC 0805 C123,C223

49-47312 6 EACH 0.047UF SMT 10% FILM 0805 50V

C3,C4,C9,C11,C105,C205

49-82052 2 EACH 82PF SMT 5% CERAMIC 0805 C121,C221

52-10015 1 EACH RES 10.00 OHM .50W 5% CARBON R27

55-03300 24 EACH RES .33 OHM 5W 5% SB VERT R142,R143,

R144,R145,R146,R147,R148,R149,R150,

R151, R152,R153,R242,R243,R244,R245,

R246,R247,R248,R249, R250,R251,

R252,R253

55-05025 4 EACH RES 5.00 OHM 5W 5% SB VERT

R120,R121,R220,R221

55-30035 2 EACH RES 3.00KOHM 5W 5% SB WIRE R42,R43

56-35010 2 EACH RES 350.00 OHM 10W 10% SB SDOF

R44,R45

58-00035 2 EACH 0.0 SMT JUMPER 1206 R181,R282

58-10025 2 EACH 100.5 SMT .25W 1206 1% R128,R228

58-10035 9 EACH 1K SMT .25W 1206 1% R8,R15,R22,R34,

R111,R129,R211,R229,R187

58-10045 24 EACH 10K SMT .25W 1206 1% R5,R13,R19,R28,

R30,R35,R100,R101,R113,R154,R156,

R200,R201,R213,R254,R256,R183,

R185,R190 R283,R285,R290,R189,R289

58-10055 7 EACH 100K SMT .25W 1206 1%

R21,R114,R157,R214,R257,R184,R284

58-10065 2 EACH 1M SMT .25W 1206 1% R115,R215

58-15025 2 EACH 150ohm SMT .50W 1206 1% R141,R241

58-15035 1 EACH 1.5K SMT .25W 1206 1% R18

58-15045 9 EACH 15K SMT .25W 1206 1% R23,R102,R103,

R202, R203, R112, R212,R155,R255

58-15055 3 EACH 150K SMT .25W 1206 1% R11,R12,R260

58-22035 5 EACH 2.2K SMT .25W 1206 1% R1,R137,R237,

R191,R291

58-22045 9 EACH 22K SMT .25W 1206 1% R26,R29,R106,

R107, R125,R130,R206,R230,R225

58-22055 6 EACH 220K SMT .25W 1206 1% R31,R119,

R140,R219,R240,R186

58-27025 6 EACH 270.5 SMT .25W 1206 1% R108,R131,

R132,R208,R231,R232

58-47025 2 EACH 470.5 SMT .25W 1206 1% R24,R32

58-47035 9 EACH 4.7K SMT .25W 1206 1% R2,R7,R10,

R14,R188,R288,R135,R235,R20

58-47045 6 EACH 47K SMT .25W 1206 1% R33,R126,

R226,R180,R280,R281

58-47055 6 EACH 470K SMT .25W 1206 1% R16,R25,

R109,R209, R110, R210

58-68035 2 EACH 6.8K SMT .25W 1206 1% R104,R204

58-68045 1 EACH 68K SMT .25W 1206 1% R17

58-92201 8 EACH 22 SMT 1W 2512 20% R38,R39,R40,

R41,R133,R134,R233,R234

58-95102 8 EACH 510 SMT 1W 2512 5% R6,R9,R36,

R37,R127,R136,R227,R236

60-00014 1 EACH TRANS MPSA14 DRLNGTN NPN T0-92 Q1

60-15032 2 EACH TRANS MJE15032 NPN T0-220

Q107,Q207

60-15033 2 EACH TRANS MJE15033 PNP T0-220 Q108,Q208

60-21193-1 *STD 12 EACH TRNS BIPOLAR MJL21193-PREPPED

Q109,Q110,Q111,Q112,Q113,

Q114,Q209,Q210,Q211,Q212, Q213,Q214

60-21194-1 *STD 12 EACH TRNS BIPOLAR MJL21194-PREPPED

Q115,Q116,Q117,Q118,Q119,Q120,

Q215,Q216,Q217,Q218, Q219,Q220

60-31000 3 EACH BIPOLAR PWR TIP31C NPN 3A 100V

Q4,Q106,Q206

60-35041 2 EACH RECTIFIER BRIDGE 35AMP/400V PC

BR100,BR200

60-50200 4 EACH DIODE GEN REC 1N5402 3A 200V

D107,D108,D207,D208

60-50253 2 EACH OPTO ISOLATOR VACTROL AXIAL

OP100,OP200

60-75320 3 EACH LED RED DIFFUSED 3MM T-1.00

D2,D31,D181

60-75330 2 EACH LED GREEN DIFFUSED 3MM T-1.00

D32,D180

60-75340 1 EACH LED YELLOW DIFFUSED 3MM T-1.00

D3

60-78150 1 EACH REGULATOR VOLTAGE 15 +V 1 AMP

VR1

60-79120 1 EACH REGULATOR VOLTAGE 12 -V 500mA

Q7

60-79150 1 EACH REGULATOR VOLTAGE 15 -V 1 AMP

VR2

61-04733 1 EACH DIODE ZENER 1N4733A 5.1V 1W

Z1

61-40030 1 EACH DIODE RECT GEN 1N4003 200V 1A

D24

62-00014 2 EACH MMBTA14 SOT-23 SMT Q100,Q200

62-06001 7 EACH DIODE ULTRA FAST 600V 1A SMA

D11,D12,D4,D5,D6,D7,D9

62-19140 24 EACH 1N914 HI SPD SMT 250mW DIODE

D1,D8,D10,D13,D14,D19,D20,

D21,D22,D23,D100,D104,D106,

D200,D204,D206,D15,D16,D25,

D26,D27,D28,D29, D30

62-20430 4 EACH NJM2043SMT(TESTED) DUAL HFREQ

A1,A5,A100,A200

62-29010 1 EACH NJM2901SMT SNGLE SUPPLY A3

62-45650 3 EACH NJM4565 SMT DUAL HI FREQ A6,A7,A2

62-54001 5 EACH MMBT5401LT1 PNP SOT-23 SMT

Q2,Q3,Q6,Q101,Q201

62-55500 5 EACH MMBT5550 NPN SOT-23

Q5,Q102,Q202,Q8,Q9

70-05712 4 EACH RELAY SPDT 12A@120VAC/24V COIL

K100,K200,K1,K2

70-22125 1 EACH FUSE MDA 25.00A SLOW 6.35X32MM

71-09251 2 EACH POT 9 D-P 25F B10K THREAD BSH

P100,P200

71-24450 2 EACH POT VERT TRIMMER 500ohm

P101,P102